Abstract

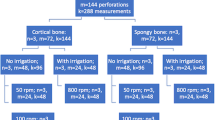

The objective of this study is assessing the influence of the use of different drill types and external irrigation on heat generation in the bone. In-vitro study to compare two different sequences for implant-bed preparation by means of two stainless steels: precipitation-hardening stainless steel (AISI 420B) (K drills), and martensitic stainless steel (AISI 440) (S drills). Besides, the drilled sequences were realized without irrigation, and with external irrigation by means of normal saline solution at room temperature. The study was realized on bovine ribs using: K without irrigation (KSI) and with irrigation (KCI) and S without irrigation (SSI) and with irrigation (SCI) with five drills for each system. Each drill was used 100 times. Bone temperature was measured with a thermocouple immediately after drilled. Average bone temperature with irrigation was for K drills 17.58 ± 3.32 °C and for S drills 16.66 ± 1.30 °C. Average bone temperature without irrigation was for K drills 23.58 ± 2.94 °C and for S drills 19.41 ± 2.27 °C. Statistically significant differences were found between K without irrigation versus S with irrigation and K with irrigation (p < 0.05, Bonferroni correction). Lower temperature variation coefficient throughout the 50 measurements was observed in irrigated groups (K = 5.6 %, S = 5.1 % vs. without irrigation groups K = 9.4 %, S = 9.3 %). The first K drill generated more heat than the remaining drills. No significant differences were detected among temperature values in any of the analyzed drill groups. Unlike irrigation, drill use and type were observed to have no significant impact on heat generation. The stainless steel AISI 420B presents better mechanical properties and corrosion resistance than AISI440.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Osseointegration—defined as bone-implant surface direct contact—requires meeting a series of conditioning factors [1]. The factors behind correct osseointegration include: implant material and design, surface quality, bone condition, implant-load conditions, and the surgical technique employed. The last must be correctly implemented during bed preparation to prevent possible thermal injuries on the adjacent bone due to excessive temperature. For this reason, the term non-traumatic surgical preparation is used, since it is considered essential in implant placement. The amount of bone in contact with the implant after placement and initial healing can vary and depend on several factors such as osteotomy-related thermal bone injury [2]. However, not only osseointegration is influenced, but resulting bone necrosis can lead to complete osseointegration failure. In-vivo studies prove the harmful effect of bed overheating on adjacent bone healing when the bone was determined to have tolerated critical temperatures. The critical temperature threshold was found to be at 47 °C, below which no necrosis takes place [3]. Thus, heat generation during drilling is considered an important factor, influenced by other aspects related to drill type and bone features. The latter factors include drill design, material, diameter, use and torque, and drilling speed, and irrigation. The bone-dependent factors include cortical thickness, patient healing capacity, and bone density [4]. These last factors depend on patient features, so they cannot be influenced to reduce generated heat. However, improvement of drill features is crucial to optimize implant bed-preparation performance. Surgical drill design is aimed at adapting drilling to the implant type used in each case, as there is a wide variety of both drilling systems and materials currently available in market that can influence both shearing and wearing capacity. The possible relationship between drill use and increased heat was studied [5]. With this purpose, human cortical bone temperature was measured after the use of 3.2 mm-diameter drills. Significantly higher temperatures were measured when previously-eroded drills were used, relative to new drills. Several studies have proven that drill wear is related to the force applied by the operator during drilling, the number of times drills have been used, and the sterilization method [6]. Drill irrigation is an important factor, as abundant irrigation is known to reduce temperature [5, 7]. In the last years different stainless-steel alloys have been used: titanium- and zirconium oxide-covered stainless steel [8–11]. These studies were aimed at improving drill properties such as stability, thermal conductivity, resistance, and wear, which can influence temperature during osteotomy. Allsobrook et al. [12] compare heat generation during 50 drilling processes with three drill types: Straumann, Nobel Biocare, and Neoss. These authors observed that Nobel Biocare drills show lower corrosion, wear and heat generation than the other two drill types. They attribute it to the drills’ different composition and their tungsten carbide covering. Another work [13] compares 3i, Straumann, Lifecore, Nobel Biocare, Implamed and Paragon drills, concluding that—although differences are observed in wear patterns—no differences were observed in heat generation.

