Abstract

Many attempts have been conducted for green synthesis of biofunctional scaffolds and implant coatings. Hydroxyapatite Ca5(OH)(PO4)3 (HA), is an excellent material for these purposes. HA is a major mineral component of vertebrate bones and teeth; it constitutes 70 wt% of human bones. This paper reports on the sustainable fabrication of HA particles in different morphologies including nanoplates (400 nm L and 150 nm W), and nanorods (10 nm D and 500 nm L). XRD diffractogram revealed highly crystalline structure. HA nanoplates were surface modified with poly(ethylene-co-AA) polymeric surfactant; organic modified HA nanoplates demonstrated complete change in surface properties from hydrophilic to hydrophobic. It demonstrated effective phase transfer from aqueous phase to organic phase, with decrease in nanoplate size to 100 nm L, 50 nm W. Layered HA plates were further developed via surface modification with dodecanedioic acid; this approach can offer laminated or exfoliated plates for effective integration into bio-compatible polymers. This manuscript shaded the light on facile green synthesis of HA nanoparticles with controlled morphology and surface properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Development of man-made implant is vital to orthopaedic and dental applications. Recently, dental ceramics based on ZrO2, layered double hydroxides, magnesium phosphates, and hydroxyapatite (Ca5(OH)(PO4)3) (HA) were investigated as the major components of artificial bones, teeth, and soft dental tissues [1, 2]. Amongst these materials, HA is the main mineral component of biological hard tissues; it constitutes about 70 wt% of human bones [3,4,5]. Different synthetic methods of HA have received great attention due to its high bioactivity and osteo-conductive characteristics [6,7,8,9]. Additionally, HA was investigated as functionalized carrier for drug delivery, tooth and cartilage repair [10,11,12]. So far, synthetic methods such as sol–gel process, chemical precipitation, solid-state reaction, chemical vapour deposition cannot offer mono-dispersed particles with controlled morphologies and surface properties [4, 13,14,15]. Hydrothermal synthesis offers a relatively simple route which is inherently scalable and chemically much more benign than many other nano-production technologies [16, 17]. Hydrothermal synthesis is characterized by excellent reproducibility and micro-structure controlling [18,19,20,21,22]. Through hydrothermal synthesis, the nanoparticle surface properties can be considerably altered from hydrophilic to hydrophobic by the proper selection of surface coating agent [21,22,23,24]. Surface modification was reported to have the potential to enhance the dispersion characteristics of inorganic nanoparticles into organic polymeric matrix [25,26,27].

This paper reports the sustainable synthesis of HA nanoparticles in different morphologies including nanoplates and nanorods. Surface modification of HA nanoplates was performed using poly(ethylene-co-acrylic acid) copolymer as polymeric surfactant. Poly(ethylene-co-AA) offered complete change in HA surface properties from hydrophilic to hydrophobic, with effective phase transfer from aqueous phase to organic phase. Additionally, surface modification with dodecanedioic acid (DDA) (di-carboxylic ligand) was performed in an attempt to develop exfoliated HA platelets. This approach can offer exfoliated HA plates with constant inter-planer distance for integration of different bio-polymers such as chitosan and collagen.

2 Experimental

2.1 Materials

Precursors for HA synthesis included calcium nitrate tetra hydrate (Ca(NO3)2·4H2O) and ammonium phosphate dibasic ((NH4)2 HPO4) (Aldrich). Poly(ethylene-co-acrylic acid 15 wt%) (Aldrich) was employed as polymeric surfactant. Dodecanedioic acid (Aldrich) was employed as di-carboxylic ligand surfactant.

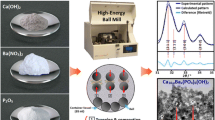

2.2 Synthesis of HA Nanoparticles

HA was formulated using hydrothermal synthesis technique which includes instant mixing of two counter-current streams. The superheated solution passed down an inner nozzle pipe (A) against an up flow of cold precursor salt (B). Nanoparticles formed at the interface of the two fluids inside the reactor (R) (Fig. 1).

Synthesis of HA nanoplates was conducted using hydrothermal synthesis technique. Flow A was superheated aqueous solution of 0.015 M ammonium phosphate dibasic at 300 °C and 240 bars (20 mL/min). Flow B was aqueous solution of 0.05 M calcium nitrate tetra hydrate (10 mL/min) at 25 °C and 240 bars. Nanoparticle flow stream was cooled down prior to collection at point (D). HA nanorods were developed in the manner; the pH of stream B precursor was adjusted to 10 using ammonium hydroxide.

