Abstract

Lead-free Ba0.85Ca0.15Zr0.10Ti0.90O3 (BCZT) ceramic with different BaO–Na2O–Nb2O5–WO3–P2O5 (BNNWP) glass contents, forming (1–x)BCZT–xBNNWP lead-free ceramics (abbreviated as BCZTx; x = 0, 2, 4, 6, and 8wt%) were synthesized using the conventional solid-state processing route. The XRD investigation shows the coexistence of tetragonal and orthorhombic phases in BCZT pure. Likewise, only the tetragonal phase was detected in BCZTx (x = 2–8 wt%) ceramics. The SEM findings indicate that the average grain size decreases as the amount of BNNWP glass additives increases. In addition, BCZT ceramics modified with glass additions showed narrower hysteresis loops and a large electric field. The BCZT4 showed the highest recovered energy density of 0.52 J/cm3 at 135 kV/cm with an energy storage efficiency of 62.4%, which is increased by 6.6 compared to BCZT0 (0.075 J/cm3). The energy density was also calculated using the Landau–Ginzburg–Devonshire (LGD) theory.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Pulse power technology has found significant application in electron beam, nuclear technologies, hybrid electric cars, and medical defibrillators. As a result of fast industrial development, it has continuously progressed into industrial and civil fields [1, 2]. Capacitors with higher storage density, faster charge–discharge rate, higher breakdown strength (BDS), and better thermal stability are required in modern electrical and electronic equipment [3, 4]. The fundamental obstacle to their use in electrical and high power systems is their poor energy density [5, 6]. The energy storage density is affected by the material's dielectric constant and the electrical breakdown resistance [7, 8]. Dielectric ceramics have a comparatively high dielectric constant and a low breakdown strength when compared to other energy storage materials [3, 9].

Dielectric materials based on BaTiO3 have been widely investigated for energy storage systems due to their high constant dielectric and low dielectric loss [10,11,12,13]. Numerous recent research have discussed the impact of Ca2+ and Zr4+ substituting for Ba2+ and Ti4+ in BaTiO3 ceramics to form Ba0.85Ca0.15Zr0.10Ti0.90O3 (BCZT) ceramic. The results show that BCZT shows interesting piezoelectric and dielectric properties due to the closeness to morphotropic phase boundary (MPB) [14,15,16]. Unfortunately, pure BCZT ceramic displays low breakdown strength and low energy efficiency, resulting in poor energy storage properties and restricting its usage as an energy storage device. Hence, numerous researchers have developed several methods to enhance the BDS of ceramics in order to ensure sufficient energy storage performances [17,18,19]. The findings reveal that these drawbacks can be overcome by modifying the microstructure and the chemical composition of the ceramics. For instance, by adding additives like oxides and glasses to the dielectric ceramics one can considerably hence the breakdown strength (BDS) and hence improve the energy efficiency [4, 9, 20]. The addition of glass can significantly increase the breakdown resistance of dielectric ceramics. An appropriate amount of glass liquid phase will promote the rearrangement of grain microstructure, decreasing the sintering temperature and densifying the ceramics [4, 21].

Recent literature investigations found that BCZT ceramics modified by glass addition presents improved energy storage and BDS. Among various reported glass systems, B2O3–SiO2-based glasses such as B2O3–Al2O3–SiO2, Bi2O3–B2O3–SiO2, and BaO–B2O3–ZnO present the particular interest [2, 22, 23]. The BDS of BCZT ceramics with glass additions was greatly improved by decreasing the grain size and densifying the microstructure [2, 22]. However, a little number of researches was allocated to use phosphate glass with a low melting temperature compared to the SiO2 and B2O3 glasses [24, 25]. In addition, phosphate glasses exhibit a simple composition and good glass-forming ability [26].

In this work, Ba0.85Ca0.15Zr0.10Ti0.90O3 (BCZT) ceramics with phosphate glass BaO–Na2O–Nb2O5–WO3–P2O5 (BNNWP) addition were synthesized using the conventional solid-state technique. The effect of BNNWP glass addition on dielectric and energy storage performances of BCZT ceramics was studied. The main objective is to obtain (1–x)BCZT–xBNNWP ceramics with enhanced energy storage properties. Furthermore, the energy storage densities were calculated using the Landau–Ginzburg–Devonshire (LGD) phenomenological theory. The modeling result confirms the experimental finding for BaTiO3–BaSnO3 as described by Yao et al. [27].

