Abstract

In the present work, the effect of different annealing-time on the properties of Bi2Sr2Ca1Cu1.75Na0.25Oy (Bi-2212) superconducting compound is presented. First, the samples were produced by hot-pressing method under 33 MPa pressure at 750 °C in accordance with previous works. After annealing, the samples were kept at 840 °C for 15, 30 and 60 h, respectively, for postannealing process. XRD results demonstrate the formation of Bi-2212 phase in large amount in all samples. SEM images show the formation of different grain morphologies depending on the postannealing time. The sample postannealed for 60 h at 840 °C has the highest superconducting transition temperature (Tc, onset), 91 K, obtained from M–T measurements. The magnetic properties of samples have been investigated using M–H hysteresis loops at 15 K in the range − 1.6 × 106 to + 1.6 106 A/m. The widest M–H curves were obtained in the postannealed sample for 60 h at 840 °C, probably as a result of both the improvement of crystallinity, cleaner grain boundaries and better grain orientation. In addition, the widest hysteresis curve observed in that sample in the entire applied magnetic field range is an indication that it has strong pinning behavior. The critical current density (Jc) was investigated via Bean’s model from these data. Finally, the sample postannealed at 840 °C for 60 h reached a Jc value of 2.903 × 106 A/cm2 at H = 1.9 T and T = 15 K, which is, approximately, 44% higher than the determined in annealed samples (2.015 × 106 A/cm2).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It is clear that the more we can reduce the losses in energy transmission, the more successful we will be in preventing climate change problems in the global world. One of the key technologies that will enable a full transition to lossless energy transmission is the use of high temperature superconductors such as YBCO and BSCCO in technological fields [1,2,3]. Among these superconducting families, the Bi2Sr2Ca1Cu2Oy, abbreviated as Bi-2212 phase, is intensively studied due to its high stability in a broad range of temperatures and compositions [4, 5]. However, these materials have optimal working conditions and when the applied temperature and/or magnetic field values are increased from these optimal values, it is very difficult to maintain the superconducting state.

Especially in ceramic superconductors, parameters such as the applied magnetic field direction with respect to CuO2 planes, grain sizes and orientation, as well as grain boundaries, seriously affect their superconducting response. Obviously, keeping these parameters under control means that not only the critical transition temperature Tc, but also the critical current density (Jc) values can be significantly improved [6, 7].

Undoubtedly, it is possible to reach high Jc values, especially when ceramic superconductors are produced with the appropriate preparation technique that controls the orientation and sizes of the grains, such as the laser floating zone (LFZ) and the electrically assisted LFZ (EALFZ) techniques [8, 9]. In addition, the application of postannealing treatments along with techniques that provide grain orientation also appear to significantly increase the superconducting properties [10, 11]. Recently, Bi2Sr2Ca1Cu1.75Na0.25Oy ceramics have been prepared by hot-pressing under different pressures and temperatures and their properties have been studied in detail. The best superconducting properties in that work have been determined in the sample prepared under 33 MPa at 750 °C with a critical current density value of 20.15 × 105 A/cm2 at T = 15 K and H = 1.9 T [12].

In this work, the objective is improving the Jc values of hot-pressed Bi2Sr2Ca1Cu1.75Na0.25Oy ceramics by decreasing the amount of secondary phases through annealing at 850 °C for 96 h, and adjusting their oxygen content through postannealing treatments at 840 °C for different times. The structural and microstructural characteristics of these samples will be determined and related to the superconducting ones.

