Abstract

Ba(Cu0.5W0.5)O3 (BaCW)-doped (1−x)Pb(Zr0.5Ti0.5)O3–x(Bi0.5Na0.5)ZrO3 [(1−x)PZT–xBNZ, x = 0.025–0.1] ceramics were prepared by solid-state reaction method. Low-temperature sintering is realized at around 1000 °C sintering temperature due to adding BaCW sintering aid and (Bi0.5Na0.5)ZrO3 (BNZ) second component. All low-temperature sintered BaCW-doped (1−x)PZT–xBNZ ceramics exhibit pure perovskite structure, in which the structure changes successively from tetragonal, across morphotropic phase boundary (MPB) and to rhombohedral with increasing the BNZ content. All samples have large density, high resistivity, and rather uniform morphology with decreased grain size. All ceramics present apparent relaxation characteristic, and the MPB effect is confirmed by dielectric, ferroelectric, and piezoelectric performance characterization, whereas extremum performance appears at different compositions. High Curie temperature (TC) with acceptable piezoelectricity (d33) is obtained in the BaCW-doped (1−x)PZT–xBNZ system prepared by low-temperature sintering technique, i.e., the 1000 °C sintered 2 wt% BaCW-doped 0.9PZT–0.1BNZ having d33 = 209 pC/N with TC = 281 °C, and 0.95PZT-0.05BNZ having d33 = 151 pC/N with TC = 345 °C, which present broad application possibility in piezoelectric-related fields under extreme condition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Because of low Curie temperature (TC), inferior piezoelectric performance, high sintering temperature, etc., of lead-free piezoelectric materials [1,2,3], Pb(Zr,Ti)O3 (PZT)-based piezoelectric ceramics have still dominated applications in piezoelectric components due to the superior comprehensive performance [4]. The progress in technology and society has triggered many novel application fields, such as metallurgy, aerospace, oil and gas exploration, in which extreme working condition requires high TC piezoelectric materials [5]. Due to the existence of depolarization phenomenon and low-temperature ferroelectric phase transition [6, 7], safe working temperature of piezoelectric materials is far less than the corresponding TC temperature [8], which stimulates enthusiastic interest in searching high TC piezoelectric materials.

Besides developing novel compositions [9,10,11], PZT still attracts our interest due to scale production, widespread application, and cost considerations. Based on the study of morphotropic phase boundary (MPB), normally representing coexistence region of rhombohedral phase and tetragonal phase [10], Pb(Zr0.5Ti0.5)O3 was selected as matrix in this work, in which Ti content was slightly larger than the MPB region, and could increase TC temperature [12].

Pb(Zr0.5Ti0.5)O3 deviates from the MPB region slightly, its structure approaches tetragonal phase, and its electrical performance decreases but has slightly higher TC temperature, which requires further adjustment. Constructing MPB is still a useful method to increase electrical properties in developing novel ferroelectric materials [12,13,14], where (Bi0.5Na0.5)ZrO3 was chosen as a second component in this work, which could also help decrease sintering temperature due to low melting point of Bi-based oxide [15]. (Bi0.5Na0.5)ZrO3 is similar to the well-known (Bi0.5Na0.5)TiO3, in which Ti and Zr have similar outer electron orbit, and Zr will affect ion interaction force and polarization state due to difference of atomic orbital number [16,17,18,19]. Lv et al. studied the role of Bi0.5A0.5ZrO3 (A = K, Na, Ag, and (Na0.82K0.18)) on the potassium sodium niobate (KNN) ceramics, and found that Zr4+ acted as a buffer, Bi3+ was an accelerator, and A+ acted as a stabilizer. The synergetic effects reduced the orthorhombic–tetragonal phase transition, providing a novel strategy to design phase boundary in KNN without destroying long-range ordering [17]. Then, pseudo-binary solid solution Pb(Zr0.5Ti0.5)O3–(Bi0.5Na0.5)ZrO3 could be formed, and stabilized perovskite structure and improved electrical performance could be anticipated.

Ceramic processing and physical performance have closed relationship [20], in which sintering temperature is very important for preparing lead-based ceramics. The sintering temperature of preparing the PZT-based piezoelectric ceramics is relatively high, usually 1250 °C or above [21]. In a recent work reported by Lin et al., in order to obtain large transduction coefficient and high TC temperature in PZT, the sintering temperature was still as high as 1180 °C to prepare the (Pb1 − xBix)((Zr0.53Ti0.47)1−xFex)O3 ceramics even though co-doped Bi2O3 and Fe2O3 [22]. Such high sintering temperature not only causes severe evaporation of Pb during sintering, leading to reduce phase purity and deteriorate electrical properties, but also endangers health and pollutes environment [23].

