Abstract

In this experiment, new high-temperature piezoelectric ceramics (1−x)K0.45Na0.55NbO3−x(Bi0.5Li0.5)0.9Sr0.1ZrO3 were prepared by the conventional solid-state sintering method, and the effect of the doping amount of (Bi0.5Li0.5)0.9Sr0.1ZrO3 on the microstructure and electrical properties of this system ceramics were systematically investigated. XRD, SEM, EDS, and other modern test technology analysis results show that all the doped ions have entered the KNN lattice in the studied range, forming a dense solid solution with a pure perovskite structure, and forming orthorhombic–tetragonal polymorphic phase boundaries at 0.02 ≤ x ≤ 0.035, the ceramics exhibit rhombohedral–tetragonal polymorphic phase coexistence in the range of 0.04 ≤ x ≤ 0.05. The electrical properties tests show that the ceramics of this system exhibit excellent electrical properties in the multiphase coexistence region at x = 0.04, which are: d33 = 307pC/N, kp = 46%, εr = 1363, tanδ = 2.79%, Pr = 16.7 µC/cm2, Ec = 12.65 kV/cm, and TC = 368 °C. These excellent electrical properties and the high Curie temperature predict that the ceramics of this system have great prospects for future applications in the field of lead-free piezoelectric ceramics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, there has been great progress in the modification research for potassium sodium niobate (KNN) based ceramics, especially through the substitution of A- and B-site ions to optimize the components and adjust the phase boundaries to appear to have multiple phases coexisting close to room temperature, such as R–O and O–T, which can significantly enhance the piezoelectric properties of KNN-based lead-free ceramics but still cannot be compared with commercial PZT ceramics in the overall performance [1,2,3,4,5,6,7,8]. In order to achieve superior piezoelectric properties in 2016, Xu et al. created the ceramics system KNNS-BZ-BKH and successfully designed a new R–T ceramic phase boundary, proving that the existence of R–T phase boundaries is a proven method to improve the performance of KNN-based piezoelectric ceramics [9]. However, this method typically results in a large reduction in TC and an improvement in the piezoelectric characteristics of KNN-based ceramics [10,11,12]. It is therefore difficult to enhance the piezoelectric qualities without decreasing the TC, necessitating the construction of an entirely new system to solve both problems simultaneously [13,14,15].

In recent years, many studies have confirmed that the construction of new phase boundaries in KNN-based piezoelectric ceramics is conducive to the enhancement of piezoelectric performance, but it will also lead to a significant decrease in the Curie temperature. In this experiment, the introduction of the second component (Bi0.5Li0.5)0.9Sr0.1ZrO3 in KNN-based ceramics mainly has the following reasons, first of all, we choose to doping Li ions can effectively enhance the sintering activity of KNN-based ceramics, so that the density of ceramics is improved, and it is conducive to improving the Curie temperature of ceramics [16, 17]. Secondly, doping (Bi0.5Na0.5)ZrO3 in KNN-based ceramics can increase the rhombohedral–orthorhombic phase transition temperature (TR−O), and also reduce the orthorhombic–tetragonal phase transition temperature (TO−T), thereby effectively construct a new R–T phase boundary [15, 18]. Finally, the use of Sr2+ doping with a similar radius to the A ion can effectively control the TR−T phase transition to stabilize to room temperature, while well reducing the O–T phase transition temperature, at present, many related studies report that this polymorphic phase boundary adjustment to near room temperature can make ceramics have more unstable polarization state, so ceramics in the polarized state of ceramic domain flipping is easier, thereby improving the piezoelectric properties of ceramics [19, 20]. In this experiment, the group designed new (1−x)K0.45Na0.55NbO3−x(Bi0.5Li0.5)0.9Sr0.1ZrO3 ceramics system and systematically investigated the correlation mechanism between the microstructure and electrical properties of the ceramics. This was done with the goal of constructing a new R–T phase boundary without lowering the Curie temperature.

