Abstract

Tissue culture under microgravity provides a venue which promotes cell–cell association while avoiding the detrimental effects of high shear stress. Hepatocytes cultured on carriers or entrapped within matrices under simulated microgravity conditions showed improved cell function and proliferation. In the present study, a new approach was adopted where a non-cell adherent scaffold was incorporated with hepatospheroids (HepG2) under microgravity. Gum arabic (GA) was cross-linked with gelatin (GA-Gel) and collagen (GA-Col) to prepare non-cell adherent scaffolds. Microgravity experiments with GA-Gel and GA-Col indicated that GA-Col is a better substrate compared to GA-Gel. Microgravity experiments of GA-Col scaffolds with HepG2 cells confirmed that the non-adherent surface with porous architecture can incorporate hepatocyte spheroids and maintain liver specific functions. Albumin and urea synthesis of hepatocytes was sustained up to 6 days under microgravity conditions in the presence of GA-Col scaffold. This new approach of using non-cell adherent matrix and microgravity environment for developing biological substitutes will be beneficial in tissue engineering, bioartificial liver devices and in vitro safety assessment of drugs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Liver tissue engineering demands functionally active hepatocytes that sustains and survives the in vitro manipulation. Hepatocyte that can express differentiated functions of liver is the primary requirement in the biological compartment of bio-artificial liver (BAL) device. In BAL, the biological compartment is known as the bioreactor, where functionally active hepatocytes are maintained to support the liver specific functions. The bioreactor should be able to provide suitable environment for hepatocytes to express maximum viability as well as functionality with efficient mass transport between cells and blood [1]. Based on the method of hepatocyte maintenance and supply, different configurations of BAL bioreactors can be classified into encapsulated suspension [2, 3], perfused scaffold bed [4], flat plate and monolayer [5, 6] and hollow fiber systems [7]. Adherent hepatocytes quickly lose their differentiated liver specific functions if proper extracellular and soluble cell signalling cues are not provided. Hence different ways to present hepatocytes inside the bioreactor chamber are being explored and can be in the form of cell suspension [8], encapsulated cells [9], cell aggregates [10] and cells on carriers [11]. In all these systems, uniform distribution of high concentration of liver cells is required for the successful functioning of the device. High seeding density without limiting the nutrient and gas transfer thus becomes the critical factor in development of in vitro engineered tissues [12], especially in devices like BAL. Creating bioengineered tissues requires homotypic or heterotypic cell interaction in addition to high cell density as a means to provide natural cellular functions. It has been shown that three dimensional (3D) multicellular aggregates or spheroids cultured in vitro perform functions similar to the actual tissues [13]. Culturing cells under microgravity is an advanced field in tissue engineering, where, muticellular spheroids are created without forming necrotic centres and achieve cell aggregates larger than those from a two dimensional culture system [14].

Bioreactors designed to simulate microgravity creates a unique environment with low shear force and high-mass transfer [15]. The development of advanced bioreactors for microgravity cell and tissue culture has helped in developing relevant in vitro model systems for studies of astronaut wellbeing. Cells alone or cells in combination with cell adhesion substrates are cultured in microgravity bioreactors for tissue engineering [16, 17].

Three dimensional cell culture systems require suitable scaffolds or micro-carriers in which the cells are attached and grown. However, when there is need for more cell–cell contact rather than cell to scaffold adhesion, a cytocompatible non-adherent surface is necessary.

In this study, we combined two aspects of in vitro culture systems such as (1) providing a scaffold and (2) simulation of microgravity in order to simultaneously generate hepatocyte spheroid formation and its incorporation into scaffolds. The scaffold was fabricated from gum arabic, gelatin and collagen that keeps low cell adherent profile.

2 Materials and methods

2.1 Materials

Gum arabic (from acacia tree) of approximate molecular weight 250,000, gelatin (Type A), collagen, sodium metaperiodate, sodium tetraborate (borax), minimum essential medium (MEM), propidium iodide (PI), neutral red, fluorescein diacetate (FDA), and glutaraldehyde were purchased from Sigma Aldrich, Saint Louis, USA. Sodium chloride, sodium hydrogen carbonate, sodium dihydrogen phosphate, disodium hydrogen phosphate, hydroxylamine hydrochloride, sodium hydroxide and isopropanol were obtained from Merck (Mumbai, India). Trypsin EDTA (0.25, 0.02 %) was procured from Invitrogen, USA. Dialysis tubing (6000–8000 MWCO) was procured from Spectrum Laboratories Inc.CA, US.