Low-temperature sintering technique provides a possibility to solve such dilemma. To realize low-temperature sintering, besides adding low melting point second component, such as (Bi0.5Na0.5)ZrO3 [18, 19], and obtaining high sintering active precursor powder via liquid method [24,25,26], adding appropriate sintering aid is mostly used method and is very effective to decrease sintering temperature [27, 28]. Ba(Cu0.5Wu0.5)O3 (BaCW) is a perovskite structure sintering aid and has been used in lead-free system [29, 30]. Wang et al. reported adding 0–6 mol% Ba(Cu1/2W1/2)O3 into the (Bi1/2Na1/2)TiO3 ceramics, and densified ceramics were sintered at 1130 °C. The addition of BaCW facilitated poling process, and improved piezoelectric performance and decreased dielectric loss with minor impure phase were achieved at appropriate doping amount [29]. Li et al. investigated low-temperature sintering of the (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 ceramics by Ba(Cu0.5W0.5)O3 addition, and the sintering temperature was reduced from 1540 to 1350 °C. At small BaCW doping amount, sintering ability was improved, high piezoelectricity was retained, and the TC temperature was increased slightly [30].

In this paper, Ba(Cu0.5Wu0.5)O3 (BaCW) was used as sintering aid, which was expected that not only realized low-temperature sintering in the (1−x)Pb(Zr0.5Ti0.5)O3–x(Bi0.5Na0.5)ZrO3 [(1−x)PZT–xBNZ] ceramics, but also affected crystal structure and electrical performance due to the tetragonal perovskite structure of BaCW [29, 30]. This work would verify that BaCW could also promote sintering capability in lead-containing system. However, both BNZ second component and BaCW sintering aid could decrease sintering temperature and TC temperature simultaneously. Then, it was necessary to find a balance between increasing TC temperature to satisfy requirement of extreme condition application and decreasing sintering temperature to facilitate ceramic processing.

The strategy of adding Bi-based second component and BaCW sintering aid can decrease sintering temperature, avoid evaporation of Pb, and save energy, presenting possibility to obtain high TC and high-performance piezoelectric ceramics and prospect application in multi-layer co-sintered ceramic industry where low-cost silver electrode was recommended first as inner electrode [31]. Therefore, low-temperature densified sintering at around 1000 °C was realized in the (1−x)PZT–xBNZ system due to adding BNZ second component and BaCW sintering aid. The 1000 °C sintered 2 wt% BaCW-doped 0.95PZT–0.05BNZ and 0.9PZT–0.1BNZ ceramics have high TC temperature and acceptable piezoelectricity, presenting broad application prospect in high-temperature piezoelectric-related fields under extreme condition.

2 Experimental procedure

(1−x)Pb(Zr0.5Ti0.5)O3–x(Bi0.5Na0.5)ZrO3 [(1−x)PZT–xBNZ, x = 0.025, 0.05, 0.075, 0.1) ceramics were prepared by low-temperature sintering technique using Ba(Cu0.5Wu0.5)O3 (BaCW) as sintering aid. High purity PbO, ZrO2, TiO2, Bi2O3, Na2CO3, BaCO3, CuO, and WO3 were used as raw materials. After fully drying, stoichiometric weighing, and well mixing, perovskite precursor powder (1−x)PZT–xBNZ was prepared by calcining well mixed stoichiometrically weighed PbO, ZrO2, TiO2, Bi2O3, and Na2CO3 at 775 °C for 2 h, and perovskite sintering aid BaCW was prepared by calcining well mixed stoichiometrically weighed BaCO3, CuO, and WO3 at 870 °C for 2 h, separately. To fully utilize promoting sintering effect of sintering aid, BaCW was added into the calcined (1−x)PZT–xBNZ precursor powder before granulation and pressing into circular green pellets. In order to achieve goal of 1000 °C low-temperature sintering, 2 or 2.5 wt% calcined BaCW powder was added. Such doping amount was selected since when the BaCW doping amount was too low, the sintering temperature could not be decreased to around 1000 °C; when the BaCW doping amount was too large, the dielectric loss was unacceptable large. Sintering process was undertaken at sintering temperature of 980–1010 °C and soaking time of 2 h, after separate burning out of polyvinyl alcohol binder at 600 °C for 2 h.

