Abstract

A series of colloidal Ag3PO4 sphere loaded onto multi-walled carbon nanotube (CAPS-MWCNT) photocatalysts containing different mass ratio of MWCNT for the removal of RhB and phenol from waste water were synthesized. The photocatalysts were characterized by X-ray diffraction, UV–Vis diffuse reflectance spectroscopy, thermogravimetry, scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray photoelectron spectroscopy. By SEM and TEM test, the obtained Ag3PO4 form precipitated and colloidal method present different structure morphology and this showed an important effect on the photocatalytic activity. The CAPS-MWCNT photocatalysts were applied to the removal of Rhodamine B (RhB) and phenol from waste water; and the results indicated that CAPS-MWCNT sample can exhibit the high adsorption and photodegradation efficiency under visible light irradiation. For RhB, the removal efficiency of CAPS-MWCNT-4 reaches 99.8% within 50 min, of which adsorption efficiency is 76.5% within the former 30 min; for phenol, the removal efficiency of CAPS-MWCNT-4 reaches 90.6% within 110 min, of which adsorption efficiency is 14.2% within the former 30 min. The experiment results show that CAPS-MWCNT-4 has the highest removal efficiency for RhB while it presents an excellent reusability for removing phenol from waste water. The present work illustrates a new train for the design and synthesis of stable and high efficiency catalysts, applicable for the removal of various organic pollutants by adsorption and photodegradation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Photocatalytic semiconductors have attracted worldwide attention for renewable energy and clean environment in various systems [1]. Among multitudinous photocatalysts, TiO2 was considered as one of the most frequently used. However, TiO2 can generate electron–hole pairs only when illuminated by ultraviolet light, which is a limit to the photo-electronic transition efficiency of solar photocatalysis because the portion of UV-light in the solar spectrum is only about 3–5% of total sunlight [2, 3]. The poor solar efficiency has hindered the commercialization of this technology, thus the designing of novel visible-light-driven photocatalysts is a necessary and significant work.

In recent years, silver orthophosphate (Ag3PO4) has been studied as a highly active visible-light-driven photocatalyst, which exhibited extremely high photocatalytic efficiency for organic dye decomposition under visible light irradiation [4,5,6,7,8,9]. In practical, however, the application results of pure Ag3PO4 reported so far are still far from ideal. In order to further improve the photocatalysis efficiency, more and more studies have focused on a target which is to explore the suitable supporter for catalyst to enhance application of photocatalysts [10]. Besides some reported supporters [4,5,6, 11,12,13,14], such as attapulgite, flaky-layered double hydroxides, carbon quantum dots, graphene oxide, TiO2, AgCl, SnO2 and multi-walled carbon nanotube (MWCNT) would be a great potential supporter to study.

Since their discovery, carbon based nanostructures have been extensively studied owing to their outstanding physical and chemical properties such as high mechanical strength, high electrical conductivity and high thermal conductivity [15]. Among various research, photocatalysis and adsorption applications are the most frequently. Firstly, Due to its high electrical conductivity, specific surface area, flexibility and graphitized tube-walls [16, 17], the use of MWCNT has been drawing attention as supporter in tailoring the catalyst properties to specific needs in recent years. Surisetty et al. [18] reported that MoS2 catalyst was supported on multi-walled carbon nanotube and used to produce higher alcohols from synthesis gas; Secondly, because of its high chemical stability and gigantic specific surface area, MWCNT has potential to be applied as the absorbents for organic and inorganic substances in the analytical sciences [19]. For example, Arasteh et al. [20] reported adsorption of 2-nitrophenol by multi-wall carbon nanotube from aqueous solutions and the results show that the carbon nanotube can be used as potential adsorbent for phenolic derivate in wastewater; Gong et al. [21] reported removal of cationic dyes from aqueous solution using magnetic multi-wall carbon nanotube and the prepared MWCNT adsorbent displayed the main advantage of separation convenience compared to the present adsorption treatment.