2 Experimental procedure

In this experiment, new lead-free piezoelectric ceramics (1−x)K0.45Na0.55NbO3−x(Bi0.5Li0.5)0.9Sr0.1ZrO3 [abbreviated as KNN-xBLSZ] (x = 0, 0.02, 0.03, 0.035, 0.04, 0.05, 0.06) were prepared by the conventional solid-phase reaction route. The raw materials used in the experiments were as follows: K2CO3 (99%), Na2CO3 (99.8%), Nb2O5 (99.5%), Li2CO3 (98%), SrCO3 (99%), Bi2O3 (99.99%), and ZrO2 (99%). The mass of the necessary raw materials were calculated using the stoichiometric ratio and weighed using a balance. These weighed powders were then ball-milled in an ethanol medium for 12 h, placed in a high-temperature furnace for 6 h at 850 °C for pre-combustion, added 8 to 10 wt% of PVB for granulation and pressing, and then heated for 4 h at 600 °C to release gum and all samples were calcined at 1090–1150 °C for 3 h, after all samples were poled in silicone oil at 120 °C under a DC electric field of 3–4 kV/mm for 30 min. Finally, the performance was evaluated following a 24 h period of rest [21].

The Archimedes method was used to determine the bulk density of ceramics, the phase structure of ceramics was examined by X-ray diffraction (XRD) using Cu Kα radiation (Rigaku, Tokyo, Japan), the surface micromorphology of ceramics was characterized by scanning electron microscopy (SEM) (S-4800, Hitachi, Japan), in order to test the dielectric constant and dielectric loss of ceramics in the temperature range of − 150 to 100 °C and room temperature to 500 °C, and the surface microscopic morphology was assessed using an LCR meter (HP4980A, Agilent, USA). A piezo-d33 meter (ZJ-3 A, China Institute of Acoustics) and an impedance analyzer were used to measure the piezoelectric constant d33 and the planar electromechanical coupling factor kp (HP4294A, Agilent, USA). The hysteresis lines were measured at room temperature using a ferroelectric measurement system (Trek 609B, Radiant Technologies, Inc. Albuquerque) [21].

3 Results and discussion

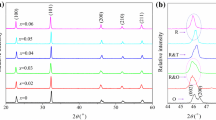

All ceramics samples are solid solutions with a pure perovskite structure, as shown by the XRD patterns measured at room temperature for KNN-xBLSZ ceramics (2θ = 20°–60°) in Fig. 1a. This along with the results of the EDS test in Fig. 6, suggests that BLSZ has been fully incorporated into the KNN lattice. The main reason for this result is that the ions at the A and B sites have similar ionic radii, Bi3+(RBi3+ = 0.145 nm), Li+(RLi+ = 0.125 nm), Sr2+ (RSr2+ = 0.144 nm) with A-site K+(RK+ = 0.164 nm), Na+(RNa+ = 0.139 nm), Zr4+ (RZr4+ = 0.072 nm) with B-site Nb5+ (RNb5+ = 0.064 nm), they all conforms to the law of fusion of doped ions of solid solution [22, 23]. The XRD diffraction peaks at diffraction angles 43.5°–47.5° are magnified in Fig. 1b, and it is clear that as x is gradually increased, the peak pattern of the system ceramic at these angles considerably changes, the peak pattern of the system ceramic at diffraction angles 43.5°–47.5° changes significantly. Two distinct subpeaks (002) and (020) can be seen at 45° when x = 0. The (002) peak has a significantly higher intensity than the (020) peak, and its I(002)/I(020) ratio is approximately 2:1, which is typical of the presence of orthorhombic (O) phase in KNN ceramics [24, 25]. When x = 0.02–0.035, the intensity of the (002) and (020) diffraction peaks is approximately 1:1, when the ceramics are O–T coexistence, this conclusion has been reported reasoning [26]. In order to better determine, the XRD data was refined using MAUD program and found that when x = 0.02, the proportion of orthorhombic phase is 73.2% and the proportion of tetragonal phase is 26.8%, When x = 0.04–0.05, the intensity ratio of (002)/(020) diffraction peaks is 1:2, which can be judged as the coexistence of R–T phase, and the proportion of rhombohedral phase is 26.4% and tetragonal phase is 73.6% when combined with the software refinement x = 0.04 [27,28,29]. When x = 0.06 of the ceramics, the R–T phase is suppressed due to the excessive refinement of the grains [30].

