Abstract

Bacillus subtilis has shown success in antagonizing plant pathogens where strains of the bacterium produce antimicrobial cyclic lipopeptides (CLPs) in response to microbial competitors in their ecological niche. To gain insight into the inhibitory role of these CLPs, B. subtilis strain B9–5 was co-cultured with three pathogenic fungi. Inhibition of mycelial growth and spore germination was assessed and CLPs produced by B. subtilis B9–5 were quantified over the entire period of microbial interaction. B. subtilis B9–5 significantly inhibited mycelial growth and spore germination of Fusarium sambucinum and Verticillium dahliae, but not Rhizopus stolonifer. LC-MS analysis revealed that B. subtilis differentially produced fengycin and surfactin homologs depending on the competitor. CLP quantification suggested that the presence of Verticillium dahliae, a fungus highly sensitive to the compounds, caused an increase followed by a decrease in CLP production by the bacterium. In co-cultures with Fusarium sambucinum, a moderately sensitive fungus, CLP production increased more gradually, possibly because of its slower rate of spore germination. With co-cultures of the tolerant fungus Rhizopus stolonifer, B. subtilis produced high amounts of CLPs (per bacterial cell) for the duration of the interaction. Variations in CLP production could be explained, in part, by the pathogens’ overall sensitivities to the bacterial lipopeptides and/or the relative growth rates between the plant pathogen and B. subtilis. CLP production varied substantially temporally depending on the targeted fungus, which provides valuable insight concerning the effectiveness of B. subtilis B9–5 protecting its ecological niche against the ingress of these pathogens.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plant diseases cause approximately 20% of pre- and post-harvest losses of fruit and vegetable crops worldwide. The majority of these diseases are caused by fungal phytopathogens that affect both crop yield and quality (Kharwar et al. 2014). Current management strategies for plant pathogens rely on pesticide applications, use of disease-free or resistant cultivars, as well as crop rotation (Ongena et al. 2005). Synthetic chemical fungicides are the most common and effective method available for the control of fungal phytopathogens. However, fungicide resistant pathogenic strains, growing fungicide costs, and accumulation of chemical residues are among potential risks and drawbacks for synthetic fungicide use. The persistence of these compounds in the environment is a growing concern because of the potential adverse effects on humans and other non-target organisms (Grover et al. 2010). In this context, alternative fungal plant pathogen control measures are required to replace fungicides or mitigate their risks.

Among alternatives to fungicides, biocontrol agents (BCAs), specifically biofungicides, are currently showing great promise for phytoprotection applications (Ongena et al. 2005). Biocontrol agents are beneficial antagonistic organisms used to control harmful organisms such as plant pathogens. BCAs have been shown to reduce pathogenic microorganism growth by direct parasitism, competition, antimicrobial compound production (antibiosis), and/or stimulation of induced systemic resistance (ISR) in the host plant (Ongena et al. 2005).

Bacillus species, particularly B. subtilis, are effective biocontrol agents and incorporated into several biofungicide formulations currently on the market such as Serenade® and Kodiak® (Falardeau et al. 2013). The Bacillus species is widely distributed as rhizobacteria in soil and soil adjuncts such as manures and composts, and play a crucial role in the ecology of plant rhizospheres. The beneficial ecological role of these bacteria are, in part, related to their production of a wide variety of antimicrobial compounds including non-peptide (Hamdache et al. 2011; Wise et al. 2012) and peptide compounds such as cyclic lipopeptides (CLPs) (Stein 2005). CLPs are a large class of amphiphilic molecules composed of a polar cyclic peptide moiety with a hydrophobic fatty acid tail (Stein 2005). CLPs are non-ribosomally produced compounds distinguishable by the variable composition of their cyclic amino acid structures and fatty acid chains (Ali et al. 2016). This large group of antimicrobials is composed of three main families: fengycins, iturins, and surfactins.

CLPs from the surfactin and iturin families are lipoheptapeptides. Surfactins are known to have both antiviral and antibacterial activities, although they may not show strong antifungal inhibitory properties. Iturins have strong antifungal and hemolytic activities, with limited antibacterial properties (Ongena and Jacques 2008; Stein 2005). The fengycin family is composed of lipodecapeptides and have particularly strong antifungal activities towards filamentous fungi (Farace et al. 2015).

The antimicrobial activity of CLPs primarily involves their ability to interact with and disrupt permeability of cell membranes. This activity is attributable to their overall amphiphilic structures. Specifically, CLPs modify surface tension of cell membranes allowing pore formation and, ultimately, triggering cell apoptosis (Ongena and Jacques 2008; Tao et al. 2011). The mode of action and structural diversity of this group of lipopeptides is presumably the source of their broad antimicrobial activity, acting on a wide variety of both bacterial and fungal phytopathogens (Falardeau et al. 2013). Individual B. subtilis strains have been shown to co-produce multiple lipopeptide families and homologs (Malfanova et al. 2012; Mohamed et al. 2017). It has previously been shown that various lipopeptides have differential antimicrobial effects and that interaction among the lipopeptides present has been found to influence the bacterium’s ability to successfully affect growth of other microorganisms (Akpa et al. 2001; Liu et al. 2014).

