Abstract

In the present work, Chitosan/bentonite, Chitosan/Ag-bentonite and Chitosan/AgNPs-bentonite composite materials were prepared and shaped in form of beads, and characterized using several methods. After that, their thermal stability, swelling properties and antibacterial and antifungal activity were evaluated. In the case of Chitosan/AgNPs-bentonite, the XRD analysis confirms the partial intercalation of chitosan in the interlayer of bentonite and the formation of silver nanoparticles, AgNPs, with an average diameter between 10 and 25 nm. The latter is confirmed by UV–Visible diffuse reflectance spectroscopy by the apparition of the large absorption band at 442 nm. For all prepared materials, the FTIR analysis shows the presence of strong interaction between chitosan reactive groups and bentonite interlayer materials. This result is confirmed by thermal analysis where it is observed that these composite materials exhibit a higher thermal stability than the biopolymer alone. The composite materials present also a very good swelling capacity. Indeed, the swelling rate carried out in water media at pH 7 and a temperature of 30 °C is 160% higher than that of the corresponding dried material. Otherwise, Chitosan/AgNPs-bentonite sample displays a very high antibacteriaPseudomonas aeruginosal activity against pathogen bacteria strains such as Staphylococcus aureus ATCC 25923 and ATCC 27853. This activity is less important for S. aureus ATCC 43300 and no activity is observed for Escherichia coli ATCC 25922 and Candida albicans ATCC 10231. Since the starting chitosan and bentonite materials showed no antibacterial or antifungal activity, the antibacterial activity of Chitosan/AgNPs-bentonite sample is attributed to loaded AgNPs species.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Due to the increasingly pronounced occurrence of conventional antibiotic-resistant bacteria, considerable efforts have been made over the past decade to develop new classes of materials with antibacterial and antifungal activity that can address this public health problem. The basic idea is to use properties of certain metals such as intrinsic antibacterial [1,2,3,4], especially silver nanoparticles. Indeed, the latter are widely applied as an antibacterial agent thanks to the numerous advantages compared to the conventional antimicrobial [5,6,7,8,9,10], such as chemical stability, safety for the user, a prolonged period and excellent antibacterial activity [11]. However, used alone, silver nanoparticles have disadvantages related to leaching and aggregation phenomena that can generate environmental problems and limit their antibacterial activity. To avoid these limitations and maintain their antibacterial activity for a prolonged time as possible, these nanoparticles can be loaded into solid matrix. This approach will certainly give rise to a new class of environmentally friendly antibacterial materials that retain the antibacterial properties of silver and can be used in many applications. Thus, the recent emergence of new metal matrix-supported antibacterial materials has been a very promising alternative to conventional antimicrobials [12, 13]. Indeed, these materials have found several applications in the coating for manufacturing medical instruments [14], in agriculture [15, 16].

Clay minerals are a good support of metals ions [17, 18]. The low cost and eco-friendly are most important upsides of these solids [19]. Their high specific surface area and cation exchange capacity, and their good thermal and chemical stability provide them a various of surface and structural properties. This makes them excellent support for metallic nanoparticles [20, 21], a good adsorption [22, 23] and high dispersion. Due to their 2:1 arrangement [24], bentonite is able to expand and contract the interlayer space while preserving two-dimensional crystallographic integrity. In this context, researchers have recently multiplied efforts by combining the characteristics of this material with those of other inorganic or organic substances in order to obtain novel hybrid materials with singular properties that have achieved interesting results in the fields of the environment [25, 26] and biology [27, 28].

Chitosan, the deacetylated product of chitin, is the second-most abundant biopolymer in nature [29]. This anionic polysaccharide has several intrinsic characteristics that make it an effective biosorbent for the removal of many pollutants and is also used in medical applications [30, 31]. Its use as a biosorbent is justified by numerous advantages and properties such as low cost compared to others materials, biodegradability, environmentally friendly, non-toxicity and abundance. Another important property that it can be easily shaped in different forms. However, because to its limited applications due to its moisture permeability and high brittleness [32], it is possible to combine this biopolymer with bentonite to improve its thermal, chemical and mechanical properties.