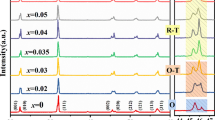

To further confirm the effect of (Bi0.5Li0.5)0.9Sr0.1ZrO3 content on the phase transition of the ceramic samples, the curves of the dielectric constant with the temperature at low temperatures (−150–100 °C) were tested in this experiment at a frequency of 10 kHz. This dielectric temperature spectrum shows that the curves for pure KNN ceramics are in general agreement with those reported in previous articles [4, 31]. As shown in Fig. 2a–g, as x = 0 increases to 0.035, there are two distinct dielectric constant anomalies in the range of −150 to 100 °C for the ceramic samples, TR−O at low temperature and TO−T at high temperature. TR−O gradually increases while TO−T moves closer to room temperature [32, 33]. When x = 0-0.035, the orthorhombic–tetragonal phase transition temperatures (TO−T) are 202 °C, 115 °C, 57 °C, and 30 °C, and the rhombohedral–orthorhombic phase transition temperatures (TR−O) are − 112 °C, − 78 °C, − 31 °C, and − 6 °C, respectively. When 0.04 ≤ x ≤ 0.05 samples, TR−O and TO−T move further to lower temperatures, and the two dielectric anomalies peaks are essentially fused into one, at which time the ceramic forms a new phase boundary of R–T at room temperature. At x = 0.06, the dielectric peak exhibits suppressed R–T phase structure due to the suppression of the phase boundary caused by the excessive refinement of the ceramic grains [30].

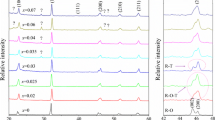

In order to investigate the crystal structure of the ceramics, the Rietveld refinement of the XRD patterns at room temperature for the ceramics with x = 0.02, 0.035, and 0.04 is shown in Fig. 3. By performing R3m (rhombohedral), Amm2 (orthorhombic), and P4mm (tetragonal) symmetry models on the coexisting phases analyzed by Rietveld analysis, we can find that the variation analysis of the XRD peak patterns is consistent with the crystal structure parameters, which are shown in Table 1. The results show that there is a good agreement between the intensity distributions of the simulated and experimental results through the Sig and Rw values. In addition, by observing Table 1, it can be found that the O-phase ratios increase with the increase of x, while the corresponding T phase ratio is decreasing.

Figure 4a elucidates the εr–T curves of (1−x)K0.45Na0.55NbO3−x(Bi0.5Li0.5)0.9Sr0.1ZrO3 ceramics with dielectric constants measured at 10 kHz in the range of 30–450 °C. Through the dielectric curves, it can be observed that there is a dielectric peak, whose peak corresponds to the Curie temperature (TC), and when x is small, the Curie peak is high and narrow, and as x increases, the peak pattern gradually becomes wider, showing the characteristics of diffuse phase transition, which is mainly due to the excessive doping of BLSZ leading to the inhomogeneity of the microscopic region composition, and this inhomogeneity seriously affects the diffusion of the phase transition [34]. From the doping of BLSZ as observed in Fig. 4b, the Curie temperature of the ceramics is reduced, but always remains relatively high, showing excellent Curie temperature TC = 368 °C and electrical properties when x = 0.04, implying easier application in high-temperature environments. Figure 4c shows the phase structure of KNN-xBLSZ ceramics, from which it can be seen that the TC and TO−T of the ceramics. Decreases with increasing x, while TR−O increases with increasing x. As x increases, the peak slowly approaches the room temperature region and evolves into a new phase boundary from the rhombohedral to the tetragonal (R–T) phase near the room temperature when x = 0.04–0.05.

Figure 5a–f shows the SEM surface morphology of the KNN-xBLSZ ceramics samples. It can be observed that all ceramics samples have a dense microstructure and no excess impurity phases are produced. When 0 ≤ x < 0.04, it is observed that there are many pores between the grains, the ceramic grain size has a considerable inhomogeneous distribution, and the density of the ceramic is poor. At x = 0.04, the ceramic grains have good homogeneity, the pores between the grains are kept at a minimum, the ceramic has good densification, and the domain wall density becomes more homogeneous at this time, which is conducive to the flipping of the electric domains during the polarization process, which improves the electrical properties. When 0.04 < x ≤ 0.06, combined with the density analysis in Fig. 9, there is a tendency for the pores between the grains to increase, the density of the ceramic decreases, and the ceramic grains start to refine, which is because Bi3+ and Zr4+ ions tend to accumulate at the grain boundaries, making it more difficult for the grain boundaries to move, which hinders the growth of the ceramic grains, resulting in a rise in non-uniform nucleation points, which hinder grain growth during sintering and lead to excessive refinement, which diminishes sintering activity, intensifies pores in the ceramic, and makes domain flipping more complicated during polarization [19, 35, 36]. The sintering activity is reduced, the porosity within the ceramics is increased, and the electric domain flipping during polarization is more difficult, which leads to the degradation of electrical properties [16]. Therefore, the doping of KNN ceramics with appropriate BLSZ can promote the growth of ceramics grains and improve the denseness of ceramics.