2.3 Surface Modification of HA Nanoplates

HA nanoplates was modified with poly(ethylene-co-AA) was performed via post-synthesis surface modification approach. Solution of poly(ethylene-co-AA) in toluene was injected (5 mL/min) at the capping point (E). Poly(ethylene-co-AA)-HA demonstrated complete change in HA surface properties; it offered effective phase transfer from aqueous phase to organic phase (Fig. 2).

It is apparent that poly(ethylene-co-AA) could bind effectively with HA particles via covalent bonding between pendant carboxylic groups along the polymeric surfactant chain and abundant OH groups on HA surface. Integration of inorganic HA particles into organic polymeric matrix could result in poor dispersion characteristics as there is no affinity between inorganic particles and organic hosting medium. Surface modification with poly(ethylene-co-AA) could offer enhanced compatibility and dispersion characteristics of HA particles in different bio-compatible organic polymers.

The synthesis of exfoliated HA platelets (linked together and separated by a constant interspacing distance) was investigated in an attempt to achieve HA nanocomposites with fully separated platelets (individually dispersed or delaminated within the polymeric matrix). A dispersant that has the ability to anchor two platelets at the same time might be able to keep them separated at fixed distance. Synthesis of exfoliated HA nanoplates was conducted via online surface modification; 0.01 M DDA in ethanol was employed as surfactant at (5 mL/min).

2.4 Characterization of HA Nanoparticles

TEM (Joel JEM-2100F) was employed to investigate nanoparticle size and shape. Crystalline structure was investigated using XRD diffractometer D8 advance by Burker Corporation; the tested sample was scanned over the angle range 2θ from 5 to 65. FTIR (Nicolet 380 FTIR spectrometer) was employed to verify the attachment of the organic surfactant to the nanoparticle surface. The surfactant loading level was evaluated using TGA; the sample was heated from 100 to 800 °C (5 °C/min), under N2 flow gas at 50 mL/min.

3 Results and Discussions

3.1 HA Nanoparticles

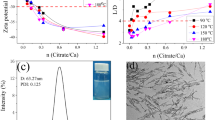

TEM micrographs of synthesized HA nanoplates demonstrated high quality plates of 400 nm length and 150 nm width (Fig. 3). It is apparent that hydrothermal synthesis offered a straight forward route for fabrication of colloidal HA plates for biomedical applications.

HA nanorods were developed via controlled pH of the starting precursor. TEM micrographs demonstrated mono-dispersed HA nanorods of 500 nm length and 10 nm diameter (Fig. 4).

It is apparent that hydrothermal synthesis offered controlled morphologies via controlled reaction pH. This route can offer relatively direct route for green synthesis of HA particles with controlled morphology and high crystalline structure. The crystalline structure of dry HA particles was investigated with XRD. XRD diffractogram revealed ten distinctive peaks that match with Joint Committee on Powder Diffraction Standards (JCPDS), card number 09-0432 (Fig. 5). XRD diffractogram revealed highly crystalline HA particles.

3.2 Poly(ethylene-co-AA)-HA Nanoplates

HA nanoplates was surface modified with poly(ethylene-co-AA) as polymeric surfactant; polymeric surfactant can enhance the compatibility and dispersion characteristic into bio-compatible polymers such as chitosan, collagen, and polyethylene glycol. The morphology of poly(ethylene-co-AA)-HA was investigated with TEM. TEM micrographs demonstrated nanoplates of 100 nm L and 50 nm W (Fig. 6).

The platelet dimensions were found to decrease with surface modification. This can be mainly ascribed to polymeric surfactant conformation at the solid–liquid interface. The abundant COOH groups along the polymeric chains could secure surfactant conformation in the form of trains (polymeric segments at the solid/liquid interface) (Fig. 7). This conformation mechanism could render any further particle growth.

Schematic diagram of adsorbed polymer molecule at the solid–liquid interface [28]

The conformation of the adsorbed polymer is a major controlling factor for steric barrier stability [29, 30]. The adsorbed polymer has three possible segments:

Trains, segments at the solid–liquid interface.

Loops, segments bound at both ends.

Tails, segments bound at one end.

Non-interacting groups are responsible for the occurrence of tails and loops [29, 31]. Variation in train, loop, and tail length controls the adsorbed layer thickness [28]. Polymer conformation mechanism at the solid–liquid interface could hinder any further platelet growth. Poly(ethylene-co-AA)-HA was investigated with FTIR to verify the attachment of the polymeric surfactant to HA surface (Fig. 8).