To our knowledge, no literature review reports the use of natural Algerian bentonite as an antibacterial and antifungal material or in the preparation of biocomposite materials by reaction with a biopolymer, chitosan. Thus, the present work reports the preparation of new AgNPs- nanocomposite materials from Ag-bentonite and chitosan. All the obtained materials are characterized by X-ray diffraction analysis (XRD), Fourier transforms infrared (FTIR) and UV–Visible diffuse reflectance (UV–Vis DR) spectroscopy and thermal (TG) analysis. The objective is to evaluate the swelling, thermal, antibacterial and antifungal properties. The antibacterial and antifungal properties are evaluated through growth inhibition towards pathogen bacteria strains such as Staphylococcus aureus ATCC 25923, Escherichia coli ATCC 25922, S. aureus ATCC 43300, Pseudomonas aeruginosa ATCC 27853 and Candida albicans ATCC 10231.

2 Experimental

2.1 Materials

The natural clay (Bentonite) obtained by deposit of Maghnia west of Algeria [33], silver nitrate (AgNO3; Sigma-Aldrich 99.8–100.5%), sodium tetrahydridoborate (NaBH4; Sigma-Aldrich 99%), Sodium Hydroxide (NaOH; Sigma-Aldrich > 98%) and biopolymer Chitosan (degree of acetylation of 10% as measured by IR spectroscopy, MW = 700,000 g mol−1 determined by viscosimetry) from crab shell provided from Sigma-Aldrich. Deionized water was used for all preparations.

2.2 Preparation of Ag-Bentonite Material

The preparation of Ag-bentonite sample was carried out by ion-exchange method as follow: 2 g of bentonite was suspended in deionized water and stirred for 30 min. Then, a silver nitrate solution, prepared by dissolving the required amount of AgNO3 in desionized, water was added. The reaction mixture obtained was vigorously stirred for 24 h at a temperature of 60 °C. The resulting exchanged Ag-bentonite sample was recovered by filtration, and then dried at a temperature of 80 °C for 24 h.

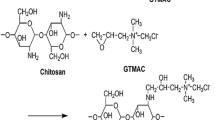

2.3 Preparation of Chitosan/Ag-Bentonite and Chitosan/AgNPs-Bentonite Composites Beads

The Chitosan/Ag-bentonite composite beads is prepared as follow: A solution A is prepared by dispersing 1.5 g of Ag-bentonite sample in 50 ml of deionized water and stirred for 30 min at room temperature. Otherwise, a second solution of chitosan (100 ml, 1 wt%) (solution B) is prepared by solubilization of chitosan in acetic acid solution of pH 4.5 under constant stirring for 45 min at 40 °C and then filtered to remove the insoluble biopolymer. The two solutions are mixed in a chitosan/Ag-bentonite ratio of 2 and stirred vigorously for 2 h at room temperature. The final mixture was then extruded in the form of droplets, using a syringe ~ 2 mm of diameter, into NaOH solution. The resulting composite beads formed are allowed to stand for 1 h in the NaOH solution in order to crosslink. After that, they are filtered and washed several times with distilled water to remove excess of NaOH from the surface. In order to keep their spherical morphology, the beads are immersed in a concentrated ethanol solution to oust water from them and then dried for 24 h at room temperature (Fig. 1).

The preparation procedure of Chitosan/AgNPs-bentonite is the following: the dried Chitosan/Ag-bentonite composites beads were immersed for 24 h into a NaBH4 solution. After that, they were filtered and washed several times with deionized water to remove un-reacted NaBH4 on the surface of beads and then dried for 24 h at room temperature.

2.4 Swelling Experiment

The swelling rate of Chitosan/bentonite, Chitosan/Ag-bentonite and Chitosan/AgNPs-bentonite composites materials was determined by immersing the corresponding dried beads in water at pH 7 and a temperature of 30 °C. The study was carried out until the swelling equilibrium was reached after 500 min of immersion, then the composite beads were removed at regular time intervals and weighed after carefully blotting with tissue paper to remove surface water. The swelling rate (%) for each sample was calculated using the following equation [34, 35]:

where W0 is the initial weight and Wt the final weight of the prepared beads at time t.