As shown in Fig. 6 the elemental distribution of the ceramic sample was analyzed by EDS measurements at x = 0.04. All elements were detected and close to stoichiometric ratios, where the element Li has a relatively small atomic number and is a very light element, so the elemental distribution could not be detected by the electron probe [37]. The other elements were mapped on the surface by EDX analysis and the results showed that all elements were uniformly distributed in the ceramics.

Figure 7a shows the variation curves of KNN-xBLSZ ceramics dielectric constant ɛr and dielectric loss tanδ with x, measured in the test frequency of 10 kHz and at room temperature. The curve of dielectric loss tanδ with x shows fluctuations, and the dielectric constant ɛr shows an increase with increasing x, and then a decrease with x > 0.04. The KNN-xBLSZ ceramic has the best dielectric properties (ɛr = 1363, tanδ = 2.79%) when x = 0.04. The piezoelectric properties of KNN-xBLSZ ceramics with the addition of x are shown in Fig. 7b. With the increase of x, the d33 and kP values show a trend of increasing and then decreasing. When x = 0.04, the system has the best piezoelectric properties (d33 = 307pC/N, kp = 46%). On the one hand, the superior piezoelectric properties of this ceramic system are attributed to the coexistence of R–T phase at room temperature, which can make the domain reversal during polarization easier, and on the other hand, the dense nature of the ceramic is improved by doping with BLSZ, which improves the piezoelectric properties [10]. When x > 0.04, the electrical properties begin to deteriorate, owing predominantly to a drop in sintering activity, which causes the tiny grains to become increasingly abundant, an elevation in domain walls and the challenge of deflection, and a fall in ceramic density.

As shown in Fig. 8a, the hysteresis loops of KNN-xBLSZ ceramics measured at 10 Hz at room temperature, it can be observed that the hysteresis loops of all component ceramics show typical ferroelectric P–E loops, and all hysteresis loops have good symmetry, from which it can be inferred that the ceramics have fewer internal defects. With the increase of x, all the P–E curves changed significantly. In order to analyze the ferroelectric properties more clearly, the remnant polarization (Pr) and coercive field (Ec) curves with x are shown in Fig. 8b. The Ec changes very little with the increase of x, and the change of Ec is related to the appearance of R phase, in addition, Ec may be influenced by grain size and domain wall mobility [7, 38]. The Pr shows a trend of increasing and then decreasing sharply, and the maximum value Pr = 16.7 µC/cm2 is obtained at x = 0.04, indicating that the flip of ferroelectric domains within the ceramic will increase with the doping of BLSZ after the number of spontaneous polarization increases with the doping of BLSZ when the ceramic is in multiphase coexistence state with a lower potential barrier. When x = 0.06, on the one hand, the possible explanation may be attributed to the difficulty of deflection during polarization due to grain refinement; on the other hand, it may be because of the various ionic radii and valence states of the substituted ions at A and B sites, culminating in charge imbalance and local lattice distortion, which leads to the formation of polar nano-regions (PNRs), curbing their ferroelectric properties, and potentially creating the decline of Pr [15, 19].

For ferroelectric ceramics, the relationship between the piezoelectric constant and the ferroelectric and dielectric properties can be described by the equation (d33 = 2Qε0εrPr), Q and ε0 are the electrostricstive coefficient and the free-space permittivity which is related to the ordered arrangement of cations and is generally regarded as an invariant [39, 40]. εr denotes the main parameter of the polarization properties of piezoelectric materials in the presence of an electrostatic field, depending on is polarization, domain wall motion and activity of polar nanoregions (PNRs), and Pr denotes the intensity of dielectric polarization after voltage withdrawal, with the main influencing factors being the stability of the long-range ferroelectric sequence and the meritocratic orientation of the electric domains. The piezoelectric constants (d33) and εrPr versus x for KNN-xBLSZ ceramics are plotted in Fig. 9a, and the trends of d33 and εrPr can be seen to be largely fitted, the maximum value is obtained at x = 0.04 (d33 = 307pC/N), which is in the state of R–T phase coexistence. Once an electric field is applied to a material for directional polarization, the flipping of ferroelectric domains within the ceramic becomes simpler, giving rise to an augmentation in the number of polarizable dipoles, which in turn leads to a rise in the polarization strength of the ceramic, which is mirrored in an increase in the dielectric and ferroelectric properties [41]. On the other hand, the enhancement of the piezoelectric properties of the ceramics are directly related to the density of the ceramics, as shown in Fig. 9b.

