Abstract

The purpose of the study was to develop a novel, efficient, stable, chemically crosslinked polymeric system that have pH responsive behaviour and can effectively release 5-FU in a controlled manner. Furthermore it can target colonic cancer minimizing the side effects of in vivo chemotherapy via 5-FU. Swelling and drug release studies were performed to evaluate its in vitro release behaviour. Hydrogels were also characterized by FTIR, SEM and DSC. In vitro cytocompatibility and cytotoxicity of the hydrogels were determined by MTT assay using HeLa cells. Developed hydrogels were then administered to rabbits orally to evaluate its pharmacokinetic behaviour in vivo. Maximum swelling, drug loading and release were observed at pH 7.4. Similarly maximum absorption was achieved at pH 7.4 in rabbits. It is concluded that CMC-co-poly(AA) have a great potential to be used for controlled drug delivery and colonic targeting for the delivery for various anticancer drugs.

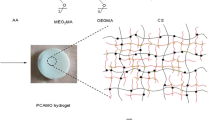

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Predominantly, the pharmaceutical researchers have been focusing to discover the novel drugs and unusual drug administration systems, out of which controlled release systems have great importance. Among the diverse categories of polymeric systems employed by the researchers as release rate controlling barriers, hydrogels gained a remarkable attraction to be exploited for the development of a range of novel drug delivery systems [1]. The mechanisms of drug release from the controlled drug delivery systems (DDSs) depend upon the polymeric network systems in which the therapeutic agents are incorporated. The retention times of the drugs to be released from the formulations of polymeric networks are variable, which could be from few hours to months or a year, depending upon the type of formulations. A three-dimensional, cross-linked polymeric network system consisting of various natural or synthetic substances acquiring a high degree of adaptability due to high amounts of water imbibing ability are said to be as hydrogels [2]. Hydrogels exhibit the property of being flexible and soft rubbery consistency and strength, resembling living tissues in swollen form due to the capability to retain large amount of water or biological fluids under various physiological conditions. Owing to the presence of linkages both physical and chemical in hydrogel systems, the penetration of water to polymeric network in hydrogel, the systems is only swelled up but not dissolved [2,3,4,5,6,7]. The hydrophilic characteristic of the network is because of the chemical groups present in the polymer structure which include hydroxyl (–OH), amidic (-–CONH–),carboxylic (–COOH), sulphonic (–SO3H), etc. [1]. Hydrogels can be fabricated using both the natural and synthetic polymers [6].The rate and extent of hydration of hydrogel systems depend on the nature of polymeric network, aqueous environment and available hydrophilic groups in the structures [8]. Smart hydrogels are able to respond to the external stimulus or environmental conditions like temperature and pH by using smart polymers with such potentialities [9]. Such hydrogel systems have been exclusively reported for the targeted and controlled delivery of a range of drug compounds [10].

There has been reported still an important issue and a challenge for the scientists both from academia and pharmaceutical R&D sector to develop the site specific drug delivery systems to effectively and in a controlled way deliver the active pharmaceutical ingredients to the colon [11]. It has been determined that CRC is one of the major cause of the death worldwide [12]. Chemotherapeutic agents play a valuable role in the treatment of cancers at different stages [13]. Paul Ehrlich, proposed an idea of “magic bullet”, where the drug would only target the diseased cells without harming the health cells [14]. A successful colonic delivery is achieved when a drug is secured from the upper GIT environment and eventually releases by reaching the colon [15].

Chitin, a natural polysaccharide undergoes deacetylation and yields a derivative, chitosan, which shows better biodegradability and biocompatibility. Chitosan undergoes carboxymethylation yielding Carboxymethyl chitosan (CMC) by substituting some of the chitosan’s –OH groups with –CH2COOH groups [16]. CMC is widely used in controlled or sustained release and pH responsive drug delivery systems. CMC is an amphoteric polyelectrolyte acquiring both charges including positive and negative, and many researchers developed hydrogels as matrices for controlled drug delivery systems. The difference of Osmotic pressure between inside of the gel and its surroundings is the key factor which tunes swelling of the CMC gel [17, 18]. CMC which is a water-soluble derivative of chitosan, has received a noticeable attraction for its important biomedical and pharmaceutical applications. Additionally, Carboxymethyl chitosan shows distinctive properties including low toxicity, biocompatibility, high viscosity and better potential to be formulated as films and hydrogels [16]. CMC hydrogel systems have shown significant swelling behaviour in basic solutions and thus are widely been studied for controlled delivery [19].

Acrylic acid (AA) is a commercial polyelectrolyte super-absorbent and a pH responsive monomer used in variety of drug delivery devices for site-specific delivery of various drugs [20]. Polyacrylic acid formed of acrylic acid shows promising biocompatibility and bioadhesivness at the mucosal lining due to the presence of certain groups such as carboxylic, that interacts by hydrogen bonding with the mucin, a glycoprotein [10]. AA is non toxic and quite sensitive to temperature and pH and customarily shows swelling behaviour above pH 5. One of the main applications and potentially novel property of AA gels is its prominent role to develop sustained gastro-intestinal drug delivery system [21].

5-Fluorouracil (5-FU) the most important anti-cancerous agent, which has been used via oral administration for different types of cancers; however it has got certain severe adverse effects that cannot be neglected and imminently required to be addressed. Therefore to overcome the adverse drug reactions of 5-FU, a hydrogel system is formulated to deliver the drug at its specific site of colon cancer which is the main purpose of study as well. This objective was achieved by pH responsive behaviour of the developed hydrogel and consequently controlled release of the drug both in vitro and in vivo.