Crystal structure and free-surface morphology were characterized by Rigaku D/max-2500/PC X-ray diffractometer (XRD) and JEOL JSM-6510 scanning electron microscopy (SEM), respectively, using well-ground BaCW-doped (1−x)PZT–xBNZ ceramics. High-temperature silver electrode was formed by manually coated with silver paste and fired at 850 °C for 0.5 h. Based on which, room-temperature resistance was measured using Agilent 4339B Meter, dielectric performance-temperature relationship was measured by Partulab HDMS-1000 measurement system, room-temperature ferroelectric properties were measured using Radiant Precision Premier LC II, and piezoelectric properties were measured by ZJ-6 A meter and TH2826 LCR Meter after poling in silicone oil for 1 min at room temperature under several electric field [32].

3 Results and discussion

3.1 Structure change and density analysis

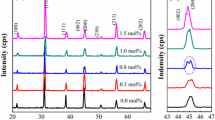

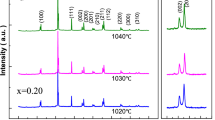

In this work, (1−x)PZT–xBNZ composition and BaCW doping amount are 2 studied variables, and sintering temperature no higher than 1000 °C with acceptable densification is pursued goal. Based on preliminary experiments, 2 and 2.5 wt% BaCW doping amount are selected, and the influence on sintering behavior of 0.975PZT–0.025BNZ and 0.95PZT–0.05BNZ is analyzed by XRD measurement as shown in Figs. 1 and 2. All sintered ceramics present pure perovskite structure, showing that BNZ second component and BaCW sintering aid can stabilize perovskite structure, form complete solid solution, and realize low-temperature sintering, partially relating to being perovskite structure for both BNZ and BaCW. All BaCW-doped 0.975PZT–0.025BNZ and 0.95PZT–0.05BNZ ceramics present crystal structure dominated by tetragonal phase, in which most diffraction reflections, including {100}, {110}, {200}, {210}, {220}, and {310}, show apparent doublet peaks. With the increase of BaCW doping amount and sintering temperature, although overall XRD patterns remain basically unchanged, the doublet splitting and peak intensity ratio change slightly but have no straightforward change trend. Therefore, the 2 and 2.5 wt% BaCW-doped 0.975PZT–0.025BNZ and 0.95PZT–0.05BNZ ceramics sintered between 980 and 1010 °C have tetragonal phase dominant crystal structure.

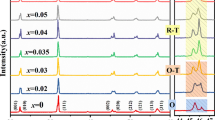

The influence of (1−x)PZT–xBNZ composition on crystal structure is studied further as shown in Fig. 3. For x = 0.075 and x = 0.1 compositions, 2 wt% BaCW is added and sintering temperature of 1000 °C is utilized based on analyzing density data of the former samples. The diffraction peaks of all ceramics are indexed according to standard material Pb(Zr0.44Ti0.56)O3 with PDF card 50-0346. All 2 wt% BaCW-doped (1−x)PZT–xBNZ ceramics still exhibit pure perovskite phase without detectable impurity. Combined Figs. 1, 2, and 3 it can be seen, with the increase of BNZ content x, diffraction reflections and peak intensity ratio change gradually for all the 1000 °C sintered ceramics. For the x = 0.025 sample, almost all diffraction peaks show doublet splitting peaks, showing mainly tetragonal phase structure. When x = 0.05, the high 2θ angle diffraction peaks tend to be broad and singlet peak, showing the appearance of rhombohedral phase in tetragonal matrix. When x = 0.075, most diffraction peaks are broad and singlet peak besides the {200} and {300} peaks, revealing that rhombohedral phase becomes main structure feature. For the 2 wt% BaCW-doped 0.9PZT–0.1BNZ sample, most diffraction peaks exhibit sharp, symmetric, and singlet shape besides small broadened peaks {220} and {300}, approaching pure rhombohedral phase. Such structure change mainly relates to tetragonal structure of Pb(Zr0.5Ti0.5)O3 and rhombohedral structure of (Bi0.5Na0.5)ZrO3, and partially correlates with tetragonal structure of Ba(Cu0.5Wu0.5)O3 [12, 18]. XRD characterization confirms successful construction of MPB in the (1−x)PZT–xBNZ ceramics prepared by low-temperature sintering, which is expected to present enhanced electrical properties due to the MPB effect [33].