For these reasons, this study is aimed at assessing the behavior of both drill types (with different stainless steels), as well as the influence of external irrigation and drill use on heat generation by means of registration of temperature in an in vivo model.

2 Material and experimental methodology

For this in vitro study two drilling models were tested: one of them made use of precipitation-hardening stainless steel (AISI 420B) (K drills) (SOADCO, Klockner® Implant System Essential Cone, Barcelona, Spain) and other used martensitic stainless steel (AISI 440) (S drills) (Straumann® Drills Implants Tissue Level AG, Basel, Switzerland). Drilling was completed on 25-cm bovine ribs with average 4 mm thickness of cortical bone. Ribs had been preserved at −20 °C, and taken out and held at room temperature (25 °C) 12 h prior to drilling.

2.1 Procedure

Twenty new drills to the market were used, (ten K drills and ten S drills). These were used in four types of tests:

-

K drills with irrigation (KCI) (n = 5).

-

K drills without irrigation (KSI) (n = 5).

-

S drills with irrigation (SCI) (n = 5).

-

S drills without irrigation (SSI) (n = 5).

Five drill bits of each type were submitted to 100 mechanical cycles. In Fig. 1a can be observed the drill before the tests.

Drilling were performed by the same experienced surgeon, who had ample experience in the use of both implant systems, by means of an implant motor (motor NSK® Surgic XT Plus, Shanghai, China; with 32:1 handpiece), 35-Ncm torque, at 700 rpm. External irrigation was completed with normal saline solution at room temperature (25 °C). The drill was allowed to acquire enough speed prior to contacting the bone. Drilling time was controlled and uniform (10 s). No controlled pressure system was applied to simulate the clinical conditions in a dentist’s office. Bed preparation depth was 12 mm. Drills were kept submerged in normal saline solution at room temperature between usages. Bone temperature was measured with a temperature gauge every two drilling.

2.2 Drill design and composition

12 mm long K and S drills were used at water temperature (25 °C). Precipitation-hardening stainless-steel K drills were: pointed drill Ø 2.35 mm (a), pilot drill Ø 2.8 mm (b), counterbore drill (c), finishing drill Ø 3.6 mm (d). These were iron, chrome and nickel alloys such as stainless steel, yet their structure shows precipitation of intermetallic compounds that produce importantly increased mechanical strength of steel as well as also higher wear resistance. Manufacturer-recommended usage limit is approx. 12×. The use of the pointed drill is also recommended to drill the cortical bone. However, it was not used in the present study in order to test it in the worst clinical case scenario. Martensitic stainless steel S drills were: pilot rounded drill Ø 2.3 mm (a), pilot drill Ø 2.2 mm (b), pilot drill Ø 2.8 mm (c), and spiral drill Ø 3.5 mm (d). Martensitic stainless steel is an iron, chrome and carbon alloy whose most outstanding features are its corrosion, and mechanical resistance, and hardness. The manufacturer-recommended usage limit is approx. 10×. Table 1 shows the chemical composition of each drill type (S and K).

2.3 Mechanical properties

Ten tensile specimens for each stainless steel were machined with a ratio diameter to gauge length of 1/5. The tensile specimens were tested in a universal screw-driven testing machine (Bionix, MTS, USA) of 100 kN capacity at a cross-head speed of 1 mm/min. The hardness distribution in a cross-section of shot-blasted specimens was measured using a Vickers hardness tester (Akashi, Matsusawa, Japan). The tests were carried out under load of 1 kg applied for 15 s.

The drills were weighed after ultrasound-cleaned with a precision of 0.00001 g in order to determine the wear of the drill bits that were tested after 100 mechanical cycles.

2.4 Temperature measurement

Measurement in this study was completed by the temperature measuring device Thermocouple (Thermodigit® PM = 3900, Felix Mateo®, Barcelona, Spain). Thermocouple is designed for instant measurement of a temperature with enhanced sensitivity between 0.1 and 110 °C, being previously calibrated by means of a certified power-supply source (voltmeter). We used a Probe Pt-Pt100 with an austenitic stainless steel pyrometric cone.

2.5 Corrosion tests

Five samples were tested in the form of small cylinders (2 mm diameter and 3 mm height) for each stainless steel studied. Samples were kept immersed in the electrolyte for all the measurements taken. The electrolyte was artificial saliva at a temperature of 37 °C and pH 6.7 with the composition given in the Table 2. The electrolyte was changed after each experiment.