The three families of lipopeptides are not always produced by all B. subtilis strains and significant amounts of these metabolites are only produced when the antagonist is under stress conditions. A change in available space, nutrients, pH, light, and/or oxygen occurs with the presence of a nearby competitor (such as a plant pathogen), which acts to introduce significant environmental stress on the CLP-producing microorganism (Posada-Uribe et al. 2015; Stein 2005).

There are still many unknowns regarding the success of using living organisms for phytoprotection due to the substantial impact that the presence of competitors has on the survival and proliferation of BCAs (Ali et al. 2016). Additional research is required to determine the potential ecological outcomes from the interactions between BCAs and targeted fungal phytopathogens. Specifically, there is little work on the effect of competing microorganisms on the antagonistic and/or antimicrobial activities of BCAs.

Previous work identified and quantified the production of CLPs by B. subtilis strains isolated from soil, as well as determined their effectiveness against selected pathogenic species (Dunlap et al. 2011; Liu et al. 2014; Ongena et al. 2005). To our knowledge, there are no studies focused on the relative timing of lipopeptide production by B. subtilis in the presence of a plant pathogen. Time-course studies aimed at quantifying metabolite production by antagonistic bacteria provide valuable information regarding the potential outcome of interactions with competing microorganisms. This information is crucial in determining the spectrum of effectiveness of an antimicrobial-producing species.

The production of CLPs by B. subtilis strain B9–5 was investigated in the presence of three fungal phytopathogens potentially found within the bacteria’s ecological niche in plant rhizospheres. The objectives of this study were (i) to determine inhibitory effects of B. subtilis B9–5 on mycelial growth and spore germination of the fungi and (ii) to identify and quantify bacterial CLP production when co-inoculated with competing fungal species.

Methods and Materials

Microbial Material

Bacillus subtilis (Ehrenb.) Cohn strain B9–5 was extracted from disease suppressive compost composed of bovine manure and peat moss (Mohamed et al. 2017). The isolated bacterium was stored as a frozen glycerol stock (−80 °C) and maintained on tryptic soy agar (TSA, Becton Dickinson, Sparks, MD) at 23 °C.

The plant pathogenic fungal species Fusarium sambucinum Fuckel (strain 2351), Rhizopus stolonifer (Ehrenb.) Vuill. (strain 198), and Verticillium dahliae Kleb. (strain 175) were provided by the Laboratoire de diagnostic en phytoprotection (MAPAQ, Quebec, QC). These pathogenic fungi were stored as freeze-dried stocks and maintained on potato dextrose agar (PDA, Becton Dickinson) at 23 °C.

Effect of B. subtilis B9–5 on Mycelial Growth of Plant Pathogens

In vitro confrontation bioassays were performed on PDA by placing a 5-mm plug of actively-growing mycelia in the center of a 100 × 15 mm Petri dish. Four 1-cm streaks of freshly-cultured B. subtilis B9–5 were then inoculated at each of the four cardinal points. Inocula of the bacterium were placed at distances of 1 cm (V. dahliae) or 3.5 cm (F. sambucinum and R. stolonifer) from the mycelial plugs. Controls were prepared by placing a fungal plug in the center of a PDA dish without bacterial inoculations. The prepared dishes were incubated in the dark at 23 °C for 6.5, 1.5, and 9 days for F. sambucinum, R. stolonifer, and V. dahliae, respectively.

Following incubation, growth was recorded and the percentage of inhibition was calculated according to the following formula: percent inhibition = (C-T)/C × 100, where C = average diameter of fungal thallus of control treatments and T = average diameter of fungal thallus of B. subtilis B9–5 treatments. The experiment was performed according to a randomized complete block design with ten repetitions per treatment.

Preparation of Fungal Spore and Bacterial Cell Suspensions

Fungal spore suspensions were prepared from PDA cultures of F. sambucinum, R. stolonifer, and V. dahliae. Sterile distilled water (2 mL) was added to individual Petri dishes and the fungal thallus was lightly scraped with a sterile glass rod to dislodge spores. The spore suspensions were transferred to sterile 1.5-mL microcentrifuge tubes. Bacterial cell suspensions were prepared by collecting cells from day-old TSA cultures of B. subtilis B9–5 with a sterile inoculation loop. Bacterial cells were transferred to 1 mL of sterile distilled water in 1.5-mL microcentrifuge tubes. Spore suspensions were adjusted to 2.5 × 104 spores/mL and bacterial suspensions were adjusted to 1.2 × 106 cells/mL using a hemocytometer.