Based on Jade full XRD pattern refinement, cell parameters are calculated according to tetragonal and rhombohedral phase, respectively, depending on composition as shown in Tables 1 and 2, combining with density measured by water immersion method. Density is an important parameter for piezoelectric materials, and high densification normally predicts excellent electrical performance [34]. For the studied compositions, cell volume and density increase first and then decrease with elevating sintering temperature, exhibiting maximum densification at sintering temperature of 1000 °C. Adding 2 wt% BaCW sintering aid is appropriate, where adding smaller or larger amount sintering aid cannot reduce sintering temperature adequately or maximum relative density is less than 90%. BNZ also promotes sintering, and the largest relative density reaches 96.81% for the 2 wt% BaCW-doped 0.95PZT–0.05BNZ ceramics sintered at 1000 °C. The densification is larger than 93% for the x = 0.075 and x = 0.1 samples, whose optimized sintering temperature may be reduced to below 1000 °C due to more BNZ content in the (1−x)PZT–xBNZ system [35].

3.2 SEM morphology and grain size distribution

Sintering mechanism and morphology characteristics were studied by SEM observation as shown in Fig. 4 using the sample with largest relative density as an example. Although there are some pores-like position, due to free surface used for the SEM measurement, density measurement and performance characterization are not influenced since ceramics are ground and polished. Even sintered at low sintering temperature of 1000 °C, grains grow well, producing clear grain boundary, intact densification, and rather uniform micro-morphology. Due to adding BNZ second component and BaCW sintering aid, liquid-phase sintering mechanism plays major densification role in BaCW-doped (1−x)PZT–xBNZ sintering process since most grains have deformed spherical shape, and there is over-fusion phenomenon as shown by red circle in Fig. 4a [35]. Most grains have grain size of 1.5–2.1 μm, and the average grain size is 2.21 μm, exhibiting narrow grain size distribution. Such grain size is rather small, relating mainly to low-temperature sintering, as compared with several to over ten micrometers for the Pb-based piezoelectric ceramics sintered normally above 1250 °C [4].

3.3 Resistance and dielectric performance

High insulation is fundamental requirement for electrical-related application [30]. As shown in Tables 1 and 2, all BaCW-doped (1−x)PZT–xBNZ ceramics have high resistivity, being larger than 109 Ω cm, which are expected to exhibit excellent electrical properties. On the whole, resistivity of the 2 wt% BaCW-doped ceramics is normally larger than that of the 2.5 wt% BaCW-doped ceramics, partially relating to the density change. With elevating sintering temperature, resistivity shows change trend of first increasing and then decreasing, but is not coincidence with the change sequence of relative density. As for the influence of composition, for 2 wt% BaCW doping amount and same sintering temperature, resistivity increases with the increase of x value, reaches maximum value at x = 0.05, and then decreases 1–2 magnitude order, respectively, with further increasing the BNZ content to 0.075 and 0.1. The 1000 °C sintered 2 wt% BaCW-doped 0.95PZT–0.05BNZ ceramics have the largest resistivity, being 1.6314 × 1011 Ω cm. Such complicated resistivity variation relates to many factors, such as composition heterogeneity, density and porosity difference, microstructural morphology, point defects, etc. [32].

For extreme condition application, high TC temperature is urgently required. Figure 5 shows dielectric properties versus temperature relationship of the 2 wt% BaCW-doped (1−x)PZT–xBNZ ceramics sintered at 1000 °C. For ferroelectrics, spontaneous polarization Ps decreases with the increase of temperature, and ferroelectric phase transition occurs at the TC temperature at which the Ps value normally decreases to zero accompanied by the appearance of maximum dielectric constant εm peak [36]. In this work, the ferroelectric phase to paraelectric phase transition is from mainly tetragonal phase, MPB, and mainly rhombohedral phase with elevating the BNT content, to cubic phase. With the increase of BNZ content, dielectric peak changes from narrow to wide shape, TC decreases almost linearly from 354 to 280 °C accompanied by decrease of εm from 14200.9 to 8227.6, and the 2 wt% BaCW-doped 0.95PZT–0.05BNZ sample presents excellent dielectric performance, corresponding well with the structure change from mainly tetragonal phase, across MPB region, and to mainly rhombohedral phase, and revealing the MPB effect [12]. The increased difference between TC and the temperature of dielectric loss tanδ maximum indicates the increase of relaxation degree [16].