2.2 Preparation of oxidized gum arabic

Gum arabic was oxidized to gum arabic aldehyde (GA) using sodium metaperiodate [18]. Briefly, gum arabic (10 g, 0.058 mol) was dissolved in distilled water (80 mL) and appropriate amount of sodium periodate, required for 10 % (1.24 g, 0.0058 mol) oxidation was added. The reaction mixture was stirred at 20 °C for 6 h in dark. Oxidized gum arabic was purified by dialysis using a dialysis tube of MWCO 6000–8000 for 3 days against distilled water. After the complete removal of periodate, the dialysate was freeze dried. Gum arabic aldehyde obtained was analyzed for aldehyde content according to the reported procedure [19].

2.3 Preparation of polysaccharide–protein scaffolds

Scaffolds were prepared by cross-linking oxidized gum arabic with gelatin. The free amino groups of protein and aldehyde groups of GA [10 % (w/v) solution in 0.1 M borax] undergo Schiff’s base reaction. GA solution when mixed with equal volume of gelatin [10 % (w/v) solution in deionized water] formed a smooth clear hydrogel. The hydrogel thus obtained was freeze dried for 12 h and rinsed with distilled water to remove borax. The samples were again freeze dried and the dry scaffolds were sterilized by ethylene oxide before using for cell culture.

GA-Col scaffolds were prepared from GA, gelatin and collagen (3 mg/mL bovine dermal Type I in 0.1 M HCl) and studied the variation in cell adhesion with respect to proteins. To 500 μL of GA solution, 500 μL of a mixture of gelatin and collagen in the ratio of 3:1 [gelatin (375 μL): collagen (125 μL)], [3:1 (v/v)] was added and vortexed to prepare GA-Col hydrogel which was freeze dried to obtain GA-Col scaffolds. Hereafter, the gelatin alone and gelatin–collagen based scaffolds will be referred as GA-Gel and GA-Col respectively. The detailed physicochemical characterisation of the GA-Gel scaffold was published recently [20]. Porosity of the GA-Col scaffold was determined by micro computed tomography (Micro-CT). The sample was imaged (Scanco Medical Micro CT, model μCT40, Switzerland) and values obtained were recorded. Duplicate Micro-CT was done to calculate the porosity.

2.4 Characterization of GA-Gel and GA-Col scaffold

2.4.1 Gelation time

Gelation time of GA-Gel and GA-Col scaffold was determined. Gum arabic aldehyde solution (10 %) was prepared in 0.1 M borax. Gum arabic aldehyde (0.5 mL) solution was taken in a glass vial of 5 mL capacity and a mixture of gelatin and collagen (0.375 and 0.125 mL) was added and then vortexed. Gelling time was determined as the time taken for all the solutions to cross-link completely and forms a solid gel upon vortexing. All the values reported are the average of 4–5 determinations.

2.4.2 Degree of cross-linking

TNBS assay was used to determine the degree of cross-linking [17]. GA-Gel and GA-Col scaffolds were treated with 1 mL of 4 % sodiumbicarbonate solution and 0.05 % (w/v) TNBS solution and heated at 60 °C for 4 h. After 4 h, 3 mL of 6 N HCl was added to 1 mL of the above mixture and heated at 40 °C for one and half hours. Absorbance of the solution was measured spectrophotometrically (Cary 100 UV–Visible Spectrophotometer, USA) at 334 nm. Degree of cross-linking was found out by the following Eq. 1:

2.4.3 Swelling studies

Swelling studies were conducted on GA-Gel and GA-Col scaffolds. Accurately weighed scaffolds were taken in vials and phosphate buffered saline (PBS, 5 mL) was added. At regular intervals of time, PBS was aspirated and scaffolds were gently blotted by filter paper and then weighed. All the experiments were done in triplicate. Swelling ratio was calculated from the Eq. 2 [43].

Where Ws and Wd are weights of the swollen and dry scaffolds respectively.

Degree of swelling (Q) of the scaffold was determined by Eq. 3. It is defined as the reciprocal of the volume fraction of the polymer in the swollen scaffold (ν2).

Where, ρp is the density of polymer (0.653 g/cm3), ρs is density of water (0.9971 g/cm3 at 25 °C) and Qm is swelling ratio [44].