Inoculation in Mixed Cultures

Microorganisms were co-cultured in 100 mL of MOLP medium containing 20 g/L of sucrose, 30 g/L of peptone, 7 g/L of yeast extract, 1.9 g/L of KH2PO4, 0.45 g/L of MgSO4, 9 mL/L of trace element solution (TES), and 9 mL/L of a citric acid solution (10 g/L ddH2O) as described previously (Akpa et al. 2001; Mohamed et al. 2017). TES was prepared by adding CuSO4 (0.001 g), FeCl3 (0.005 g), Na2MoO4 (0.004 g), KI (0.002 g), ZnSO4 (0.014 g), H3BO3 (0.01 g), and MnSO4 (0.0036 g) to 1 L of sterile ultra-pure water. Media were co-inoculated with 1 mL of one of the three fungal spore suspensions and 1 mL of the bacterial cell suspension. One mL of the bacterial suspension alone served as the control. Inoculated media were incubated at 30 °C with shaking (120 rpm) for 72 h with periodic sampling as described below.

Effect of B. subtilis B9–5 on Conidial Germination of Plant Pathogens

Inhibition of fungal spores was tested using a germination assay. Samples were taken at 24 h for the co-cultures with R. stolonifer and 48 h for F. sambucinum and V. dahliae. One hundred μL of co-cultured microorganisms were spread on water agar (15 g/L agar, Becton Dickinson) containing 8 mg/L chloramphenicol (Sigma-Aldrich, Oakville, ON). These experiments were incubated for 24 h at 23 °C in the dark. Following the incubation period, Petri dishes were observed under visible light using an inverted microscope. Spores were considered germinated when the length of the germ tube equaled at least the length of the spore. The percentage of germinated cells was calculated as follows: percent germination = germinated spores/total spores × 100. The experiment was performed according to a randomized complete block design with three replicates.

Effect of Fungal Spores on Cyclic Lipopeptide Production by B. subtilis B9–5

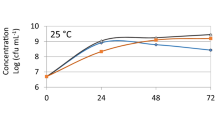

One flask of each treatment was recovered following 24, 48, and 72 h incubation periods to evaluate lipopeptide production over time. One mL of each flask was recovered, serial diluted and 100 μL of each dilution were transferred to TSA containing 50 mg/L of nystatin (Sigma-Aldrich) to selectively enumerate bacteria. Bacteria were expressed as colony forming units (cfu) per mL.

Extraction of Lipopeptides

Following incubation, samples were removed and centrifuged at 15,400×g for 30 min to pellet the majority of the biomass. The resulting supernatants were filtered through 0.45-μm polyethersulfone filters to obtain cell-free filtrates. Filtrates were acidified to a pH range of 1.9 to 2.0 with 5 M HCl and samples were kept at 4 °C overnight to precipitate lipopeptides.

Following precipitation, samples were centrifuged at 4400×g for 30 min at 4 °C and the supernatant was discarded. Resulting pellets were each washed with 3 mL of methanol and were re-centrifuged at 4400×g for 30 min at 4 °C. Supernatants containing the lipopeptides were transferred to sterile 15-mL tubes and stored at 4 °C until use.

Supernatants were dried using a rotary evaporator and re-dissolved in 5 mL of HPLC-grade methanol. Samples were filtered through 0.22-μm polytetrafluoroethylene filters, diluted 1:10 with HPLC-grade methanol and transferred to glass HPLC vials with 250-μL inserts.

LC-MS Analysis

Samples were screened by LC-UV-MS using a Waters 2795 separation module with a Waters 996 diode array detector and Micromass Quatro LC mass spectrometer. The fractions were separated on a Phenomenex Kinetix C18 column (100 × 4.60 mm, 2.6 μm, 100 Å) (Torrance, CA) and the peaks were scanned at wavelengths between 210 and 400 nm. The mobile phase consisted of acetonitrile-water with formic acid [0.1%, (v/v)]. The solvent gradient was linearly programmed from 5% to 100% acetonitrile over 13 min at a flow rate of 1 mL min−1 and was held at 100% acetonitrile for 2 min. Concentrations of total and individual homologs for both surfactins and fengycins were quantified using calibration curves of authentic standards analyzed with the same conditions. Authentic fengycin standards were isolated and purified from B. subtilis strain B9–5 as described previously (Akpa et al. 2001). Surfactin and iturin A from B. subtilis were purchased from Sigma-Aldrich. The identity of fengycin and surfactin homologs was determined chromatographically and spectroscopically by comparison with authentic standards and published data.

Statistical Analysis

For mycelial growth and spore germination bioassays, two-tailed t-tests were conducted to compare B. subtilis strain B9–5 treatments to the respective controls. A significant difference was declared if P ≤ 0.05.

For lipopeptide time-course studies, analysis of variance (ANOVA) was conducted on the lipopeptide concentration values of the treatments obtained from the analysis of the LC-UV-MS chromatograms. When significant (P ≤ 0.05), means were separated using Fisher’s protected least significant difference (LSD) test (α level = 0.05).