Figure 6 compares temperature-dependent dielectric performance at 10 kHz of the 2 and 2.5 wt% BaCW-doped 0.975PZT–0.025BNZ and 0.95PZT–0.05BNZ ceramics, respectively. The sole dielectric peak correlates with tetragonal or MPB ferroelectric phase to cubic paraelectric phase transition. Overall, the 1000 °C sintered ceramics present best dielectric properties, relating to the largest relative density, besides the 1010 °C sintered 2.5 wt% BaCW-doped 0.975PZT–0.025BNZ sample, relating to the largest dielectric loss [37]. The variation of TC temperature caused by different sintering temperatures is less than 10 °C, but TC is all higher than 320 °C, showing prospect application in high-temperature and high-power piezoelectric-related fields under extreme condition [4]. Particularly noteworthy is that TC has little change for the 2 wt% BaCW-doped 0.975PZT–0.025BNZ ceramics sintered at 980–1010 °C, all being around 350 ℃.

Figure 7 shows frequency-dependent dielectric properties of 2 wt% BaCW-doped (1−x)PZT–xBNZ ceramics sintered at 1000 °C. The relatively narrow dielectric peaks in BaCW-doped 0.975PZT–0.025BNZ relate to the mainly tetragonal perovskite structure, and the relatively wide dielectric peaks in BaCW-doped 0.9PZT–0.1BNZ correlate with the mainly rhombohedral perovskite structure. Whether in normal ferroelectric state or in relaxor ferroelectric state, the dielectric frequency dispersion is very apparent around the TC temperature. Overall, the BaCW-doped 0.95PZT–0.05BNZ ceramics show excellent dielectric properties, attributing to the MPB effect [12].

Combined Figs. 5, 6, and 7, it can be seen that dielectric loss tanδ increases sharply above the TC temperature in all ceramics, especially at low frequency of 100 Hz. In piezoelectric materials, dielectric loss is mainly caused by polarization hysteresis loss under alternating current electric field, leakage current induced loss, and defects induced loss correlating with manufacturing process [38]. In this work, the third mechanism dominates the main cause of loss. Although low-temperature sintering is realized for preparing the BaCW-doped (1−x)PZT–xBNZ ceramics, the evaporation of Pb2+ and Bi3+ is inevitable since the melting points of Pb and Bi oxides are still lower than the sintering temperature, resulting in formation of oxygen vacancy defects as shown below [9]:

Such generated oxygen vacancies exhibit typical thermal excitation and lossy-type conductivity characteristic, resulting in sharp increase of leakage current and dielectric loss at high temperatures, especially above the TC temperature [9].

The frequency dispersion and relaxation characteristic can be studied by dielectric performance fitting as shown in Fig. 8 using exponential law \(\frac{1}{\varepsilon }\, - \,\frac{1}{{\varepsilon _{{\text{m}}} }}\, = \,\frac{{(T\, - \,T{\text{m}})^{\gamma } }}{{C^{\prime}}}\) [9, 39]. The dielectric behavior above the TC temperature of all samples can be fitted well by the exponential law with high fitting accuracy, in which the fitted diffusive coefficient γ of all samples is larger than 1.7, showing high relaxation degree. With the increase of BNZ content, the γ value tends to increase, where BaCW-doped 0.95PZT–0.05BNZ has increased γ, relating to the complicated coexistence of multi-ferroelectric phases around MPB [12]. Such phenomena show that all BaCW-doped (1−x)PZT–xBNZ ceramics have apparent relaxor characteristic whatever in tetragonal or rhombohedral structure, revealing complex influence of forming solid solution on dielectric relaxation characteristic. Important electrical properties are summarized in Tables 3 and 4.

3.4 Ferroelectric and strain properties

Figure 9 compares influence of composition on ferroelectric performance, including polarization–electric field (P–E) hysteresis loops and strain–electric field (S–E) butterfly-like curves, of the 2 wt% BaCW-doped (1−x)PZT–xBNZ ceramics sintered at 1000 °C. The normal change from narrow P–E loop to nearly rectangular P–E loop accompanied by the appearance of extremum values of remnant polarization Pr and coercive field Ec with changing composition across the MPB region is not observed [12]. All P–E hysteresis loops of the 1000 °C sintered 2 wt% BaCW-doped (1−x)PZT–xBNZ ceramics are rather saturate and have nearly rectangular shape, in which the Pr and Ec values show increase trend with increasing the BNZ content, and BaCW-doped 0.925PZT–0.075BNZ has the largest Pr, proving that MPB is not composition point but has composition region [10, 13, 14, 33]. BaCW-doped 0.95PZT–0.05BNZ has the largest positive strain and BaCW-doped 0.9PZT–0.1BNZ shows the largest negative strain at 25 kV/cm, and the S–E curves are rather symmetric, also reflecting the complex relationship between structure and performance in solid solution.