The corrosion cell used is a glass cell with the working electrodes and a saturated Ag/AgCl electrode used as a reference (Vidra Foc. Spain). The distance from the reference electrode to samples was 25 mm. The ratio of anode surface to the cathode surface was equal to one.

The anodic polarizarion was controlled by a Hewlett Packard potentiostat (USA). The variation of the potentials in an open short circuit was controlled by a Digital Multimeter and Scanner Resistance (Volatalab Radiometer, France). The overall system was controlled using PC-compatible computer. The preparations of the samples and the corrosion test carried out followed the ASTM standards G8 and G15 [14].

The samples were subjected to the following measuring cycle:

-

Immersion in the de-aerated electrolyte for 250 min with recording of the open potential of each electrode.

-

By means of a potentiostat the potential at intervals of 50 mV until 1.6 V was increased. Recordings of the variation of the galvanic current density, potential, among others parameters were obtained and the Tafel slopes were determined from the Evans´ diagrams. In order to determine these diagrams, it is very important to record the polarization curves in a pseudostationary manner. In this study, the 250 min of immersion of specimens was regarded sufficient.

2.6 Statistical analysis

Temperatures values were described by means and standard deviations. To compare drilling temperatures among groups the Kruskal–Wallis test was used, given the non-normality of the data (Shapiro–Wilk test). In case of a significant Kruskal–Wallis test result, test-differing groups were identified with a Bonferroni test. To compare the values obtained in the 1st and 50th measurements in the 4 groups, a repeated-measure MANOVA was used with one intrasubject value (drilling) and one intersubject factor (group). To analyze variance in the consecutive measurements obtained with the 4 drills in each group, variance coefficients (expressed as %) were calculated, as well as 95 % confidence intervals for these coefficients. In order to compare among the 1st and 50th measurements for each drill and irrigation type Student’s t test was used to verify normality or the Wilcoxon test was used to verify non-normality.

3 Results

The results of the mechanical properties (Table 3) showed that the measured values of strength, resistance and hardness are higher for K drills (AISI 420B) than for S drills (AISI 440). Consequently, this material improved the cutting of the bone. Also the measurements of wear were lower than S drills, as can be observed in Table 4 where the drill bit weight-loss decreased around 30 % with the K drills with the established number of cycles, thus reducing the debris of the drill bit which can produce undesirable effects in the surrounding tissues. In Fig. 1b can be observed the tip of the drill after 100 mechanical cycling. This is the zone where occurs mainly the weight loss location of the drill. In Fig. 1c and d can be observed the surface of a K-drill after 100 cycles and in Fig. 1e and f can be observed the surface of S-drill at the same number of cycles. From the above figures it can be seen, the highest wear the S-drills than K ones.

Consequently, the AISI 420B stainless steel alloy improved the cutting of the bone. Also the measurements of wear will be lower than S drills.

The mean of all temperature measurements obtained for all drills was 17.58 ± 0.95 °C (KCI), 23.58 ± 0.84 °C (KSI), 16.66 ± 0.37 °C (SCI), and 19.41 ± 0.65 °C (SSI). Overall significant differences were observed among groups (p < 0.05, Kruskal–Wallis test). Intergroup differences were statistically significant for KSI vs. SCI and KCI (p < 0.05, Bonferroni test). When average temperature values were analyzed according to drill type (Table 5) differences were observed among the drills in all groups (Kruskal–Wallis test). In KCI and KSI differences were found between a drill and the remaining drills, while it was between a and c drills in SCI, and between c and d drills in SSI (p < 0.05, Bonferroni test). The average values obtained in each of the 50 measurements with each of both drill types according to irrigation is shown in Fig. 2. Throughout the 50 measurements, KSI was observed to show statistically-significant higher temperature values (MANOVA). Besides, analysis of the variations in generated temperature throughout the 50 measurements showed a variation coefficient of 5.6 in KCI (IC 95 % 4.67–6.98 %), 5.1 in SCI (IC 95 % 4.26–6.36 %), 9.4 in KSI (IC 95 % 7.84–11.72 %), and 9.3 in SSI (IC 95 % 7.76–11.60 %). Lower variance was observed in both drill types in presence of irrigation.