2.5 Preparation of Bacterial Cultures

The same method presented in our previous works was used to prepare the bacterial medium [36]. The Chitosan/AgNPs-bentonite composite beads were tested as antibacterial and antifungal agents against pathogenic bacteria and fungal strains using the dishes inhibition method. A same amount of beads are deposited on the surface of solid mass medium seeded with pure bacterial culture. Pathogenic bacteria strains studied are S. aureus ATCC 25923, E. coli ATCC 25922, S. aureus ATCC 43300 and P. aeruginosa ATCC 27853. For antifungal activity study, C. albicans ATCC 10231 was used. 0.5 ml culture (108 cell/ml) obtained after incubation at 37 °C for 24 h was mixed with 10 ml of medium (PDA) liquid at 40 °C. The latter, probably solid, is melted by heating and then cooled before placing in contact with the microbial suspension. The mixture was placed in Petri dishes of 90 mm. The Chitosan/AgNPs-bentonite composite beads, previously sterilized at 180 °C for 30 min, are then deposited in the bacterial medium carrying the bacteria. The antimicrobial activity is determined after incubation of the dishes in an oven at 37 °C for 24 h for bacteria and 48 h at 30 °C for C. albicans. The inhibition zone for bacterial growth was detected visually and immediately photographed.

2.6 Characterization

X-ray powder diffraction (XRD) patterns were recorded in the 2θ range of 2–80° at a scan rate 2°/min, on a Philips diffractometer model PW 1830, with Ni-filtered CuKα (λ = 1.5406 Å) radiation operated at a tube voltage of 40 kV and a tube current of 30 mA. The FTIR spectra were recorded between 400 and 4000 cm−1 on a JASCO 4100 spectrometer. Ultraviolet visible (UV–Vis) absorbance spectra were recorded on a Specord 210 Analytik Jena spectrometer with a holmium oxide filter. Thermogravimetric analysis (TGA) was performed on LABSYS Evo SETARAM under nitrogen atmosphere in the temperature range 20–800 °C with a heating rate of 10 °C/min.

3 Results and Discussion

3.1 X-ray Diffraction (XRD) Analysis

XRD patterns of Bentonite, Chitosan, Chitosan/Bentonite, Chitosan/Ag-bentonite and Chitosan/AgNPs-bentonite samples are exhibited in Fig. 2. The XRD pattern of bentonite material exhibits several reflections (00l) corresponding to a basal spacing, d001, of 12.60 Å characteristics of the sodic form of such a material. Otherwise, the XRD pattern of chitosan shows the presence of all diffractions peaks of this material namely, its two important characteristic crystalline peaks observed at 0.86 nm (10.17° 2θ) and 0.44 nm (20.15° 2θ) and the broad peak belonging to amorphous located at 26.5° 2θ. As shown in the Fig. 2, the dispersion of Ag-bentonite material in the chitosan matrix leads practically to no change in the basal spacing of the clay mineral suggesting that this biopolymer is not intercalated in the interlayer space of the corresponding Chitosan/Ag-bentonite sample. For Chitosan/AgNPs-bentonite sample, the XRD pattern shows a shift of the basal spacing, d001, from 12.60 to 14.74 Å indicating probably a partial intercalation of chitosan after reduction of interlayer Ag+ ions into AgNPs species whose characteristic peaks are also present in this pattern at 2θ = 38.42°, 44.47°, 64.74° and 77.61° (JCPDS Number 04-783) [37,38,39]. The calculated average diameter of these loaded AgNPs species varies between 10 and 25 nm.

3.2 Fourier Transform Infrared (FTIR) Spectroscopy

FTIR spectra of Bentonite, Chitosan, Chitosan/Bentonite, Chitosan/Ag-bentonite and Chitosan/AgNPs-bentonite samples are displayed in Fig. 3. The composite beads spectra show clearly the presence of vibration bands characteristic of the bentonite clay and biopolymer chitosan. The vibration bands of bentonite are observed as follow: the OH stretching band in the region of 3631–3444 cm−1, the Si–O–Si stretching band in the 1091–1039 cm−1 region, and the Si–O stretching vibration band at 795 cm−1 [40,41,42]. The most frequent characteristic absorption bands of the biopolymer assigned to the stretching vibrations of –CH in –CH2 and –CH3 groups appear at 2888 and 2942 cm−1, respectively [43]. Those observed at 1590 and 1653 cm−1 are assigned to C=O stretching (amide I) and N–H bending (amide II), consecutively [44, 45], and the large absorption band in the region of 3000–3500 cm−1 corresponds to O–H stretching, overlapped with N–H stretching [27, 43]. The FTIR analysis gives a valuable information concerning the interaction between the mineral material and the biopolymer. Indeed, the vibration band of the interlayer ≡Si–O− groups of bentonite as well as those of –CH in –CH2 and –CH3 groups at 2888 cm−1 and 2942 cm−1, respectively, shifted to the high frequencies for Chitosan/AgNPs-bentonite material. This shift is due probably to strong interactions between chitosan reactive groups and the mineral matrix, in good agreement with XRD results.