Influence of sintering temperature on ferroelectricity is shown in Fig. 10. For the 2 wt% BaCW-doped samples, sintering temperature affects ferroelectric performance greatly for both the 0.975PZT–0.025BNZ and 0.95PZT–0.05BNZ compositions, in which the P–E loops change from narrow to nearly rectangular shape accompanied by great increase of the Pr and Ec values with elevating sintering temperature. As comparison, S–E performance is affected less besides the 2 wt% BaCW-doped 0.95PZT–0.05BNZ, especially for the 2.5 wt% BaCW-doped 0.975PZT–0.025BNZ and 0.95PZT–0.05BNZ ceramics, almost having no change as sintering temperature increasing. On the whole, maximum positive strain is larger than maximum negative strain for all samples. Slight asymmetry and small breach exist in the P–E loops, correlating with frictional resistance-induced energy loss, which is normally caused by polarization rotation, domain wall motion, and especially point defects as discussed above in this work [4, 37].

3.5 Piezoelectric properties

Figure 11 shows piezoelectric constant d33 poling electric field relationship of 2 wt% BaCW-doped (1−x)PZT–xBNZ ceramics sintered at 1000 °C. For all samples, the d33 values increase almost linearly with the increase of poling electric field. At 2 wt% BaCW doping amount sintering aid and same sintering temperature, 0.9PZT–0.1BNZ presents extra-large piezoelectricity of d33 = 209 pC/N, whose TC is only 281 °C. The relatively large d33 of 151 pC/N for 0.95PZT–0.05BNZ also attributes to the MPB effect [10, 33], whose TC is high as 345 °C.

Figure 12 shows the influence of sintering temperature on piezoelectric performance for 2 systems of BaCW-doped (1−x)PZT–xBNZ ceramics. Overall, the 2.5 wt% BaCW-doped samples have higher d33 value as compared with the 2 wt% BaCW-doped samples with same (1−x)PZT–xBNZ composition. Higher sintering temperature tends to induce larger piezoelectric constant, but the difference becomes almost negligible at higher poling electric field of 25 kV/cm, besides the 2 wt% BaCW-doped 0.95PZT–0.05BNZ. Under 25 kV/cm poling electric field, the 1010 °C sintered 2.5 wt% BaCW-doped 0.975PZT–0.025BNZ ceramics achieve the largest d33 value of 163 pC/N. The complicated change of piezoelectricity with composition, sintering temperature, and poling electric field partially relates to uniformity change of ceramics caused by sublimation of Pb and Bi during sintering [9, 26].

Figure 13 shows impedance and phase angle resonance curves using the 1000 °C sintered 2 wt% BaCW-doped (1−x)PZT–xBNZ ceramics poled under 25 kV/cm as examples. All curves have excellent resonant and anti-resonant characteristics, providing effective energy conversion between mechanical energy and electrical energy. Based on Fig. 13 and according to formulae \(K_{{\text{p}}} \, \approx \,\sqrt {\frac{{f_{{\text{p}}} \, - \,f_{{\text{s}}} }}{{f_{{\text{s}}} }}\, \times \,2.33}\) and \(Q_{{\text{m}}} \, = \,\frac{{f_{{\text{p}}}^{2} }}{{2\pi \cdot f_{{\text{s}}} \cdot C^{{\text{T}}} \cdot R(f_{{\text{p}}}^{2} - f_{{\text{s}}}^{2} )}}\) [26], electromechanical coupling coefficient Kp and mechanical quality factor Qm are obtained as shown in Tables 3 and 4. Overall, higher density samples have larger Kp. The phase angle θ is normally less than 50°, showing possibility to improve poling effect by other poling techniques, such as alternating current poling [40]. The Qm value is around several dozens or slightly larger than 100, being typical soft piezoelectric materials, and relating to generation of oxygen vacancies due to evaporation of Pb and Bi during sintering [9, 26]. The high TC temperature combined with acceptable piezoelectric performance studied in the (1−x)PZT–xBNZ system prepared by low-temperature sintering via adding BaCW sintering aid shows prospect application in extreme high-temperature piezoelectric-related fields.