To our knowledge, there are adsorption and photodegradation steps during photocatalytic degradation of organic pollutants [22]. It is hence desirable to prepare photocatalysts that are synergetically effective in both adsorption and photodegradation. In the view of Ag3PO4 with good photocatalytic activity and MWCNT with high adsorption performance, colloidal Ag3PO4 sphere was loaded on to MWCNT (as supporter) would exhibit an excellent efficiency in the photocatalyst design. In this work, colloidal Ag3PO4 was synthesized and used as a precursor to obtain the coated crystalline grains of Ag3PO4 onto MWCNT. For the elucidation of the related adsorption and photocatalytic mechanism, the synergetic adsorption-degradation effects on the decomposition of RhB and phenol under visible-light irradiation over the as-prepared catalysts were investigated. With the method inspired, Ag3PO4 or other photocatalysts can be applied as a coating onto many kinds of supporters, e.g., clay, silica, ATP and active carbon. Moreover, the present work provides a new strategy for the design to remove organic pollutants by synergetic adsorption-degradation.

2 Experimental

2.1 Regents

Disodium hydrogen phosphate hydrate (Na2HPO4·12H2O), silver nitrate (AgNO3), Rhodamine B (RhB), phenol and other reagents used in the experiments were obtained from Aladdin Chemical Reagent Co., Ltd. Multi-walled carbon nanotube (MWCNT) (purity > 98%, outer diameters: 20–30 nm, lengths: 10–30 µm) was purchased from Beijing Dk Nano technology Co., Ltd, China and purified by HNO3 reflux solution. Deionized water was used throughout this study. All other chemicals were of analytical grade and were used without further purification.

2.2 Preparation of Colloidal Ag3PO4 Loaded Onto MWCNT (CAPS-MWCNT)

Regular Ag3PO4 (RAP) was prepared by simple precipitation method. In a typical synthesis process, a certain amount of disodium hydrogen phosphate hydrate was dissolved in water followed by addition of silver nitrate. The solution was stirred mechanically until it form the yellow precipitate of silver phosphate and the obtained precipitate was then washed with distilled water, centrifuged and dried at 70 °C for 12 h.

Colloidal Ag3PO4 sphere (CAPS) was synthesized according to the method described by Khan et al. with some modifies [23]. Before the synthesis, the concentrations of disodium hydrogen phosphate hydrate and silver nitrate were both adjusted to 0.04 mol/L. The above two solutions were mixed thoroughly under stirring with the same volume and the stirring was performed for 1 h. (no precipitation was found, but colloid was observed). Then, a certain amount of MWCNT was added to the colloid and the stirring was performed for 3 h. Afterwards, the mixture was centrifuged, collected, and dried at 70 °C for 12 h. The colloidal Ag3PO4 sphere loaded onto multi-walled carbon nanotube (CAPS-MWCNT) photocatalyst was obtained.

Hereinafter, according to the different mass ratio of MWCNT to colloidal Ag3PO4, a series of photocatalysts are denoted as CAPS-MWCNT-1, CAPS-MWCNT-2, CAPS-MWCNT-3, CAPS-MWCNT-4, and CAPS-MWCNT-5, respectively (the mass ratios of MWCNT to colloidal Ag3PO4 are 10%, 20%, 30%, 40% and 50%, respectively).

2.3 Characterizations

X-ray diffraction (XRD) patterns of samples were scanned on the Shimadzu LabX-6000 X-ray Diffractometer (40 kV, 30 mA, λ = 0.154 nm) with a Cu Kα radiation source at a scanning rate of 4◦/min within the range of 15–85◦. UV–Vis diffuse reflectance spectroscopy (DRS) was carried out on a Hitachi UV-3010 UV–Vis spectrophotometer. BaSO4 was as reference sample. Scanning electron microscopy (SEM, S-4800, Hitachi, Tokyo, Japan) was obtained at accelerating voltage of 0.5–30 kV. The size and morphology of the nanoparticles were viewed on a PHI-Tecnai 12 transmission electron microscope (TEM). Thermogravimetry (TG) was done on STA-449C Jupiter (NETZSCH Corporation, Germany) thermal analysis instruments at a heating rate of 10 K/min under the flow of N2 gas. The X-ray photoelectron spectroscopy (XPS) of sample was performed on the ESCALAB250 XPS spectrometer with an Al Ka monochromatized source. The Brunauer-Emmett-Teller (BET) specific surface areas (SBET) of the samples were carried out on the basis of nitrogen adsorption and desorption isotherms in an NDVA2000e Quntachrome Corporation analytical system.