The main focus of the present study was to effectively deliver the most widely used anti cancer drug, 5-Fluorouracil to its site of action for the treatment of colon cancer and to avoid the systemic side-effects and decreased bioavailability. Owing to the most imperative pharmaceutical attributes of biocompatible polymers and monomers, this study was designed to utilise them for formulation of a novel pH-sensitive carboxymethyl chitosan-co-poly(AA) hydrogel by free radical polymerization technique using N,N-methylenebisacrylamide (MBA) as a cross-inking agent. In this regards, by varying compositions of polymer, monomer and the cross-linker, various formulation were synthesized to investigate the swelling characteristics, thermal stability, morphological properties and drug release from the drug delivery matrices. In addition, to establish the cytotoxicity level of the produced hydrogel, the cell line study on Cells (HeLa cells and Vero cells) was also performed. The comparative cell viability study on both free form of 5-FU and encapsulated in hydrogel at various concentrations (1, 2, 4, 6, 8, 10, 15 and 20 µg/ml) by MTT Assay was also performed. Furthermore the developed hydrogels CMC-co-poly(AA) was subjected to in vivo study using animal models (rabbits) to validate the controlled and targeted (pH-responsive) drug delivery.

2 Materials and methods

2.1 Chemicals

Carboxymethyl chitosan (CMC) was purchased from Shangai chemicals limited, (China). Acrylic acid, Sodium hydroxide pellets, Potassium dihydrogen phosphate were purchased from DAEJUNG Company (Korea). Hydrochloric acid was purchased from Scharlau, (Spain). N,N-methylene(bis)acrylamide (MBA) was purchased from Fluka (Germany). Benzoylperoxide (BPO) and ethanol were purchased from Daejung, (Korea). Distilled water was freshly prepared in the laboratory of COMSATS institute of information technology, Abbottabad.

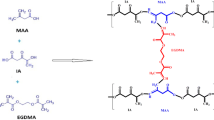

2.2 Synthesis of carboxymethyl chitosan-co-poly(AA) hydrogels

Various ratios of polymer, monomer and cross-linker were used to formulate hydrogels by chemical cross-linking method known as free radical polymerization technique. Weighed amount of CMC was dissolved in water and stirred continuously using a magnetic stirrer until a clear solution obtained. The dissolved oxygen from the polymer solution was removed by purging the nitrogen stream for 30 min at room temperature. Benzoyl peroxide (BPO), the initiator used was weighed and dissolved in specified amount of ethanol at room temperature with continuous stirring until the clear solution obtained and then this initiator solution was added slowly to the Acrylic Acid (AA), which is the monomer. Additionally, solution of N,N-methylene(bis)acrylamide (MBA), was separately prepared by adding up distilled water in specific amount. At room temperature, BPO-AA solution was slowly added to the CMC solution with continuous stirring. Finally, the MBA solution was added drop-wise to the polymer-monomer solution. The prepared solution was finally added to the glass tubes which were then placed in the water bath at 55 °C for 4 h, followed by 60 °C for 8 h and finally 65 °C for 8 h. The glass tubes were placed at room temperature for an hour and then the hydrogels were treated with ethanol-water (70:30) to wash un-reacted contents. The produced discs were dried in vacuum oven at 40 °C for one week. Table 1 shows the composition of all formulations and Figure S1 represents proposed chemical structure of developed hydrogel.

2.3 Fourier transform infrared spectroscopy (FT-IR)

The produced hydrogel samples were properly crushed/milled for analysis. Confirmation of CMC-AA hydrogels formation was investigated using fourier transform infrared spectroscopy. FT-IR analysis of the polymer, monomer and hydrogels was performed. The FT-IR spectra were scanned over a range of 4500–500 cm−1.

2.4 Differential scanning calorimetry (DSC)

Differential scanning calorimetry (DSC) analysis of the produced hydrogel formulation, CMC and AA was carried out to determine the glass transition temperature (Tg) of the samples using diamond series thermal analysis system (Perkin Elmer, USA). In the standard aluminium pan, sealing of 0.5 to 3 mg samples by keeping temperature between 20–500 °C at a heating rate of 20 °C/min with purging of nitrogen and the samples were analysed three times.

2.5 Scanning electron microscopy (SEM)

Investigation of the structural morphology and porosity of prepared hydrogel samples was evaluated using JEOL analytical SEM apparatus (JSM-5910, Japan). All the samples for SEM analysis were prepared by grinding to the optimum sized particles and then mounted on the aluminium stub with double adhesive tape. Gold coating of the produced samples was carried out under argon atmosphere, using gold sputter coater. At different magnifications, photomicrographs were obtained to carry out the morphology studies.

2.6 Swelling studies

The humid weight measurements and the pH-sensitivity determination were conducted by immersing the weighed hydrogel discs into the prepared HCl solution (pH: 1.2) and buffer solution (pH: 7.4) at room temperature. The discs were drawn from the solution and tapped on the blotted paper to remove excess liquid and then weighed at predetermined time intervals from all the containers and placed back in the same solution. Weighing process was continued until a constant weight of the hydrogel discs was achieved. Following equation was used to calculate the percent swelling ratio

where, Ws is the weight of swollen disc

2.7 Sol–gel fraction

Evaluation of the consumed reactants in developing the CMC-co-poly(AA) hydrogels is determined by sol-gel fraction. Soluble unreacted contents are generally the sol contents of the polymerization reaction. For this purpose, hydrogels were cut into discs that are almost 2 mm thick and were dried at 55 °C until the weight of the disc is equilibrated. These dried discs were then subjected to extraction by placing them in the soxhlet apparatus for 4 h in deionized boiling water and again dried at same temperature until weight reaches an equilibrium. Sol and gel fraction were determined using the following equation:

whereas, Wi = initial weight of dried hydrogel disc before extraction

We = dried hydrogel weight after extraction

2.8 Drug loading studies

Post-synthesis diffusion method has been adopted to load the drug in hydrogels. CMC/AA hydrogels discs were loaded with model drug 5-Fluorouracil (5-FU) by swelling of gels in suitable medium. Immersion of the dried hydrogel discs into 1% drug solution prepared in buffer solution with pH 7.4 was ensured at room temperature for 72 h. Discs were then collected and washed with distilled water. The 5FU loaded discs were initially dried at room temperature followed by drying in oven at 40 °C until equilibrium is attained.