HA and poly(ethylene-co-AA)-HA demonstrated similar signature over finger print region (from about 500 to 1500 cm−1). The difference in IR absorption of poly(ethylene-co-AA)-HA compared with uncoated HA was correlated the carboxylic group stretch (C=O and O–H stretch) of the attached polymer [32]. The polymeric surfactant loading level of poly(ethylene-co-AA)-HA was evaluated with TGA (Fig. 9).

TGA profiles demonstrated polymeric surfactant loading level of 8.6 wt%. This high surfactant loading level can be ascribed to the high affinity of the polymeric surfactant to anchor HA platelet surface via strong covalent bonding.

3.3 Dodecanedioic Acid-HA Nanoplates

Poly-carboxylate ligands are able to attack many sites at a time. DDA ligand can offer exfoliated HA platelets. TEM micrographs demonstrated DDA-HA nanoplates of 200 nm L and 50 nm W (Fig. 10).

The synthesis of exfoliated HA platelets (linked together and separated by a constant interspacing distance) is essential to develop HA nanocomposites with fully separated platelets (individually dispersed or delaminated within the polymeric matrix). A dispersant which has the ability to anchor two platelets at the same time might have the ability to keep them separated at a constant distance. Figure 11 is a schematic for the chemical structure of layered HA plates via surface modification with DDA ligand.

This structure could lead to HA nanocomposites with an exfoliated structure similar to that of modified layered silicates. Well-dispersed HA platelets into a polymeric matrix with polymer chains into the galleries between the parallel plates, might improve the mechanical properties and performance of the developed nanocomposite. The dried powder was investigated with FTIR to verify the attachment of DDA to HA surface. Figure 12 shows the FTIR spectrum of DDA-HA to uncoated HA.

The difference in IR absorption of DDA-HA compared with uncoated HA was correlated the carboxylic group stretch (C=O and O–H stretch) of DDA [32]. DDA-HA demonstrated a decrease in O–H absorption compared with uncoated HA; as surface OH groups could be involved into covalent bonding with DDA [32]. DDA loading level was determined by TGA. DDA loading level of 27 wt% was reported from TGA profile (Fig. 13).

This high surfactant loading level could be ascribed to the high affinity of DDA to bind to the HA surface. The DDA carboxylic groups could be chemically bonded as they were easily exposed without steric hindrance. This high surfactant loading level might secure HA platelets with uniform interspacing distance; therefore exfoliated HA nanocomposites could be developed.

4 Conclusion

HA is the major important material for biomedical application. Sustainable fabrication of HA nanoparticles is vital for biofunctional scaffolds and implant coatings. HA nanoparticles with consistent quality were developed in sustainable manner using hydrothermal synthesis technique. HA particles were developed in different morphologies including nanoplates and nanorods. Surface properties of HA nanoplates were controlled via surface modification with different organic surfactant including: polymeric surfactant and di-carboxylic ligand. Surface modification with polymeric surfactant offered complete change in surface properties from hydrophilic to hydrophobic. This approach can offer enhanced compatibility between inorganic nanoparticles and organic bio-polymers. Additionally surface modification with di-carboxylic ligand can offer exfoliated or delaminated HA plates into the hosting organic medium.

References

J. Kozlowska et al., Preliminary in vitro and in vivo assessment of modified collagen/hydroxyapatite composite. Mater. Lett. 221, 74–76 (2018)

M. Schiavoni et al., Focus on the catalytic performances of Cu-functionalized hydroxyapatites in NH3-SCR reaction. Appl. Catal. A 563, 43–53 (2018)

A. Dündar et al., Effects of citric acid modified with fluoride, nano-hydroxyapatite and casein on eroded enamel. Arch. Oral Biol. 93, 177–186 (2018)

A. Sobczak-Kupiec et al., Synthesis and characterization of ceramic—polymer composites containing bioactive synthetic hydroxyapatite for biomedical applications. Ceram. Int. 44(12), 13630–13638 (2018)

K. Sangeetha et al., Strontium and ciprofloxacin modified hydroxyapatites as functional grafts for bone prostheses. Ceram. Int. 44(12), 13782–13789 (2018)

M. Harja, G. Ciobanu, Studies on adsorption of oxytetracycline from aqueous solutions onto hydroxyapatite. Sci. Total Environ. 628–629, 36–43 (2018)

B. Kaczmarek et al., In vivo study on scaffolds based on chitosan, collagen, and hyaluronic acid with hydroxyapatite. Int. J. Biol. Macromol. 118, 938–944 (2018)

G. Ciobanu, M. Harja, Cerium-doped hydroxyapatite/collagen coatings on titanium for bone implants. Ceramics International (2018)

