Abstract

WO3 thin film is one of the most important and applied metal oxide semiconductors that have attracted the scientist’s attention in recent decades. WO3 thin films by two different methods: reactive and non-reactive RF magnetron sputtering deposited on soda lime glass. The effect of presence and absence of oxygen gas in system and RF power on structural, morphological and optical properties of thin films were investigated. The XRD analysis of the films shows the amorphous structure. Spectrophotometer analysis and calculation show that the optical properties of reactive sputtered layers were better than the non-reactive sputtered thin films. By changing deposition parameters, over 70 % transmission achieved for WO3 films. The results showed that reactive sputtering method improved the optical properties of layers and increased band gap up to 3.49 eV and on the other hand reduced roughness of thin films. On the whole, presence of oxygen in the chamber during sputtering improved properties of WO3 thin films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Tungsten oxide (WO3) is a wide band gap semiconductor [1] with a band gap of 2.6–3.6 eV [2–4], which has been extensively studied because of various distinctive properties, such as electrochromism, gas sensing, thermoelectric and catalytic properties [5–11]. Among the transition metal oxides, WO3 exhibits electrochromic properties in the visible and infrared regions which have relatively low cost and high color efficiency [12]. In addition, WO3 is a well-established n-type semiconductor employed as a sensing layer for the detection of many toxic gases such as H2S, CO, CO2, NOx [13–15], Ozone [16, 17], Benzene and Methane [18].Varied composition and structure of WO3 films are generally preferred for different applications. An amorphous WO3 film with high coloring efficiency and fast coloration/bleaching kinetics is an important electrochromic material in electric displays and colour memory devices, which polycrystalline WO3 films with high gas sensing Sensitivity can be widely used as environmental gas sensors [19]. The characteristics of the WO3 films strongly depend on the conditions and methods used in their deposition [20], so several techniques have been applied in order to improve the fabrication of WO3 thin films, including: pulsed laser deposition (PLD) [19], chemical vapor deposition (CVD) [21], spray pyrolysis [22, 23], electrodeposition [24], sol–gel methods [25, 26], sputtering [27–30] and thermal evaporation [31]. Among these methods, magnetron sputtering has the advantage to deposit uniform films on large area substrates [32]. The present work, focuses on deposition of WO3 films on glass substrate of reactive and non-reactive RF magnetron sputtering and the purpose of this study is to investigate the influence of film thickness, RF power and the presence and the absence of Oxygen gas during the sputtering process on structural, optical and morphological properties of the formed WO3 thin films.

2 Experimental Setup

The substrate used in this work was soda lime glass. Before depositing the WO3 thin films, Commercial glass slides, used as substrates, were cleaned with acetone and ethanol ultrasonically. The WO3 thin films were deposited by RF magnetron sputtering and using tungsten as a target (92.55 % pure and 2 in. diameter). The vacuum pumping system was employed to use a combination of turbo and rotary pumps to achieve a pressure of 9 × 10−6 Torr. At first WO3 thin films deposited at the present of argon gas as a sputtering gas, but in the second step, O2/Ar mixed (30 % Oxygen) were used, that oxygen was applied as reactive gas. The RF powers for both conditions set at 50 and 100 W and deposition time were 15 min, respectively. Conditions maintained during the preparation of WO3 films are given in Table 1. The thickness of the films were measured by DekTak3 profilometer, X-ray diffraction (STADI modle Mp) with CuKα source (λ = 1.54 Å) was used to determine the crystallographic structure of the films. The optical transmittances of layers formed on glass were recorded by UV–VIS–NIR spectrophotometer (Varian model Cary 500 Scan). Auto probe atomic force microscope (Park Scientific Instruments model Cp) in non-contact mode was used for surface morphology of the WO3 deposited layers.

3 Results and Discussion

The deposition rate and thickness of WO3 thin films are shown in Table 2. We had two groups of samples, first group W1 and W2 has been sputtered by non-reactive sputtering and then these two metallic tungsten coatings have been oxidized in the air, out of the sputtering chamber. Group W3 and W4 have been deposited by reactive sputtering. The results were investigated and the deposition rate of the second group was lower than the first group. In fact, the ionization energy of oxygen (48.76 eV) is higher than that of argon (15.76 eV) [30] so oxygen affects the deposition rate of films by reducing the number of incident Ar ions on the tungsten target. Therefore, the deposition rate was dropped [29].

