Abstract

The generation of soft X-rays in a 2.8 kJ plasma focus operated with argon as a filling gas is studied using a system of five pin Si diodes filtered with different thicknesses of Mylar, Aluminium and Copper. Attention is paid to finding the pressure range for highest X-ray emission. The plasma focus device has been supplied by capacitors bank with 25 μF, 20 kV, 200 nH and a closed spark gap, to give a maximum current about 120 kA at working voltage of 15 kV. On this device, some diagnostics were carried out on the plasma focus using ohm voltage divider to record the voltage curves, Rogowskii coil for measuring the current, and five channel diodes to evaluate the temporal evolution of X-rays generated in the device working on argon versus pressure varying between 0.15 and 1.25 mbar. The analysis based on the recorded X-ray signals shows that there are two components in the X-ray emissions: one arising from the focus argon plasma with temperature of 2.5 keV and the other arising from the electron beam activity on copper anode with a temperature of 10 keV. The second component is predominant in most of investigated experiments due to the use of solid anode. In addition to that, the variation of X-ray intensity versus the energy of device was also studied. From the obtained results, it is obvious that the intensity is increased with the energy increasing. The obtained X-ray intensity versus pressure was compared with similar results taken from references and almost similar behavior was observed. The maximum energy of emitted X-rays in 4π geometry is estimated to be about 1.3 J, with an efficiency of 0.046 % at pressure of 0.15 mbar. This PF device is capable to generate X-rays, which was confirmed by making radiography for metallic pieces, electronic elements and other objects.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The attention on the plasma as a source of X-ray radiation has been paid since 1960, when strong X-ray spectra were observed from several plasma devices developed for nuclear fusion research like Z and θ-pinch machines, tokamaks and others. The plasma focus (PF) is a kind of pinch discharge. It reproduces a high energy density, intense beams of charged and neutral particles and radiation emission [1, 2].

The plasma focus is a special z-pinch-like device which can produce plasma with electron density (ne > 1020 cm−3) and temperature (Te > 500 eV). Because of its simple construction, cost-effectiveness and easy maintenance, the plasma focus appears to be a promising device for X-ray generation. Also it is a simple device, which does not require complicated high voltage techniques and expensive facilities in comparison with other pulsed X-ray sources. Experiments show that the radiation spectrum of the plasma focus in the X-ray region covers a large range from below 1 keV up to 500 keV in a time range varying from a few nanoseconds to a few hundred nanoseconds [3, 4].

The generated X-rays by plasma focus are used in many ways such as: plasma diagnostics, X-ray spectroscopy, lithography, X-ray microscopy and X-ray laser pumping, micro-machining and radiography.

The five channel diode X-ray spectrometer (DXS) can be used to obtain the temporal behavior of X-ray emission from the plasma which can determine the intensity of the X-ray yield. The used diodes in the DXS system are the BPX65 pin diodes [5].

There is a continued interest in operating plasma focus with argon for greater X-ray emission.

Ng et al. [6] studied the variation of soft X-ray emission in a low-energy (3 kJ, 15 kV) plasma focus over a pressure range in Ar and Ar–H2 admixture. Soft X-rays originating from the plasma and from electron beam activity on the copper anode were observed.

Zakaullah et al. [7–10] investigated X-ray emission from low-energy plasma focus (2.3 kJ) with filling gases hydrogen, neon and argon, at different filling pressures, where a hollow anode was used to prevent hard X-ray emission.

Favre et al. [11] studied the temporal and spatial characteristics of the X-ray emission in a 3 kJ plasma focus when operating in H2 with Ar admixture using UNU//ICTP plasma focus device.

Lee et al. [12] developed two compact plasma focus devices operating with neon, to use as an intense soft X-ray (SXR) source for microelectronics lithography because of its high performance and high repetition rate.

Wong et al. [13] studied the emission characteristics of a high-performance low energy (3 kJ) plasma focus device NX2 as an intense source of soft X-rays for microlithography and micromachining.

Hussain et al. [14] have reported a study of X-ray emission from a low energy (1.8 kJ) plasma focus device as a possible X-ray source for good contrast radiography. Rawat et al. [15] used a 3 kJ Mather—type UNU/ICTP plasma focus device with neon filling as a soft X-ray source for radiography.