2 Experimental procedure

2.1 Synthesis of (1–x)BCZT–xBNNWP ceramics

A series of (1–x)BCZT–xBNNWP ceramics (BCZTx, x = 0, 2, 4, 6, and 8wt%) designated as BCZT0, BCZT2, BCZT4, BCZT6, BCZT8 were synthesized via the conventional solid-state technique. Meanwhile, BCZT powders and BaO–Na2O–Nb2O5–WO3–P2O5 glass were prepared according to our previous works [16, 26]. For BCZTx formation, both powders were weighed according to the nominally (1-x) BCZT–xBNNWP composition and then milled in an agate mortar with ethanol. Subsequently, the obtained powders were formed into 13 mm discs and sintered in air for 7 h at temperatures between 1300 and 1250 °C. The BCZTx ceramics were sintered at temperatures with the highest bulk density. The appropriate sintering temperature corresponds to the highest density and the value is 1350 °C, 1300 °C, 1275 °C, 1250 °C, and 1250, respectively, when x = 0, 2, 4, 6, and 8wt%.

2.2 Characterizations

The phase structure of BCZTx ceramics was analyzed by the X-ray diffraction(XRD, Panalytical™ X-Pert Pro spectrometer) using CuKα radiation (λ ~ 1.5406 Å). The density (d) of the BCZTx was measured at room temperature by Archimedes method. Scanning electron microscope (SEM, Tescan VEGA3) was used to examine the morphology of BCZTx ceramics. For electrical measurements, sintered ceramics coated with a silver paste form electrodes. The dielectric properties were measured by using an impedance analyzer (LCR meter hp 4284A 20 Hz-1 MHz). The polarization–electric field (P–E) hysteresis loops of a BCZTx ceramics with a thickness of 0.25 mm were investigated with the CPE1701, PolyK, USA, with a high voltage power supply (Trek 609-6, USA).

3 Results and discussions

3.1 Phase structure evolution

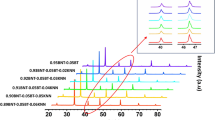

Figure 1 depicts the XRD patterns of BCZTx ceramics. The prepared ceramic BCZT0 reveals the coexistence of tetragonal (T) and orthorhombic (O) phases. The splitting of the peaks at 2θ≈44–46° confirms the quadratic phase’s existence [16, 28]. Moreover, the formation of the BCZT sample at the Morphotropic Phase Boundary (MPB) is evidenced by the presence of the triplet (022)O/(200)T/(200)O around 2θ≈45° as reported in our previous work [16]. However, the MPB disappears after the BNNWP glass addition. BCZT glass-modified only shows the existence of tetragonal phase. This indicates that combining the glass phase with the BCZT structure results in the formation of the tetragonal phase instead of the coexisting of two phases (O and T). It seems that the introduction of the glass inhibits the crystal growth of the orthorhombic structure and promotes the transformation of the O phase into the more stable T phase. Additionally, the peak intensity of secondary phases (α) increases as the glass content rises.

3.2 Microstructure analysis and density

Figure 2 illustrates SEM micrographs of BCZTx ceramics. The inclusion of small amounts of BNNWP glass reduces the average grain size of BCZTx ceramics. It decreases from 6.4 to 1.25 µm when x increases from 0 to 8wt%. This decrease could be attributed to the BNNWP liquid glass phase acting as an inhibitor of grain growth and grain boundary migration [2, 21, 29]. In addition, this reduction in grain size could be beneficial in increasing the compactness of ceramics. Moreover, the fine grain size and highest density could improve the breakdown strength, required for high-energy storage density [4, 9]. Accordingly, the addition of glass enhances the densification of BCZTx ceramics, as shown in Fig. 3. The liquid BNNWP glass at high temperature decreases the sintering temperature and increases the density of BCZTx ceramics. The average relative density of samples is between 93 and 97% of the theoretical maximum density, indicating the improvement of the material density and the reduction of pores.