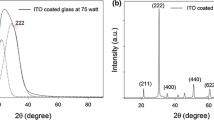

Figure 1 shows the X-ray diffraction patterns of the thin films. This graph indicates that WO3 films are amorphous. According to Madhavi et al. [32] and Kawasaki et al. [33], amorphous WO3 films are suitable for electrochromic applications. The optical transmittance spectra of the films deposited at the presence and absence of O2 are shown in Fig. 2. The samples W1 and W2 which have been deposited by non-reactive method had lower transmittance than reactive sputtered samples W3 and W4. In fact, without O2 we have just heavy tungsten ions (compared to oxygen atoms) that should travel through the plasma and reach at the substrate, but in reactive deposition, in chamber, both the oxygen and tungsten will effectively react on the substrate surface, hence the optical transmittance increases. These results are in accordance with Kaushal and Kaur [34] and Lethy et al. [35] works.

The optical absorption coefficient (α) was calculated from the following function:

In which d is the film thickness, T is transmittance.

The absorption coefficient of WO3 was shown in Fig. 3.

Then the optical band gaps of the samples were calculated using the Tauc relation [36]:

where β is constant, hν (eV) is the photon energy, Eg (eV) is the optical energy band gap and α is the absorption coefficient.

The exponent m depends on the type of optical transition in the gap region. Specifically, m is 1/2, 3/2, 2 and 3 for transitions being direct and allowed, direct and forbidden, indirect and allowed, and indirect and forbidden, respectively. Since the top of the valence band is completely dominated by the O, 2p states, while the bottom of the conduction band is constituted by W, 5d orbital’s to some ninety percent, the transitions are allowed. Furthermore, the band gap is indirect, so the exponent is expected to be 2. This is in accordance with experiments [32, 37, 38]. The extrapolation of the linear portion of the plots to α = 0 leads to the optical band gap. Indirect band gaps were shown in Fig. 4.

The band gap values in Table 3 show that the layers were deposited with mixed gases (O2/Ar) have a higher band gap than the two other samples. It means by the use of oxygen in deposition process, the optical band gap will increase. Furthermore, the band gaps of films are exactly in the range of 2.6–3.6 eV that was reported in the research results [2–4].

Figure 5 shows the two-dimensional (2D) and three-dimensional (3D) AFM images of the WO3 thin films deposited at different deposition condition. The surface roughness and grain size were calculated and were collected in Table 4.

With the increase in surface roughness, the grain sizes decrease and reactive layers (W3 and W4) have lower roughness. In literature for good gas sensing characteristics, layers with smaller grain size were demanding [18, 39]; hence non-reactive sputtered films can be better gas sensors than reactive sputtered ones. On the whole it can be said non-reactive sputtered films (W1 and W2) have more uniform distribution with defined boundaries than the layers which were deposited by reactive sputtering. It seems in the presence of O2 gas in sputtering process, the uniformity of the surface was decreased.

4 Conclusion

WO3 thin films were deposited in two ways: non-reactive and reactive RF sputtering. The influence of oxygen on the properties of tungsten oxide thin films was studied. Oxygen improved the transmittance of films from 2 to 8 % in W1 and W2 up to 45 and 70 % in W3 and W4 reactive sputtered layers. Also band gap of reactive films were higher than two other layers. Of course O2 changed morphological properties too. The grain sizes of reactive films were bigger than non-reactive films. Hence O2 optimized the optical properties, but for morphological properties was not suitable. Furthermore, structural properties of both groups (non-reactive and reactive) were the same.

Change history

30 December 2023

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1007/s10904-023-02990-5

References

P.P. González-Borrero, F. Sato, A.N. Medina, M.L. Baesso et al., Appl. Phys. Lett. 96, 061909 (2010)

R. Sivakumar, R. Gopolakrishnan, M. Iayachandran, C. Sanjeeviraja, Opt. Mater. 29, 679 (2007)

W. Smith, Z.-Y. Zhang, Y.-P. Zhao, Vac. Sci. Technol. B 25, 1875 (2007)

D.B. Migas, V.L. Shaposhnikov, V.N. Rodin, V.E. Borisenko, J. Appl. Phys. 108, 093713 (2010)

H.M.A. Soliman, A.B. Kashyout, M.S. El Nouby, A.M. Abosehly, Mater. Sci. Mater. Electron. 21, 1313–1321 (2010)

J. Li, Q.L. Zhao, G.Y. Zhang, J.Z. Chen, L. Zhong, L. Li, J. Huang, Z. Ma, Solid State Sci. 12, 1393–1398 (2010)

M. Ahsan, T. Tesfamichael, M. Ionescu, J. Bell, N. Motta, Sens. Actuators B Chem. 162, 14–21 (2012)

R. Boulmani, M. Bendahan, C. Lambert-Mauriat, M. Gillet, K. Aguir, Sens. Actuators B Chem. 125, 622–627 (2007)

O.U. Nimittrakoolchai, S. Supothina, Mater. Chem. Phys. 112, 270–274 (2008)