3.3 UV–Visible Diffuse Reflectance (UV–Vis DR) Spectroscopy Analysis

UV–Visible spectroscopy is one of the most generally used techniques for structural characterization of metals species [6, 46]. The UV–Vis (DRUV) spectra of samples were presented in Fig. 4. All samples showed two absorption bands at 215 nm and 230 nm arising from the Si–O and the Al–O charge-transfer of four coordinated framework silicon and aluminum atoms [36, 47]. Compared to starting bentonite sample each modification in clay mineral either by exchange reaction with silver ions or reduction of this metal by NaBH4 shows a change in adsorption bands. The UV–Vis (DRUV) spectrum of Chitosan/AgNPs-bentonite sample revealed a remarkable broad absorption band in the visible region between 400 and 650 nm attributed to silver nanoparticles, AgNPs, species [48, 49].

3.4 Thermogravimetric (TG) Analysis

TG curves of Bentonite, Chitosan, Chitosan/bentonite, Chitosan/Ag-bentonite and Chitosan/AgNPs-bentonite samples are shown in Fig. 5. It can be seen clearly that TG curves of composites beads are practically similar to that of pure chitosan [50]. However, these composites beads present higher decomposition temperatures than that of the biopolymer alone. Otherwise these composite materials have better thermal stability which increases with increasing the clay content of the sample. This result can be explained by the establishment of strong interactions between the reactive groups of chitosan and bentonite interlayer materials such as Ag+, H+ and Na+ cations and terminal interlayer ≡Si–O− groups, which has the consequence of displacing the decomposition of these materials to high temperatures and thus increase their thermal stability [51, 52].

3.5 Swelling Behavior

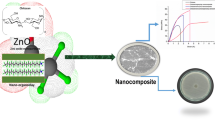

The swelling behavior of the prepared composites beads in the pH 7 at 30 °C is presented in Fig. 6. Figure 6b shows photographed images of composites beads in dried and swelling states. As shown in Fig. 6a, the swelling increases with time, first quickly then slowly, to reach a plateau after 500 min of reaction. Compared to chitosan alone [53, 54], all composite materials exhibit a very high swelling rate which is certainly due to the presence of bentonite. However, the swelling rate of the Chitosan/AgNPs-bentonite beads was a little lower. This is probably due to the presence of silver species in the interlayer space of Bentonite which leads to an increase in the interaction between the clay and the biopolymer, and consequently a decrease in the swelling rate [55].

3.6 Antibacterial and Antifungal Activities

Antibacterial and antifungal properties of pure Chitosan and raw Bentonite are presented in the Table 1. No activity was showed for these started sample. Chitosan/AgNPs-bentonite against five different human pathogens strains Gram-negative (E. coli ATCC 25922, P. aeruginosa ATCC 27853), Gram-positive (S. aureus1 ATCC 25923, S. aureus2 ATCC 43300) bacteria and also as antifungal against C. albicans ATCC10231 are displayed in Fig. 7. The inhibition zone for bacterial growth under and around the tested Chitosan/AgNPs-bentonite beads was seen visually. The results of the antibacterial and antifungal activity tests suggest that the composites beads shown a great antibacterial activity against Gram-positive bacteria (S. aureus1 ATCC 25923 and S.aureus2 ATCC 43300) and Gram-negative bacteria (P. aeruginosa ATCC 27853), with a very clear inhibition zone with a diameter more than ~ 35 mm (Fig. 8). On the other hand, the composite beads did not shown any antifungal activity. This antimicrobial activity of Chitosan/AgNPs-bentonite is effectively related to the presence of loaded silver nanoparticles.

In the meantime, studies have been carried out to explore the application of silver nanoparticles and their antibacterial properties. Table 2 presents a summary of some works using different materials as supports for silver for antibacterial applications. As shown in Table 2, Chitosan/AgNPs-bentonite composite displays a very high antibacterial activity and it is far more effective than other materials cited in the literature. Furthermore, it is also a broad-spectrum antibacterial material that will certainly find use in many areas.