3.3 Dielectric properties

Figure 4 displays the temperature dependency of the dielectric constant (εr) of BCZTx ceramics at various frequencies. Table 1 provides the dielectric properties obtained for all the ceramics. BCZTx ceramics exhibit two distinct polymorphic phase transitions that correspond to the orthorhombic–tetragonal (O–T) and tetragonal–cubic (T–C) transitions. The dielectric peak temperature of the O–T phase transition (TO-T) is about 35.0, 24.7, 22.3, 23.4, and 29.5 °C for BCZT0, BCZT2, BCZT4, BCZT6, and BCZT8 ceramics, respectively. In addition, the Curie temperature (Tc) depends significantly on the glass content. The Tc drops from 92 to 63 and then increases to 86, 84, 80 °C as the glass content rises from 0 to 2, 4, 6, and 8 wt%, respectively. The drop in Tc may be ascribed to the transition from a long-term to a short-term order [30], which promotes the generation of polar nanoregions (PNRs) [31] and the internal clamping originating from the existence of an immobile non-ferroelectric glass phase[32]. For instance, the value of the εr at Tc decreases significantly from 5400 for BCZT0 to 524 for BCZT8 with increasing BNNWP glass ratio. In addition, Table 1 indicates that the difference between εm (1 kHz, Tc) and εr (1 kHz, 30 °C) for BCZT ceramics decreases with increasing glass addition. Hence, introducing the BNNWP glass phase improves the thermal stability of the dielectric constant which is advantageous for capacitor materials[33]. The temperature dependence of the dielectric constant (εr) of BCZTx ceramics at 1 kHz is illustrated in Fig. 5. In addition, it is noticed that the dielectric constant decreases gradually as the glass content increases and the dielectric temperature curves of BCTZ4 and BCTZ6 are almost coincided. For instance, the dielectric constant of the pure BCZT drops significantly from 2640 to 1587, 692, 630, and 488 for BCZT2, BCZT4, and BCZT8, respectively. This behavior is associated with the dilution of the low εr of BNNWP glass (εr = 34) [22, 29]. In addition, this decrease could be attributed to the ceramic’s grain size reduction. It has been stated that smaller ceramic grain size leads to a lower dielectric constant [4, 34]. Moreover, the similarity of the dielectric temperature curves of BCTZ4 and BCTZ6 could be attributed to the formation of similar bond defects and the heterogeneous phase within these samples.

Figure 6 depicts the temperature dependence of the dielectric losses (tan δ) of BCZTx ceramics at 1 kHz. A significant increase in tanδ is observed near the O–T phase transition. This could be associated with the increase in conductivity, the internal stress, and space charge caused by the interface of BCZT and glass phase [35]. Note that except for the BCZT2 composition, a small increase of tan δ is noted beyond 40 °C. However, the values of the dielectric losses are still low (< 0.15).

Figure 7 shows the frequency dependence of εr and tanδ of BCZTx ceramics at room temperature. The frequency evolution of εr reveals excellent dielectric stability for all compositions except BCZT0 and BCZT8. Furthermore, tanδ decreases with increasing the frequency in the range of 100 Hz-10 kHz. However, the evolution of tanδ remains stable in the frequency range of 10 kHz-1 MHz. It is worth noting that this result is beneficial for ceramics used in electrical energy storage [22, 33].

3.4 Energy storage performances

Figure 8a–e illustrates the room temperature electric field dependence of the P–E hysteresis loops of BCZTx ceramics at 100 Hz. It is evident that BCZT ceramics display typical ferroelectric behavior. Additionally, the hysteresis loops get thinner and the applied electric field increases as the glass content increases. Furthermore, under the same electric field, the polarization of the modified BCZTx ceramics is less than that BCZT0 because of the added BNNWP glass’s low permittivity, as indicated by the dielectric constant characteristics. Figure 8f displays the variation of the maximum polarization (Pmax), remnant polarization (Pr), and the maximal electric field (Emax) of BCZTx ceramics. It is noted that the Pmax and Emax values of BCZTx ceramics increase to a maximum and then decrease as the glass content increases. Besides, Pr value decreases steadily as glass content increases. It is worthy to mention that the remnant polarization of the ceramics coincides to the dielectric constant's variation. (Fig. 5). Despite the fact that the dielectric characteristics deteriorate when more glass is added, the drop in Pr is critical for improving energy storage density. This drop could be ascribed to the formation of polar nanoregions (PNRs) as observed in the behavior of the decrease of Tc. PNRs have lower energy barriers and better thermal stability than typical ferroelectric domains, yielding in thin P–E hysteresis loops with low Pr and high breakdown strength [31].