2 Experimental

2.1 Samples preparation

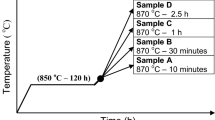

Polycrystalline Bi2Sr2Ca1Cu1.75Na0.25Oy precursors (Bi-2212) were produced through the solid state reaction method by using Bi2O3 (Aldrich, 99%), SrCO3 (Panreac, 98+%), CaCO3 (Aldrich, 99.9%), CuO (Aldrich, 99.99%), and Na2CO3 (Aldrich, 99.99%) commercial powders. They were weighed in stoichiometric proportions, mixed and ball milled for 30 min at 300 rpm. The mixture was then cold uniaxially pressed in the form of disks (13 mm diameter) under 375 MPa and calcined at 750 °C for 12 h. The calcined pellets were manually ground, repressed, and recalcined twice at 820 °C for 24 h. The calcined material was finally cold uniaxially pressed into disks (~ 25 mm diameter) under 200 MPa, followed by a hot-pressing process at 33 MPa and 750 °C for 12 h to increase density and grain orientation, as previously reported [12]. Finally, the disks were cut and subjected to an annealing procedure at 850 °C for 96 h and postannealed at 840 °C, due to the presence of Na, which is known to decrease melting point of Bi-2212 phase [13], for 15, 30 and 60 h, which be called hereafter, as samples A, B, and C, respectively. The annealing and postannealing schema is shown in Fig. 1.

2.2 Characterization techniques

Powder X-ray diffraction (XRD) analyses were carried out to determine the phases present in the samples using a Rigaku Ultima IV X-Ray Diffractometer with a constant scan rate (2°/min) in the range 2θ = 3°–60°. Lattice parameters have been automatically calculated by the PDXL software version 1.6.0.1 with the ICDD version 6.0 database. Fractured sections and polished surfaces of samples were studied with a field emission scanning electron microscope (FESEM) Zeiss-Merlin, with an attached EDS analysis system. Magnetic measurements were carried out using PPMS DynaCool-9 model in a Quantum Design PPMS system (from 1.8 to 400 K) which can reach the cryogenic temperatures. With these data Jc has been calculated using Bean’s model [14].

3 Results and discussion

3.1 XRD studies

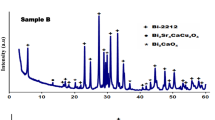

Figure 2 shows the powder XRD patterns for all samples. As it can be observed in this graph, all samples present very similar diffraction patterns where the Bi-2212 phase is the major one [15], accompanied by minor amounts of Bi2CuO4 and Bi2Sr2CuO6 (Bi-2201) secondary phases. These results suggest that Bi-2212 phase has reached the maximum content in the samples, as it is well known that the reaction for its formation is an equilibrium one [16].

When the lattice parameters were calculated, no significant changes have been observed in lattice parameters (see Table 1). On the other hand, as it can be seen in the table, the c lattice parameter is 30.649 Å in samples A and B, while it is increased to 30.813 Å in sample C. It is well known that the increase in the c-axis length indicates that the distance between the Bi-O layers increases [17, 18]. This undoubtedly occurs with the change in the net positive charge in the Bi–O plane of the unit cell of Bi-2212. It is clear that the relatively long dwell time of 60 h for the heat treatment procedure applied at a relatively low temperature of 840 °C affects the oxygen diffusion, reflected in changes on Tc values, as previously reported [19,20,21].

3.2 SEM analysis

Figure 3a shows a representative fractured surface obtained on the center of sample B. As it is illustrated in the image, the core of all samples maintains a relatively good grain orientation along the perpendicular direction to the applied pressure during the hot-pressing process. This fact clearly shows that the effect of postannealing process is mostly limited to the region close to the samples surfaces.

In order to evaluate the effect of postannealing on the samples surfaces, micrographs of polished sections of all samples are shown in Fig. 3b–d. As it can be observed in these images, three contrasts can be seen (identified by arrows and numbers for clarity), which have been associated through EDS to different phases. These contrasts are gray (#1) as the major one corresponding to Bi-2212 phase, while minor ones are white (#2), and black (#3), identified as Bi-2201, and (Sr,Ca)14Cu24O41. As it can be also observed in these micrographs, the only clear modification in the samples surfaces is a slight decrease of #3 contrasts when increasing postannealing duration. Consequently, these microstructural modifications are expected to have minor impact on the electrical properties of these samples, as no drastic changes in density or grain size and orientation are observed, which could decrease the electrical conduction [22]. In order to evaluate the grain size evolution with the postannealing duration, the average crystallite size for all samples was determined from XRD analyses using the wellknown Debye–Scherrer formula [23], and the results are shown in Table 2. It should be highlighted that the Bi-2212 phase crystallizes in form of plate-like grains with large area in the ab plane, while they are very thin along the c direction. As a consequence, taking into account the observations in Fig. 3a, where large grain sizes can be seen, it is clear that the results shown in Table 2 reflect the grain thickness, which is increased with the postannealing time.