For practical applications of piezoelectric materials, excellent electrical properties and high TC are indispensable to ensure their use in the temperature range. Table 2 provides a comparison of the performance of this work with some of the reported KNN-based piezoelectric ceramics. It is observed that KNN-xBLSZ obtains superior piezoelectric properties, and it is worth mentioning that the ceramic system has a ultra-Curie temperature TC = 368 °C than most of the reported ones, which is perfectly suitable for applications in higher temperature scenarios.

4 Conclusion

In this study, new high-temperature piezoelectric ceramics (1−x)K0.45Na0.55NbO3−x(Bi0.5Li0.5)0.9Sr0.1ZrO3 were successfully prepared by the conventional solid-state method. Through modern analytical testing techniques such as XRD, SEM, and EDS, it was confirmed that the ceramics of this system in the range of 0 ≤ x ≤ 0.06 ceramics formed a pure perovskite structure and all the elements were detected, especially when the multiphase coexistence of x = 0.04 showed excellent electrical properties, which were d33 = 307 pC/N, kp=46%, εr = 1363, tanδ = 2.79%, Pr = 16.7µC/cm2, Ec = 12.65 kV/cm, and TC = 368 °C. Therefore, we believe that the ceramics system will advance the development of KNN-based lead-free piezoelectric ceramics.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable.

References

J. Hao, W. Li, J. Zhai, H. Chen, Progress in high-strain perovskite piezoelectric ceramics. Mater. Sci. Eng. R Rep. 135, 1 (2019)

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Lead-free piezoceramics. Nature 432, 84 (2004)

J. Lin, Y. Cao, K. Zhu, F. Yan, C. Shi, H. Bai, G. Ge, J. Yang, W. Yang, Y. shi, G. Li, H. Zeng, J. Zhai, Ultrahigh energy harvesting properties in temperature-insensitive eco-friendly high-performance KNN-based textured ceramics. J. Mater. Chem. A 10, 7978 (2022)

X. Lv, Z. Li, J. Wu, J. Xi, M. Gong, D. Xiao, J. Zhu, Enhanced piezoelectric properties in potassium-sodium niobate-based ternary ceramics. Mater. Des. 109, 609 (2016)

B. Wu, H. Wu, J. Wu, D. Xiao, J. Zhu, S.J. Pennycook, Giant piezoelectricity and high curie temperature in nanostructured alkali niobate lead-free piezoceramics through phase coexistence. J. Am. Chem. Soc. 138, 15459 (2016)

J. Wu, H. Tao, Y. Yuan, X. Lv, X. Wang, X. Lou, Role of antimony in the phase structure and electrical properties of potassium–sodium niobate lead-free ceramics. RSC Adv. 5, 14575 (2015)

J. Xing, Z. Tan, X. Chen, L. Jiang, W. Wang, X. Deng, B. Wu, J. Wu, D. Xiao, J. Zhu, Rietveld analysis and electrical properties of BiInO3 doped KNN-based ceramics. Inorg. Chem. 58, 428 (2019)

X. Yan, B. Peng, X. Lu, Q. Dong, W. Li, Structure evolution and enhanced piezoelectric properties of (K0.5Na0.5)NbO3–0.06LiTaO3–SrZrO3 lead-free ceramics. J. Alloys Compd. 653, 523 (2015)

K. Xu, J. Li, X. Lv, J. Wu, X. Zhang, D. Xiao, J. Zhu, Superior piezoelectric properties in potassium–sodium niobate lead-free ceramics. Adv. Mater. 28, 8519 (2016)

T. Zheng, J. Wu, D. Xiao, J. Zhu, Recent development in lead-free perovskite piezoelectric bulk materials. Prog. Mater. Sci. 98, 552 (2018)

T. Zheng, Y. Yu, H. Lei, F. Li, S. Zhang, J. Zhu, J. Wu, Compositionally graded KNN-based multilayer composite with excellent piezoelectric temperature stability. Adv. Mater. 34, 2109175 (2022)