Akel and Lee [16] carried out some numerical experiments using five phase radiative model RADPF5.15E with Ar as a filling gas on plasma focus device AECS PF-2 in purpose to find its characterization and soft X-ray optimization.

Since the detailed characteristics of the X-ray emission of a given focus plasma device depend in a rather complicated way on the design and operating parameters of the plasma focus device (such as the storage energy, the plasma current, and the driver impedance; the electrode and insulator material shape, and configuration; the gas pressure and composition). This motivates us to investigate the X-ray radiation emitted from our local plasma focus device (AECS PF-2 with 2.8 kJ). Because, this differs from other devices in some aspects (like: its electrical circuits, construction and parameters).

So the goal of this work is to define the working conditions of our device to be served as X-ray source for suitable applications like plasma diagnostics and radiography [16–18].

In this paper, we report the results of some X-ray measurements with argon using DXS spectrometer, to determine the X-ray intensity produced in the argon plasma of AECS PF-2, versus the argon pressure and the applied energy. Also we make some comparisons with other devices and evaluate X-ray yield of our device using the code RADPF5.15E [16].

Experimental Set Up

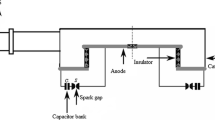

The schematic diagram of the AECS PF-2 Mather type device is shown in Fig. 1. The system is energized by a bank of two capacitors (12.5 μF, 20 kV each) connected in parallel to give 25 μF, 20 kV with maximum stored energy of 5 kJ, inductance 200 nH, and stray resistance of 14 mΩ (as nominal values). The device is provided with a high current triggering switch, a purge valve using nitrogen gas for cleaning the spark gap and a remote control unit. The cleaning process of the spark gap is carried out before and after each discharge shot several times in the device.

Experimental Set-up which consists of: a discharge chamber that can be connected to a rotary vacuum pump and gas provider, pressure meter, high voltage power supply (PS), capacitor bank, spark gap (SG), triggering circuits, high voltage (HV) probe divider, Rogowskii coil, five channel detector (DXS), digital storage oscilloscope, and a personal computer (PC)

AECS PF-2 has a central solid copper anode of length 16 cm and diameter 1.9 cm, and an outer cathode of six copper rods of length 16 cm arranged in a circle of diameter 6.4 cm, concentric with the anode. The anode is insulated from the cathode by a Pyrex glass tube of 5 cm length and 2.4 cm diameter. In the present work, argon is used as a filling gas.

The X-rays are measured with a spectrometer consisting of five BPX 65 pin diodes. The silicon diode has an effective detection area of 1 mm2, an intrinsic wafer thickness of 10 μm and a rise time of 0.5 ns.

The device was evacuated to a vacuum (2 × 10−3 mbar) by two stage rotary pump (ALCATEL 2010SD) and filled with the required gas pressure before operation. To reduce the impurity effect, after every shot, the previous gas is purged and fresh argon is filled. We have recorded about 3–10 shots for each pressure. The current in the discharge circuit and the voltage across the electrodes of PF device versus time during the plasma focus process, were monitored by Rogowskii coil as a current transformer and an ohmic voltage divider 1:100 probe, respectively. Two digital Tectronix oscilloscopes (TDS 520 C and TDS 3054 C) with 1:10 attenuators were used. The Rogowskii coil was calibrated and it was found that the calibration coefficient is 2.57 kA/V in a real scale; it corresponds to a maximum total current about 120 kA. The operational conditions were found as in the following [17]:

The charging voltage V0 = 15 kV; the bank capacitance C0 = 25 μF; the measured inductance L0 = 270 nH, the stray resistance 35 mΩ, the gas filling is argon; the pressure range is 0.15–1.25 mbar [19].

To record the X-ray signals and protect the diodes from visible and UV lights emitted from the plasma focus, the central diode is covered with a aluminized mylar foil of 22 μm thickness and the 2, 3, 4th diodes are covered with aluminium foils of thicknesses 30, 60 and 90 μm and the 5th diode is covered with a copper foil of 10 μm thickness. The X-ray spectrum may be analyzed using the recorded signals. The BPX 65 diode covered with the 22 μm aluminized mylar is sensitive to X-rays in the range of 1–10 keV [11].