Results

Effect of B. subtilis B9–5 on Plant Pathogen Mycelial Growth and Spore Germination

In vitro confrontation bioassays indicated that B. subtilis B9–5 significantly reduced the mycelial growth of F. sambucinum and V. dahliae by 26 and 37%, respectively (Fig. 1). Conversely, the bacterium did not affect the growth of R. stolonifer.

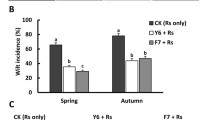

In germination assays, treatment with B. subtilis B9–5 significantly reduced germination of F. sambucinum and V. dahliae by 58 and 96%, respectively (Fig. 2). Germination of R. stolonifer spores was not affected by the presence of the bacterium.

Effect of Bacillus subtilis strain B9–5 on germination of Fusarium sambucinum, Rhizopus stolonifer, and Verticillium dahliae spores. Germination in the absence (black) or presence (white) of B. subtilis B9–5. Asterisks (*) denote significant differences from the control, according to a t-test (P ≤ 0.05)

Effect of Fungal Spores on Cyclic Lipopeptide Production by B. subtilis B9–5

LC-MS analysis revealed mixtures of CLP homologs produced by B. subtilis strain B9–5. No iturin homologs were found when comparing CLP production with authentic reference materials. Conversely, multiple fengycin and surfactin peaks were observed. Fig. 3 shows a chromatogram displaying five fengycin peaks between 8.80 min to 9.98 min and four surfactin peaks between 12.39 min to 13.46 min.

Chromatogram of extracted lipopeptides showing five peaks of fengycin homologs and four surfactin homolog peaks. Time is in min. F1 = fengycin A [C16], F2 = fengycin A [C17 & C18], F3 = fengycin A [C19], F4 = fengycin B [C14 & C15], F5 = fengycin B [C16], S1 = surfactin [C12], S2 = surfactin [C13], S3 = surfactin [C14], S4 = surfactin [C15]

More specifically, Fig. 4 shows the mass spectra of seven fengycin homologs derived from peaks F1-F5 in Fig. 3 and were in accordance with the authentic standards. Analysis showed that homologs of both fengycin A and B were produced, with fengycin A homologs eluting earlier than fengycin B homologs. The F1 peak (Fig. 4a) had a protonated molecular ion ([M + H]+) at m/z = 1464 and was identified as fengycin A with a C16 fatty acid chain. The F2 peak (Fig. 4b) had molecular ions ([M + H]+) at m/z = 1478 and 1492, corresponding to fengycin A with C17 and C18 fatty acid chains, respectively, which had co-eluted. The F3 peak (Fig. 4c) had a molecular ion ([M + H]+) at m/z = 1506 and was identified as fengycin A with a C19 fatty acid chain. Fengycin B C14 and C15 co-migrated (peak F4, Fig. 4d). These homologs had molecular ions ([M + H]+) at m/z = 1462 and m/z = 1476, respectively. The F5 peak (Fig. 4e) had a molecular ion ([M + H]+) at m/z = 1490, which corresponded to fengycin B with a C16 fatty acid chain.

Figure 5 shows the mass spectra of the four surfactin homologs identified in the prepared samples. The S1 peak (Fig. 5a) had a protonated molecular ion ([M + H]+) at m/z = 994 and was identified as surfactin with a C12 fatty acid chain. The S2 peak (Fig. 5b) had a molecular ion ([M + H]+) at m/z = 1008, corresponding to surfactin with a C13 fatty acid chain. The S3 peak (Fig. 5c) had a molecular ion ([M + H]+) at m/z = 1022 and was identified as surfactin with a C14 fatty acid chain. Finally, the S4 peak (Fig. 5d) had a molecular ion ([M + H]+) at m/z = 1036, which corresponded to surfactin with a C15 fatty acid tail.