2.4 Photocatalytic Activity Under Visible Light Irradiation

Adsorption activities of the as-prepared CAPS-MWCNT samples were evaluated for the removal of RhB or phenol in the dark. Photocatalytic activities of the as-prepared photocatalysts were evaluated in terms of the photodegradation of RhB (100 mL, 10 mg/L) and phenol (100 mL, 5 mg/L) aqueous solutions. The light source was a 300W Xe lamp (80 mW/cm2) equipped with wavelength cutoff filters for λ ≤ 420 nm. Prior to irradiation, the suspensions were ultrasonicated for 10 min and then stirred in dark for 30 min to achieve the adsorption–desorption equilibrium established [24]. After turning on the lamp, 3 mL of suspensions was sampled at certain time intervals and centrifuged by centrifuger at 10,000 rpm for 10 min to remove the particles. The upper clear liquid was analyzed by recording the characteristic absorption peak of RhB at 552 nm and phenol at 270 nm (as shown in Fig. S1, Supplementary material). The degradation efficiency (η) was calculated by using the Eq. (1):

where C0 (mg L−1) is the initial concentration of RhB or phenol, C (mg L−1) is the RhB or phenol concentration at time t (min), A0 is the UV–Vis absorption of the original solution and A is the UV–Vis absorption of degraded solution at time t (min).

3 Results and Discussion

3.1 Materials Characterization

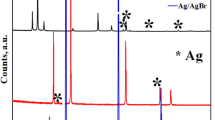

The structure and phase composition of MWCNT (a), colloidal Ag3PO4 sphere (b) and CAPS-MWCNT-4 (c) was measured by XRD, and the results are shown in Fig. 1. As shown in Fig. 1a, the typically strong diffraction peak at around 25.9° can be indexed as the (002) reflection of the hexagonal graphite structure for MWCNT supporter [25]. As for colloidal Ag3PO4 sphere, all the diffraction peaks suggested the formation of single phase and crystalline structure and these peaks could be indexed to the body-centered cubic structure of silver phosphate (JCPDS No. 06-0505). As shown in Fig. 1b, the diffraction pattern of pure Ag3PO4 shows peaks at 21.2, 29.9, 33.6, 36.9, 42.8, 48.1, 53.0, 55.3, 57.5, 62.1, 66.0, 70.2, 72.1 and 74.1°, which are corresponding to planes (110), (200), (210), (211), (220), (310), (222), (320), (321), (400), (411), (420), (421) and (322), respectively [26]. It is obvious from the patterns that the colloidal approach neither affected the crystal structure nor the crystallinity of catalyst [23]. Figure 1c shows all the peaks of CAPS-MWCNT-4. After coated with Ag3PO4, this peak for MWCNT appears also at 25.9° correspondingly, which inferred that all the reactions just occur on the surface of MWCNT during the composite process without destroying the crystalline structure of it. Based on the above result, it can be concluded that Ag3PO4 is loaded onto the surface of MWCNT successfully.

To further obtain the pore size distributions and specific surface area of the as synthesized samples, N2 adsorption–desorption measurements were performed. The BET specific surface areas of CAPS, RAP, MWCNT and CAPS-MWCNT-4 materials are 10.78, 12.54, 22.23 and 50.71 m2 g−1, respectively. Meanwhile, the corresponding pore volume distributions of these samples were calculated by the BJH method from the adsorption branch of the isotherms. The average pore size of CAPS, RAP, MWCNT and CAPS-MWCNT-4 materials are 10.11, 12.23, 13.25 and 18.44 nm, respectively.

UV–Visible DRS spectra of colloidal Ag3PO4 sphere (a) and CAPS-MWCNT-4 (b) were measured and the results are shown in Fig. 2. The intercept of the tangent to the plot is called λg, and the λg of Ag3PO4 and CAPS-MWCNT-4 are 561 and 593 nm, respectively. As can be seen from Fig. 2, an obviously red shift to longer wavelength regions occurred for CAPS-MWCNT-4 photocatalysts compared with pure Ag3PO4. Band gap energy (Eg) can be calculated as following Eq. (2) [27]:

where h is planck constant (6.626 × 10− 34 J·s); c is light speed (3.0 × 108 m/s).