2.9 Drug loading evaluation

Extraction technique has been employed to measure the drug loading efficiency. Fresh buffer with pH 7.4 has been used to extract the drug, 5-FU. Samples were collected and analysed at different time of intervals. The process continued till the solution is left with no more drug. The calibration curve of various 5-FU dilutions was constructed and used for determination of drug contents in hydrogel. The analysis of drug quantification was carried out at wavelength 266 nm using UV–vis-spectrophotometer (UV-1601 Shimadzu). All the samples were analysed in triplicate.

2.10 Drug release studies

Dissolution properties were evaluated for the estimation of pH-responsive targeted delivery and controlled drug release at different pH. Drug release profile was analyzed by immersion of each of the loaded hydrogel discs in 900 ml solutions at both low pH (1.2) and high pH (7.4) in USP Dissolution apparatus-II (Semi-automated Dissolution Tester with auto-sampler of Pharma Test Germany) at 37 ± 0.5 °C. Samples were withdrawn at estimated time intervals and assessed using UV-Spectrophotometer (UV-1601 Shimadzu) at 266 nm wavelength. Maintenance of sink condition with fresh dissolution medium was ensured after every withdrawal of samples.

2.11 Cell cultures and cell viability studies

To perform cell cytotoxicity study, Cells (HeLa cells and Vero cells) were cultured in a medium containing RPMI-1640 supplemented with l-glutamine (2 mM), penicillin (100 UmL−1) and streptomycin (100 ug mL−1) accompanied with 10% FBS grown in a 75 cm2 tissue culture flask and stored in an incubator supplied with 5% CO2 at a constant temperature of 37 ◦C. After 80% confluency, the cells were harvested, seeded and cultured at 10,000 cells/well in a 96-well flat bottom cell culture plate and used for cell viability studies. The comparative cell viability study was conducted for 5-FU both in free form and encapsulated in hydrogel form at various concentrations (1, 2, 4, 6, 8, 10, 15 and 20 µg/ml) by MTT Assay. Cell viability study was conducted in 24 well plate. 5-FU in free form was used as positive control while untreated cells were used as negative control respectively. The cytotoxicity of the hydrogel was determined by placing the drug loaded disk in 24 well plate containing different concentrations of 5-FU. Cell culture medium containing RPMI-1640 supplemented with l-glutamine (2 mM), penicillin (100 UmL−1) and streptomycin (100 ug mL−1) was added on the top of the hydrogel disk followed by incubation for 24 h at 37 °C. The absorbance was calculated with BioTek synergy HT (BioTek Instruments, Inc.; Winooski, VT) at 490 nm. The cell viability % was calculated by using the following formula;

where Asample and A control refer to the absorbance’s of the sample and control wells respectively. The measurements were performed in triplicate. The compiled data were presented as Mean Cell Viability ± SD.

2.12 In vivo evaluation

In vivo analysis of 5-FU in rabbit plasma was performed using an accurate, simple, sensitive and reproducible HPLC-UV method developed and validated by [22]. The HPLC method was used to quantify drug in rabbit plasma after the administration of 5-FU loaded hydrogel discs in rabbits. Healthy albino rabbits (2.0–2.6 kg) were obtained from the animal house of Faculty of Pharmacy and Alternative Medicine, the Islamia University of Bahawalpur-Pakistan. The study protocols were evaluated and approved by Pharmacy Research Ethics Committee (PREC). Health rabbits were selected and divided in to two groups of 12 rabbits each (Group A and Group B). Drug solution (5-FU, 50 mg/kg) was administered to group-A (as control) using feeding tube in the first phase. In second phase, 5-FU loaded discs of hydrogels were administered orally to group-B of rabbits. After regular intervals, the blood samples (0.5 ml each) were drawn from the jugular vein of rabbits. Heparinized polypropylene tubes were used for collection of plasma and stored at −70 °C in ultra-low freezer (Sanyo, Japan).

After dosing in rabbits, estimation of drug concentration in rabbit plasma was performed using Microsoft® Office Excel 2007 program. Pharmacokinetic parameters were calculated using Kinetica® version 4.1.1 (Thermo Electron Corporation).

3 Results

3.1 Physical appearance

The hydrogels were smooth in texture and upon drying a slight change in colour was observed from transparent to yellowish colour. Physical appearance of CMC-AA hydrogels synthesized by free radical polymerization is shown in Figs. S2 and S3.

The polymerisation of CMC and AA occurred by crosslinking and consequently resulted in stable polymeric networks. There was observed that the few of the freshly prepared gels were transparent and few of them appeared cloudy or milky white, depending on the difference in the concentration of the polymers and monomers in inconsistent formulations. After drying in oven, formulations became light yellowish and golden yellow in colour depending upon polymer-monomer ratios in the prepared matrices. The hydrogels with higher monomer concentrations were shiny, non-sticky and non-abrasive showed great mechanical strength and the formulations with maximum concentration of cross-linker attained excellent strength and stability [2]. Hydrogels with more polymeric ratio were brittle and difficult to grind. All the produced hydrogels exhibited appropriate gelling and retained shape in swelled form as well.