For a more detailed look at the effect of irrigation, an analysis of the temperature reached with each of the 4 K drills (Fig. 3) and S drills (Fig. 4) showed a higher temperature with K drills and in groups without irrigation.

To analyze the influence of use, Figs. 5 and 6 show the values of means and standard deviations in each drill type according to irrigation in the 1st 50th measurements. No significant differences are observed in any of analyzed drill groups (p > 0.05), in spite of the greater differences observed with K drills and in groups without irrigation.

It should be pointed out that none of the drills in both sequences came near the considered risk temperature: 47 °C.

Five specimens of each alloy were tested by anodic polarization. Figure 7 shows the polarization curves. Each specimen was polarized five times and polished before the tests, then the mean values were calculated: the critical current density (icr), the passive current density (ip), the corrosion potential (Ecorr) and the critical pitting potential (Ecp), as can be observed in Table 6. The different polarization tests for each sample did not show changes in the results for the different magnitudes.

The stainless steel with higher current density at a given potential, is the more prone to corrode. The K Drill (AISI420B) had the most passive (0.96 μA/cm2) and the S drill (AISI 440) had the most active (1.90 μA/cm2) critical current density values. If passive current density is low, the alloy is said to passivate more easily. The passive current density values were 0.88 μA/cm2 for the K drill and 1.00 μA/cm2 for the S drill. On the other hand, the S drill was the most active alloy, with a pitting potential value of +90 mV. This was the reason of the pitting observed in the S drill after the 100 cycles.

4 Discussion

Our results showed that average temperature in the 4 drill groups and the temperature values registered were always higher for group KSI relative to KCI and SCI. Drill design seemed to have no significant impact on results, as differences were only found when comparing the temperature generated with each of the four drills in each of the four groups. However, Table 5 showed that differences in groups SCI (a vs. c) and SSI (c vs. d) was only 1 °C; in KCI and KSI the a drill performed better than the remaining drills by at least 2 °C. This may have been due to the fact that the pointed drill generated more friction due to its conical design and was also used to reach up to 12 mm deep, unlike the first S drill, which was used only to pierce the cortical bone. Some in vitro studies proved that drill design had a bearing on heat generation [10, 11, 15]. Our results could be explained by the heat dissipation effect due to the alloy’s features [16]. On the other hand, temperature changes according to drill diameter were not found statistically significant in any group. Drill design and diameter are additional factors that can influence heat generation. A direct proportional relationship between drill diameter and heat generation was reported by Sun-Jong et al. [17]. Others such as Flanagan [18] found that lower drill diameter led to greater heat generation. Bulloch et al. [19] compared heat generation in several drilling sequences and reported that the highest heat generation was observed with the first drill. These authors attributed this to the fact that the lowest-diameter drill had a lower mass and therefore lower heat-dissipation capacity. Another study proved that the time needed for temperature to come back to baseline is twice higher in 2 mm-diameter drills relative to 3.3 mm-diameter ones [20]. Therefore, worse heat dissipation was observed in greater-diameter drills. This aspect could explain our result.

Another possible explanation for these data could lie in the influence of irrigation on heat generation. Our results proved statistically significant differences, temperature values generated with irrigation being always lower, and the lowest values being obtained with S drills. If the measures registered throughout the 50 measurements were observed, the observed variability was similar to that reported by Sumer et al. [21]. The influence of this variability on measurements was analyzed with the variance coefficient, which measured variability in registers. It showed a negative behavior when no irrigation was used for both drill types. Therefore, according to our results, irrigation was the most influential factor on heat generation, thus in agreement with several works [13, 22, 23]. We disagree with some authors who question the need to irrigate [18], they use the drills in a few numbers of low-speed.

Our results showed no significant differences in all 50 temperature measurements in any of the analyzed drill groups. Used throughout the 100 drilling appeared to have no impact on heat generation. This may seem rather contradictory because—although use has been proven to wear drills—it did not effect heat generation [12, 13]. These authors stated that the most important factors were appropriate irrigation and the use of non-sterilized drills, as in our case. The effect of sterilization on different drill types (3i, Nobel-Biocare, Straumann, and Lifecore) was studied by Harris and Hirsch [6], and their influence on heat generation was also studied. Chacon et al. [11] performed drill sterilization after two uses and observed that higher temperature was generated after 25 uses, yet they attributed it to drill design and, particularly, to the attack angle used in the shearing surface. Jochum and Reichart [24] compared two groups of sterilized and non-sterilized drills and observed by scanning electron microscopy that drill sterilization led to reduced shearing capacity. Allan et al. [25] proved that the use of previously-used drills led to higher heat generation. The last work included previous use of 600 drilling, while some other studies that reached similar results to ours complete around 50 [12] and 100 [13] drilling.