X. Zhou, G. Xue, H. Luo, C.R. Bowen, D. Zhang, Phase structure and properties of sodium bismuth titanate lead-free piezoelectric ceramics. Prog. Mater. Sci. 122, 100836 (2021)

K. Chen, J. Ma, C. Shi, W. Wu, B. Wu, Enhanced temperature stability in high piezoelectric performance of (K, na)NbO3-based lead-free ceramics trough co-doped antimony and tantalum. J. Alloys Compd. 852, 156865 (2021)

X. Lv, T. Zheng, C. Zhao, J. Yin, H. Wu, J. Wu, Multiscale structure engineering for high-performance Pb-free piezoceramics. Acc. Mater. Res. 3, 461 (2022)

J. Wu, D. Xiao, J. Zhu, Potassium–sodium niobate lead-free piezoelectric materials: past, present, and future of phase boundaries. Chem. Rev. 115, 2559 (2015)

Z. Cen, W. Feng, P. Zhao, L. Chen, C. Zhu, Y. Yu, L. Li, X. Wang, Design on improving piezoelectric strain and temperature stability of KNN-based ceramics. J. Am. Ceram. Soc. 102, 2675 (2018)

Z. Fu, J. Yang, P. Lu, L. Zhang, H. Yao, F. Xu, Y. Li, Influence of secondary phase on polymorphic phase transition in Li-doped KNN lead-free ceramics. Ceram. Int. 43, 12893 (2017)

X. Wang, J. Wu, D. Xiao, J. Zhu, X. Cheng, T. Zheng, B. Zhang, X. Lou, X. Wang, Giant piezoelectricity in potassium-sodium niobate lead-free ceramics. J. Am. Ceram. Soc. 136, 2905 (2014)

Y. Cheng, J. Xing, C. Wu, T. Wang, L. Xie, Y. Liu, X. Xu, K. Wang, D. Xiao, J. Zhu, Investigation of high piezoelectric properties of KNNSb-SrxBNZ ceramics. J. Alloys Compd. 815, 152252 (2020)

J. Zhou, G. Xiang, J. Shen, H. Zhang, Z. Xu, H. Li, P. Ma, W. Chen, Composition-insensitive enhanced piezoelectric properties in SrZrO3 modified (K, na)NbO3-based lead-free ceramics. J. Electroceram. 44, 95 (2019)

Q. Yin, C. Wang, Y. Wang, S. Li, Q. Zhang, J. Yang, C. Tian, Structure and properties of (K0.5Na0.5)0.98Ag0.02Nb0.96Ta0.04O3 piezoelectric ceramics doped by CuO. J. Mater. Sci.: Mater. Electron. 29, 9268 (2018)

R.D. SHANNON, Revised effective ionic radii and systematic studies of interatomie distances in halides and chaleogenides. Acta Cryst. A32, 751 (1976)

Y. Zhang, J.-F. Li, Review of chemical modification on potassium sodium niobate lead-free piezoelectrics. J. Mater. Chem. C 7, 4284 (2019)

H. Du, W. Zhou, F. Luo, D. Zhu, S. Qu, Y. Li, Z. Pei, Design and electrical properties’ investigation of (K0.5Na0.5)NbO3–BiMeO3 lead-free piezoelectric ceramics. J. Appl. Phys. 104, 034104 (2008)

K. Wang, J.-F. Li, Analysis of crystallographic evolution in (na,K)NbO3-based lead-free piezoceramics by X-ray diffraction. Appl. Phys. Lett. 91, 262902 (2007)

Y. Zhang, L. Li, B. Shen, J. Zhai, Effect of orthorhombic–tetragonal phase transition on structure and piezoelectric properties of KNN-based lead-free ceramics. Dalton Trans. 44, 7797 (2015)

M.H. Jiang, G.Q. Zhao, Z.F. Gu, G. Cheng, X.Y. Liu, L. Li, Y.S. Du, In-depth structure characterization and properties of (1 – x)(Li0.05Na0.475K0.475)(Nb0.95Sb0.05)O3 – xBiFeO3 lead-free piezoceramics. J. Mater. Sci.: Mater. Electron. 26, 9366 (2015)

W. Liu, G. Tan, P. Xiong, X. Xue, H. Hao, H. Ren, Phase transition and piezoelectric properties of (1−x)K0.5Na0.5NbO3–x LiSbO3 ceramics by hydrothermal powders. J. Mater. Sci.: Mater. Electron. 25, 2348 (2014)