4 Conclusion

To sum up, Chitosan/AgNPs-bentonite composite beads with a good antibacterial activity against Gram-positive and Gram-negative bacteria strains were successfully prepared. The XRD, infrared FTIR spectroscopy and thermal TG analysis showed an establishment of strong interactions between the reactive groups of chitosan and bentonite interlayer materials, leading a partial intercalation of chitosan between the aluminosilicate sheets of bentonite. These strong interactions between chitosan and the mineral matrix result in a significant improvement in the thermal stability of the composites obtained, which increases with the bentonite content of the corresponding composite material. Compared to chitosan alone, the presence of bentonite in the composite materials prepared also leads to a marked improvement in their swelling property. In the case of chitosan/AgNPs-bentonite material, the XRD analysis shows the presence of AgNPs nanoparticles with an average diameter between 10 and 25 nm. The formation of these silver nanoparticles was confirmed also by UV–Vis DR spectroscopy. Evaluated as antibacterial and antifungal against pathogen strains, the Chitosan/AgNPs-bentonite material displays a very high antibacterial activity against gram+ and gram− bacteria strains. However, no antifungal activity was observed for this sample. This biological activity is directly related to the presence of loaded silver nanoparticles.

References

K. Kaviyarasu, N. Geetha, K. Kanimozhi, C.M. Magdalane, S. Sivaranjani, A. Ayeshamariam, J. Kennedy, M. Maaza, In vitro cytotoxicity effect and antibacterial performance of human lung epithelial cells A549 activity of zinc oxide doped TiO2 nanocrystals: investigation of bio-medical application by chemical method. Mater. Sci. Eng. C 74, 325–333 (2017)

K. Kaviyarasu, K. Kanimozhi, N. Matinise, C.M. Magdalane, G.T. Mola, J. Kennedy, M. Maaza, Antiproliferative effects on human lung cell lines A549 activity of cadmium selenide nanoparticles extracted from cytotoxic effects: investigation of bio-electronic application. Mater. Sci. Eng. C 76, 1012–1025 (2017)

A.M. Amanulla, S.J. Shahina, R. Sundaram, C.M. Magdalane, K. Kaviyarasu, D. Letsholathebe, S. Mohamed, J. Kennedy, M. Maaza, Antibacterial, magnetic, optical and humidity sensor studies of β-CoMoO4-Co3O4 nanocomposites and its synthesis and characterization. J. Photochem. Photobiol. B 183, 233–241 (2018)

C.M. Magdalane, K. Kaviyarasu, N. Matinise, N. Mayedwa, N. Mongwaketsi, D. Letsholathebe, G. Mola, N. AbdullahAl-Dhabi, M.V. Arasu, M. Henini, Evaluation on La2O3 garlanded ceria heterostructured binary metal oxide nanoplates for UV/Visible light induced removal of organic dye from urban wastewater. S. Afr. J. Chem. Eng. 26, 49–60 (2018)

C.M. Magdalane, K. Kaviyarasu, A. Raja, M. Arularasu, G.T. Mola, A.B. Isaev, N.A. Al-Dhabi, M.V. Arasu, B. Jeyaraj, J. Kennedy, Photocatalytic decomposition effect of erbium doped cerium oxide nanostructures driven by visible light irradiation: investigation of cytotoxicity, antibacterial growth inhibition using catalyst. J. Photochem. Photobiol. B 185, 275–282 (2018)

Z.A.M. Kebir, A. Mokhtar, M. Adjdir, A. Bengueddach, M. Sassi, Preparation and antibacterial activity of silver nanoparticles intercalated kenyaite materials. Mater. Res. Express 5, 8 (2018)

A.R. Shahverdi, A. Fakhimi, H.R. Shahverdi, S. Minaian, Synthesis and effect of silver nanoparticles on the antibacterial activity of different antibiotics against Staphylococcus aureus and Escherichia coli. Nanomed. Nanotechnol. Biol. Med. 3, 168–171 (2007)

S. Magana, P. Quintana, D. Aguilar, J. Toledo, C. Angeles-Chavez, M. Cortes, L. Leon, Y. Freile-Pelegrín, T. Lopez, R.T. Sánchez, Antibacterial activity of montmorillonites modified with silver. J. Mol. Catal. A 281, 192–199 (2008)

G. Franci, A. Falanga, S. Galdiero, L. Palomba, M. Rai, G. Morelli, M. Galdiero, Silver nanoparticles as potential antibacterial agents. Molecules 20, 8856–8874 (2015)

H. Xu, X. Shi, H. Ma, Y. Lv, L. Zhang, Z. Mao, The preparation and antibacterial effects of dopa-cotton/AgNPs. Appl. Surf. Sci. 257, 6799–6803 (2011)

G. Xu, X. Qiao, X. Qiu, J. Chen, Preparation and characterization of nano-silver loaded montmorillonite with strong antibacterial activity and slow release property. J. Mater. Sci. Technol. 27, 685–690 (2011)