Bovine bone was used for our design because it is the one that imitates human bone best. Yacker and Klein [7] studied bovine bones by means of computed tomography, and cortical thickness and bone density values by means of Hounsfield scale, obtaining similar values to those obtained with human bones. For this reason, we thought that our results could be extrapolated to human bone. Bone temperature registration was completed by means of a thermocouple whose most outstanding feature is its dynamic precision, which is characterized by short response times to sudden temperature changes, optimized by the nature of the thermocouple’s platinum and platinum–rhodium threads. Besides, it is a good temperature conductor due to pyrometric cone design [19]. An important aspect is that no standardized drilling pressure control was used, being completed manually. Heat generation is known inversely proportional to pressure [6, 26]. Manual pressure has no constant values, yet we have intended to reproduce—as accurately as possible—conditions to obtain as similar as possible results to those obtained in everyday clinical work. In a study with manual drilling [27] analyzed temperature on 51 patients and report that registration differences depend on the bone the implant is placed on.

It must be highlighted that drills were submerged in room-temperature normal saline solution during intervals between drilling. As in Sumer et al. [21], this is aimed at assuring that generated heat is produced by the drill, starting from the same baseline temperature conditions. Besides, the normal saline solution used for irrigation purposes was kept at 25 °C. This temperature is enough for appropriate refrigeration and to avoid bone necrosis [28]. External refrigeration was used, as it is proven to provide appropriate refrigeration, no internal irrigation being necessary, as proven when both systems are compared [15].

Mechanical properties play an important role in the wear of the drills. High strength and hardness produce an important decrease of the presence of debris and the cutting capacity is increased. The drills made with AISI 420B can be used by the surgeon more than 20 % in relation with the AISI440 maintaining the mechanical properties and with an excellent corrosion resistance.

5 Conclusions

Unlike irrigation, drill use and type can be said to have no significant impact on heat generation. In the case of no irrigation, more negative results are obtained with K drills. Greater temperature increase was observed with the pointed drill. Even though, temperature never reached values near bone necrosis risk (i.e., 47 °C). Stainless steel AISI 420B displays better mechanical properties, wear resistance and corrosion resistance than AISI 440.

References

Branemark P. Osseointegration and its experimental background. J Prosthet Dent. 1983;50:399–410.

Eriksson RA, Alberktsson T. The effect of heat on bone regeneration: an experimental study in rabbit using the bone growthchamber. J Oral Maxillofac Surg. 1984;42:705.

Eriksson RA, Albrektsson T. Temperature threshold levels for heat-induced bone tissue injury: a vital-microscopic study in the rabbit. J Prosthet Dent. 1983;50:101–7.

Tehemar SH. Factors affecting heat generation during implant site preparation: a review of biologic observations and future considerations. Int J Oral Maxillofac Implants. 1999;14:127–36.

Matthews LS, Hirsch C. Temperatures measured in human cortical bone when drilling. Bone Joint Surg. 1972;54:297–308.

Harris BH, Kohles SS. Effects of mechanical and thermal fatigue on dental drill performance. Int J Oral Maxillofac Implants. 2001;16:819–26.

Yacker MJ, Klein M. The effect of irrigation on osteotomy depth and bur diameter. Int J Oral Maxillofac Implants. 1996;11:634–8.

Piconi C, Maccauro G. Zirconia as a ceramic biomaterial: review. Biomaterials. 1999;20:1–25.

Bayerlein T, Proff P, Richter G, Dietze S, Fanghanel J, Gedrange T. The use of ceramic drills on a zirconium oxide basis in bone preparation. Folia Morphol (Warsz). 2006;65:72–4.