Quantitation of the CLPs indicated a much larger amount of fengycin compared to surfactin following co-culture incubations. The content of fengycin was 7.3- to 13.9-fold higher than that of surfactin at 48 and 72 h (Fig. 6). There was no significant difference in total fengycin or surfactin per volume (Fig. 6a, b) or per cfu (Fig. 6c, d) of the 24-h co-cultures relative to the control. After 48 h, the total CLP per volume was not significantly different than the control, with the exception of a 28% lower concentration in surfactin in the F. sambucinum co-culture (Fig. 6b). However, the 48 h co-cultures showed marked differences in lipopeptide concentration per bacterial unit (cfu). Co-culture with R. stolonifer resulted in a 2.0-fold and 1.7-fold increase in fengycin and surfactin concentration, respectively (Fig. 6c, d). Conversely, other co-cultures showed a decrease in lipopeptide concentration per cfu at 48 h. More specifically, the presence of F. sambucinum resulted in 56 and 49% lower fengycin and surfactin amounts, respectively. Furthermore, the presence of V. dahliae revealed 19% less surfactin compared to the control (Fig. 6d). After 72 h co-culture incubation, the presence of F. sambucinum showed a 3.0- and 3.5-fold higher concentration of fengycin and surfactin, respectively, compared to controls (Fig. 6a, b). In addition, R. stolonifer and V. dahliae presence revealed a 2.4- and 1.8-fold increase in fengycin concentration per volume, respectively, compared to controls (Fig. 6a). Finally, on a per cfu basis, R. stolonifer co-cultures showed the highest fengycin concentration of all the treatments (3.5-fold higher than the control). V. dahliae co-cultures also showed significantly higher fengycin concentration than the control (1.5-fold) albeit less than R. stolonifer. All co-cultures also showed significantly higher surfactin concentrations (per cfu) than the control. Co-culture with F. sambucinum and V. dahliae showed similar surfactin increase (1.8-fold average increase) whereas R. stolonifer revealed the highest concentration increase (2.1-fold) relative to the control (Fig. 6d).

Effect of Fusarium sambucinum, Rhizopus stolonifer, and Verticillium dahliae on production of total fengycin and surfactin by Bacillus subtilis strain B9–5. a Fengycin, μg/mL; b surfactin, μg/mL; c fengycin, μg/colony forming unit (cfu); d surfactin, μg/cfu. Bars with the same letter are not significantly different according to Fisher’s protected least significant difference test (α level = 0.05)

When fengycin A and fengycin B homologs were analyzed separately, fengycin A homologs were the most abundant, ranging from 53 to 80% of total fengycin produced. On a per volume basis, there was no difference between the B. subtilis B9–5 control and the co-cultures for either fengycin A or B homologs after 24 or 48 h (Fig. 7a, b). At 72 h, all cultures showed an average of 2.7-fold higher fengycin A concentration, whereas only F. sambucinum show a higher fengycin B concentration (5.2-fold) when compared to their respective controls. On a per microbial unit (cfu) basis, co-culture with R. stolonifer caused a 2.1-fold higher fengycin A concentration at 48 h and a 4.6-fold higher fengycin B concentration at 72 h (Fig. 7c, d). There were no other significant changes in fengycin A and B production per cfu for any other treatment-time combination when compared to the controls.

Effect of Fusarium sambucinum, Rhizopus stolonifer, and Verticillium dahliae on production of fengycin A and B by Bacillus subtilis strain B9–5. a Fengycin A, μg/mL; b fengycin B, μg/mL; c fengycin A, μg/colony forming unit (cfu); d fengycin B, μg/cfu. Bars with the same letter are not significantly different according to Fisher’s protected least significant difference test (α level = 0.05)

When surfactin was analyzed, surfactin homologs with C13 and C14 chain lengths were the dominant homologs, representing approximately 65–75% of all surfactin produced. No significant differences were found with any treatment-time combination in these homologs with the exception of a 2.0-fold higher surfactin C13 homolog concentration (on a per cfu basis) with a co-culture of R. stolonifer and B. subtilis B9–5 when compared to the control (Fig. 8c).

Effect of Fusarium sambucinum, Rhizopus stolonifer, and Verticillium dahliae on production of surfactin C13 and C14 by Bacillus subtilis strain B9–5. a Surfactin C13, μg/mL; b surfactin C13, μg/mL; c surfactin C14, μg/colony forming unit (cfu); d surfactin C14, μg/cfu. Bars with the same letter are not significantly different according to Fisher’s protected least significant difference test (α level = 0.05)

Discussion

The antimicrobial potential of B. subtilis B9–5 and its CLP production was investigated in order to gain insight into potential outcomes of interactions of the bacterium with microorganisms present in its ecological niche in plant rhizospheres. The results of our LC-MS analysis indicate that fengycins were the predominant class of CLP produced by B. subtilis B9–5 in response to the presence of fungal competitors. Varying quantities of surfactin homologs were also consistently produced while no iturin homologs were identified. The strong antifungal activity of fengycin may explain their abundance in the presence of fungal competitors (Deleu et al. 2005). Although surfactins are not known for their high antifungal properties, these CLPs are important for B. subtilis biofilm development and swarming motility (Liu et al. 2014), which may have been important in the co-cultures. The lack of production of members of the iturin family by B. subtilis B9–5 is consistent with previous results from our laboratory (Mohamed et al. 2017), although the production of iturin A and bacillomycin (two members of the iturin family) is common among other strains of B. subtilis (Ongena and Jacques 2008; Romero et al. 2007).

In general, the production of fengycin A homologs were predominant over fengycin B for all treatments with the exception of F. sambucinum co-cultures. These results were similar to those of Malfanova et al. (2012), which also showed that fengycin A homologs were present in much larger amounts compared with fengycin B homologs. Our results also indicated that surfactins C13 and C14 were the dominant homologs produced from this CLP family. Malfanova et al. (2012) also reported the prevalence of these two homologs from B. subtilis strain HC8 samples in addition to the C15 surfactin homolog. Previous studies indicated that fatty acid chain length may affect the activity of CLPs including surfactin (Bonmatin et al. 2003; Eeman et al. 2006).