3.2 Fourier transform infrared spectroscopy (FTIR)

The FTIR spectra of polymer, monomer and developed hydrogels are shown in Fig. 1. The FTIR spectra of carboxymethyl chitosan has shown following main peaks: the peak at 1030 and 1063 cm−1 represent the C–O stretch of –CH2–OH in primary alcohols and –CH–OH in cyclic alcohols. The peaks found at 1400 and 1600 cm−1 show symmetric and asymmetric stretch of –COO in corresponding carboxylic acid salt. The peak existing at 2900 cm−1 shows –C–H stretch and similar results have been reported by [23], while working on superporous hydrogels containing poly(acrylic acid-co-acrylamide)/O-carboxymethyl chitosan interpenetrating polymer networks. The peak appearing at 1741 cm−1 reveals the presence of –COOH group and at 1506 cm−1 the presence of –NH3 group has been confirmed. Similar findings have been reported by [24]. A peak at 3400 cm−1, occupancy of –OH stretch has been unveiled, resembling with already reported CMC spectra by [23, 25]. Peaks at 3429 cm−1 accredited to both the hydrogen bonded (–O–H and –N–H) groups. A band at 1765 cm−1 is assigned to the amino group (–NH2 deformation) [26].

The acrylic acid spectrum present remarkable peaks at 1600 cm−1 due to –C–C stretch and –C–O stretching at 1700 cm−1 [9]. A stretching vibration at 2972 cm–1 reveals –CH2 presence and C–C stretch at 1296 cm−1. The band at 1173 cm−1 represents –C–O stretching vibration whereas –C = O stretch is represented at 1635 cm−1 by [8]. A broader peak at 3000 cm−1 represents –O–H stretching and band at 2922 cm−1 is evident of –C–H group [9, 27]. N–H stretching vibrations appeared between 3330 and 3060 cm−1 and C–N stretching at 1650 cm−1 are the indication of presence of cross-linking agent, methylene-bis-acrylamide (MBA) [27].

The FTIR spectrum of CMC-co-poly(AA) testifying the major changes between 1200–2800 cm−1 region, which indicates that a broad peak is formed showing interactions between CMC and AA, in which hydroxyl groups of CMC are substituted with acrylate [28] and new bonds formation between them confirming new cross-linked polymeric system. Thus, displaying AA grafting on the polymeric backbone of CMC via MBA cross-linking agent.

3.3 Differential scanning calorimetry (DSC)

DSC of pure polymer CMC and CMC-co-poly(AA) hydrogels were performed to understand the thermal behaviour and stability of the compound and formulation. Figure 2 shows DSC thermograms of CMC and CMC-co-poly (AA). CMC-co-poly(AA) hydrogel matrix and the polymer, carboxymethyl chitosan (CMC) went through DSC cycle runs to analyse the thermal behaviour at a temperature starting from 0–500 °C. In the present study, hydrogel appeared to be thermally more stable than that of individual polymer and monomer components. Comparatively, smaller peaks in the formulation unveiling new polymeric structure.

In the DSC investigation, an initial endothermic peak appeared at 280 °C corresponding to water loss, which has also been reported by [29] in CMC. The expectation of water evaporation in the endothermic peak reflects the physical or molecular changes in carboxymethylation. In the DSC thermogram of CMC-co-poly(AA) hydrogel, Fig. 2 showed similarity of endothermic peak has been observed with minor changes. Smaller endothermic peak appeared at a slight difference from the one appeared in CMC thermogram at about 300 °C and minor fluctuations at 400 °C were observed.

3.4 Scanning electron microscopy (SEM)

To evaluate the morphological characteristics of the produced hydrogels, SEM study was carried out. Samples were crushed to desired size in order for better evaluation. Samples were analysed by taking micrographs ranging from 100× to 10,000 × level. Micrographs of SEM are shown in Fig. 3. Scanning electron microscopy has been conducted for evaluating the surface morphology of the prepared hydrogel formulation.

Scanning Electron Microscopy is essential in regard of investigating the constitution of prepared matrices from open surfaces and cross-sectional parts by SEM. A smoother outer texture, an interconnected denser inner part has shown in the Fig. 3. With the progression of polymerization reaction, a reduction in the solubility of polymeric network occurs causing water molecules evaporation, leading to a compact interconnected polymeric network when the copolymerization reaction ends. Swelling capability of the hydrogel matrices depends on how much the network structure is porous [22].

3.5 Sol–gel analysis

Sol–gel analysis was performed to determine the uncross-linked polymer fraction in hydrogel structure. Table S1 shows calculations for sol and gel fractions of each hydrogel formulation. The sol-gel fraction of prepared CMC-co-poly(AA) formulations were inquired to appraise the influence of increasing CMC and AA contents on sol-gel fraction shown in Table S1. The extraction process emerges the uncross-linked polymer removal of the gel structure. The extracted gels were then dried in drying oven at 45 °C until consistent or stable weight was achieved. Increased gel reaction reveals increasing quantity of both polymer and monomer (Table 2

).

3.6 Determination of drug loading efficiencies (%DLE)

Diffusion method was employed for entrapment of 5-FU (Table 3). The difference of weights in solutions before and afterwards the swelling experiments were determined by UV–visible spectrophotometry at 266 nm wavelength, thus results obtained reflect the weight of entrapped drug in the hydrogel. Table S2 shows the entrapped drug in the hydrogel discs in various formulations along with the release at various pH. There was observed increase in the drug loading in the formulations with increasing polymeric content. However, a decrement in the entrapment of model drug was observed by increasing both the monomer and cross-linker’s content in the formulation as shown in Table S2.

3.7 Effect of pH on swelling

Investigating the swelling behaviour of CMC-co-poly(AA) hydrogels at pH 1.2 and 7.4 indicating that hydrogel discs underwent pH dependant swelling. Studies were conducted on formulations with increasing concentrations of polymer, monomer and cross-linker. With increased concentration of polymer and keeping the other variables i.e. monomer and cross-linker ratios constant, there was observed a remarkable pH dependant swelling assigning to the ionizable functional groups. All the hydrogels formulations demonstrated a significant difference in the swelling index at both pH values. Dynamic swelling was evaluated with respect to time. Figure 4 shows the swelling behaviour of hydrogel formulation at various pH.