H.-L. Su, C.-C. Chou, D.-J. Hung, S.-H. Lin, I.-C. Pao, J.-H. Lin, F.-L. Huang, R.-X. Dong, J.-J. Lin, The disruption of bacterial membrane integrity through ROS generation induced by nanohybrids of silver and clay. Biomaterials 30, 5979–5987 (2009)

S.K. Pillai, S.S. Ray, M. Scriba, J. Bandyopadhyay, M. Roux-van der Merwe, J. Badenhorst, Microwave assisted green synthesis and characterization of silver/montmorillonite heterostructures with improved antimicrobial properties. Appl. Clay Sci. 83, 315–321 (2013)

E. Bennion, L. Sotheby’s, Antique Dental Instruments (Sotheby’s publications, London, 1986)

S. Raut, R. Ralegaonkar, S. Mandavgane, Development of sustainable construction material using industrial and agricultural solid waste: a review of waste-create bricks. Constr. Build. Mater. 25, 4037–4042 (2011)

J. Sen, P. Prakash, N. De, Nano-clay composite and phyto-nanotechnology: a new horizon to food security issue in Indian agriculture. J. Global Biosci. 4, 2187–2198 (2015)

T. Tsoufis, L. Jankovic, D. Gournis, P.N. Trikalitis, T. Bakas, Evaluation of first-row transition metal oxides supported on clay minerals for catalytic growth of carbon nanostructures. Mater. Sci. Eng. B 152, 44–49 (2008)

R.S. Varma, Clay and clay-supported reagents in organic synthesis. Tetrahedron 58, 1235–1255 (2002)

M. Chiban, M. Zerbet, G. Carja, F. Sinan, Application of low-cost adsorbents for arsenic removal: a review. J. Environ. Chem. Ecotoxicol. 4, 91–102 (2012)

L.-N. Shi, X. Zhang, Z.-L. Chen, Removal of chromium (VI) from wastewater using bentonite-supported nanoscale zero-valent iron. Water Res. 45, 886–892 (2011)

S.C. Motshekga, S.S. Ray, M.S. Onyango, M.N. Momba, Microwave-assisted synthesis, characterization and antibacterial activity of Ag/ZnO nanoparticles supported bentonite clay. J. Hazard. Mater. 262, 439–446 (2013)

D. Bouazza, H. Miloudi, M. Adjdir, A. Tayeb, A. Boos, Competitive adsorption of Cu(II) and Zn(II) on impregnate raw Algerian bentonite and efficiency of extraction. Appl. Clay Sci. 151, 118–123 (2018)

Y.S. Reddy, C.M. Magdalane, K. Kaviyarasu, G.T. Mola, J. Kennedy, M. Maaza, Equilibrium and kinetic studies of the adsorption of acid blue 9 and Safranin O from aqueous solutions by MgO decked FLG coated Fuller’s earth. J. Phys. Chem. Solids 123, 43–51 (2018)

F. Bergaya, G. Lagaly, Developments in clay science. Elsevier 5, 1–19 (2013)

V.N. Tirtom, A. Dinçer, S. Becerik, T. Aydemir, A. Çelik, Comparative adsorption of Ni(II) and Cd(II) ions on epichlorohydrin crosslinked chitosan–clay composite beads in aqueous solution. Chem. Eng. J. 197, 379–386 (2012)

A. Bée, L. Obeid, R. Mbolantenaina, M. Welschbillig, D. Talbot, Magnetic chitosan/clay beads: a magsorbent for the removal of cationic dye from water. J. Magn. Magn. Mater. 421, 59–64 (2017)

A. Mokhtar, A. Djelad, A. Bengueddach, M. Sassi, CuNPs-magadiite/chitosan nanocomposite beads as advanced antibacterial agent: synthetic path and characterization. Int. J. Biol. Macromol. 118, 2149–2155 (2018)

Y.-S. Han, S.-H. Lee, K.H. Choi, I. Park, Preparation and characterization of chitosan–clay nanocomposites with antimicrobial activity. J. Phys. Chem. Solids 71, 464–467 (2010)

K. Kurita, Chitin and chitosan: functional biopolymers from marine crustaceans. Mar. Biotechnol. 8, 203 (2006)

Y. Liu, Z. Zhong, Extraction of heavy metals, dichromate anions and rare metals by new calixarene-chitosan polymers. J. Inorg. Organomet. Polym. Mater. 28, 962–967 (2018)