The energy storage performances of BCZTx ceramics were determined from the recorded P–E hysteresis loops [26].

Figure 9 presents the evolution of Wrec and η as a function of the applied electric field for all the samples. It can be seen that Wrec of BCZTx ceramics increases as the applied electric field increases. This indicates that the increase of the applied external voltage can help to increase the recovered energy density. However, a significant decrease in energy efficiency was noted with this increase. This tendency could be linked to the greater energy loss caused by internal relaxation polarization in high electric fields. Pure BCZT ceramic has a low energy efficiency when compared to other ceramics. Nonetheless, adding the glass improves the energy efficiency (η) of BCZTx ceramics and keeps it at a higher level due to the reduction of energy loss. For instance, it increases from 37% for BCZT0 to 66.7% and 62.4% for BCZT2 and BCZT4, respectively.

Figure 10 presents the variation of Wloss, Wrec, and η as a function of the glass content for all the samples at the maximum electric field. It is obvious that the energy density rises and subsequently drops as the percentage of glass increases. It increases form 0.075 to 0.506 J/cm3, 0.521 J/cm3, 0.0884 J/cm3, and 0.0577 J/cm3 for BCZT0, BCZT2, BCZT4, BCZT6, and BCZT8, respectively. The increase in Wrec is related to the increase in the maximum applied electric field. Likewise, it was enhanced substantially from 25 kV/cm for BCZT0 to 135 kV/cm for BCZT4, and then decreases. However, BCZT6 and BCZT8 ceramics display a relatively large maximum electric field, 62 kV/cm and 57 kV/cm, respectively, compared to pure BCZT ceramic. It is well known that a number of variables, including porosity, grain size, the second phase, sintering temperature, charge injection, and interfacial polarization, have a significant impact on the BDS of ceramics [36, 37]. By adding a glass, the liquid phase develops between the grain boundaries during the sintering of the ceramics, which favors the microstructure densification and restrains the grain overgrowth, leading to dense ceramics with higher BDS. The addition of glass to BCZT ceramics significantly refined the microstructure, as evidenced by the SEM images. Previous research has suggested that decreasing grain size improves BDS, as demonstrated by the relation,\({E}_{BDS}\propto {G}^{-c}\), where EBDS is the breakdown strength, G is the average grain size, and c is a constant [38]. Furthermore, the glass-forming phase at the grain boundary can aid to enhance the BDS by preventing the grains from breaking at high-applied voltage. One can notice that the BDS differences between the samples are so large and significant. In fact, the BDS of BCZTx ceramics is suddenly dropped from 135 kV/cm (x = 4) to 60 kV/cm (x = 6). Meanwhile, the BDS of BCTZ0 ceramics is lower than 30 kV/cm. The enhancement of BDS was associated with the decrease of the grain, the improvement of homogeneous microstructure, and the improvement in the density of BCZTx ceramics. However, the decrease of BDS for BCZT4 and BCZT6 could be associated to the decrease of the density of samples and the formation of the impurity phase [39], which is evident from Figs. 1 and 3. Moreover, this degradation of BDS may be caused by the coarsening of glass and formation of discontinuous grain boundary precipitates in ceramics [35].

The optimum energy density is obtained for BCZT4 ceramic with the highest maximal electric field. It reaches 0.52 J/cm3 at 135 kV/cm with an energy efficiency of (η∼62.4%), which is multiplied by 6.6 compared to BCZT0 the BCZT0 (Wrec∼0.075 J/cm3). As predicted, the addition of glass to BCZTx ceramics can considerably increase the energy efficiency and recoverable energy density.

Table 2 summarizes the εr, Wtot, Wrec, and η of other glass-modified lead-free ferroelectric ceramics and BCZTx samples at the high electric field. BCZT4 sample shows improved energy storage density than other ceramics at room temperature, [40, 41]. Note that a Wrec of 0.192 J/cm3 with an η of 78% was achieved for Ba(Zr0.2Ti0.8)O3–0.15(Ba0.7 Ca0.3)TiO3 ceramic [40]. Meanwhile, Wang et al.[22] reported a large Wrec of 2.12 J/cm3 and high η of 90.5% in Ba0.85Ca0.15Zr0.1Ti0.9O3/Bi2O3–B2O3–SiO2 ceramic under an applied electric field of 330 kV/cm.