3.8 Effect of polymer, monomer and crosslinking agent on swelling

Results showed that by increasing the concentration of CMC in hydrogel formulations, while keeping the Acrylic acid contents constant resulted in comparative increase in swelling index at acidic pH 1.2. At basic pH 7.4, a drop of swelling ratio was noticed with increasing CMC concentration. This study demonstrated that hydrogel formulations exhibited higher swelling as compared to the acidic pH 1.2. The results have been shown in Fig. S4. At higher pH values, the effect of keeping constant polymeric ratio and increasing the contents of acrylic acid, the maximum swelling was observed in hydrogel formulations with higher amounts of acrylic acid as compared to the formulation with minimum amount of monomer used and the results are shown in Fig. S5. A decrement in the swelling at both the low as well as high pH was observed with increasing cross-linker’s percentage as shown in Fig. S6, respectively.

3.9 In vitro drug release studies

Drug release was performed at pH 1.2 and pH 7.4 in order to investigate the release behaviour of 5-Fluorouracil to interpret the targeting and controlled release. Percent drug release of 5-FU from CMC-co-poly (AA) has been shown in Fig. 5 to better compare the findings. Different percentages of release rate were observed with increasing polymer concentration which includes 95, 93.2 and 92.5%, respectively (Fig. S7). Likewise, percent release obtained by increasing monomer concentration were 91.4, 96.2 and 96.7%, whereas a decrease in drug release was observed with increasing cross-linking agent in hydrogels with 93, 93 and 89%, respectively (Figure S8 and S9). In vitro drug release behaviour of gels were carried out to predict the release characteristics of CMC-co-poly(AA) hydrogels in the simulated gastro-intestinal fluids [30]. 5-Fluorouracil, as a model drug was loaded for evaluating its release against the pH stimuli. Maximum drug loading was noticed in the discs that showed better swelling behaviour as well. The percentage release of 5-Fluorouracil studies at pH 1.2 and pH 7.4 has been shown in Fig. 1.

3.10 Effect of hydrogel composition on drug release behaviour

Release studies were conducted on CMC-co-poly(AA) hydrogels with varying CMC concentrations of 0.2 gm (F1), 0.4 gm (F2) and 0.6 gm (F3) in the three formulations whereas the other two variables i.e. monomer and cross-linker ratios were kept constant. Results showed a decline in the drug release percentage with increasing the polymer concentration and this phenomenon can be explained relatively with swelling kinetics of the hydrogel. Cumulative drug release percentage with different concentrations of carboxymethyl chitosan as a function of time is shown in Fig. S7. The release profile of 5-Fluorouracil from selected samples with increase in monomer concentration at pH 1.2 and pH 7.4 at 37 °C are presented in Fig. S8. Higher drug release percentage was observed as the AA contents were increased at both low as well as at high pH. A reduction in drug release was observed with an increase in MBA concentration. Cumulative percent release is shown in Fig. S9.

3.11 Determination of cell viability

The in vitro cytocompatibility and cytotoxicity of the hydrogels were determined by MTT assay. Figure (A) shows the in vitro cytocompatibility against Vero cells (Normal cells). Saline and distilled water (DW) were used as a control with above 85% cell viability in this experiment. The results shown in Fig. 6 clearly represent that the hydrogel sample (F2, 20 µg/ml) has good cytocompatibility with no detectable cytotoxicity. For the determination of cell cytotoxicity, HeLa cells previously cultured were subjected to MTT assay. Figure 6 shows the comparative anticancer activities of 5-FU on free and loaded form at various concentrations.

3.12 In vivo evaluation

In order to evaluate the in vivo absorption of 5-FU loaded hydrogels, discs were administered to animal models (rabbits) and blood samples were collected up to 24 h and were analysed via an accurate, simple and reproducible HPLC-UV method [22]. The chromatograms of 5-FU in blank and spiked plasma are shown in Fig. 7. CMC-co-poly(AA) hydrogels loaded with 5-FU showed an increased plasma concentration up to 24 h. The maximum drug concentration Cmax observed was (Mean ± SD) (121.262 ± 5.332 μg/mL) at Tmax of (Mean ± SD) (24.00 ± 0.00 h). The results of the study has revealed that Cmax of hydrogel was less as compared to oral drug solution, so it can be expected that drug will be released in GIT up to extended period of time (24 h). Plasma drug concentrations in rabbits are summarized in Table S3 and S4 and represented in Figs. S10 and S11. The Pharmacokinetic parameters of 5-FU oral solution and hydrogels are summarized in Tables S5 and S6. The developed CMC based polymeric matrices could effectively deliver the anticancer drug to the colon part of the GIT (Tables 4–7).

4 Discussion

4.1 Structural, thermal and morphological evaluation

FTIR spectrum of CMC-co-poly(AA) showed a different pattern from carboxymethyl chitosan and acrylic acid FTIR peaks. Appearance of new peaks in synthesized hydrogels and deviation from pure ingredients spectra confirmed the formation of new bonds in cross-linked structures.

DSC graphs revealed that a thermally stable polymeric network is synthesized by combination of carboxymethyl chitosan and acrylic acid with methylene bisacrylamide.

Microscopic scanning of hydrogels showed a rough and wavy surface along with micropores and channels. Microporous structure of hydrogel network facilitates the diffusion of solvent into network. Interaction of solvent molecules initiates the ioinization of functional groups at various pH levels and creates repulsive forces between crosslinked joints. Repulsive forces produce cavities that lead to swelling and drug release.