According the above relation, the band gap energy of colloidal Ag3PO4 and CAPS-MWCNT-4 can be obtained as 2.21 and 2.09 eV respectively. From the results, it could be clearly seen that Eg of CAPS-MWCNT-4 is lower than that of pure Ag3PO4.

The X-ray photoelectron spectroscopy (XPS) of CAPS-MWCNT-4 was conducted to investigate the chemical state and composition of sample surface, and results are shown in Fig. 3. Photoelectron peaks of P, C, Ag and O elements were clearly observed in the CAPS-MWCNT-4, as shown in Fig. 3a, which confirms the presence of P, C, Ag and O elements in the composites. As shown in Fig. 3b, the binding energy at 132.5 eV appears to be attributable to the P element in PO43− [28]. From Fig. 3c, it can be observed that the Ag 3d spectra exhibit two sharp peaks centered on around 367.8 and 373.6 eV, which can be ascribed to the 3d5/2 and 3d3/2 binding energies of Ag+ in Ag3PO4 [29]. As shown in Fig. 3d, the binding energy at 284.7 eV is assigned to C element in MWCNT [30]. From Fig. 3e, it can be seen that the binding energy of XPS spectra of O 1s is 531.1 eV, corresponding to oxygen in the sample lattice [31]. The Ag3PO4 obtained from precipitated and colloidal method.

The morphologies of regular Ag3PO4, colloidal Ag3PO4 sphere and CAPS-MWCNT-4 were obtained by SEM and TEM and the results are shown in Fig. 4. From the SEM morphologies of the Ag3PO4 obtained from precipitated method (a) and colloidal method (b), it can be seen that Ag3PO4 sphere obtained by colloidal approach are highly spherical in shape, uniform and homogeneous in distribution. However, Ag3PO4 particles prepared by the chemical precipitation method are lacking uniformity, which was also presented in the early report [32]. As shown in the TEM images of regular Ag3PO4 (c) and colloidal Ag3PO4 sphere (d), it can be seen that CAPS is observed as sphere-like shape, with the mean size of 200 nm. The TEM result is consisting with the SEM. From Fig. 4e, it can be observed that colloidal Ag3PO4 sphere was successfully coated on the surface of multi-walled carbon nanotube to form CAPS-MWCNT composite. As shown in Fig. 4f, it can be seen that colloidal Ag3PO4 sphere are closely coated on surface of MWCNT.

Thermal gravimetric (TG) curves of colloidal Ag3PO4 sphere, CAPS-MWCNT-4 and MWCNT were obtained (as shown in Fig. S2, Supplementary material). As can be seen from Fig. S2a, colloidal Ag3PO4 sphere scarcely presents any mass loss under the N2 flow. For the plot of CAPS-MWCNT-4 sample, as shown in Fig. S2b, an obvious mass loss appears when the temperature is up to 600 °C, which is due to the decomposition of MWCNT composition. As shown in Fig. S2c, it can be observed that the MWCNT is fairly stable when the heat temperature is below 600 °C, and total weight loss is nearly 100% with the temperature up to 750 °C, indicating that MWCNT is decomposed.

3.2 Photodegradation Activity of RhB or Phenol Over the As-Prepared Catalysts

To evaluate the photocatalytic activity of as-prepared catalysts, the photodegradation of RhB and phenol was carried out in aqueous dispersions under visible light irradiation. Before the start of irradiation, the reaction mixture was continuously stirred in the dark for 30 min for the establishment of adsorption–desorption equilibrium. Adsorption and photodegradation performance of RhB (a) and phenol (b) over the as-prepared catalysts in the dark and under visible light irradiation are shown in Fig. 5. From Fig. 5a, b, it can be seen that the photocatalytic activity of colloidal Ag3PO4 sphere is higher than that of regular Ag3PO4 particle. This enhancement in efficiency could be collectively attributed to various factors such as uniformity and sphericity of CAPS which provides more surface-to-volume ratio. In this work, MWCNT was used as supporter; the adsorption performance and photocatalytic activity of pure MWCNT are weak. As shown in Fig. 5a, it can be seen that the removal efficiency increases with the time, and keeps unchanged at about 76.5% while coming 30 min, which implies that the system has reached adsorption–desorption equilibrium in the first 30 min. Apparently, RhB is removed from the liquid phase in the dark by means of adsorption on CAPS-MWCNT-4. Based on this phenomenon, the results suggest that after the establishment of adsorption–desorption equilibrium in the dark, the removal of RhB is by means of photocatalytic degradation.