The overall trends of lipopeptide production over time can be accounted for by comparison with the typical physiological stages of B. subtilis (Walker et al. 1998). In suitable conditions, the log growth phase of B. subtilis is between 0 and 24 h, in which low CLP production is expected. This is followed by early and late stationary phases around 24 and 48 h, respectively, followed by a vegetative cell death phase (Dunlap et al. 2011).

The production of lipopeptides in our control treatments agree with Stein (2005) as both fengycin and surfactin production peaked during the bacteria’s typical late stationary growth phase around 48 h. Indeed, the continued growth and expansion of B. subtilis colonies over time would have increased environmental stress surrounding the bacteria as both space and nutrients were depleted, thereby increasing lipopeptide production. In this case, surfactins would seem particularly important for the colonization of Bacillus spp. with regards to biofilm development and swarming motility (Perez-Garcia et al. 2011; Stein 2005).

Other results indicate that the B. subtilis B9–5 treatments did not affect the mycelial growth or spore germination of R. stolonifer, while those of F. sambucinum and, in particular, V. dahliae were significantly reduced. The plotting of lipopeptide concentrations per bacterial unit (cfu) revealed that production of fengycin and surfactin were the most substantial in co-cultures with R. stolonifer, the fungus most tolerant of CLPs. R. stolonifer is a particularly fast growing fungal species, which may allow it to outcompete B. subtilis B9–5 regardless of elevated CLP production (Bautista-Baños et al. 2014). In fact, R. stolonifer was unaffected by the bacterium and B. subtilis B9–5 appeared to produce higher CLP quantities in response to the competing fungus, perhaps in a continuous, albeit unsuccessful, attempt to protect its ecological niche. Moreover, the combined production of surfactins and fengycins by B. subtilis B9–5 may play a role in its inefficacy in controlling R. stolonifer. Indeed, Tao et al. (2011) and Liu et al. (2014) reported negative effects of surfactin on the antifungal activity of fengycin against R. stolonifer. The possible stabilizing effect of surfactin on R. stolonifer membrane lipid bilayers was indicated as a possible cause for this phenomenon as it may reduce the pore-forming abilities of fengycin (Tao et al. 2011).

Mycelial growth and spore germination of both F. sambucinum and V. dahliae were inhibited by the presence of B. subtilis B9–5. F. sambucinum was moderately sensitive, whereas V. dahliae was highly sensitive to the presence of B. subtilis. Generally, CLP production in the V. dahliae co-cultures peaked earlier, around 48 h, then declined to lower levels. These results may indicate that V. dahliae was highly and quickly inhibited by the presence of B. subtilis B9–5, which could explain the decrease in CLP production after 48 h of co-culture, a time at which CLP production may no longer have been required. This would indicate that this fungus is particularly sensitive to fengycin, surfactin, and combinations thereof as has been reported previously (Liu et al. 2014).

The lipopeptide production from the F. sambucinum co-cultures rose more slowly and continuously over 72 h. It was also shown in the germination trial that F. sambucinum controls took longer to germinate and produce mycelium than V. dahliae. Indeed, at the same time period, only 80% of the spores had germinated whereas 100% germination was found in V. dahliae. This may indicate that B. subtilis B9–5 quantitatively synchronized its CLP production with increasing active growth of F. sambucinum over time, thus explaining the higher CLP concentration later on in the incubation period. It is noteworthy that F. sambucinum co-cultures showed much higher surfactin production from B. subtilis than other co-cultures in which fengycin production prevailed, often reaching 10-fold higher levels than surfactin. Previous work from our laboratory suggested that B. subtilis strains producing surfactins displayed strong antifungal activity against F. sambucinum when compared to fengycins (Liu et al. 2014). Other work also indicated that surfactin was the dominant CLP (i.e., the one most responsible for antifungal activity) in other Fusarium spp. (Cao et al. 2012; Chan et al. 2009; Rebib et al. 2012).

B. subtilis antimicrobial cyclic lipopeptides are thought to provide the bacterium with a competitive advantage when confronted with other microorganisms in the plant rhizosphere. The interactions between two or more of these compounds may have significant impacts on the overall effectiveness of an isolate against targeted phytopathogens (Liu et al. 2014). For example, surfactin and iturin A have displayed synergistic fungitoxicity (Ongena and Jacques 2008) while surfactins are suspected of negative interactions with fengycin homologs (Tao et al. 2011). However, other work has shown multiple outcomes (additive, synergistic, negative) of CLP interactions depending on the targeted microorganism (Liu et al. 2014). It has been shown that the lipid composition of the fungal membrane could explain differences in the sensitivity or tolerance outcome to one or more CLPs (Fiedler and Heerklotz 2015; Wise et al. 2014). The potential applications of CLP-producing B. subtilis in the agricultural ecosystem are because of their influence on altering the microbial distributions within their environment to benefit both the bacterium, the plant, and humans.