4.2 Sol–gel analysis

The study revealed that by increasing quantity of both polymer and monomer, increased gel reaction was achieved. The basis of this elevation is a polymerization reaction due to cross-linking at greater extent, thus resulting in the stable product formulation. Na-Alg/CMC hydrogels (smart super-absorbent) prepared using MBA as cross-linker in already reported study by [31] showed similar findings of increasing gel fraction with an increase in sodium alginate content. It was observed that increasing the concentration of CMC (F1–F3), AA (F4–F6) and MBA (F7–F9), the sol fraction showed decreased whereas the gel fraction increased resulting in more grafting. Dergunov et al. [32] has also observed, increased in the gel fraction by increasing chitosan concentration in chitosan and polyvinyl pyrrolidone hydrogel. Similarly high AA content and cross-linking agent showed similar trend results in increased gel fraction. Similar findings were reported in pH-sensitive hydrogels of chitosan-co-acrylic acid for controlled release of verapamil by [10].

4.3 Drug loading efficiency

Chemically cross-linked CMC-co-poly(AA) hydrogels were used to incorporate the drug in the network structure. There has been reported two general methods for loading of drugs onto hydrogels, in the first method drug is added to the hydrogel synthesis solution; however, few serious drawbacks may occur as drug molecule with reactive sites can be chemically attached to hydrogel constituents with subsequent loss of efficacy. Therefore, on the basis of the mentioned side effects which could potentially be occurred, the second method i.e. absorption/diffusion method was employed to entrap/load 5-FU by immersing each disc in 1% drug solution [22].

4.4 Effect of pH on swelling

It has become evident that pH has a strong effect on swelling ability due to carboxylic groups presence in monomer in the hydrogel structure. The similar swelling behaviour by hydrogel formulations, has also been previously reported [33]. The carboxylic groups which are weak acid in nature, are mainly responsible for pH sensitivity of hydrogel formulations. At high pH, carboxylic groups get protonated causing ionic repulsion thus leading to swelled gels and at low pH, unprotonated carboxylic groups give rise to unswelled or collapsed hydrogels. Increase in the degree of ionization, is responsible for conversion of polymeric into hydrophilic network, supporting the swelling kinetics. Similar results were observed in pH-sensitive Acrylic acid/PVA hydrogels formulations [27].

4.5 Effect of hydrogel composition on swelling

Results has shown that by increasing CMC concentration while keeping acrylic acid contents constant, comparative increase in swelling index was observed at acidic pH 1.2. This could be accredited to the presence of amine groups which ionize at low pH, with subsequent increased swelling behaviour owing to the electrostatic repulsions. It was observed that at basic pH 7.4, a swelling ratio is dropped with increasing CMC concentration. It is assigned to the fact as increased number of amine groups get linked to more carboxylic groups resulting in less number of free carboxylic groups present for ionization and consequently, a decrease in swelling with increasing CMC concentration was observed. Similar results have been observed in [10] pH-sensitive chitosan-co-acrylic acid hydrogels.

Acrylic acid is an anionic monomer, comprising of carboxylic groups. It was observed that by increasing acrylic acid ratio, swelling was increased significantly at higher pH values is due to the presence of carboxylic groups, available for ionization, and the formulations with more acrylic acid contents have shown maximum swelling due to more carboxylic groups which after protonation causes ionic repulsion and increased swelling. Similar results have been reported by [10, 27, 30, 34].

As crosslinking agent’s concentration is increased, a decrement in the swelling at both the low as well as high pH was observed. The reason behind this phenomenon is; increased cross-linking causes decrease in mesh size of the hydrogels and reduced mesh-size conceals the carboxylic groups and thus hinderance in the ionization process due to higher degree of cross-linking with decreased polymeric chain relaxation. This gives rise to the reduced swelling index with higher crosslinker;s concentration.

4.6 In vitro drug release studies

The drug release from hydrogel formulations depends on the swelling characteristics and composition of the hydrogel including polymer, monomer and cross-linking agent, which in succession, is an essential parameter of chemical organization of the hydrogels. Also, environmental pH influences the release rate of the incorporated drug from hydrogel formulations. A remarkable difference in drug release at both pH was observed; a lesser amount of the drug was released at pH 1.2 and higher amounts of release was observed at pH 7.4. There has been reported that that the hydrogels showed release in phosphate buffer of pH 7.4, upto 36 h [35]. The prepared hydrogels have shown higher 5-FU release for longer period of time under sink conditions at basic pH (approximately 90% and more during 36 h) which is important for anti-cancerous drug targeting to colon. As the hydrogels swell dramatically at intestinal pH conditions and the drug was released. Practically, these matrices could bypass the acidic gastric environment with very low proportion of the encapsulated drug release, indicating them to be the ideal candidates for controlled and targeted delivery system of drugs.

4.7 Effect of hydrogel composition on in vitro drug release

In vitro drug release study revealed that by increasing CMC concentration in hydrogel composition, drug release is decreased. As already discussed, swelling decreases with increasing polymer content in the formulation and due to less number of carboxylic groups left for ionization because they get linked to the amine groups leading to less swelling and ultimately less release. Similar results reported by [23] in which by increasing CMC content, a decrease in swelling ratio of superporous hydrogels/interpenetrating networks was observed that ultimately accounted for a decline in release rate.

It was observed that by increasing acrylic acid (monomer) composition drug release is increased. Ranjha et al. [10] explained that this phenomena of swelling is due to higher number of ionizable groups at pH 7.4 with higher AA concentration leading to polymer chain relaxation and inturn providing raised swelling and drug release. Similar swelling and drug release behaviour was observed in pH-sensitive cationic guar gum and poly(acrylic acid) polyelectrolyte hydrogels. An increase in swelling and ketoprofen release with an increase in PAA component in the gel structure was observed in the study reported by [36].