2.5 Cytotoxicity evaluation

Cytotoxicity of GA-Gel and GA-Col was evaluated by direct contact method using L-929 [ATCC, USA] and HepG2 [NCCS, India] cells. L-929 cells were cultured in Minimum Essential Medium with 5 % Foetal Bovine Serum and 100 IU/mL penicillin and 100 µg/mL streptomycin (PAA Laboratories, Germany). HepG2 cells were maintained in Iscoves’ Modified Dulbeccos’ Medium (IMDM) containing 2 % FBS and antibiotics. Cell monolayer was treated with trypsin–EDTA solution and 1 × 105 cells were seeded to 24 well plates containing culture medium. GA-Gel and GA-Col scaffolds, negative control (high-density polyethylene) and positive control (stabilized polyvinyl chloride) were kept on subconfluent cells. Cellular response around the materials were assessed at 24 h under an inverted phase contrast microscope (Leica DMI 6000, Germany) and compared with negative and positive controls.

The cell viability after direct contact test was also performed to find the zone of cytotoxic reactivity. At the end of direct contact cytotoxicity test, the medium was replaced with neutral red solution (0.5 mg/mL in saline). After 5–10 min, neutral red solution was removed and cells were rinsed with PBS. The viability of cells around the materials was observed under inverted microscope (Leica DMIL, Germany). All experiments were done at least two times.

2.6 In vitro cytotoxicity analysis by MTT assay

To exaggerate the actual use conditions of the test sample, cytotoxicity was also determined by test on extract method followed by analyzing the cell metabolic activity. The extract was prepared by incubating GA-Gel and GA-Col scaffold in MEM containing serum at 37 °C for 24 h at an extraction ratio of 3 cm2/mL. L-929 cells were cultured in a 96 well plate with an initial seeding density of 5000 cells/well. The culture medium from subconfluent cells was replaced with various dilutions of extract and incubated for 24 h at 37 °C in a CO2 incubator. Phenol was taken as positive control and cells cultured in normal medium under similar conditions were considered as cell/negative control. Cells were treated with MTT reagent (0.5 mg/mL in serum free MEM) and further incubated for 2 h at 37 °C. Formazan product formed by cellular activity was solubilized in 100 µL isopropanol and the absorbance was measured at 570 nm using a multiwell plate reader (BioTek, USA) The optical density of the cells exposed to extracts was compared with cell control to calculate the percentage cell activity. Statistical significance from duplicate experiments was calculated (n = 2) using the Microsoft Excel Data Analysis Tool.

2.7 Cell adhesion on GA-Col scaffold

Adhesion of L-929 and HepG2 cells on GA-Gel scaffold was reported recently [20] and hence, not illustrated here. L-929 and HepG2 cells were seeded at a concentration of 5000 cells/cm2 on GA-Col scaffold and allowed to adhere and grow for 48 h. The adhered cells were visualized by SEM. For SEM, adhered cells were fixed using 3 % glutaraldehyde for 1 h and were dehydrated in graded alcohol followed by critical point drying. Samples were gold coated using an ion sputter device (Hitachi, E 101) and cell morphology was observed under SEM (Hitachi S 2400, Japan).

2.8 Optimization of conditions of scaffolds under microgravity

Microgravity condition was simulated in a rotating wall bioreactor (RCMW, Synthecon, USA) equipped with in-line oxygenator and perfusion apparatus. The bioreactor cell culture chamber was connected to a direct drive rotation system in a cradle roller assembly. The chambers were filled with either deionized water or culture medium and scaffolds (GA-Gel and GA-Col) with various sizes (1 × 1, 2 × 2, 3 × 3, 5 × 5 and 10 × 10 mm) were inserted into bioreactor chamber. The rotation speed of chamber was controlled by adjusting revolution per minute (rpm) of the drive from 20 to 10 rpm. The scaffolds were observed for 48 h in bioreactor to see the microgravity conditions evidenced by a steady state without floating or settling. Duplicate experiments were done to optimize the conditions.