Overall, our work determined key differences regarding the effectiveness of B. subtilis B9–5 against R. stolonifer, F. sambucinum, and V. dahliae. The comparison of fungal inhibition and differential CLP production by B. subtilis B9–5 over the interaction period suggested a higher sensitivity of V. dahliae and lower sensitivity of R. stolonifer to combinations of fengycin and surfactin homologs. Future research regarding the antimicrobial production of various strains of B. subtilis as well as mechanistic studies will help further elucidate the beneficial role of these CLPs in microbial interactions from both an ecological and plant protection perspective.

References

Akpa E, Jacques P, Wathelet B, Paquot M, Fuchs R, Budzikiewicz H, Thonart P (2001) Influence of culture conditions on lipopeptide production by Bacillus subtilis. Appl Biochem Biotechnol 91-3:551–561. https://doi.org/10.1385/abab:91-93:1-9:551

Ali GS, El-Sayed ASA, Patel JS, Green KB, Ali M, Brennan M, Norman D (2016) Ex vivo application of secreted metabolites produced by soil-inhabiting Bacillus spp. efficiently controls foliar diseases caused by Alternaria spp. Appl Environ Microbiol 82:478–490. https://doi.org/10.1128/aem.02662-15

Bautista-Baños S, Bosquez-Molina E, Barrera-Necha LL (2014) Rhizopus stolonifer (soft rot). In: Bautista-Baños S (ed) Postharvest Decay. Elsevier, Inc., London, pp 1–37

Bonmatin JM, Laprevote O, Peypoux F (2003) Diversity among microbial cyclic lipopeptides: iturins and surfactins. Activity-structure relationships to design new bioactive agents. Comb Chem High Throughput Screen 6:541–556. https://doi.org/10.2174/138620703106298716

Cao Y, Xu Z, Ling N, Yuan Y, Yang X, Chen L, Shen B, Shen Q (2012) Isolation and identification of lipopeptides produced by B. subtilis SQR 9 for suppressing Fusarium wilt of cucumber. Sci Hortic 135:32–39. https://doi.org/10.1016/j.scienta.2011.12.002

Chan Y-K, Savard ME, Reid LM, Cyr T, McCormick WA, Seguin C (2009) Identification of lipopeptide antibiotics of a Bacillus subtilis isolate and their control of Fusarium graminearum diseases in maize and wheat. BioControl 54:567–574. https://doi.org/10.1007/s10526-008-9201-x

Deleu M, Paquot M, Nylander T (2005) Fengycin interaction with lipid monolayers at the air-aqueous interface - implications for the effect of fengycin on biological membranes. J Colloid Interface Sci 283:358–365. https://doi.org/10.1016/j.jcis.2004.09.036

Dunlap CA, Schisler DA, Price NP, Vaughn SF (2011) Cyclic lipopeptide profile of three Bacillus subtilis strains; antagonists of Fusarium head blight. J Microbiol 49:603–609. https://doi.org/10.1007/s12275-011-1044-y

Eeman M, Berquand A, Dufrene YF, Paquot M, Dufour S, Deleu M (2006) Penetration of surfactin into phospholipid monolayers: nanoscale interfacial organization. Langmuir 22:11337–11345. https://doi.org/10.1021/la061969p

Falardeau J, Wise C, Novitsky L, Avis TJ (2013) Ecological and mechanistic insights into the direct and indirect antimicrobial properties of Bacillus subtilis lipopeptides on plant pathogens. J Chem Ecol 39:869–878. https://doi.org/10.1007/s10886-013-0319-7

Farace G, Fernandez O, Jacquens L, Coutte F, Krier F, Jacques P, Clément C, Barka EA, Jacquard C, Dorey S (2015) Cyclic lipopeptides from Bacillus subtilis activate distinct patterns of defence responses in grapevine. Mol Plant Pathol 16:177–187. https://doi.org/10.1111/mpp.12170

Fiedler S, Heerklotz H (2015) Vesicle leakage reflects the target selectivity of antimicrobial lipopeptides from Bacillus subtilis. Biophys J 109:2079–2089. https://doi.org/10.1016/j.bpj.2015.09.021

Grover M, Nain L, Singh SB, Saxena AK (2010) Molecular and biochemical approaches for characterization of antifungal trait of a potent biocontrol agent Bacillus subtilis RP24. Curr Microbiol 60:99–106. https://doi.org/10.1007/s00284-009-9508-6

Hamdache A, Lamarti A, Aleu J, Collado IG (2011) Non-peptide metabolites from the genus Bacillus. J Nat Prod 74:893–899. https://doi.org/10.1021/np100853e