As discussed in swelling studies increased MBA concentration in gels also reduced in vitro drug release. It was found that increasing the cross-linking agent caused an increase in entanglement between polymer and monomer due to hydrogen bonding resulting in hindrance in network expansion decreasing chain relaxation eventually reduction in drug release was observed. Similar trend of cross-linker concentration was observed in chitosan-co-acrylic acid hydrogel prepared by [10]. MBA being a cross-linking agent used in many polymeric networks and presented good biocompatibility lacking any deleterious effects on cell viability and functionality.

4.8 Cell viability studies

The results of the study demonstrates that 5-FU has dose dependent anticancer activity and the % cell viability decreased with increasing dose concentration per well. The produced results also exhibited that 5-FU has high toxicity in free form as compared to the loaded form in hydrogel formulations. The cell viability study highlights the biocompatible nature of the hydrogels. It also indicates that 5-FU has retained its anticancer activity after loading into sustained release hydrogel matrix.

4.9 In vivo evaluation

As shown in the results of the in vivo studies in rabbits, a clear difference can be observed in plasma concentrations of oral 5-FU solution and 5-FU loaded hydrogel. The low tmax value indicates the rapid absorption of pure 5-FU in solution form, while tmax value for 5-FU loaded hydrogel was much greater, that shows slower absorption of 5-FU from hydrogel disc, indicating controlled release behavior. The absorption of 5-FU from oral solution was rapid and achieved maximum plasma level (Cmax) of 304.6 ± 8.113 μg/mL within 25.00 ± 0.00 min. However, maximum plasma concentration (121.262 ± 5.332 μg/mL) after administration of hydrogel containing equivalent amount of drug was obtained after 25.00 ± 0.00 h. Cmax of 5-FU after administration of hydrogel containing equivalent amount of drug was less than that of oral solution. After administration of hydrogel formulations, the plasma concentrations were maintained for relatively longer period of time. The elimination half-life (t1/2) of 5-FU loaded hydrogel and 5-FU oral solution was 5.2403 ± 0.2363 h and 14.572 ± 1.728 min, respectively. The elimination half-life (t1/2) of 5-FU loaded hydrogel was comparatively greater than pure valsartan solution indicating that the drug is slowly eliminated from the body. The MRT of 5-FU in oral solution and hydrogel was 0.601 ± 0.052 h and 14.592 ± 0.236 h, respectively, with a large difference. AUCtot obtained after administration of oral solution and hydrogel was 94.372 ± 14.63 µg.h2/ml and 29916.372 ± 153.222 µg.h2/ml, respectively with a large difference. This was probably due to the ability of the CMC-co-poly(AA) hydrogel to control the release of 5-FU.

5 Conclusion

A stable cross-linked polymeric structure has been synthesized by a optimized solution polymerization technique. Carboxymethyl chitosan based hydrogels are prepared successfully by feed ratio of acrylic acid and methylene bis-acrylamide. Significant network swelling and drug release at higher pH while insignificant swelling and drug release at lower pH showed pH-responsive properties. Prolonged drug release behaviour of fabricated hydrogels imparted additional benefit of controlled drug delivery at administration site. In-vivo and cell viability studies confirmed the biocompatibility and efficacy of 5-FU loaded cross-linked matrices.

References

Ganji F, Vasheghani-Farahani S, Vasheghani-Farahani E. Theoretical description of hydrogel swelling: a review. Iran Polym J. 2010;19:375–98.

Sohail M, Ahmad M, Minhas MU, Ali L, Khalid I, Rashid H. Controlled delivery of valsartan by cross-linked polymeric matrices: synthesis, in vitro and in vivo evaluation. Int J Pharm. 2015;487:110–9.

Ranjha NM, Qureshi UF. Preparation and characterization of crosslinked acrylic acid/hydroxy propyl methyl cellulose hydrogels for drug delivery. Int J Pharm Pharm Sci. 2014;6:400–10.

Hoffman AS. Hydrogels for biomedical applications. Adv Drug Deliv Rev. 2012;64:18–23.

Ullah F, Othman MBH, Javed F, Ahmad Z, Akil HM. Classification, processing and application of hydrogels: a review. Mater Sci Eng C. 2015;57:414–33.

Van Tomme SR, Storm G, Hennink WE. In situ gelling hydrogels for pharmaceutical and biomedical applications. Int J Pharm. 2008;355:1–18.

Jiang S, Liu S, Feng W. PVA hydrogel properties for biomedical application. J Mech Behav Biomed Mater. 2011;4:1228–33.

Sohail M, Ahmad M, Minhas MU, Liaqat A, Munir A, Khalid I. Synthesis and characterization of graft PVA composites for controlled delivery of Valsartan. Lat Am J Pharm. 2014;33:1237–44.

Amin MCIM, Ahmad N, Halib N, Ahmad I. Synthesis and characterization of thermo-and pH-responsive bacterial cellulose/acrylic acid hydrogels for drug delivery. Carbohydr Polym. 2012;88:465–73.

Ranjha NM, Ayub G, Naseem S, Ansari MT. Preparation and characterization of hybrid pH-sensitive hydrogels of chitosan-co-acrylic acid for controlled release of verapamil. J Mater Sci: Mater Med. 2010;21:2805–16.

Paharia A, Yadav AK, Rai G, Jain SK, Pancholi SS, Agrawal GP. Eudragit-coated pectin microspheres of 5-fluorouracil for colon targeting. AAPS PharmSciTech. 2007;8:E87–E93.

Watanabe T, Itabashi M, Shimada Y, Tanaka S, Ito Y, Ajioka Y, et al. Japanese Society for Cancer of the Colon and Rectum (JSCCR) guidelines 2010 for the treatment of colorectal cancer. Int J Clin Oncol. 2012;17:1–29.