For the present work the pin diodes are placed in a radial position about 45 cm away from the focus axis, looking at the pinch column and the tip of the anode as seen in Fig. 1.

The timing of the X-ray emission with respect to the plasma focus discharge pressure in Ar is achieved by simultaneously recording the X-ray signals and the transient voltage across the electrodes. The sharp spike of the anode voltage corresponds to the maximum of the focus discharge voltage.

The BPX 65 pin diodes are used as time-resolved X-ray detectors. These detectors are mounted on one vertical disk inserted inside the vacuum chambers shown in Fig. 1, and are masked by suitable filters [20].

These detectors are normalized against each other by masking each with an identical filter. To keep the X-ray flux reaching the diode at a safe level, a 0.6 mm thick brass sheet, with a 2 mm diameter hole at the center, is used to cover the diode. The signals from the X-ray detectors are recorded by four-channel 500 MHz storage digitized oscilloscope [9].

So the results were taken as average of the experiments number carried out for this work [19].

The sensitive curve of the BPX 65 pin diode is given in Fig. 2. The X-ray transmission curves for the foil combinations used in these diodes as function of wavelength are shown in Fig. 3.

Transmission curves for Mylar, Cu, Al with different thicknesses versus X-ray wavelength in nm [22]

Determination of the Energy of X-ray Emission

To record the X-ray signals in the dense PF, DXS was used [5]. The five BPX 65 pin diodes are placed onto five holes on a circular brass plate with one of them is situated in the centre of the plate and the others are in a circle around. The glass windows are removed from the diodes to extend their spectral response to the X-ray region. Instead of that, they are covered with 22 μm of aluminized mylar (where mylar coated with 0.16 μm of aluminium foil to cut off the visible light). When the outputs of the five channel diodes are recorded simultaneously, it is possible to determine the time behavior of the X-ray intensity of the plasma.

The signals recorded by the DXS are used to determine X-ray intensity of the plasma by the X-ray foil absorption technique [21]. The pin diodes in the DXS assembly are arranged in such a way that each diode can receive almost equal intensity of X-ray from the plasma focus pinch. Each diode is reversely biased at 45 V. Individual bias voltage is provided by a regulated power supply having five output terminals each of −45 V. The bias circuit for such a detector is shown in [17]. In this project, the used X-ray filters for the five channel diodes are as were mentioned before: 22 μm aluminized Mylar (Ch1), 22 μm aluminized mylar with additional aluminium foils of 30, 60, 90 and 10 μm (Cu foil) thicknesses on Ch2, Ch3, Ch4 and Ch5, respectively. The sensitivities of the five channel of pin diodes are balanced and normalized by obtaining their signals simultaneously from a plasma focus discharge with 22 μm aluminized mylar foil for all of them. The data of X-ray transmission characteristics of the filters and the computed sensitivity of the filtered pin diode BPX65 are given in ref. [22].

The X-ray intensity from the plasma source is actually detected by the pin diode with consideration of the absorption by foil placed between the source and the detector and the solid angle (assuming point source). For the plasma focus, the spectrum is not monochromatic, but having a continuum contributed by bremsstrahlung (free–free transition) and recombination (free-bound transition) [20, 21].

For this purpose, we can estimate the average value of the total X-ray energy emitted from the X-ray PF source from the area under the X-ray pulse recorded by any of the five channels. If the X-ray pulse recorded is V(t)(measured in V), then the total X-ray energy is given by [5]:

where μ is the X-ray mass absorption coefficient of aluminium; ρ is the mass density of aluminium; S λ is the sensitivity of the BPX65 diode to X-ray of wavelength λ; x is the thickness of the aluminium foil; R is the 51 Ω terminating resistor of the biasing circuit [16]; d is the distance between the source and the diode; and A is the effective detection area of the diode.

The transmission of photons displays a sudden jump when the energy of the incident photon equals to the ionization energy from the K, L, M, etc. energy levels of the filter material. Thus every element exhibits transmission windows. For the evaluation of the curves presented in Figs. 2, 3, the data for the absorption coefficients was taken from [22]. The energy of the atomic argon K α line is 2.95 keV, whereas the ionization potential of Ar XVIII is 4.43 keV. The energies of the K α lines arising from the argon ions will lie within the energy interval of 2.95–4.4 keV.