2.9 Culture of hepatocytes under microgravity with scaffolds

The optimization of culture conditions under microgravity included assembling the bioreactor and introduction of media, GA-Gel and GA-Col scaffolds. The bioreactor was assembled and observed for leakage, contamination, behaviour of scaffolds under microgravity for 48 h inside an incubator set at 5 % CO2 and 37 °C. When the scaffolds attained stable microgravity condition, around 4.5 × 106 HepG2 cells were introduced into the chambers with scaffolds. The drive and pump rpm was set such that the scaffold will sustain a steady state. The scaffold was collected at the end of 6 days for morphology analysis and spheroid formation.

2.10 Functional evaluation of hepatocytes under microgravity with scaffolds

The culture system that showed good cell adhesion and spheroid formation by morphology analysis was selected for the functional studies. Differentiated functions of hepatocytes such as albumin synthesis and urea synthesis were evaluated at definite time periods during microgravity experiments. HepG2 cells were seeded to scaffolds under microgravity as described above. The set up was left undisturbed except for media collection and removal of the scaffold. Culture medium was aliquoted on 1, 2, 3, 4 and 6 days and stored at −80 °C for estimating albumin and urea synthesis. The hepatocyte specific functional parameters were analyzed by evaluating albumin (Rat Albumin ELISA Quantitation Kit, Bethyl Laboratories Inc., USA) and Urea (Urea Assay Kit, BioChain, USA) synthesis. All experiments were repeated at least twice.

2.11 Statistical analysis

The data collected from the independently run experiments (n = 2) were represented as Mean ± standard deviation and statistical significance was calculated by t test. A value of P < 0.05 was considered significant.

3 Results and discussions

The fabrication of tissues in vitro for analytic and therapeutic purposes has been a challenge. Tissue engineering has grown immensely over two decades since its establishment in 1988 [21]. The bioengineered tissues require enough cell mass and suitable mechanical and biological properties similar to that exhibited by extracellular matrix.

Development of tissue constructs in conventional static culture is limited by the diffusive transfer of non-circulating oxygenated nutrient carrying fluid. Different varieties of bioreactor systems have been developed and used in liver cells under three dimensional (3D) perfusion cultures. These include hollow fiber cartridges, cell carrier beads and polymeric meshes that incorporate cells [22]. The physiological functions of liver cells under in vitro conditions can be partially regained by culturing hepatocytes on appropriate ECM, coculture with hepatic non-parenchymal cells or in bioreactors. However to achieve sufficient cell–cell and cell-ECM interaction in 3D culture systems, specialized bioreactors are required.

In this study, scaffolds were prepared from gum arabic (GA), which is a highly branched and complex polysaccharide. Gum arabic was oxidized into gum arabic aldehyde by periodate oxidation. Aldehyde content in the 10 % oxidized GA was calculated as 1.125 × 10−3 mol/g by titrimetric method.

Gum arabic aldehyde-gelatin scaffold (GA-Gel) was prepared by the cross-linking of aldehyde groups in GA and free amino groups of lysine or hydroxylamine side groups of gelatin. In the present work, cross-linking and hydrogel formation was carried out using 10 % (w/v) solution of GA in 0.1 M borax with aqueous solution of gelatin [10 % (w/v)]. GA-Gel scaffold was obtained by freeze drying the hydrogel. Details of preparation and characterization of GA-Gel scaffold have been reported recently [20]. GA-Gel scaffold was modified with incorporation of collagen in 3:1 gelatin–collagen ratio (v/v) to study the effect of collagen on cell adhesion properties under microgravity [23]. Gelation time of GA-Gel hydrogel was 29 ± 2 s while GA-Col hydrogel has a gelation time of 14 ± 3 s. Introduction of collagen decreases gelation time to a considerable extent owing to the increased availability of functional groups required for the cross-linking with gum arabic aldehyde. Low gelation time also indicates high degree of cross-linking in GA-Col scaffold.

The porosity of the GA-Col scaffold was found to be 79 % on Micro-CT analysis. This is comparable with the previous report of GA-Gel scaffold with porosity of 82.5 % [20].

Since the scaffolds are designed for tissue culture under microgravity, understanding of the swelling ability of the scaffold is very important because it influences the diffusion of nutrients and movement of the cells on the scaffold. Cross-linking determines the swelling capacity of the scaffold. Scaffolds with high degree of cross-linking exhibit low swelling. Swelling characteristics of a scaffold can be understood by measuring swelling ratio and degree of swelling. Swelling ratio and degree of swelling of GA-Col scaffold is lesser than that of GA-Gel scaffold owing to the high degree of cross-linking (Table 1).