Kharwar RN, Upadhyay RS, Dubey NK, Raghuwanshi R (2014) Microbial diversity and biotechnology in food security. Springer, New Delhi

Liu JJ, Hagberg I, Novitsky L, Hadj-Moussa H, Avis TJ (2014) Interaction of antimicrobial cyclic lipopeptides from Bacillus subtilis influences their effect on spore germination and membrane permeability in fungal plant pathogens. Fungal Biol 118:855–861. https://doi.org/10.1016/j.funbio.2014.07.004

Malfanova N, Franzil L, Lugtenberg B, Chebotar V, Ongena M (2012) Cyclic lipopeptide profile of the plant-beneficial endophytic bacterium Bacillus subtilis HC8. Arch Microbiol 194:893–899. https://doi.org/10.1007/s00203-012-0823-0

Mohamed R, Groulx E, Defilippi S, Erak T, Tambong JT, Tweddell RJ, Tsopmo A, Avis TJ (2017) Physiological and molecular characterization of compost bacteria antagonistic to soil-borne plant pathogens. Can J Microbiol 63:411–426. https://doi.org/10.1139/cjm-2016-0599

Ongena M, Jacques P (2008) Bacillus lipopeptides: versatile weapons for plant disease biocontrol. Trends Microbiol 16:115–125. https://doi.org/10.1016/j.tim.2007.12.009

Ongena M, Jacques P, Toure Y, Destain J, Jabrane A, Thonart P (2005) Involvement of fengycin-type lipopeptides in the multifaceted biocontrol potential of Bacillus subtilis. Appl Microbiol Biotechnol 69:29–38. https://doi.org/10.1007/s00253-005-1940-3

Perez-Garcia A, Romero D, de Vicente A (2011) Plant protection and growth stimulation by microorganisms: biotechnological applications of Bacilli in agriculture. Curr Opin Biotechnol 22:187–193. https://doi.org/10.1016/j.copbio.2010.12.003

Posada-Uribe LF, Romero-Tabarez M, Villegas-Escobar V (2015) Effect of medium components and culture conditions in Bacillus subtilis EA-CB0575 spore production. Bioprocess Biosyst Eng 38:1879–1888. https://doi.org/10.1007/s00449-015-1428-1

Rebib H, Hedi A, Rousset M, Boudabous A, Limam F, Sadfi-Zouaoui N (2012) Biological control of Fusarium foot rot of wheat using fengycin-producing Bacillus subtilis isolated from salty soil. Afr J Biotechnol 11:8464–8475

Romero D, de Vicente A, Rakotoaly RH, Dufour SE, Veening JW, Arrebola E, Cazorla FM, Kuipers OP, Paquot M, Pérez-García A (2007) The iturin and fengycin families of lipopeptides are key factors in antagonism of Bacillus subtilis toward Podosphaera fusca. Mol Plant-Microbe Interact 20:430–440. https://doi.org/10.1094/mpmi-20-4-0430

Stein T (2005) Bacillus subtilis antibiotics: structures, syntheses and specific functions. Mol Microbiol 56:845–857. https://doi.org/10.1111/j.1365-2958.2005.04587.x

Tao Y, Bie XM, Lv FX, Zhao HZ, Lu ZX (2011) Antifungal activity and mechanism of fengycin in the presence and absence of commercial surfactin against Rhizopus stolonifer. J Microbiol 49:146–150. https://doi.org/10.1007/s12275-011-0171-9

Walker R, Powell AA, Seddon B (1998) Bacillus isolates from the spermosphere of peas and dwarf French beans with antifungal activity against Botrytis cinerea and Pythium species. J Appl Microbiol 84:791–801. https://doi.org/10.1046/j.1365-2672.1998.00411.x

Wise C, Novitsky L, Tsopmo A, Avis TJ (2012) Production and antimicrobial activity of 3-hydroxypropionaldehyde from Bacillus subtilis strain CU12. J Chem Ecol 38:1521–1527. https://doi.org/10.1007/s10886-012-0219-2

Wise C, Falardeau J, Hagberg I, Avis TJ (2014) Cellular lipid composition affects sensitivity of plant pathogens to fengycin, an antifungal compound produced by Bacillus subtilis strain CU12. Phytopathology 104:1036–1041. https://doi.org/10.1094/phyto-12-13-0336-r

Acknowledgements

The authors thank Dr. J. David Miller for use of LC-MS and Blake Green for technical assistance. This work was supported by research grant RGPIN-2015-05679 from the Natural Sciences and Engineering Research Council (NSERC) of Canada to T.J.A.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

DeFilippi, S., Groulx, E., Megalla, M. et al. Fungal Competitors Affect Production of Antimicrobial Lipopeptides in Bacillus subtilis Strain B9–5. J Chem Ecol 44, 374–383 (2018). https://doi.org/10.1007/s10886-018-0938-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10886-018-0938-0