Results and Discussion

Series of experiments were carried out to get X-ray signals generated in the argon plasma focus of AECS PF-2 during the compression phase under pressure varied between 0.15 and 1.25 mbar with step of 0.1 mbar, and applied voltage of 15 kV, using X-ray spectrometer consisted of five BPX65 pin diodes.

The electrical signals of the X-ray detectors along with the high voltage (HV) probe signal are recorded by two four channel 500 MHz digital storage oscilloscopes, and the data is transferred to a computer through a GPIB 488.2 interfacing card.

Among them, typical discharges at pressures of 0.15, 0.85 and 1.25 mbar are shown in Fig. 4a, b, c. As seen from these discharges, multiple X-ray pulses are observed in according to multiplicity of the voltage spikes in the focus region. So to prevent the diodes from saturation, the diodes are placed far away (at about 45 cm) from the anode tip or the focus axis.

As seen from Fig. 4a, b, c, these X-ray pulses are believed to be associated with the focused plasma during the maximum compression of the focus discharge, except the case where there are two bursts of X-ray emission like in Fig. 4b (at 0.85 mbar). As seen from these figures the maximum of X-ray pulses agrees well with the strongest of the voltage spikes, which correspond to the maximum of plasma compression. In the case of two bursts, the first one corresponds to the X-ray produced from the argon plasma and the second burst will correspond to X-ray emitted from the copper of anode [23]. The X-ray pulse width is about 80–150 ns [24].The pulses which occur much later are probably belonged to the 8.0–10 keV copper K α lines. From comparison, it is seen that the X-ray signal is correlated with the HV probe signal.

Figure 5a–d show the results of X-ray intensity measurements defined by (*), where Fig. 5a represents the measured X-ray intensity against the gas filling pressure for all taken shots by each diode of five diodes of spectrometer. The intensity has a high value at a lower pressure, and decreases with the pressure increasing. The highest radiation yield is recorded at a filling pressure of 0.15 mbar, which is about 1.3 J in the 4π geometry. The total discharge energy per shot in this experiment is 2.8 kJ. From which the system efficiency for X-ray radiation, is approximately about 0.046 %. The average intensity recorded versus pressure by each diode on all shots is shown in Fig. 5b. And then the average intensity estimated for all diodes and shots versus pressure with error bars is given in Fig. 5c. The comparison between our results and the results reported in ref [9] is given in Fig. 5d, where in the general behavior; there is a reasonable agreement between two taken devices.

a–d The measured X-ray intensities in J versus Ar pressure in mbar recorded by BPX-65 diodes with Mylar, Al and Cu filters (a). The average intensity versus pressure (b). The average intensity with error bars (c). Comparison of our results with the results reported in ref [9] (d)

Obviously, the results in Fig. 5a–d show the decrease of the X-ray intensity with pressure increasing. Also, from the comparison, it is seen that, there are two maxima in the X-ray yield curve, the biggest one is at 0.15 mbar and the second is at 0.85 mbar (Fig. 5d). Here the strong maximum of X-ray yield reproduced by PF is about 800 mJ in the 4π geometry, which gives an efficiency of about 0.029 %.

From the overall carried out experiments, we can observe that the dominant part of X-ray emission is produced by the fast electrons bombardment with the copper solid anode or with its evaporated copper in the radial phase of PF, where the focus action is happened, and the residual part of X-ray is emitted from the argon plasma in pinch compression. On the basis of this radiation, the plasma temperature (about 2.5 keV) was determined using the ratio method, as was done in [17].

In a similar way, at a chosen pressure of 0.35 mbar, the intensity of X-rays against the energy stored in the capacitors bank, varying the applied voltage in the range of 12–16 kV, with a stored energy between 1.8 and 3.2 kJ was found and represented in Fig. 6a. Also, the average intensity versus the voltage was found as seen in Fig. 6b for each diode. The average intensity for all diodes and shots taking error bars (accuracy) into account was given in Fig. 6c. The measuring results show the increasing of the X-ray intensity with the energy increase. The values of intensity were located between 48 and 360 mJ, according to the values of the device energy varied between 1.8 kJ and 3.2 kJ which correspond to the efficiency of 0.003 and 0.011 % respectively.