Oliveira N, Alaejos-Algarra F, Mareque-Bueno J, Ferres-Padro E, Hernandez-Alfaro F. Thermal changes and drill wear in bovine bone during implant site preparation. A comparative in vitro study: twisted stainless steel and ceramic drills. Clin Oral Implants Res. 2012;23:963–9.

Chacon GE, Bower DL, Larsen PE, McGlumphy EA, Beck FM. Heat production by 3 implant drill systems after repeated drilling and sterilization. J Oral Maxillofac Surg. 2006;64:265–9.

Allsobrook OF, Leichter J, Holborrow D, Swain M. Descriptive study of the longevity of dental implant surgery drills. Clin Implant Dent Relat Res. 2011;13:244–54.

Ercoli C, Funkenbusch PD, Lee HJ, Moss ME, Graser GN. The influence of drill wear on cutting efficiency and heat production during osteotomy preparation for dental implants: a study of drill durability. Int J Oral Maxillofac Implants. 2004;19:335–49.

Annual Book of ASTM Standards. Metals test methods and analytical procedures. Wear and corrosion; metal corrosion, vol 3.02, p. 56–85; 1992.

Benington IC, Biagioni PA, Briggs J, Sheridan S, Lamey PJ. Thermal changes observed at implant sites during internal and external irrigation. Clin Oral Implants Res. 2002;13:93–297.

Albertini M, Herrero-Climent M, Lázaro P, Ríos JV, Gil FJ. Comparative study on AISI 440 and AISI 420B stainless steel for dental drill performance. Mater Lett. 2012;79:163–5.

Sun-JongK Jaeyoung Y, Young-Soo K, Sang-Wan S. Temperature change in pig rib bone during implant site preparation by low-speed drilling. J Appl Oral Sci. 2010;18:522–7.

Flanagan D. Osteotomy irrigation: is it necessary? Implant Dent. 2010;19:241–9.

Bulloch SE, Olsen RG, Bulloch B. Comparison of heat generation between internally guided (cannulated) single drill and traditional sequential drilling with and without a drill guide for dental implants. Int J Oral Maxillofac Implants. 2012;27:1456–60.

Cordioli G, Majzoub Z. Heat generation during implant-site preparation: an in vitro study. Int J Oral Maxillofac Implants. 1997;12:186–93.

Sumer M, Ferhat A, Misir A, Tuba-Telcioglu N, Guler A, Yenisey M. Comparison of heat generation during implant drilling using stainless steel and ceramic drills. J Oral Maxillofac Surg. 2011;69:1350–4.

Reingewirtz Y, Szmukler-Moncler S, Semger S. Influence of different parameters on bone heating and drilling time in implantology. Clin Oral Implants Res. 1997;8:189–97.

Kerawala CJ, Martin C, Allan W, Williams ED. The effects of operator technique and bur design on temperature during osseous preparation for osteosynthesis self-tapping screws. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 1999;88:145–50.

Jochum RM, Reichart PA. Influence of multiple use of Timedur-titanium cannon drills: thermal response and scanning electron microscopic findings. Clin Oral Implants Res. 2000;11:139–43.

Allan W, Williams ED, Kerawal CJ. Effects of repeated drill use on temperature of bone during preparation for osteosynthesis self-tapping screws. Br J Oral Maxillofac Surg. 2005;43:314–9.

Markovic A, Misic T, Milicic B, Calvo-Guirado JL, Aleksic Z, Dinic A. Heat generation during implant placement in low density bone: effect of surgical technique, insertion torque and implant macro design. Clin Oral Implants Res. 2013;24:798–805.

Sánchez-Pérez A, Moya-Villaescusa MU, Caffesse RG. Temperature of periimplant tissues in clinically successful implants: an observational clinical study in humans. Implant Dent. 2011;20:292–8.

Sener BC, Dergin G, Gursoy B, Kelesoglu E, Slih I. Effects of irrigation temperature on heat control in vitro at different drilling depths. Clin Oral Implants Res. 2009;20:294–8.

Acknowledgments

The authors are grateful to the CICYT MAT2012-30706 and Generalitat de Catalunya and Andorra Government (CTP project) for funding the present work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bullon, B., Bueno, E.F., Herrero, M. et al. Effect of irrigation and stainless steel drills on dental implant bed heat generation. J Mater Sci: Mater Med 26, 75 (2015). https://doi.org/10.1007/s10856-015-5412-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5412-8