J.S. Jeng, J. Alloys Compd. 548, 27–32 (2013)

X. Dong, Y.J. Gan, Y. Wang, S.J. Peng, L. Dong, J. Alloys Compd. 581, 52–55 (2013)

C. K. Wang, D.R. Sahu, S.C.Wang, C.K. Lin, J.L. Huang, J. Phys. D, 45(22), Article ID 225303, (2012)

T.S. Kim, Y.B. Kim, K.S. Yoo, G.S. Sung, H.J. Jung, Sens. Actuators B Chem. 62, 102 (2000)

I.M. Szilagy, VII International Workshop on Semiconductor Gas Sensors (Kracow, Poland, 2010)

V. Khatko, S. Vallejos, J. Calderer, I. Gracia, C. Cane, E. Llobet, X. Correig, Sens. Actuators B Chem 140, 356 (2009)

M. Bendahan, R. Boulmani, J.L. Seguin, K. Aguir, Sens. Actuators B Chem. 100, 320–324 (2004)

S.R. Utembe, G.M. Hansford, M.G. Sanderson, R.A. Freshwater, K.F.E. Pratt, D.E. Williams, R.A. Cox, L. Jones, Sens. Actuators B Chem. 114, 507–512 (2006)

M.U. Qadri, M.C. Pujol, Procedia Eng. 25, 260–263 (2011)

Y.S. Zou, Y.C. Zhang, H.P. Wang et al., J. Alloys Compd. 583, 465–470 (2014)

Viacheslav Khatko, Stella Vallejos, Sens. Actuators B Chem. 126, 400–405 (2007)

Z.S. Houweling, J.W. Geus, M. de Jong, P.P.R.M.L. Harks, K.H.M. van der Werf, R.E.I. Schropp, Mater. Chem. Phys. 131, 375–386 (2011)

L.M. Bertus, C. Faure, A. Danine, C. Labrugere, G. Campet, A. Rougier, A. Duta, Mater. Chem. Phys. 140, 49–59 (2013)

P.M. Kadam, N.L. Tanwal, P.S. Shinde, S.S. Mali, R.S. Patil, A.K. Bhosale, H.P. Deshmukh, P.S. Patil, J. Alloys Compd. 509, 1729–1733 (2011)

W.L. Kwong, N. Savvides, C.C. Sorrell, Electrochim. Acta 75, 371–380 (2012)

N. Naseri, H. Kim, W. Choi, A.Z. Moshfegh, Int. J. Hydrog. Energy 38, 2117–2125 (2013)

R. Solarska, B.D. Alexander, A. Braun, R. Jurczakowski, G. Fortunato, M. Stiefel, T. Graule, J. Augustynski, Electrochim. Acta 55, 7780–7787 (2010)

C.V. Ramana, G. Baghmar, E.J. Rubio, M.J. Hernandez, ACS Appl. Mater. Interfaces 5, 4659–4666 (2013)

I. Castro-Hurtado, T. Tavera, Appl. Surf. Sci. 276, 229–235 (2013)

C. Chananonnawathorn, S. Pudwat, Procedia Eng. 32, 752–758 (2012)

H.C. Chen, D.J. Jan, Electrochim. Acta 93, 307–313 (2013)

S. Keshri, A. Kumar, D. Kabiraj, Thin Solid Films 526, 50–58 (2012)

V. Madhavi, P. Kondaiah, O.M. Hussain, S. Uthanna, ISRN optics, Article ID: 801468 (2012)

S.H. Mohamed, H.A. Mohamed, H.A. Abd El Ghani, Phys. B 406(4), 831–835 (2011)

A. Kaushal, D. Kaur, J. Nanopart. Res. 13(6), 2485–2496 (2011)

K.J. Lethy, D. Beena, R. Vinod Kumar et al., Appl. Phys. A 91(4), 637–649 (2008)

J. Tauc, Amorphous and Liquid Semiconductors, Chapter 4 (Plenum, London, 1974)

C.G. Granqvist, Sol. Energy Mater. Sol. Cells 60, 201–262 (2000)

C.G. Granqvist, Handbook of Inorganic Electrochromic Materials (Elsevier, Amsterdam, 1995)

Y. Shen, T. Yamazaki, Z. Liu, D. Meng, T. Kikuta, N. Nakatani, Thin Solid Films 517, 2069 (2009)

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Firoozbakht, S., Akbarnejad, E., Salar Elahi, A. et al. RETRACTED ARTICLE: Growth and Characterization of Tungsten Oxide Thin Films using the Reactive Magnetron Sputtering System. J Inorg Organomet Polym 26, 889–894 (2016). https://doi.org/10.1007/s10904-016-0380-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-016-0380-0