3.4.1 Landau theory

Based on the Landau–Ginzburg–Devonshire (LGD) phenomenological theory, more understanding of the calculations of the energy density parameters (Wrec, Wtot, η) can be obtained.

where a and b are quadratic and quartic factors, respectively.

In a state of equilibrium,\(\frac{\partial \mathrm{F}}{\partial \mathrm{P}}=0\), which results in

The polarization dependence of electric field (E–P) data can be fitted by Eq. (2), showing the validity of the equation and enabling the extraction of the coefficients a and b for each sample. For instance, these latter a and b coefficients are shown in Fig. 11 for BCZT4 sample. According to the Landau model, these a and b parameters are significant for energy storage density [44] since they are involved in the following expression:

where Pmax is the polarization at Emax and a and b are constant values. Equation (6) therefore tells us that only three quantities completely govern the behaviors and values of the energy density, namely a, b, and Pmax. Table 3 presents the parameter’s a and b obtained and the experimental energy density (Wrec and Wtot) and theoretical energy density calculated using Eq. (3).

4 Conclusion

Ba0.85Ca0.15Zr0.1Ti0.9O3 ceramics modified with the BaO–Na2O–Nb2O5–WO3–P2O5 glass addition were synthesized using the solid-state reaction technique. The inclusion of glass results in smaller grain sizes and a dense microstructure. The dielectric measurements showed that the dielectric constant decreased as the BNNWP glass content increases. Thin hysteresis loops with larger electric field were noticed for modified BCZTx ceramics. The maximal electric field of BCZT4 ceramic was remarkably improved for almost five times with respect to the pure BCZT ceramic. As a result, BCZT4 ceramic showed the highest recovered energy density of 0.52 J/cm3 at 135 kV/cm with an energy efficiency of 62.4%. The calculated theoretical energy densities from the Landau–Ginzburg–Devonshire (LGD) theory are compatible with the experimental findings.

Data availability

Not applicable.

Code availability

Not applicable.

References

Z. Yao, Z. Song, H. Hao, Z. Yu, M. Cao, S. Zhang, M.T. Lanagan, H. Liu, Adv. Mater. (2017). https://doi.org/10.1002/adma.201601727

H. Yang, F. Yan, F. Wang, G. Zhang, Y. Lin, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2017.05.158

J. Liu, J. Zhai, K. Yang, B. Shen, S. Wang, J. Tian, Ceram. Int. (2018). https://doi.org/10.1016/j.ceramint.2018.02.054

X. Chen, Y. Tang, X. Bo, J. Song, J. Luo, J. Mater. Sci. Mater. Electron. (2018). https://doi.org/10.1007/s10854-018-9858-6

Z. Yang, H. Du, S. Qu, Y. Hou, H. Ma, J. Wang, J. Wang, X. Wei, Z. Xu, J. Mater. Chem. A (2016). https://doi.org/10.1039/c6ta04107h

D. Li, X. Zeng, Z. Li, Z.Y. Shen, H. Hao, W. Luo, X. Wang, F. Song, Z. Wang, Y. Li, J. Adv. Ceram. (2021). https://doi.org/10.1007/s40145-021-0500-3

X. Hao, J. Adv. Dielectr. (2013). https://doi.org/10.1039/c6ta04107h10.1142/s2010135x13300016

M. Zhang, H. Yang, Y. Lin, Q. Yuan, H. Du, Energy Storage Mater. (2022). https://doi.org/10.1016/j.ensm.2021.12.037

H. Yang, F. Yan, Y. Lin, T. Wang, J. Eur. Ceram. Soc. (2018). https://doi.org/10.1016/j.jeurceramsoc.2017.11.058

S. Merselmiz, Z. Hanani, D. Mezzane, M. Spreitzer, A. Bradeško, D. Fabijan, D. Vengust, M. Amjoud, L. Hajji, Z. Abkhar, A.G. Razumnaya, B. Rožič, I.A. Luk’yanchuk, Z. Kutnjak, Ceram Int Ceram Int (2020). https://doi.org/10.1016/j.ceramint.2020.06.16

Z. Hanani, S. Merselmiz, D. Mezzane, A. Bradeško, B. Rožič, M. Lahcini, M. El Marssi, A.V. Ragulya, I.A. Luk’Yanchuk, Z. Kutnjak, M. Gouné, RSC Adv (2020). https://doi.org/10.1039/d0ra06116f