3.1 Cytotoxicity evaluation by direct contact method

Cytotoxicity of the scaffold was evaluated by direct contact method using two separate cell lines (L-929 fibroblasts and HepG2 hepatocytes) which is a standard in vitro cytotoxicity test used in biomaterial evaluation. The test material was kept on cell monolayer for 24 h and the cytotoxicity was graded based on ISO 10993-5 standard. At the end of direct contact test, viability of cells around the test sample was also assessed by neutral red uptake staining. The cells around the GA-Gel and GA-Col scaffold maintained the original cell morphology and confirmed as viable due to uptake of neutral red dye (Fig. 1a–d). The response of cells to test sample was compared with parallely run negative and positive control materials. Negative control [high-density polyethylene (HDPE)] showed non-cytotoxicity and positive control [stabilized polyvinyl chloride (PVC)] showed severe cytotoxicity when incubated with L-929 and HepG2 (Fig. 1e–h).

Direct contact cytotoxicity evaluation of GA-Gel (a and b) and GA-Col (c and d) scaffolds confirmed by neutral red viability staining. L-929 cells (a, c) and HepG2 cells (b, d) around the scaffold showed normal morphology compared to the respective negative (HDPE) controls (e and f). L-929 and HepG2 cells around positive (PVC) control show severe cytotoxicity (g and h). Phase contrast images of L-929 and HepG2 cells alone are given in supplementary data

3.2 Cytotoxicity evaluation by MTT assay

Metabolic activity of L-929 cells in contact with extracts of GA-Gel and GA-Col scaffolds were determined by MTT assay. Cells expressed metabolic activity similar to the cell control, confirming the absence of any toxic effect of the extracts. Cells in contact with GA-Gel and GA-Col scaffolds showed metabolic activity of more than 70 % after 24 h exposure (Fig. 2). The non-cytotoxic character of the scaffold indicates its suitability for in vitro cell culture applications.

3.3 Cell adhesion

Cell adhesion studies on GA-Col using L-929 and HepG2 cells were performed and observed under SEM (Fig. 3a, b). Both fibroblasts and hepatocytes were attached on to the scaffold during the initial 48 h of incubation but were unable to spread and express the characteristic morphology. This is similar to our previous observation of L-929 and HepG2 cell adhesion on GA-Gel scaffold20. This confirms the non-adherence and non-toxic property of GA-Col scaffolds.

3.4 Scaffolds under microgravity

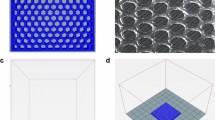

Both GA-Gel and GA-Col scaffolds were used to optimize conditions of microgravity in the bioreactor. A roller culture perfusing bioreactor was used to simulate microgravity. During the first 12 h, scaffold tends to float in the medium in the absence of rotational force. Hence the rotational speed was set at higher values of 12 rpm for 1 × 1 mm and 20 rpm for 10 × 10 mm scaffolds. After overnight incubation in water, scaffolds tend to settle down without rotation. This could be due to the swelling of scaffolds in the medium. At this state, the rotational speed was brought down to lift the scaffolds to attain a steady state. The relative positions of the scaffold over time are illustrated in Fig. 4.

Figure 5 shows the 3 × 3 × 2 mm scaffold under microgravity at steady state without movement. Microgravity experiments with scaffolds in culture medium also showed similar results.

3.5 Culture of HepG2 cells in bioreactor with GGA scaffold

Effect of space conditions on liver has been studied before [24]. Development of organs in neonatal rat during space flight did not alter the liver-to-body weight ratio [25]. Studies on DNA replication and insulin binding to rat liver cell membranes also showed similar results between flight and ground-control [26]. Rats after 20 days of space flight did not show any change in DNA where as other organs like spleen and thymus were deficient [14]. To study the effect of gravity on cells either conducted in space or in simulated microgravity on earth, cells are cultured in normal 2D culture dishes or spheroids in non-adherent surface or using microbead scaffolds. Three dimensional arrangements of cells in low shear conditions create more in vivo like intracellular and intercellular features and up-regulation of cellular functions [27]. Hepatocytes cultured in conventional static culture lose polarity and differentiated function very fast. But, hepatocytes cultured under microgravity environment rapidly form macroscopic 3D hepatospheroid structures that show ultrastructural, morphological and functional features of differentiated, polarized hepatic tissue [28].