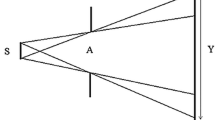

To verify the usage of the emitted X-rays in radiography, we tried to make many photos by one or two PF shots at pressure of 0.35–0.45 mbar and voltage of 15 kV. For this purpose the scheme shown in Fig. 7a was used. The obtained photos for some objects like an electric cable, a diode and some metallic pieces fixed on a vertical rubber disk are shown in Fig. 7b, c.

a, b, c The setup of radiography with PF (a), (b) is the first image of an electrical cable and (c) for a diode taken using Kodak personal monitoring film type 2 under the conditions of: argon pressure 0.35 mbar, voltage 15 kV and 2 shots, the second image is for metallic pieces was taken using Fuji 100 film under the conditions: pressure 0.36 mbar (Ar), 15 kV, and five shots (c)

However, the generated X-rays are largely originated from copper impurities arising from the interaction of energetic electrons with the anode surface. Meanwhile, the X-rays produced from the hot argon plasma constitute a small fraction from the total X-ray yield, as it was defined from the numerical experiments carried out using the code RAD PF 5.15 E of Sing Lee model. Applying this code on AECS PF-2, the calculated value of SXR yield was about 2.64 mJ at pressure of 0.15 mbar in Ar, and applied voltage of 15 kV. Comparing the measured and calculated SXR yields we found that the calculated value did not exceed 0.33 % from the measured one (at the same conditions) [16, 17]. Meanwhile, the X-rays produced from the hot argon plasma constitute a small fraction (about <10 % [16]) from the whole X-rays emitted of the plasma focus under taken conditions [17].

Also, the results of carried out experiments indicate that the anode voltage records had much variation from one shot to another. In some shots a single voltage spike is recorded, and in most shots multiple spikes are seem, the X-ray signals also show similar variations.

From the obtained results, we can conclude that the X-rays emitted from AECS PF-2 consist not only of the plasma soft X-rays (line and bremsstrahlung radiations indicated by the first burst in Fig. 4b), but of the Cu line X-rays arising from the copper anode hit by energetic electrons (presented by the second burst in the same figure). Therefore, the AECS PF-2 belongs to the PF devices which have X-rays contaminated with copper K α line.

Finally, the X-ray emission in this environment was not predominantly from hot plasma, but rather from the interaction of fast electrons with the anode tip.

A significant damage at the anode surface was observed, this enhances the interaction of electrons in the current sheath or the electron beam from the focus region with the anode tip.

It is suggested, that for improving the work of our PF device as a source of X-ray emission, it is better to use a hollow anode or an engraved anode to about several centimeters deep to minimize the interaction of the energetic electrons with the anode.

Conclusions

The five channel BPX 65 PIN diodes detector was used to study the X-ray emission from plasma focus of argon.

It is obvious that AECS PF-2 with energy 2.8 kJ is capable to generate X-ray emission in Ar as a filling gas under pressure ranging from 0.15 to 1.25 mbar and applied voltage of 15 kV. The maximum produced intensity is about 1.3 J in one shot. This intensity is decreased with increasing the pressure, which may be occurred due to the temperature decreasing with the pressure increasing. Also it was observed the existence of two X-ray bursts: the first one is related to the argon plasma X-ray emission and the second to the copper contamination ejected from the solid anode under fast electrons bombardment. The second part dominates the total X-ray radiation generated from the AECS PF-2.

The X-ray intensity in related to the gas pressure and energy of the PF device was determined and compared with some results obtained from other PF device. The behavior of the variation X-ray intensity versus pressure was very close to each other.

The calculated results of the SXR intensity produced in AECS PF-2 at a certain Ar pressure using the code RAD PF 5.15 E of Sing Lee model confirms the results obtained on our device.

It is worthy to notice that the emitted X-ray from the argon plasma was very weak in comparison with the X-ray emitted from the copper anode especially on the copper K α line which is accompanied with electron temperature equals to 10 keV.

In addition to that, the variation of X-ray intensity versus the energy of device was also studied, where the intensity is increasing with the energy increase. Also, clear radiographic images for various objects were obtained, this result serves as a good tool for X-ray emission from our PF device.