S.S. Merselmiz, Z. Hanani, U. Prah, D. Mezzane, L. Hajji, Z. Abkhar, M. Spreitzer, D. Vengust, H. Uršič, D. Fabijan, A. Razumnaya, O.G. Shapovalova, I.A. Luk’yanchuk, Z. Kutnjak, Phys. Chem. Chem. Phys. (2022). https://doi.org/10.1039/D1CP04723J

Y. Lin, D. Li, M. Zhang, S. Zhan, Y. Yang, H. Yang, Q. Yuan, A.C.S. Appl, Mater. Interfaces. (2019). https://doi.org/10.1021/acsami.9b10819

Z. Hanani, D. Mezzane, M. Amjoud, S. Fourcade, A.G. Razumnaya, I.A. Luk’yanchuk, M. Gouné, Superlattices Microstruct. (2019). https://doi.org/10.1016/j.spmi.2018.03.004

H. Kaddoussi, A. Lahmar, Y. Gagou, B. Manoun, J.N. Chotard, J.-L. Dellis, Z. Kutnjak, H. Khemakhem, B. Elouadi, M. El Marssi, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2017.04.148

S. Merselmiz, Z. Hanani, D. Mezzane, A.G. Razumnaya, M. Amjoud, L. Hajji, S. Terenchuk, B. Roˇziˇc, I.A. Luk’yanchukc, Z. Kutnjak, RSC Adv (2021). https://doi.org/10.1039/d0ra09707a

Z. Dai, J. Xie, Z. Chen, S. Zhou, J. Liu, W. Liu, Z. Xi, X. Ren, Chem. Eng. J. (2020). https://doi.org/10.1016/j.cej.2020.128341

W.S.M. Maraj, W. Wei, B. Peng, Materials (Basel). (2019). https://doi.org/10.3390/ma12213641

Y. Lin, Y. Zhang, S. Zhan, C. Sun, G. Hu, H. Yang, Q. Yuan, J. Mater. Chem. A. (2020). https://doi.org/10.1039/D0TA07937E

T. Wu, Y. Pu, T. Zong, P. Gao, J. Alloys Compd. (2014). https://doi.org/10.1016/j.jallcom.2013.09.072

Z. Luo, L. Han, A. Lu, J. Song, Q. Feng, T. Liu, J. Mater. Sci. Mater. Electron. (2018). https://doi.org/10.1007/s10854-018-8566-6

X.W. Wang, B.H. Zhang, Y.C. Shi, Y.Y. Li, M. Manikandan, S.Y. Shang, J. Shang, Y.C. Hu, S.Q. Yin, J. Appl. Phys. (2020). https://doi.org/10.1063/1.5138948

V.S. Puli, A. Kumar, R.S. Katiyar, X. Su, C.M. Busta, D.B. Chrisey, M. Tomozawa, J. Non. Cryst. Solids. (2012). https://doi.org/10.1016/j.jnoncrysol.2012.05.018

A. Ihyadn, D. Mezzane, M. Amjoud, A. Lahmar, L. Bih, A. Alimoussa, I.A. Luk’Yanchuk, M. El Marssi, Today Proc (2022). https://doi.org/10.1016/j.matpr.2021.03.570

E. Haily, L. Bih et al., Mater. Chem. Phys. (2020). https://doi.org/10.1016/j.matchemphys.2019.122434

A. Ihyadn et al., Mater Res Express (2019). https://doi.org/10.1088/2053-1591/ab4569

Y. Yao, C. Zhou, D. Lv, D. Wang, H. Wu, Y. Yang, X. Ren, EPL (2012). https://doi.org/10.1209/0295-5075/98/27008

Z. Hanani, E.-H. Ablouh, M. Amjoud, D. Mezzane, M. Gouné, S. Fourcade, Ceram. Int. (2017). https://doi.org/10.1016/j.ceramint.2018.03.022

L.Z. Wang, W.Q. Luo, Z.M. Wang, Y.M. Li, Mater Electron J Mater Sci (2017). https://doi.org/10.1007/s10854-017-8010-3

