Abstract

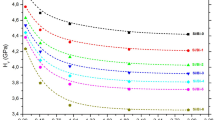

The role of diffusion annealing temperatures intervals 600–850 °C on durable tetragonal phase, surface morphology, and main mechanical performance parameters of Co surface-layered Bi2.1Sr2.0Ca1.1Cu2.0Oy (Bi-2212) samples has extensively been examined by scanning electron microscopy (SEM), Electron Dispersive X-ray (EDX) technique and microindentation Vickers hardness (Hv) tests. The experimental findings have shown that every material prepared has presented different composition distributions on the specimen surface as a consequence of the successful production of materials. Besides, the mechanical characteristics and durable tetragonal phase have been noted to enhance significantly with the enhancement of annealing temperature up to 650 °C due to the formation of new slip systems, surface residual compressive stress regions, connections between grains, and chemical bonding between the foreign and host atoms. Further, the optimum temperature has led to the reduction in stored internal strain energy and degree of granularity in the Co-diffused Bi-2212 crystal system. In this respect, the sample with the least sensitive to the external forces has exhibited the highest elastic modulus of 0.5445 GPa, shear modulus of 17.8515 GPa, yield strength of 181.5 MPa, and resilience of 369.1 MPa under 0.295 N. Accordingly, the cracks and dislocations have preferred to propagate throughout the transcrystalline regions, and crack growth size was easily controlled. Similarly, the saturation limit region has begun at relatively higher applied test load magnitudes. Conversely, the excess annealing temperature has caused the increase in the agglomeration of cobalt ions throughout the intergranular regions. Correspondingly, the activation of stress-induced phase transformation has been triggered seriously. Bi-2212 ceramic compound exposed to the optimum diffusion annealing temperature exhibits the most uniform surface view and crystalline quality with the densest surface morphology and the largest particle distributions and orientations. Moreover, every material studied has perfectly presented the characteristic indentation size effect behavior. The examination of granularity degree depending on elasticity moduli has verified all the Hv test results and discussions. All in all, this study guides the use of engineering ceramics in more application areas due to the increase in their service life.

Similar content being viewed by others

References

H. Kamerlingh Onnes, Further experiments with Liquid Helium. D. On the change of electrical resistance of pure metals at very low temperatures, etc. V. The disappearance of the resistance of mercury. Koninklijke Nederlandse Akademie van Wetenschappen Proceedings Series B Physical Sciences 14, 113–115 (1911)

T. Turgay, G. Yildirim, Effect of aliovalent Si/Bi partial substitution on propagation mechanisms of cracking and dislocation in Bi-2212 crystal system. J. Mater. Sci.: Mater. Electron. 30, 7314–7323 (2019)

E. Kara, P. Özkurt, B. Özkurt, Effects of different dwell-times under low pelletization pressure on the physical properties of the Bi-2212 ceramics. J. Mater. Sci. Mater. Electron. 33, 14951–14960 (2022). https://doi.org/10.1007/s10854-022-08412-5

N.K. Sarıtekin, M. Dogruer, Y. Zalaoglu, G. Yildirim, C. Terzioglu, O. Gorur, Filling of electronic density of states in Y-123 superconducting ceramics by nano Nd substitution on Ba site in crystal structure. J. Alloy. Compd. 659, 31–37 (2016)

Y. Slimani, M.A. Almessiere, E. Hannachi, M. Mumtaz, A. Manikandan, A. Baykal, F.B. Azzouz, Improvement of flux pinning ability by tungsten oxide nanoparticles added in YBa2Cu3Oy superconductor. Ceram. Int. 45(6), 6828–6835 (2019)

E. Hannachi, Y. Slimani, A. Ekicibil, A. Manikandan, F.B. Azzouz, Magneto-resistivity and magnetization investigations of YBCO superconductor added by nano-wires and nano-particles of titanium oxide. J. Mater. Sci.: Mater. Electron. 30, 8805–8813 (2019)