4 Conclusions

Low-temperature densified sintering was realized in the (1−x)PZT–xBNZ system at around 1000 °C sintering temperature due to adding BNZ second component and BaCW sintering aid. All sintered BaCW-doped (1−x)PZT–xBNZ ceramics present pure perovskite structure, which changes from mainly tetragonal phase, across MPB region and to mainly rhombohedral phase with increasing the BNZ content. High density ceramics are obtained at low sintering temperature, which present decreased grain size, narrowed grain size distribution, and enhanced homogenous morphology, mainly relating to low-temperature sintering. The 2 wt% BaCW-doped 0.95PZT–0.05BNZ ceramics sintered at 1000 °C achieve the largest relative density of 96.81%. All BaCW-doped (1−x)PZT–xBNZ ceramics have high resistivity larger than 109 Ω cm, and the MPB effect is confirmed in dielectric, ferroelectric, and piezoelectric properties. The 1000 °C sintered 2 wt% BaCW-doped 0.95PZT–0.05BNZ ceramics have the largest resistivity of 1.6314 × 1011 Ω cm. All samples have apparent relaxation characteristic whatever in tetragonal or rhombohedral structure, and the diffusive coefficient γ increases with elevating the BNZ content, revealing complex influence of forming solid solution on electrical properties. The 1000 °C sintered 2 wt% BaCW-doped (1−x)PZT–xBNZ ceramics have rather saturate and nearly rectangular shape P–E loops, in which the Pr and Ec values show increase trend with increasing the BNZ content. The 1000 °C sintered 2 wt% BaCW-doped 0.9PZT–0.1BNZ has d33 = 209 pC/N with TC = 281 °C and 0.95PZT–0.05BNZ has d33 = 151 pC/N with TC = 345 °C. The low-temperature sintered BaCW-doped (1−x)PZT–xBNZ ceramics exhibit broad application prospect in high-temperature piezoelectric-related fields due to the high TC temperature and acceptable piezoelectric performance.

Data availability

All data that support the findings of this study are included within the article.

References

J.-H. Lee, G.-J. Lee, A.-P. Hoang, T. Frömling, T.-L. Pham, J.-S. Lee, W. Jo, J. Eur. Ceram. Soc. 42, 1388–1395 (2022)

P. Li, J. Zhai, B. Shen, S. Zhang, X. Li, F. Zhu, X. Zhang, Adv. Mater. 30, 1705171 (2018)

X. He, B. Fang, S. Zhang, X. Lu, J. Ding, J. Alloys Compd. 925, 166249 (2022)

L. Chen, H. Liu, H. Qi, J. Chen, Prog Mater. Sci. 127, 100944 (2022)

Z. Liu, H. Wu, Y. Yuan, H. Wan, Z. Luo, P. Gao, J. Zhuang, J. Zhang, N. Zhang, J. Li, Y. Zhan, W. Ren, Z.-G. Ye, Curr. Opin. Solid State Mater. Sci. 26, 101016 (2022)

T.Y. Ansell, D.P. Cann, E. Sapper, J. Rödel, J. Am. Ceram. Soc. 98, 455–463 (2015)

Y. Wang, H. Ma, G. Yuan, H. Luo, D. Viehland, J. Am. Ceram. Soc. 100, 1751–1759 (2017)

J. Chen, J. Li, L. Fan, N. Zou, P. Ji, L. Liu, L. Fang, H. Kang, X. Xing, J. Appl. Phys. 112, 1–7 (2012)

W. Ji, S. Feng, B. Fang, X. Zhao, S. Zhang, J. Ding, H. Luo, Curr. Appl. Phys. 18, 289–296 (2018)

T. Zhao, C. Fei, K. Pu, X. Dai, J. Song, C. Wang, S. Dong, J. Alloys Compd. 873, 159844 (2021)

Y. Wei, C. Bai, C. Jin, W. Zhu, Z. Jian, R. Nan, L. Hu, Z. Dai, J. Mater. Sci. 56, 11838–11846 (2021)

E. Hou, Y. Yan, M. Zhang, D. Zhang, Z. Li, Ceram. Int. 46, 27394–27400 (2020)

Y. Yang, C. Liu, Y. Ji, L. He, X. Ren, Acta Mater. 208, 116720 (2021)

S.R. Maity, B. Tiwari, M. Rath, M.S. Ramachandra Rao, J. Solid State Chem. 325, 124131 (2023)

F. Luo, H.W. Guan, R. Peng, J. Jian, J.G. Chen, J.R. Cheng, J. Am. Ceram. Soc. 102, 5958–5965 (2019)

J. Zidani, M. Zannen, M. Hadouchi, H.A.H. Alzahrani, E. Birks, H. Khemakhem, M. Majdoub, A. Lahmar, Phys. B 653, 414680 (2023)