In addition, the relative concentration (C/C0) of RhB decreases with the increasing of MWCNT content under stirring in the dark for 30 min; and there is no apparent decrease when the mass ratio of MWCNT to colloidal Ag3PO4 sphere achieves 40%. Under the irradiation of visible light irradiation, the concentration of RhB presents a continuous decrease, which is due to the photodegradation over as-prepared catalysts. From Fig. 5a, it can be seen that the catalysts with Ag3PO4 loaded on MWCNT perform better than that without, especially so for the one with 40 wt% MWCNT (i.e. CAPS-MWCNT-4). The removal efficiency of CAPS-MWCNT-4 reaches 99.8% within 20 min, whereas in the cases of other catalysts, the removal efficiency is not as significant as CAPS-MWCNT-4 within 40 min. With the increasing of MWCNT content, the photocatalytic activity presents a decline for the catalyst, although the adsorption performance increases. In consideration of adsorption and photocatalysis, CAPS-MWCNT-4 presents the best removal efficiency within 20 min, which demonstrates that an appropriate amount of MWCNT as supporter for Ag3PO4 is crucial for high performance.

As for the photodegradation of phenol over RAP, CAPS, MWCNT, CAPS-MWCNT-1, CAPS-MWCNT-2, CAPS-MWCNT-3, CAPS-MWCNT-4 and CAPS-MWCNT-5, the results are shown in Fig. 5b, which exhibit a similar trend expect the photodegradation time and adsorption performance. Photodegradation time of phenol is larger than that of RhB. It takes 120 min for as-prepared catalysts to arrive the highest photocatalytic activity, except CAPS-MWCNT-4 (80 min). As shown in Fig. 5b, it can be seen that the removal efficiency of CAPS-MWCNT-4 is the highest and attains 90.6% within 80 min under visible-light irradiation. Meanwhile, the adsorption efficiency of phenol on CAPS-MWCNT-4 in the dark was investigated to confirm the adsorption–desorption time. From Fig. 5b, it can be seen that the result is similar to that of RhB, except that the removal efficiency keep unchanged at about 14.2% while coming 30 min.

According to the above results, the evolutions of absorption spectra of RhB in the presence of CAPS-MWCNT-4 with time were obtained (as shown in Fig. S3, Supplementary material). The former 30 min was in the dark and the later 20 min was under visible-light irradiation. From the evolution spectra, it can be observed that the characteristic absorbance of RhB solution at 552 nm gradually diminishes in intensity with the increasing time, which indicates the removal of RhB. As shown in Fig. S3b (The former 30 min was in the dark and the later 80 min was under visible-light irradiation), it can be observed that the characteristic absorbance of phenol solution at 270 nm gradually diminishes in the presence of CAPS-MWCNT-4 with the increasing time, which indicates the removal of phenol.