M. Rinaudo, Chitin and chitosan: properties and applications. Prog. Polym. Sci. 31, 603–632 (2006)

C. Branca, G. D’Angelo, C. Crupi, K. Khouzami, S. Rifici, G. Ruello, U. Wanderlingh, Role of the OH and NH vibrational groups in polysaccharide-nanocomposite interactions: a FTIR–ATR study on chitosan and chitosan/clay films. Polymer 99, 614–622 (2016)

Z. Cherifi, B. Boukoussa, A. Zaoui, M. Belbachir, R. Meghabar, Structural, morphological and thermal properties of nanocomposites poly (GMA)/clay prepared by ultrasound and in situ polymerization. Ultrason. Sonochem. 48, 188 (2018)

B. Liu, J. Luo, X. Wang, J. Lu, H. Deng, R. Sun, Alginate/quaternized carboxymethyl chitosan/clay nanocomposite microspheres: preparation and drug-controlled release behavior. J. Biomater. Sci. Polym. Ed. 24, 589–605 (2013)

S. Farhoudian, M. Yadollahi, H. Namazi, Facile synthesis of antibacterial chitosan/CuO bio-nanocomposite hydrogel beads. Int. J. Biol. Macromol. 82, 837–843 (2016)

M. Zahraoui, A. Mokhtar, M. Adjdir, F. Bennabi, R. Khaled, A. Djelad, A. Bengueddach, M. Sassi, Preparation of Al-magadiite material, copper ions exchange and effect of counter-ions: antibacterial and antifungal applications. Res. Chem. Intermed. 1, 12 (2018)

A. Saravanakumar, M. Ganesh, J. Jayaprakash, H.T. Jang, Biosynthesis of silver nanoparticles using Cassia tora leaf extract and its antioxidant and antibacterial activities. J. Ind. Eng. Chem. 28, 277–281 (2015)

J. Balavijayalakshmi, V. Ramalakshmi, Carica papaya peel mediated synthesis of silver nanoparticles and its antibacterial activity against human pathogens. J. Appl. Res. Technol. 15, 413–422 (2017)

T. Kayalvizhi, S. Ravikumar, P. Venkatachalam, Green synthesis of metallic silver nanoparticles using Curculigo orchioides rhizome extracts and evaluation of its antibacterial, larvicidal, and anticancer activity. J. Environ. Eng. 142, C4016002 (2016)

C. Paluszkiewicz, M. Holtzer, A. Bobrowski, FTIR analysis of bentonite in moulding sands. J. Mol. Struct. 880, 109–114 (2008)

F.G. Alabarse, R.V. Conceição, N.M. Balzaretti, F. Schenato, A.M. Xavier, In-situ FTIR analyses of bentonite under high-pressure. Appl. Clay Sci. 51, 202–208 (2011)

H. Moussout, H. Ahlafi, M. Aazza, O. Zegaoui, C. El Akili, Adsorption studies of Cu(II) onto biopolymer chitosan and its nanocomposite 5% bentonite/chitosan. Water Sci. Technol. 73, 2199–2210 (2016)

A. Mokhtar, A. Djelad, A. Bengueddach, M. Sassi, Biopolymer-layered polysilicate micro/nanocomposite based on chitosan intercalated in magadiite. Res. Chem. Intermed. 1, 10 (2018)

F.G. Torres, J. Arroyo, R. Alvarez, S. Rodriguez, O. Troncoso, D. López, Molecular dynamics of carboxymethyl κ/ι-hybrid carrageenan films doped with NH4I. Polym.-Plast. Technol. Eng. 1, 14 (2018)

A.R. Nesic, S.J. Velickovic, D.G. Antonovic, Characterization of chitosan/montmorillonite membranes as adsorbents for bezactiv orange V-3R dye. J. Hazard. Mater. 209, 256–263 (2012)

A. Mokhtar, A. Djelad, A. Bengueddach, M. Sassi, Structural and antibacterial properties of HyZnxNa2−xSi14O29nH2O layered silicate compounds, prepared by ion-exchange reaction. J. Inorg. Organomet. Polym. Mater. 1, 10 (2019)

J.P. Montañez, S. Gómez, A.N. Santiago, L.B. Pierella, TiO2 supported on HZSM-11 zeolite as efficient catalyst for the photodegradation of chlorobenzoic acids. J. Braz. Chem. Soc. 26, 1191–1200 (2015)