3.3 Resistivity measurements

The transition temperature (Tc) of high-Tc superconductors can be estimated from the temperature dependence of magnetization (M–T curve). Figure 4 shows the temperature dependence of magnetization (M–T curves) under zero-field cooling (ZFC) mode for all samples. In these plots, it can be observed that all samples present a diamagnetic effect between 81 and 91 K, which correspond to their transition temperatures. The differences on Tc (onset) values can be associated to slightly different amounts of Bi-2212 phase when the postannealing process is longer and, more importantly, to differences on the oxygen content. Consequently, sample C has the highest Tc (onset) value with superconducting transition temperature of 91 K, while these values are 86 K and 81 K in samples A and B, respectively. These results clearly point out to the optimization of oxygen content through the postannealing process.

3.4 DC magnetic properties

Figure 5 shows the magnetic hysteresis cycles (M–H) obtained between ± 1.6 103 A/m applied fields at 15 K for all the samples. In the plot, it can be clearly seen that all samples show a wide M-H magnetization loop due to their diamagnetic properties. Moreover, the largest hysteresis curve in this study has been determined in sample C, which had the longest dwell time.

In general, at low temperatures (below 30 K), the M–H curves can show similar shapes in the different samples, as superconductors have a stronger effect on resisting the external magnetic field at those temperatures. However, at higher temperatures, the M–H curves can display significant differences due to the easier penetration of the magnetic field into the material.

On the other hand, the type and amount of impurity phases in the samples, the size and orientation of the grains, and the presence of effective pinning centers affect the M–H curves in all temperature ranges below Tc. The fact that Sample C has the largest hysteresis curve is an indication that the superconducting properties are improved with the dwell time of 60 h applied at 840 °C, when compared to the other samples.

Other important parameter affecting the size of magnetization curves is the oxygen stoichiometry in the Bi-2212 phase, and postannealing process may modify oxygen content in the samples [24]. In this study, extra heat treatment was applied to ensure ideal oxygen content in the Bi-2212 phase at a constant temperature of 840 °C, or to the observed effect of the decrease of the amount and sizes of impurity phases that would form effective pinning centers.

The Jc values of the samples were calculated for 15 K, using Bean’s model [14]:

where Jc is the critical current density in Ampéres per square centimeter of a sample, ΔM = M+ − M− is measured in electromagnetic units per cubic centimeter, and d is the thickness of the sample.

The calculated critical current density values (Jc) of all the samples are presented in Fig. 6. The highest Jc values in the whole magnetic field range applied in accordance with the M–H results belong to the sample C, in accordance to the previously discussed data. In addition, another important factor for the high ZFC magnetization and high Jc value is the better grains interconnections [25] achieved with the postannealing process. The highest Jc value has been obtained in sample C with a value of 10.771 × 106 A/cm2 at H = 2.4 105 A/m and T = 15 K. Finally, Table 3 shows the comparison of Jc values of some Bi-2212 samples produced under different conditions in the literature. The results clearly show that a postannealing procedure for 60 h at 840 °C effectively increases the superconducting properties of the Bi-2212 phase by, at least, for 3 times the reported in similarly processed materials.

4 Conclusion

In this work, the effect of different dwell times (15, 30 and 60 h) at 840 °C on hot-pressed samples at 33 MPa and 750 °C, has been studied. XRD data showed that all samples are mainly composed by the Bi-2212 phase, accompanied by small amounts of secondary phases. Microstructural studies have revealed that the core of samples is maintained unchanged with the postannealing procedure, while the amount and size of secondary phases in the surface, are slightly reduced with postannealing duration. All samples show diamagnetic transition in the range of 81–91 K, leading to higher Tc when the dwell time is larger. The highest Tc determined in this work is 91 K, which is higher than the typical in Bi-2212 phase, pointing out to the optimal oxygen content obtained through postannealing. Moreover, the M–H measurements showed that larger postannealing times lead to larger area loops. Consequently, the highest Jc values, determined through the Beans Model, 10.771 × 106 A/cm2 at H = 2.4 105 A/m and T = 15 K, have been obtained for the largest postannealing process. This value is much larger than the obtained in Bi-2212 samples processed in similar conditions, clearly pointing out to the beneficial effect of postannealing procedures to enhance superconducting properties in the Bi-2212 compounds.