3.3 Effect of Reaction Conditions on Photodegradation Activity of RhB or Phenol Over the As-Prepared Catalysts

The effects of air and several radical scavengers were investigated on the photodegradation of RhB or phenol over CAPS-MWCNT-4. As shown in Fig. 6, it can be observed that there is no influence on the adsorption performance of RhB or phenol, and the adsorption efficiency of RhB and phenol is still 76.5 and 14.2%, respectively, which keeps consist with the above results. It is well known that ·O2−, as an important active species, is formed from O2 in the photodegradation process. From the comparison between air (a) and nitrogen (e) flow, it can be clearly observed that there is no photodegradation reaction with nitrogen flow under visible-light irradiation. In the photodegradation reaction, H2O2 could form through the photogenerated electrons and holes with adsorbed oxygen/water, whereas ·O2− and ·OH were possibly involved [33]. In the experiments, several radical scavengers (methanol, EDTA, and p-benzoquinone) were introduced into the photocatalytic reaction process to validate the effect with air flow under visible-light irradiation. Figure 6 also shows a comparison of photocatalytic activity of the CAPS-MWCNT-4 sample for the degradation of RhB and phenol in presence of methanol, EDTA, and p-benzoquinone. When 0.2 M EDTA (holes scavenger) is introduced into reaction solution, it can be seen that a large activity loss of CAPS-MWCNT-4 presents for all the degradation of RhB and phenol. Moreover, it can be seen that the addition of 0.2 M p-benzoquinone (·O2− scavenger) in the reaction solution results in the fast deactivation of CAPS-MWCNT-4 for the degradation of RhB and phenol. However, it is observed that the addition of 0.2 M methanol (·OH scavenger) has little effect on the photocatalytic activity. Methanol is hardly adsorbed on the catalyst and mainly scavenged ·OH in the solution, which makes less influence on the photocatalytic reaction. Based on the above results, it can be seen that h+ and ·O2− are the main reactive oxidizing species in photodegradation reaction process of CAPS-MWCNT-4. While ·OH may only play a less importance role in the photocatalytic process.

3.4 Removal Mechanism of CAPS-MWCNT

It is well known that photoinduced holes, hydroxyl (·OH) and superoxygen (·O2−) radicals are extremely active and they trigger the oxidation attack of organic pollutants in a photodegration process [34]. The mechanism of CAPS-MWCNT by adsorption and photodegradation under visible light irradiation is shown in Fig. 7.

As can be seen from Fig. 7, it can be seen that electron–hole pairs of CAPS-MWCNT photocatalyst are produced under visible-light irradiation, yielding radicals and holes as oxidants. Moreover, it can be known that, the photon-excited electrons are transported through the MWCNT into the solution instead of going back to the holes. For RhB, adsorption performance (76.5%) plays an important role in the removal process, which is due to that RhB is a kind of cationic dye which can be adsorbed easily by electrostatic forces on negatively charged surfaces of MWCNT and RhB is also a planar molecule, which is easily adsorbed by MWCNT by π–π stacking interactions between the aromatic backbone of the dye and hexagonal skeleton of MWCNT. From Fig. 7, it can be seen that RhB and phenol were attacked by ·OH and ·O2− radicals and degraded into H2O and CO2 [35]. However, adsorption performance (14.2%) on phenol is weak, because the adsorption mechanism is just upon π-π stacking interactions.

Photoluminescence (PL) test was carried out to study the electron–hole pair separation of CAPS-MWCNT. It is well known that a lower recombination rate or a higher transfer of those electrons and holes can result in a lower PL intensity. As shown in Fig. 8, the emission peak of CAPS-MWCNT is lower than that of pure CAPS, indicating that it has lower recombination rate of photo-generated electron–hole pairs. It is the cause that the photo-generated electrons in conduction band of Ag3PO4 may quickly transfer to the surface of the MWCNT to participate in the photocatalytic reaction, thus decrease the probability of photo-generated electron–hole pairs recombination.

3.5 Reusability Studies

In terms of practical application and resource saving, reusability is an important factor for an outstanding photocatalyst. In this study, CAPS-MWCNT-4 was selected for the recycling experiment. As shown in Fig. 9a, the removal efficiency of RhB is about 86% in the fifth run. The decline of removal efficiency is plausibly on the account of decline in adsorption performance. However, photocatalytic performance keeps stably after five runs. From Fig. 9b, it can be seen that phenol removal efficiency is as high as 88% after five runs. Compared with RhB, CAPS-MWCNT-4 has a higher stability in the removal of phenol, which may be because that the adsorption performance takes a relatively weak role in the removal of phenol. The experiment results indicate that photocatalytic performance has an excellent reusability.

XRD patterns (a) and DRS spectra (b) of CAPS-MWCNT-4 were examined further to verify durability before and after the photocatalytic reaction and the results are shown in Fig. 10. As can be seen from Fig. 10, XRD patterns and DRS spectra change little before and after photocatalytic reaction, indicating that the prepared CAPS-MWCNT-4 photocatalyst is stable under light irradiation and has the ability to be reused.