S.A. Babu, H.G. Prabu, Synthesis of AgNPs using the extract of Calotropis procera flower at room temperature. Mater. Lett. 65, 1675–1677 (2011)

M. Zahran, H.B. Ahmed, M. El-Rafie, Alginate mediate for synthesis controllable sized AgNPs. Carbohyd. Polym. 111, 10–17 (2014)

H. Moussout, H. Ahlafi, M. Aazza, A. Amechrouq, Bentonite/chitosan nanocomposite: preparation, characterization and kinetic study of its thermal degradation. Thermochim. Acta 659, 191–202 (2018)

A. Mokhtar, Z.A.K. Medjhouda, A. Djelad, A. Boudia, A. Bengueddach, M. Sassi, Structure and intercalation behavior of copperII on the layered sodium silicate magadiite material. Chem. Pap. 72, 39–50 (2018)

X. Wang, Y. Du, J. Yang, X. Wang, X. Shi, Y. Hu, Preparation, characterization and antimicrobial activity of chitosan/layered silicate nanocomposites. Polymer 47, 6738–6744 (2006)

K. Gupta, M.R. Kumar, Drug release behavior of beads and microgranules of chitosan. Biomaterials 21, 1115–1119 (2000)

G. Pasparakis, N. Bouropoulos, Swelling studies and in vitro release of verapamil from calcium alginate and calcium alginate–chitosan beads. Int. J. Pharm. 323, 34–42 (2006)

Q. Wang, X. Xie, X. Zhang, J. Zhang, A. Wang, Preparation and swelling properties of pH-sensitive composite hydrogel beads based on chitosan-g-poly (acrylic acid)/vermiculite and sodium alginate for diclofenac controlled release. Int. J. Biol. Macromol. 46, 356–362 (2010)

S. Ravindra, Y.M. Mohan, N.N. Reddy, K.M. Raju, Fabrication of antibacterial cotton fibres loaded with silver nanoparticles via “Green Approach”. Coll. Surf. A 367, 31–40 (2010)

J.S. Gabriel, V.A. Gonzaga, A.L. Poli, C.C. Schmitt, Photochemical synthesis of silver nanoparticles on chitosans/montmorillonite nanocomposite films and antibacterial activity. Carbohyd. Polym. 171, 202–210 (2017)

L.F. Giraldo, P. Camilo, T. Kyu, Incorporation of silver in montmorillonite-type phyllosilicates as potential antibacterial material. Curr. Opin. Chem. Eng. 11, 7–13 (2016)

K. Shameli, M.B. Ahmad, W.M.Z.W. Yunus, N.A. Ibrahim, R.A. Rahman, M. Jokar, M. Darroudi, Silver/poly (lactic acid) nanocomposites: preparation, characterization, and antibacterial activity. Int. J. Nanomed. 5, 573 (2010)

K. Shameli, M.B. Ahmad, W.M.Z.W. Yunus, A. Rustaiyan, N.A. Ibrahim, M. Zargar, Y. Abdollahi, Green synthesis of silver/montmorillonite/chitosan bionanocomposites using the UV irradiation method and evaluation of antibacterial activity. Int. J. Nanomed. 5, 875 (2010)

K. Shameli, M.B. Ahmad, M. Zargar, W.M.Z.W. Yunus, N.A. Ibrahim, Fabrication of silver nanoparticles doped in the zeolite framework and antibacterial activity. Int. J. Nanomed. 6, 331 (2011)

Z.A.M. Kebir, M. Adel, M. Adjdir, A. Bengueddach, M. Sassi, Preparation and antibacterial activity of silver nanoparticles intercalated kenyaite materials. Mater. Res. Express 5, 085021 (2018)

S.K. Jou, N.A.N.N. Malek, Characterization and antibacterial activity of chlorhexidine loaded silver-kaolinite. Appl. Clay Sci. 127, 1–9 (2016)

Y. Zhang, Y. Chen, H. Zhang, B. Zhang, J. Liu, Potent antibacterial activity of a novel silver nanoparticle-halloysite nanotube nanocomposite powder. J. Inorg. Biochem. 118, 59–64 (2013)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdelkrim, S., Mokhtar, A., Djelad, A. et al. Chitosan/Ag-Bentonite Nanocomposites: Preparation, Characterization, Swelling and Biological Properties. J Inorg Organomet Polym 30, 831–840 (2020). https://doi.org/10.1007/s10904-019-01219-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-019-01219-8