H. Fallah-Arani, A. Sedghi, S. Baghshahi, R.S. Moakhar, N. Riahi-Noori, N.J. Nodoushan, Bi-2223 superconductor ceramics added with cubic-shaped TiO2 nanoparticles: structural, microstructural, magnetic, and vortex pinning studies. J. Alloy. Compd. 900, 163201 (2022)

Y. Slimani, M.A. Almessiere, E. Hannachi, A. Baykal, A. Manikandan, M. Mumtaz, F.B. Azzouz, Influence of WO3 nanowires on structural, morphological and flux pinning ability of YBa2Cu3Oy superconductor. Ceram. Int. 45(2), 2621–2628 (2019)

N.K. Saritekin, M. Oz, C. Terzioglu et al., Significant development on pinning of vortices in Y-123 superconductor with homovalent Ba/Nd substitution. J. Mater. Sci. Mater. Electron. 27, 6992–7003 (2016)

P. Zagura, I. Kim, F. Follows, C. Barker, Z. Melhem, A. Twin, S. Ball, C. Grovenor, S. Speller, T. Mousavi, Development of persistent joints for superconducting Bi-2212 coils. Supercond. Sci. Technol. 37, 055003 (2024)

S.H. Jeong, J.B. Song, Y.H. Choi, S.G. Kim, B.S. Go, M. Park, H. Lee, Effect of micro-ceramic fillers in epoxy composites on thermal and electrical stabilities of GdBCO coils. Compos. B Eng. 94, 190–196 (2016)

A. Xu, J. Jiang, C. Tarantini, F. Kametani, E. Hellstrom, D.C. Larbalestier, Flux pinning enhancement of Bi-2212 tapes by increasing Sr Content,". IEEE Trans. Appl. Supercond. 34(3), 1–5 (2024)

U. Erdem, G. Yildirim, M.B. Turkoz, A.T. Ulgen, A. Mercan, Change intransition balance between durable tetragonal phase and stress-induced phase of cobalt surface-layered in Bi-2212 materials by semi-empirical mechanical models. Phys. Scr. 98, 075702 (2023)

E. Takayama-Muromachi, High-pressure synthesis of homologous series of high critical temperature (T c) superconductors. Chem. Mater. 10(10), 2686–2698 (1998)

H. Yamauchi, M. Karppinen, Application of high-pressure techniques: stabilization and oxidation-state control of novel superconductive and related multi-layered copper oxides. Supercond. Sci. Technol. 13(4), R33 (2000)

A. Harabor, P. Rotaru, N.A. Harabor, P. Nozar, A. Rotaru, Structural, thermal and superconducting properties of Ag2O-doped YBa2Cu3O7-x composite materials. Ceram. Int. 49(9), 14904–14916 (2023)

S.Y. Oh, H.R. Kim, Y.H. Jeong, O.B. Hyun, C.J. Kim, Joining of Bi-2212 high-Tc superconductors and metals using indium solders. Physica C: Supercond Appl 463, 464–467 (2007)

A.T. Ulgen, U. Erdem, Y. Zalaoglu, T. Turgay, G. Yildirim, Effect of vanadium addition on fundamental electrical quantities of Bi-2223 crystal structure and semi-empirical model on structural disorders-defects. J. Mater. Sci.: Mater. Electron. 31(16), 13765–13777 (2020)

T.P. Sheahen, Introduction to high-temperature superconductivity, 1st edn. (Kluwer Academic Publishers, New York, 2002)

A.K. Saxena, High-temperature superconductors, 2nd edn. (Springer, Heidelberg New York Dordrecht London, 2012)

N. Plakida, High temperature cuprate superconductors, in Springer series in solid-state sciences. (Springer, New York, 2010), p.480. (ISBN 9783642126321)