3.6 Comparison with Other Photocatalysts for the Removal of RhB and Phenol

The removal efficiency of CAPS-MWCNT-4 was compared with those of other photocatalysts reported in literature [30, 36,37,38,39,40,41], and the results are listed in Table 1. From the results, it can be seen that the degradation efficiency of CAPS-MWCNT-4 is higher than that of other photocatalysts, and the reaction time is lower than that of other samples. Hence, CAPS-MWCNT-4 could be acted as an excellent photocatalyst in the application for the removal of organic pollutants.

4 Conclusion

In this work, colloidal Ag3PO4 sphere was synthesized and loaded onto multi-walled carbon nanotube by a simple method. The photocatalytic activity of CAPS-MWCNT was investigated by the removal of RhB and phenol from waste water. Due to the uniformity and sphericity of colloidal Ag3PO4 sphere, it presents a higher activity than that of regular Ag3PO4 particle. With excellent adsorption and degradation abilities, CAPS-MWCNT-4 sample exhibits the best adsorption and photodegradation efficiency under visible-light irradiation. The experiment results show that the removal efficiency of CAPS-MWCNT-4 is as high as 99.8% for RhB while it presents a higher performance in reusability for removing phenol from waste water. The present work illustrates that changing the morphology structure of catalyst and finding a suitable supporter were used to enhance the photocatalytic activity; in addition, as-prepared catalyst has potential application in the removal of various organic pollutants by adsorption and photodegradation.

References

X.Y. Guo, C.F. Chen, W.Y. Song, X. Wang, W.H. Di, W.P. Qin, J. Mol. Catal. A 387, 1–6 (2014)

J.R. Chen, F.X. Qiu, W.Z. Xu, S.S. Cao, H.J. Zhu, Appl. Catal. A 495, 131–140 (2015)

L.Y. Min, G.Q. He, R.B. Li, W. Zhao, Y.C. Chen, Sep. Purif. Technol. 106, 97–104 (2013)

W.F. Yao, B. Zhang, C.P. Huang, C. Ma, X.L. Song, Q.J. Xu, J. Mater. Chem. 22, 4050–4055 (2012)

Z. Yi, J. Ye, N. Kikugawa, T. Kako, S. Ouyang, H. Stuart-Williams, H. Yang, J. Cao, W. Luo, Z. Li, Y. Liu, R.L. Withers, Nat. Mater. 9, 559–564 (2010)

Y. Wang, X. Li, Y. Wang, C. Fan, J. Solid State Chem. 202, 51–56 (2013)

X. Cui, Y. Li, Q. Zhang, H. Wang, Int. J. Photoenergy 2012, 1–6 (2012)

X. Miao, X. Yue, X. Shen, Z. Ji, H. Zhou, G. Zhu, J. Wang, L. Kong, M. Liu, C. Song, Catal. Sci. Technol. 8, 632–641 (2018)

C.T. Dinh, T.D. Nguyen, F. Kleitz, T.O. Do, Chem. Commun. 47, 7797–7799 (2011)

J.F. Ma, J. Zou, L.Y. Li, C. Yao, Y. Kong, B.Y. Cui, R.L. Zhu, D.L. Li, Appl. Catal. B 144, 36–40 (2014)

H. Zhang, H. Huang, H. Ming, H. Li, L. Zhang, Y. Liu, Z. Kang, J. Mater. Chem. 22, 10501–10506 (2012)

L. Zhang, H. Zhang, H. Huang, Y. Liu, Z. Kang, New J. Chem. 36, 1541–1544 (2012)

H. Cui, X. Yang, Q. Gao, H. Liu, Y. Li, H. Tang, R. Zhang, J. Qin, X. Yan, Mater. Lett. 93, 28–31 (2013)

Y. Bi, S. Ouyang, J. Cao, J. Ye, Phys. Chem. Chem. Phys. 13, 10071–10075 (2011)

S.Y. Sawant, R.S. Somani, H.C. Bajaj, Carbon 48, 668–672 (2010)

P. Serp, M. Corrias, P. Kalck, Appl. Catal. A 253, 337–358 (2003)

E. van Steen, F.F. Prinsloo, Catal. Today 71, 327–334 (2002)

V.R. Surisetty, A. Tavasoli, A.K. Dalai, Appl. Catal. A 365, 243–251 (2009)