Three dimensional cell culture systems require either non-adherent scaffolds or cell adhesion free culture surface. Non-adherent substrates promote more cell–cell contact than cell matrix adhesion and favours cell aggregate or spheroid formation [29]. Hepatocytes cultured on poly-HEMA coated culture dishes formed spheroids and expressed liver specific functions [30]. Simulating microgravity conditions using bioreactors can also promote spontaneous spheroid formation without shear stress on the cells with improved cell functions. Hepatocytes under microgravity aggregates and express complex stromal structures, reticulin fibers, bile canaliculi, and tight junctions [31]. Additionally, key metabolic functions of hepatocytes are also reported to be maintained under simulated microgravity [32]. In this study, the non-cell adhesive substrate and simulation of microgravity was combined in generating hepatocyte spheroids. The key advantage of this system is that hepatocyte spheroids with normal liver functions such as albumin and urea synthesis can be achieved within a non-cell adherent porous scaffold. Liver cell spheroids under microgravity have been proved successful as components in bioartificial liver devices and as a candidate for high throughput drug screening studies. This is the first report on the evaluation of hepatocyte spheroid functions within a non-cell adherent porous scaffold under simulated microgravity.

3.6 Hepatocytes with GA-Gel and GA-Col scaffolds under microgravity

The GA-Gel and GA-Col scaffolds were introduced into bioreactor chamber filled with culture medium. HepG2 cells were introduced into the chamber and the bioreactor was adjusted to keep a steady microgravity condition. On 1st day of culture, number of cells adhering to each other was more than those attaching to the GA-Gel scaffold (Fig. 6a). Cells didn’t express morphology or spreading on scaffold surface. Clustered cells were a good indication of cell–cell interaction and adequate extra cellular matrix. On the second day, scaffolds and cells under microgravity still showed cell adhesion on the material (Fig. 6b). However, the cell morphology changed considerably, showing immense blebbing on cell surface. At the end of 6 days, HepG2 cells were entrapped into few pores but spheroid was found to be disintegrated with loss of cell–cell integrity and cell morphology (Fig. 6c).

Since the cell clusters got disintegrated after 7 days with GA-Gel scaffolds, the experiment was repeated with GA-Col scaffolds having gelatin:collagen ratio of 3:1. The scaffolds together with cells maintained under microgravity were retrieved and processed for SEM to analyze cell morphology. It was observed that HepG2 cell could form and sustain spheroids within the pores of the GA-Col scaffolds up to 6 days (Fig. 7a–c).

Morphology of HepG2 cells (black arrow) on GA-Col (white arrow) scaffold under microgravity, cultured for 6 days. Cells formed spheroids and were distributed all along the scaffold (a). HepG2 cells formed spheroids within the pores of scaffold with individual cells showing round morphology (b). The spheroid under higher magnification showing intact cell–cell contact (c)

3.7 Functional evaluation of hepatocytes under microgravity with scaffolds

HepG2 cells encapsulated and maintained under microgravity has been reported to express improved proliferation, total protein synthesis and detoxification capacity [33]. Similarly, hepatocytes cultured on macroporous microcarriers under microgravity are also shown to express improved cell functions [34]. Here, hepatocytes were incorporated inside oxidized gum arabic cross-linked with gelatin and collagen under microgravity condition. The initial experiments of HepG2 cells with GA-Gel and GA-Col scaffolds under microgravity showed that only GA-Col scaffolds supported the spheroid formation for more than 2 days. Hence the functional evaluation was performed in the microgravity experiments that included GA-Col scaffolds and HepG2 cells for a duration of 6 days. Hepatocytes under microgravity can express improved differentiated functions like albumin synthesis and ammonia detoxification [32, 33]. In the present study, hepatocytes and porous matrix were introduced together in microgravity condition in order to allow spheroid formation within the pores of scaffold. Clustered cells indicated cell–cell interaction and hence expected to give better cell function. The albumin synthesis showed a continuous increase up to 4 days and was stable at higher level of protein expression till 6th day. This is achieved due to the in vitro tissue organization under microgravity in the presence of GA-Col scaffold. After 4th day, the synthesis of albumin was steady which indicated that the culture system attained optimized conditions with growth medium and extracellular matrix (Fig. 8).