A. Szcześ, L. Hołysz, E. Chibowski, Synthesis of hydroxyapatite for biomedical applications. Adv. Colloid Interface Sci. 249, 321–330 (2017)

K. Nakagawa et al., Template effect of phosphate surfactant on formation of hydroxyapatite nanostructures with various shapes. Mater. Chem. Phys. 213, 183–190 (2018)

E. Skwarek et al., Heats of immersion of hydroxyapatite and hydroxyapatite/fumed oxides composites in water and n-decane. Mater. Chem. Phys. 215, 99–103 (2018)

F.E. Baştan et al., Electrophoretic co-deposition of PEEK-hydroxyapatite composite coatings for biomedical applications. Colloids Surf. B 169, 176–182 (2018)

Z. Chen et al., Effect of cation doping on the structure of hydroxyapatite and the mechanism of defluoridation. Ceram. Int. 44(6), 6002–6009 (2018)

H.-P. Yu, Y.-J. Zhu, B.-Q. Lu, Highly efficient and environmentally friendly microwave-assisted hydrothermal rapid synthesis of ultralong hydroxyapatite nanowires. Ceram. Int. 44(11), 12352–12356 (2018)

Q. Wang et al., Universal and biocompatible hydroxyapatite coating induced by phytic acid-metal complex multilayer. Colloids Surf. B 169, 478–485 (2018)

T. Adschiri, Y. Hakuta, K. Arai, Hydrothermal synthesis of metal oxide fine particles at supercritical conditions. Ind. Eng. Chem. Res. 39(12), 4901–4907 (2000)

E. Lester et al., Reaction engineering: the supercritical water hydrothermal synthesis of nano-particles. J. Supercrit. Fluids 37(2), 209–214 (2006)

S. Elbasuney, Dispersion characteristics of dry and colloidal nano-titania into epoxy resin. Powder Technol. 268, 158–164 (2014)

S. Elbasuney, Surface engineering of layered double hydroxide (LDH) nanoparticles for polymer flame retardancy. Powder Technol. 277, 63–73 (2015)

S. Elbasuney, Continuous hydrothermal synthesis of AlO(OH) nanorods as a clean flame retardant agent. Particuology 22, 66–71 (2015)

S. Elbasuney, Sustainable steric stabilization of colloidal titania nanoparticles. Appl. Surf. Sci. 409, 438–447 (2017)

S. Elbasuney, Novel multi-component flame retardant system based on nanoscopic aluminium-trihydroxide (ATH). Powder Technol. 305, 538–545 (2017)

S. Elbasuney, Novel colloidal molybdenum hydrogen bronze (MHB) for instant detection and neutralization of hazardous peroxides. TrAC, Trends Anal. Chem. 102, 272–279 (2018)

S. Elbasuney, Novel colloidal nanothermite particles (MnO2/Al) for advanced highly energetic systems. J. Inorg. Organomet. Polym. Mater. 28(5), 1793–1800 (2018)

S. Elbasuney et al., Stabilized super-thermite colloids: a new generation of advanced highly energetic materials. Appl. Surf. Sci. 419, 328–336 (2017)

S. Elbasuney, H.E. Mostafa, Synthesis and surface modification of nanophosphorous-based flame retardant agent by continuous flow hydrothermal synthesis. Particuology 22, 82–88 (2015)

S. Elbasuney, S.F. Mostafa, Continuous flow formulation and functionalization of magnesium di-hydroxide nanorods as a clean nano-fire extinguisher. Powder Technol. 278, 72–83 (2015)

S. Farrokhpay, A review of polymeric dispersant stabilisation of titania pigment. Adv. Colloid Interface Sci. 151(1–2), 24–32 (2009)

J. Fleer, A. Cohen, M. Scheutjens, Polymers at Interfaces (Chapman & Hall, London, 1993)

X. Yu, P. Somasundaran, Role of polymer conformation in interparticle-bridging dominated flocculation. J. Colloid Interface Sci. 177(2), 283–287 (1996)

S. Farrokhpay, Interaction of Polymeric Dispersants with Titania Pigment Particles 2004 (University of South Australia, Adelaide, 2004)

D. Skog, F. Holler, Principles of Instrumental Analysis (Sunders Golden, Philadelphia, 1999)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Elbasuney, S. Green Synthesis of Hydroxyapatite Nanoparticles with Controlled Morphologies and Surface Properties Toward Biomedical Applications. J Inorg Organomet Polym 30, 899–906 (2020). https://doi.org/10.1007/s10904-019-01247-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-019-01247-4