X. Lv, N. Zhang, J. Wu, X. Zhang, Acta Mater. 197, 224–234 (2020)

P. Li, Z. Fu, F. Wang, Y. Huan, Z. Zhou, J. Zhai, B. Shen, S. Zhang, Acta Mater. 199, 542–550 (2020)

K. Batra, N. Sinha, B. Kumar, J. Phys. Chem. Solids. 170, 110953 (2022)

M.A. Beuerlein, N. Kumar, T.-M. Usher, H.J. Brown-Shaklee, N. Raengthon, I.M. Reaney, D.P. Cann, J.L. Jones, G.L. Brennecka, J. Am. Ceram. Soc. 99, 2849–2870 (2016)

K. Liu, Y. Xia, Q. Zhang, Y. Du, Y. Shi, S. Joshi, C. Yan, Y. Wu, S. Huang, H. Sun, Ceram. Int. 49, 20024–20033 (2023)

J. Lin, B. Cui, J. Cheng, Q. Tan, J. Chen, Ceram. Int. 49, 474–479 (2023)

K. Li, E. Sun, Y. Zhang, Z. Song, X. Qi, Y. Sun, J. Li, B. Yang, J. Liu, W. Cao, J. Mater. Chem. 9, 2426–2436 (2021)

E. Chandrakala, J.P. Praveen, B.K. Hazra, D. Das, Ceram. Int. 42, 4964–4977 (2016)

R. Zhu, B. Fang, X. Zhao, S. Zhang, D. Wu, J. Ding, J. Eur. Ceram. Soc. 38, 1463–1472 (2018)

L. Tan, X. Wang, W. Zhu, A. Li, Y. Wang, J. Alloy Compd. 874, 159770 (2021)

L. Zhao, B. Zhangn, W. Wang, Y. Ding, S. Zhang, L. Zhu, N. Wang, Ceram. Int. 42, 7366–7372 (2016)

Y. Ying, X. Xiong, N. Wang, J. Zheng, J. Yu, W. Li, L. Qiao, W. Cai, J. Li, H. Huang, S. Che, J. Eur. Ceram. Soc. 41, 5924–5930 (2021)

X. Wang, H.L. Chan, C. Choy, J. Am. Ceram. Soc. 86, 1809–1811 (2003)

W. Li, X. Liu, J. Ma, Y. Wu, Y. Cui, J. Mater. Sci. Mater. Electron. 24, 1551–1555 (2013)

T. Avanish Babu, W. Madhuri, Chem. Phys. Lett. 799, 139641 (2022)

Y. Zhou, B. Fang, S. Zhang, X. Lu, J. Ding, J. Korean Ceram. Soc. 59, 551–564 (2022)

D. Lin, S. Zhang, E. Gorzkowski, S. Zhou, W. Liu, F. Li, J. Eur. Ceram. Soc. 37, 2813–2823 (2017)

K. Tsuji, A. Ndayishimiye, S. Lowum, R. Floyd, K. Wang, M. Wetherington, J. Maria, C.A. Randall, J. Eur. Ceram. Soc. 40, 1280–1284 (2020)

R.M. German, P. Suri, S.J. Park, J. Mater. Sci. 44, 1–39 (2009)

K. Xu, J. Li, X. Lv, J. Wu, X. Zhang, D. Xiao, J. Zhu, Adv. Mater. 28, 8519–8523 (2016)

T. Zheng, J. Wu, D. Xiao, J. Zhu, Prog. Mate. Sci. 98, 552–624 (2018)

Y. Wang, W. Jie, C. Yang, X. Wei, J. Hao, Adv. Funct. Mater. 29, 1808118 (2019)

K. Uchino, S. Nomura, Ferroelectr. Lett. 44, 55–61 (1982)

H. Wan, C. Luo, C. Chung, Y. Yamashita, X. Jiang, Appl. Phys. Lett. 118, 102904 (2021)

Funding

This work was supported by the Top-notch Academic Programs Project of Jiangsu Higher Education Institutions and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Contributions

BF contributed toward conceptualization; BF and JD contributed toward supervision; HL, BF and JD contributed toward methodology; HL and SZ contributed toward formal analysis; HL, SZ, and XL contributed toward investigation; HL and XL contributed toward data curation; HL and BF contributed toward writing—original draft; BF contributed toward Writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Fang, B., Zhang, S. et al. Low-temperature sintering PZT-based ceramics for extreme condition application. J Mater Sci: Mater Electron 34, 1970 (2023). https://doi.org/10.1007/s10854-023-11409-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11409-3