The ammonia detoxification was estimated by measuring synthesis of urea by the hepatocytes over 6 days. The urea synthesis by hepatocytes was normalized with the culture medium to get the net urea synthesis by the cells. Hepatocytes with GA-Col scaffolds showed increase in urea production on 2nd day and then showed a decrease on 3rd day which was subsequently increased continuously till 6 days (Fig. 9). The variation in functionality could be speculated as the adjustment of cells during spheroid formation.

4 Conclusions

A non-cell adherent cytocompatible porous scaffold was prepared by cross-linking gum arabic with gelatin and collagen. The hepatocyte spheroids were incorporated within the scaffolds by providing microgravity conditions inside a bioreactor. The GA-Col scaffold was found to support hepatocytes compared to GA-Gel. Hepatocytes with GA-Col within microgravity bioreactor expressed steady maintenance of albumin and urea synthesis. This novel approach to develop cell spheroids within scaffolds will be beneficial in applications like tissue engineering, bioartificial devices and in vitro safety assessment of drugs.

References

Tilles AW, Berthiaume F, Yarmush ML, Tompkins RG, Toner M. Bioengineering of liver assist devices. J Hepatobiliary Pancreat Surg. 2002;9:686–96.

Cai ZH, Shi ZQ, O’Shea GM, Sun AM. Microencapsulated hepatocytes for bioartificial liver support. Artif Organs. 1988;12:388–93.

Miura Y, Akimoto T, Kanazawa H, Yagi K. Synthesis and secretion of protein by hepatocytes entrapped within calcium alginate. Artif Organs. 1986;10:460–5.

Gion T, Shimada M, Shirabe K, Nakazawa K, Ijima H, Matsushita T, Funatsu K, Sugimachi K. Evaluation of a hybrid artificial liver using a polyurethane foam packed-bed culture system in dogs. J Surg Res. 1999;82:131–6.

Shito M, Tilles AW, Tompkins RG, Yarmush ML, Toner M. Efficacy of an extracorporeal flat-plate bioartificial liver in treating fulminant hepatic failure. J Surg Res. 2003;111:53–62.

Uchino J, Tsuburaya T, Kumagai F, Hase T, Hamada T, Komai T, Funatsu A, Hashimura E, Nakamura K, Kon T. A hybrid bioartificial liver composed of multiplated hepatocyte monolayers. ASAIO Trans. 1988;34:972–7.

Xu Q, Sun X, Qiu Y, Zhang H, Ding Y. The optimal hepatocyte density for a hollow-fiber bioartificial liver. Ann Clin Lab Sci. 2004;34:87–93.

Powers MJ, Janigian DM, Wack KE, Baker CS, Stolz DB, Griffith LG. Functional behavior of primary rat liver cells in a three-dimensional perfused microarray bioreactor. Tissue Eng. 2002;8:499–513.

Tostoes RM, Leite SB, Miranda JP, Sousa M, Wang DI, Carrondo MJ, Alves PM. Perfusion of 3D encapsulated hepatocytes–a synergistic effect enhancing long-term functionality in bioreactors. Biotechnol Bioeng. 2011;108:41–9.

Wang YJ, Li MD, Wang YM, Nie QH, Chen GZ. Experimental study of bioartificial liver with cultured human liver cells. World J Gastroenterol. 1999;5:135–7.

Gao Y, Xu XP, Hu HZ, Yang JZ. Cultivation of human liver cell lines with microcarriers acting as biological materials of bioartificial liver. World J Gastroenterol. 1999;5:221–4.

Dvir-Ginzberg M, Gamlieli-Bonshtein I, Agbaria R, Cohen S. Liver tissue engineering within alginate scaffolds: effects of cell-seeding density on hepatocyte viability, morphology, and function. Tissue Eng. 2003;9:757–66.

Hoffman RM. To do tissue culture in two or three dimensions? That is the question. Stem Cells. 1993;11:105–11.

Unsworthand BR, Lelkes PI. Growing tissues in microgravity. Nat Med. 1998;4:901–7.

Schwarz RP, Goodwin TJ, Wolf DA. Cell culture for three-dimensional modeling in rotating-wall vessels: an application of simulated microgravity. J Tissue Cult Methods. 1992;14:51–7.

Freedand LE, Vunjak-Novakovic G. Cultivation of cell-polymer tissue constructs in simulated microgravity. Biotechnol Bioeng. 1995;46:306–13.