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

W.G. Garlik, Power system applications of high temperature superconductors. Cryogenics 37, 649–652 (1997)

J. Zhu, S. Chen, Z. Jin, Progress on second-generation high-temperature superconductor tape targeting resistive fault current limiter application. Electronics 11, 297 (2022)

Y. Takeda, H. Maeda, K. Ohki, Y. Yanagisawa, Review of the temporal stability of the magnetic field for ultra-high field superconducting magnets with a particular focus on superconducting joints between HTS conductors. Supercond. Sci. Technol. 35, 043002 (2022)

P. Majewski, B. Hettich, H. Jaeger, K. Schulze, The phase-equilibrium diagram of Bi2O3-SrO-CaO-CuO—a tool of processing the high-TC superconducting bismuth-compounds. Adv. Mater. 3, 67–69 (1991)

P. Majewski, H.L. Su, B. Hettich, The high-TC superconducting solid-solution Bi2+x(Sr, Ca)3Cu2O8+δ (2212 phase) - chemical-composition and superconducting properties. Adv. Mater. 4, 508–511 (1992)

P. Majewski, B. Hettich, N. Ruffer, F. Aldinger, The influence of the phase-equilibria on the critical-temperatures TC of the high-TC Bi-Sr-Ca-Cu-O and Y-Ba-Cu-O compounds. J. Electron. Mater. 22, 1259–1262 (1993)

M.F. Carrasco, F.M. Costa, R.F. Silva, F. Gimeno, A. Sotelo, M. Mora, J.C. Diez, L.A. Angurel, Textured Bi-Sr-Ca-Cu-O rods processed by laser floating zone from solid state or melted precursors. Physica C 415, 163–171 (1994)

B. Özkurt, M.A. Madre, A. Sotelo, M.E. Yakinci, B. Özçelik, J.C. Diez, Relationship between growth speed and magnetic properties in Bi-2212/Ag textured composites. J. Supercond. Novel Magn. 26, 1093–1098 (2013)

F.M. Costa, Sh. Rasekh, N.M. Ferreira, A. Sotelo, J.C. Diez, M.A. Madre, Effect of current polarity on BSCCO/Ag ceramics textured by electrically assisted laser floating zone. J. Supercond. Novel Magn. 26, 943–946 (2013)

B. Özkurt, M.A. Madre, A. Sotelo, J.C. Diez, The influence of postannealing on structural and superconducting properties of Bi-2212 ceramics. J. Supercond. Novel Magn. 26, 3247–3252 (2013)

P. Majewski, B. Hettich, S. Elschner, F. Aldinger, Increased pinning in Bi2Sr2CaCu2O8 ceramics. Appl. Supercond. 2, 93–99 (1994)

B. Öner, P. Özkurt, M.A. Madre, B. Özkurt, A. Sotelo, Enhanced superconducting properties in Bi2Sr2Ca1Cu1.75Na0.25Oy ceramics prepared by hot-pressing under different pressures and temperatures. J. Supercond. Novel Magn. 35, 1831–1838 (2022)

O. Nane, B. Özçelik, H. Amaveda, A. Sotelo, M.A. Madre, Improvement of structural and superconducting properties of Bi−2212 textured rods by substituting sodium. Ceram. Int. 42, 8473–8477 (2016)

C.P. Bean, Magnetization of hard superconductors. Phys. Rev. Lett. 8, 250–253 (1962)

T.A. Vanderah, Chemistry of Superconductor Materials (Noyes, Park Ridge, 1992)

P. Majewski, H.L. Su, M. Quilitz, Relationships between the chemical composition and properties of the high-temperature superconductor Bi2+xSr2-yCa1+yCu2O8+δ. J. Mater. Sci. 32, 5137–5141 (1997)