References

M. Liu, ‘Soft X-ray from compact plasma focus’. PhD Thesis, School of Science, Nanyang Technological University (1996)

L. Soto, Plasm Phys. Control. Fusion 47, A361–A381 (2005)

M. Shafiq, S. Hussaina, M. Sharif, M. Zakaullah, A. Waheed, Phys. Lett. A 302, 23–27 (2002)

T. Zhang, X. Lin, K.A. Chandra, T.L. Tan, S.V. Springham, A. Patran, P. Lee, S. Lee, R.S. Rawat, Plasm Sour. Sci. Technol. 14, 368–374 (2005)

C.S. Wong, Five channel diode X-ray spectrometer (type B), instruction manual, ICACUM/DXS-3 (University of Malaya, Malaysia, 1992)

C.M. Ng, S.P. Moo, C. San Wong, IEEE Trans. Plasm Sci. 26(4), 1146–1153 (1998)

M. Zakaullah, K. Alamgir, M. Shafiq, M. Sharif, A. Waheed, IEEE Trans. Plasm Sci. 30(6), 2089–2094 (2002)

M. Zakaullah, K. Alamgir, M. Shafiq, M. Sharif, A. Waheed, G. Murtaza, J. Fusion Energ. 19(2), 143–157 (2000)

M. Zakaullah, K. Alamgir, G. Murtaza, A. Waheed, Plasm Sour. Sci. Technol. 9, 592–596 (2000)

M. Zakaullah, I. Ahmead, M. Shafique, G. Murtaza, M. Yassin, M.M. Beg, Phys. Scr. 57, 136–141 (1998)

M. Favre, S. Lee, S.P. Moo, C.S. Wong, Plasm Sour. Sci. Technol. 1, 122–125 (1992)

S. Lee, P. Lee, G. Zhang, X. Feng, V.A. Gribkov, M. Liu, A. Serban, T.K.S. Wong, IEEE Trans. Plasm Sci. 26(4), 1119–1126 (1998)

D. Wong, A. Patran, T.L. Tan, R.S. Rawat, P. Lee, IEEE Trans. Plasm Sci. 32(6), 2227–2235 (2004)

S. Hussain, M. Shafiq, R. Ahmad, A. Waheed, M. Zakaullah, Plasm Sour. Sci. Technol. 14, 61–69 (2005)

R.S. Rawat, T. Zhang, G.J. Lim, W.H. Tan, S.J. Ng, A. Patran, S.M. Hassan, S.V. Springham, T.L. Tan, M. Zakaullah, P. Lee, S. Lee, J. Fusion Energ. 23(1), 49–53 (2004)

M. Akel, S. Lee, J. Fusion Energ. 31, 122–129 (2012)

S. Al-Hawat, M. Akel, C.S. Wong, J. Fusion Energ. 39(6), 503–508 (2011)

S.P. Moo, C.S. Wong, J. Fiz. Mal. 15, 37–45 (1994)

S. Al-Hawat, M. Akel, S. Lee, S.H. Saw, J. Fusion Energ. 31(1), 13–20 (2012)

C.S. Wong, Five channel diode X-ray spectrometer, instruction manual, ICAC-UM/DXS-4 (University of Malaya, Malaysia, 1992)

C.S. Wong, Elements of plasma technology (University of Malaya, Malaysia, 2002)

X-ray interaction with matter, http://www-cxro.lbl.gov/optical constants

C.S. Wong, S.P. Moo, J. Singh, P. Choi, C. Dumitrescu-Zoita, C. Silawatshananai, Mal J Sci 17B, 109–117 (1996)

V.A. Gribkov, M. Liu, P. Lee, S. Lee, A. Srivastava, Nanyang Technological University, NIE, Singapore, 151–159, (2000)

Acknowledgments

The authors would like to thank general director of AECS for support, guidance and encouragement. Also, many thanks to Prof. C. S. Wong former president of Asian African Association for Plasma Training (AAAPT) for providing us with a set of five channel diode X-ray spectrometer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Hawat, S., Akel, M. & Shaaban, S. X-ray Intensity Measurements in 2.8 kJ Plasma Focus Device Operated with Argon Using a Five Channel Diode Spectrometer. J Fusion Energ 34, 163–171 (2015). https://doi.org/10.1007/s10894-014-9771-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10894-014-9771-9