W. Liu, W. Ping, S. Li, Energy Technol (2017). https://doi.org/10.1002/ente.201600713

Z. Yang, H. Du, L. Jin, D. Poelman, J. Mater. Chem. A (2021). https://doi.org/10.1039/d1ta04504k

Z.-Y. Shen, Y. Wang, Y. Tang, Y. Yu, W.-Q. Luo, X. Wang, Y. Li, Z. Wang, F. Song, J. Mater. (2019). https://doi.org/10.1016/j.jmat.2019.06.003

X. Du, Y. Pu, X. Li, X. Peng, Z. Sun, J. Zhang, J. Ji, R. Li, Q. Zhang, M. Chen, Ceram. Int. (2021). https://doi.org/10.1016/j.ceramint.2020.12.021

Z. Jiwei, Y. Xi, C. Xiaogang, Z. Liangying, H. Chen, Sci. Eng. B Solid-State Mater. Adv. Technol. Mater (2002). https://doi.org/10.1016/S0921-5107(02)00061-2

Y.H. Huang, Y.J. Wu, B. Liu, T. Yang, J. Wang, J. Li, L. Chen, X.M. Chen, J. Mater. Chem. A (2018). https://doi.org/10.1039/C7TA10821D

X. Wang, Y. Zhang, X. Song, Z. Yuan, T. Ma, Q. Zhang, C. Deng, T. Liang, J. European Ceramic Society. (2012). https://doi.org/10.1016/j.jeurceramsoc.2011.09.024

C. Liu, X. Chen, B. Zeng, F. Zhang, W. Song, Z. Luo, Y.L. Wang, J Adv Ceram (2023). https://doi.org/10.26599/JAC.2023.9220713

J. Wang, C. Xu, B. Shen, J. Zhai, J. Mater. Sci. Mater. Electron. (2013). https://doi.org/10.1007/s10854-013-1248-5

T. Wang, Y. Wang, H. Yangy, Y. Lin, L. Kong, J. Adv. Dielectr. (2018). https://doi.org/10.1142/S2010135X18500418

W. Liu, W. Ping, S. Li, Energy Technol. 5, 1423–1428 (2017)

Q. Xu, D. Zhan, D.P. Huang, H.X. Liu, W. Chen, F. Zhang, J. Alloys Compd. (2013). https://doi.org/10.1016/j.jallcom.2012.12.164

T. Wu, Y. Pu, K. Chen, Ceram. Int. (2013). https://doi.org/10.1016/j.ceramint.2013.02.009

D. Zhan, Q. Xu, D.P. Huang, H.X. Liu, W. Chen, F. Zhang, Phys. B Condens. Matter. (2014). https://doi.org/10.1016/j.physb.2014.01.025

Z. Jiang, S. Prosandeev, L. Bellaiche, Phys. Rev. B. (2022). https://doi.org/10.1103/PhysRevB.105.024102

Acknowledgements

The authors gratefully acknowledge the financial support of CNRST, OCP foundation, and the European Union’s Horizon H2020-MSCA-RISE research and innovation actions, ENGIMA and MELON.

Funding

CNRST Morocco, OCP foundation.

Author information

Authors and Affiliations

Contributions

All authors certify that they have participated sufficiently in the work to take public responsibility for the content. Furthermore, each author certifies that this work will not be submitted to other journal or published in any other publication before. AI: Investigation, Writing—Original Draft, visualization, and conceptualization; SM: Writing—Review & Editing; DM: Conceptualization, validation, resources, and supervision; LB: Conceptualization, resources, and supervision; AL: Writing—Review and Editing; AA: Software and supervision; MA and IAL: Reviewing and Editing; MEM: Formal analysis and Resources.

Corresponding author

Ethics declarations

Conflicts of interest

Not applicable.

Ethical approval

Not applicable.

Consent to participate

We confirm that all authors mentioned in the manuscript have participated in, read and approved the manuscript, and have given their consent for the submission and subsequent publication of the manuscript.

Consent for publication

We confirm that all the authors mentioned in the manuscript have agreed to publish this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ihyadn, A., Merselmiz, S., Mezzane, D. et al. Dielectric and energy storage properties of Ba0.85Ca0.15Zr0.1Ti0.90O3 ceramics with BaO–Na2O–Nb2O5–WO3–P2O5 glass addition. J Mater Sci: Mater Electron 34, 1051 (2023). https://doi.org/10.1007/s10854-023-10483-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10483-x