H. Hilgenkamp, J. Mannhart, Grain boundaries in high-Tc superconductors. Rev. Mod. Phys. 74(2), 485 (2002)

C. Autret-Lambert, B. Pignon, M. Gervais, I. Monot-Laffez, A. Ruyter, L. Ammor, R. Decourt, Microstructural and transport properties in substituted Bi2Sr2CaCu2O8+δ modulated compounds. J Solid State Chem 179(6), 1698–1706 (2006)

K. Salama, V. Selvamanickam, L. Gao, K. Sun, High current density in bulk YBa2Cu3Ox superconductor. Appl. Phys. Lett. 54(23), 2352–2354 (1989)

C.C. Tsuei, J.R. Kirtley, G. Hammerl, J. Mannhart, H. Raffy, Z.Z. Li, Doping effect on pairing symmetry in cuprate superconductors. J. Phys. Chem. Solids 67(1–3), 64–67 (2006)

K. Fujita, T. Noda, K.M. Kojima, H. Eisaki, S. Uchida, Effect of disorder outside the CuO2 planes on Tc of copper oxide superconductors. Phys. Rev. Lett. 95(9), 097006 (2005)

İ Öz, C. Terzioglu, M. Öz, A.T. Ülgen, M.B. Türköz, Ü. Erdem, G. Yildirim, Variation of fundamental features of cobalt surface-layered Bi-2212 superconductor materials with diffusion annealing temperature. Ceram. Int. 49, 8417–8427 (2022)

J. Bardeen, L.N. Cooper, J.R. Schrieffer, Theory of superconductivity. Phys. Rev. 108(5), 1175 (1957)

A.K. Saxena, High-temperature superconductors (Springer, Berlin, 2010)

X. Xu, J.H. Kim, S.X. Dou, S. Choi, J.H. Lee, H.W. Park, M. Tomsic, A correlation between transport current density and grain connectivity in MgB 2/Fe wire made from ball-milled boron. J Appl Phys 105(10), 103913 (2009)

M. Rekaby, N.H. Mohammed, M. Ahmed, A.I. Abou-Aly, Synthesis, microstructure and indentation vickers hardness for (Y3Fe5O12)x/Cu0.5Tl0.5Ba2Ca2Cu3O10-δ composites. Appl. Phys. A 128, 261 (2022)

E. Asikuzun, Production procedure and characterization of Zn-Doped Y-123 superconducting samples prepared by Sol-Gel method. J. Supercond. Nov. Magn. 31, 3509–3514 (2018)

W.D. Callister Jr., D.G. Rethwisch, Materials science and engineering: an introduction, 9th edn. (Wiley Binder Version, USA, 2013)

W. Abdeen, S. Marahba, R. Awad, A.I. Abou Aly, I.H. Ibrahim, M. Matar, Electrical and mechanical properties of (Bi, Pb)-2223 substituted by holmium. J. Adv. Ceram. 5, 54–69 (2016)

A.T. Ulgen, T. Turgay, C. Terzioglu, G. Yildirim, M. Oz, Role of Bi/Tm substitution in Bi-2212 system on crystal structure quality, pair wave function and polaronic states. J. Alloy. Compd. 764, 755–766 (2018)

Author information

Authors and Affiliations

Contributions

AM, UE and GY conceived the idea for the project and designed the experiments. AM, UE, ATU, TT and MG performed methodology, project administration, investigation and materials production. ATU, AM, MG and MBT performed experimental measurement and resources, formal analysis, review & editing. UE, MBT, TT and GY performed writing—original draft, writing—review & editing. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The author declares that there are no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

There is no action that requires ethics committee approval.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mercan, A., Erdem, Ü., Ülgen, A.T. et al. Evolution of residual compressive stress regions in Co-diffused Bi-2212 engineering ceramics with annealing temperature. J Mater Sci: Mater Electron 35, 1720 (2024). https://doi.org/10.1007/s10854-024-13468-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-13468-6