D.L. Xiao, H. Li, H. He, R. Lin, P.L. Zuo, New Carbon Mater. 29, 15–25 (2014)

R. Arasteh, M. Masoumi, A.M. Rashidi, L. Moradi, V. Samimi, S.T. Mostafavi, Appl. Surf. Sci. 256, 4447–4455 (2010)

J.L. Gong, B. Wang, G.M. Zeng, C.P. Yang, C.G. Niu, Q.Y. Niu, W.J. Zhou, Y. Liang, J. Hazard. Mater. 164, 1517–1522 (2009)

J. Yu, W.F. Lin, L.H. Leng, S.K. Bao, J.P. Zou, X.B. Luo, D.Z. Chen, S.L. Luo, C.T. Au, J. Mol. Catal. A 394, 121–128 (2014)

M. Khan, M. Qamar, Muneer, Chem. Phys. Lett. 519, 54–58 (2012)

J.F. Guo, B.W. Ma, A.Y. Yin, K.N. Fan, W.L. Dai, Appl. Catal. B 101, 580–586 (2011)

L.H. Ai, C.Y. Zhang, F. Liao, Y. Wang, M. Li, L.Y. Meng, J. Jiang, J. Hazard. Mater. 198, 282–290 (2011)

W. Teng, X.Y. Li, Q.D. Zhao, J.J. Zhao, D.K. Zhang, Appl. Catal. B 125, 538–545 (2012)

M. Bahrami, A. Nezamzadeh-Ejhieh, Mater. Sci. Semicond. Process. 27, 833–840 (2014)

Y.F. Wang, X.L. Li, Y.W. Wang, C.M. Fan, J. Solid State Chem. 202, 51–56 (2013)

S.N. Zhang, S.J. Zhang, L.M. Song, Appl. Catal. B 152, 129–139 (2014)

H.J. Dong, G. Chen, J.X. Sun, C.M. Li, Y.G. Yu, D.H. Chen, Appl. Catal. B 134, 46–54 (2013)

W. Liu, M.L. Wang, C.X. Xu, S.F. Chen, X.L. Fu, Mater. Res. Bull. 48, 106–113 (2013)

J. Cao, B.D. Luo, H.L. Lin, B.Y. Xu, S.F. Chen, J. Hazard. Mater. 217, 107–115 (2012)

C. Hu, Y. Lan, J. Qu, X. Hu, A. Wang, J. Phys. Chem. B 110, 4066–4072 (2006)

D.L. Zhao, G.D. Sheng, C.L. Chen, X.K. Wang, Appl. Catal., B 111, 303–308 (2012)

Y.X. Wang, S. Indrawirawan, X.G. Duan, H.Q. Sun, H.M. Ang, M.O. Tadé, S.B. Wang, Chem. Eng. J. 266, 12–20 (2015)

D.K. Lee, I.S. Cho, S. Lee, S.T. Bae, J.H. Noh, D.W. Kim, K.S. Hong, Mater. Chem. Phys. 119, 106–111 (2010)

G.D. Chen, M. Sun, Q. Wei, Y.F. Zhang, B.C. Zhu, B. Du, J. Hazard. Mater. 244, 86–93 (2013)

S.M. Sun, W.Z. Wang, L. Zhang, J.H. Xu, Appl. Catal. B 125, 144–148 (2012)

L.J. Zhu, K. Liu, H.B. Li, Y.G. Sun, M. Qiu, Solid State Sci. 20, 8–14 (2013)

M. Aslam, I.M.I. Ismail, N. Salah, S. Chandrasekaran, M.T. Qamar, A. Hameed, J. Hazard. Mater. 286, 127–135 (2015)

J. Prince, F. Tzompantzi, G. Mendoza-Damian, F. Hernandez-Beltran, J.S. Valente, Appl. Catal. B 163, 352–360 (2015)

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, G., Xing, W. Facile Preparation of Semiconductor Silver Phosphate Loaded on Multi-walled Carbon Nanotube Surface and Its Enhanced Catalytic Performance. J Inorg Organomet Polym 29, 617–627 (2019). https://doi.org/10.1007/s10904-018-1036-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-018-1036-z