Simmonds P. Palliative chemotherapy for advanced colorectal cancer: systematic review and meta-analysis. Br Med J. 2000;321:531.

Park JH, Saravanakumar G, Kim K, Kwon IC. Targeted delivery of low molecular drugs using chitosan and its derivatives. Adv Drug Deliv Rev. 2010;62:28–41.

Chourasia M, Jain S. Pharmaceutical approaches to colon targeted drug delivery systems. J Pharm Pharm Sci. 2003;6:33–66.

Farag RK, Mohamed RR. Synthesis and characterization of carboxymethyl chitosan nanogels for swelling studies and antimicrobial activity. Molecules. 2012;18:190–203.

Mourya V, Inamdar NN, Tiwari A. Carboxymethyl chitosan and its applications. Adv Mater Lett. 2010;1:11–33.

Kumar Singh Yadav H, Shivakumar H. In vitro and in vivo evaluation of ph-sensitive hydrogels of carboxymethyl chitosan for intestinal delivery of theophylline. ISRN Pharm. 2012;2012:1–9

Jankaew R, Rodkate N, Lamlertthon S, Rutnakornpituk B, Wichai U, Ross G, et al. “Smart” carboxymethylchitosan hydrogels crosslinked with poly (N-isopropylacrylamide) and poly (acrylic acid) for controlled drug release. Polym Test. 2015;42:26–36.

Huang Y, Lu J, Xiao C. Thermal and mechanical properties of cationic guar gum/poly (acrylic acid) hydrogel membranes. Polym Degrad Stab. 2007;92:1072–81.

Hussain T, Ranjha NM, Shahzad Y. Swelling and controlled release of tramadol hydrochloride from a pH-sensitive hydrogel. Des Monomers Polym. 2011;14:233–49.

Minhas MU, Ahmad M, Khan S, Ali L, Sohail M. Development and optimization of fast and new reversed-phase HPLC method for analysis of 5-fluorouracil in human and rabbit plasma. Pak Vet J. 2015;35:1.

Yin L, Fei L, Cui F, Tang C, Yin C. Superporous hydrogels containing poly (acrylic acid-co-acrylamide)/O-carboxymethyl chitosan interpenetrating polymer networks. Biomaterials. 2007;28:1258–66.

Chen X-G, Park H-J. Chemical characteristics of O-carboxymethyl chitosans related to the preparation conditions. Carbohydr Polym. 2003;53:355–9.

Guo B, Yuan J, Yao L, Gao Q. Preparation and release profiles of pH/temperature-responsive carboxymethyl chitosan/P (2-(dimethylamino) ethyl methacrylate) semi-IPN amphoteric hydrogel. Colloid Polym Sci. 2007;285:665–71.

Mohamed RR, Seoudi RS, Sabaa MW. Synthesis and characterization of cross‐linked polyethylene glycol/carboxymethyl chitosan hydrogels. Adv Poly Technol. 2015;34:1–6

Ranjha NM, Hanif M, Naz A, Shah MS, Abbas G, Afzal Z. Synthesis and characterization of cetirizine‐containing, pH‐sensitive acrylic acid/poly (vinyl alcohol) hydrogels. J Appl Polym Sci. 2016;133:1–8

Gao X, Cao Y, Song X, Zhang Z, Zhuang X, He C, et al. Biodegradable, pH‐responsive carboxymethyl cellulose/poly (acrylic acid) hydrogels for oral insulin delivery. Macromol Biosci. 2014;14:565–75.

Sabaa MW, Mohamed RR, Eltaweel S, Seoudi RS. Crosslinked poly (vinyl alcohol)/carboxymethyl chitosan hydrogels for removal of metal ions and dyestuff from aqueous solutions. J Appl Polym Sci. 2012;123:3459–69.

Minhas MU, Ahmad M, Khan S, Ali L, Sohail M. Synthesis and characterization of β-cyclodextrin hydrogels: crosslinked polymeric network for targeted delivery of 5-fluorouracil. Cellulose Chem Technol. 2016;50:2.

Pourjavadi A, Barzegar S, Mahdavinia G. MBA-crosslinked Na-Alg/CMC as a smart full-polysaccharide superabsorbent hydrogels. Carbohydr Polym. 2006;66:386–95.

Dergunov SA, Nam IK, Mun GA, Nurkeeva ZS, Shaikhutdinov EM. Radiation synthesis and characterization of stimuli-sensitive chitosan–polyvinyl pyrrolidone hydrogels. Radiat Phy Chem. 2005;72:619–23.

Byun H, Hong B, Nam SY, Jung SY, Rhim JW, Lee SB, et al. Swelling behavior and drug release of poly (vinyl alcohol) hydrogel cross-linked with poly (acrylic acid). Macromol Res. 2008;16:189–93.

Ranjha NM, Mudassir J, Sheikh ZZ. Synthesis and characterization of pH-sensitive pectin/acrylic acid hydrogels for verapamil release study. Iranian Polym J. 2011;20:147–59.

Minhas MU, Ahmad M, Ali L, Sohail M. Synthesis of chemically cross-linked polyvinyl alcohol-co-poly (methacrylic acid) hydrogels by copolymerization; a potential graft-polymeric carrier for oral delivery of 5-fluorouracil. DARU J Pharm Sci. 2013;21:44.

Huang Y, Yu H, Xiao C. pH-sensitive cationic guar gum/poly (acrylic acid) polyelectrolyte hydrogels: swelling and in vitro drug release. Carbohydr Polym. 2007;69:774–83.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Sharif, QuA., Sohail, M., Ahmad, M. et al. Novel polymeric composites based on carboxymethyl chitosan and poly(acrylic acid): in vitro and in vivo evaluation. J Mater Sci: Mater Med 28, 147 (2017). https://doi.org/10.1007/s10856-017-5952-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-017-5952-1