Ishikawa M, Sekine K, Okamura A, Zheng YW, Ueno Y, Koike N, Tanaka J, Taniguchi H. Reconstitution of hepatic tissue architectures from fetal liver cells obtained from a three-dimensional culture with a rotating wall vessel bioreactor. J Biosci Bioeng. 2011;111:711–8.

Balakrishnanand B, Jayakrishnan A. Self-cross-linking biopolymers as injectable in situ forming biodegradable scaffolds. Biomaterials. 2005;26:3941–51.

Balakrishnan B, Mohanty M, Umashankar P, Jayakrishnan A. Evaluation of an in situ forming hydrogel wound dressing based on oxidized alginate and gelatin. Biomaterials. 2005;26:6335–42.

Sarika P, Cinthya K, Jayakrishnan A, Anilkumar P, James NR. Modified gum arabic cross-linked gelatin scaffold for biomedical applications. Mater Sci Eng. 2014;43:272–9.

Langerand R, Vacanti JP. Tissue engineering. Science. 1993;260:920–6.

Martinand Y, Vermette P. Bioreactors for tissue mass culture: design, characterization, and recent advances. Biomaterials. 2005;26:7481–503.

Duan X, McLaughlin C, Griffith M, Sheardown H. Biofunctionalization of collagen for improved biological response: scaffolds for corneal tissue engineering. Biomaterials. 2007;28:78–88.

Clement JQ, Lacy SM, Wilson BL. Genome-wide gene expression profiling of microgravity effect on human liver cells. J Gravit Physiol. 2007;14:P121–2.

Miyake M, Yamasaki M, Katahira K, Waki H, Katsuda S, Ijiri K, Shimizu T. Effects of the spaceflight on organ-development in the neonatal rats: results in the Neurolab (STS-90). Biol Sci Space. 2002;16:209–10.

Macho L, Fickova M, Nemeth S, Svabova E, Serova L, Popova I. The effect of space flight on the board of the satellite Cosmos 2044 on plasma hormone levels and liver enzyme activities of rats. Acta Astronaut. 1991;24:329–32.

Freedand LE, Vunjak-Novakovic G. Spaceflight bioreactor studies of cells and tissues. Adv Space Biol Med. 2002;8:177–95.

Nelson LJ, Walker SW, Hayes PC, Plevris JN. Low-shear modelled microgravity environment maintains morphology and differentiated functionality of primary porcine hepatocyte cultures. Cells Tissues Organs. 2010;192:125–40.

Landry J, Bernier D, Ouellet C, Goyette R, Marceau N. Spheroidal aggregate culture of rat liver cells: histotypic reorganization, biomatrix deposition, and maintenance of functional activities. J Cell Biol. 1985;101:914–23.

Tong JZ, Sarrazin S, Cassio D, Gauthier F, Alvarez F. Application of spheroid culture to human hepatocytes and maintenance of their differentiation. Biol Cell. 1994;81:77–81.

Khaoustov VI, Darlington GJ, Soriano HE, Krishnan B, Risin D, Pellis NR, Yoffe B. Induction of three-dimensional assembly of human liver cells by simulated microgravity. Vitro Cell Dev Biol Anim. 1999;35:501–9.

Dabos KJ, Nelson LJ, Bradnock TJ, Parkinson JA, Sadler IH, Hayes PC, Plevris JN. The simulated microgravity environment maintains key metabolic functions and promotes aggregation of primary porcine hepatocytes. Biochim Biophys Acta. 2001;1526:119–30.

Coward SM, Selden C, Mantalaris A, Hodgson HJ. Proliferation rates of HepG2 cells encapsulated in alginate are increased in a microgravity environment compared with static cultures. Artif Organs. 2005;29:152–8.

Zhang Z, Zhou HC, Li ZG, Pan MX, Wang Z, Gao Y. Microgravity culture of hepatocytes on cellulose/gelatin macroporous microcarrier. J South Med Univ. 2010;30:704–7.

Acknowledgements

Authors thank The Director, IIST for the financial support and Director, SCTIMST for the facilities provided.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sarika, P.R., James, N.R., Anilkumar, P.R. et al. Microgravity as a means to incorporate HepG2 aggregates in polysaccharide–protein hybrid scaffold. J Mater Sci: Mater Med 27, 27 (2016). https://doi.org/10.1007/s10856-015-5638-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5638-5