S. Satyavathi, M. Muralıdhar, K. Nandakishore, V. Hari Babu, O. Pena, M. Sergent, F. Beniere, Effect of annealing on the superconducting properties of Bi1.7Pb0.3Sr2Ca1−xSmxCu2Oy (0.0 ⩽ x ⩽ 1.0) system. Appl. Supercond. 3, 187–195 (1995)

V.P.S. Awana, S.K. Agarwal, R. Ray, S. Gupta, A.V. Narlikar, Superconductivity and resistivity studies in Bi2Sr2Ca1−xMxCu2O8+y (M=Eu, Dy, Tm and 0⩽x⩽0.6). Physica C 191, 43–51 (1992)

A. Sotelo, J.I. Peña, L.A. Angurel, C. Diez, M.T. Ruiz, G.F. de la Fuente, R. Navarro, Synthesis of the Bi2Sr2CaCu2O8+δ superconductor following a polymer matrix route. J. Mater. Sci. 32, 5679–5685 (1997)

S. Kambe, T. Matsuoka, T. Takahashi, M. Kawai, T. Kawai, Superconductive transition at 98.5 K in monoclinic (Bi, Pb)2Sr2CaCu2Oy. Phys. Rev. B 42, 2669 (1990)

N.H. Wang, C.M. Wang, H.C. Kai, D.C. Ling, H.C. Ku, K.H. Lu, Preparation of 95 K Bi2CaSr2Cu2O8+δ superconductor from citrate precursors. Jpn. J. Appl. Phys. 28, 1505–1507 (1989)

M.E. Kır, B. Özkurt, M.E. Aytekin, The effect of K-Na co-doping on the formation and particle size of Bi-2212 phase. Physica B 490, 79–85 (2016)

U. Holzwarth, N. Gibson, The Scherrer equation versus the “Debye-Scherrer equation.” Nat. Nanotechnol. 6, 534 (2011)

T. Nakane, T. Mochiku, A. Matsumoto, H. Kitaguchi, H. Kumakura, Effect of oxygen-pressure post-annealing on the JC–B characteristics of Bi-2212/Ag tapes. Physica C 412, 1163–1166 (2004)

M. Mahtali, S. Chamekh, Superconductive and magnetic properties of Bi2Sr2Ca2Cu3O10+δ ceramics doped by Pb. J. Supercond. Novel Magn. 24, 351–355 (2011)

E. Kara, P. Özkurt, B. Özkurt, Effects of different dwell-times under low pelletization pressure on the physical properties of the Bi-2212 ceramics. J. Mater. Sci. 33, 14951–14960 (2022)

T. Lu, C. Zhang, S. Guo, Y. Wu, C. Li, L. Zhou, The influence of critical current density of Bi-2212 superconductors by defects after Yb-doping. Physica C 519, 24–27 (2015)

O. Nane, B. Ozcelik, Effect of V substitution on vortex pinning and superconducting properties of Bi-2212 superconductor. J. Mater. Sci. 27, 7633–7639 (2016)

Acknowledgements

All samples and SEM characterization have been made in Department of Materials Science and Metallurgical Engineering in Zaragoza in Spain. All measurements in this study have been made in the Central Research Laboratory (ÇÜMERLAB) in Çukurova University in Adana. The use of Servicio General de Apoyo a la Investigación-SAI, Universidad de Zaragoza is also acknowledged.

Funding

We declare that we have not taken any research grants from funding agencies. Moreover, we have no any interests that go financial interests that could impart bias on the work submitted for publication such as professional interests, personal relationships or personal beliefs (amongst others).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, and analysis were performed by BÖ, MM, and AS. The first draft of the manuscript was written by BÖ and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Özkurt, B., Madre, M.A. & Sotelo, A. Effect of postannealing processes on the properties of hot-pressed Bi2Sr2Ca1Cu1.75Na0.25Oy (Bi-2212) ceramics. J Mater Sci: Mater Electron 34, 1212 (2023). https://doi.org/10.1007/s10854-023-10650-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10650-0