H.E. Mgbemere, M. Hinterstein, G.A. Schneider, Structural phase transitions and electrical properties of (KxNa1–x)NbO3-based ceramics modified with mn. J. Eur. Ceram. Soc. 32, 4341 (2012)

L. Jiang, Y. Li, J. Xing, J. Wu, Q. Chen, H. Liu, D. Xiao, J. Zhu, Phase structure and enhanced piezoelectric properties in (1-x)(K0.48Na0.52)(Nb0.95Sb0.05)O3-x(Bi0.5Na0.42Li0.08)0.9Sr0.1ZrO3 lead-free piezoelectric ceramics. Ceram. Int. 43, 2100 (2017)

B. He, Y. Du, Y. Liu, J. Wang, W. Liu, H. Xu, Phase boundary design and enhanced electrical properties in (Bi0.5Li0.45Ag0.05)(Zr0.98Hf0.02)O3-modified KNN-based lead-free piezoceramic. J. Mater. Sci.: Mater. Electron. 32, 18240 (2021)

C. Shi, J. Ma, J. Wu, X. Wang, F. Miao, Y. Huang, K. Chen, W. Wu, B. Wu, Coexistence of excellent piezoelectric performance and high curie temperature in KNN-based lead-free piezoelectric ceramics. J. Alloys Compd. 846, 156245 (2020)

B. Wu, C. Zhao, Y. Huang, J. Yin, W. Wu, J. Wu, Superior electrostrictive effect in relaxor potassium sodium niobate based ferroelectrics. ACS Appl. Mater. Interfaces 12, 25050 (2020)

A. Munpakdee, K. Pengpat, J. Tontrakoon, T. Tunkasiri, The study of dielectric diffuseness in the ba(Mg1/3Nb2/3)O3–BaTiO3ceramic system. Smart Mater. Struct. 15, 1255 (2006)

X. Wang, J. Wu, X. Cheng, B. Zhang, J. Zhu, D. Xiao, Compositional dependence of phase structure and electrical properties in (K0.50Na0.50)0.97Bi0.01(Nb1 – xZrx)O3 lead-free ceramics. Ceram. Int. 39, 8021 (2013)

B. Zhang, X. Wang, X. Cheng, J. Zhu, D. Xiao, J. Wu, Enhanced d33 value in (1 – x)[(K0.50Na0.50)0.97Li0.03Nb0.97Sb0.03O3] – xBaZrO3 lead-free ceramics with an orthorhombic–rhombohedral phase boundary. J. Alloys Compd. 581, 446 (2013)

H.-C. Thong, A. Payne, J.-W. Li, Y.-Y.-S. Cheng, J.L. Jones, K. Wang, The origin of chemical inhomogeneity in lead-free potassium sodium niobate ceramic: competitive chemical reaction during solid-state synthesis. Acta Mater. 211, 116833 (2021)

H. Wang, J. Wu, Evolution of phase structure, microstructure, and electrical properties in (1 – x)(K,na)NbO3–x(Bi,na,Li,Ba)ZrO3 lead-free ceramics. J. Alloys Compd. 628, 329 (2015)

F. Li, D. Lin, Z. Chen, Z. Cheng, J. Wang, C. Li, Z. Xu, Q. Huang, X. Liao, L.Q. Chen, T.R. Shrout, S. Zhang, Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 17, 349 (2018)

X. Lv, N. Zhang, Y. Ma, X. Zhang, J. Wu, Coupling effects of the A-site ions on high-performance potassium sodium niobate ceramics. J. Mater. Sci. Technol. 130, 198 (2022)

K.-T. Lee, D.-H. Kim, S.-H. Cho, J.-S. Kim, J. Ryu, C.-W. Ahn, T.-H. Lee, G.-H. Kim, S. Nahm, Pseudocubic-based polymorphic phase boundary structures and their effect on the piezoelectric properties of (Li,na,K)(Nb,Sb)O3-SrZrO3 lead-free ceramics. J. Alloys Compd. 784, 1334 (2019)

Z. Wang, D. Xiao, J. Wu, M. Xiao, F. Li, J. Zhu, D. Damjanovic, New lead-free (1-x)(K0.5Na0.5)NbO3-x(Bi0.5Na0.5)ZrO3 ceramics with high piezoelectricity. J. Am. Ceram. Soc. 97, 688 (2014)

Q. Gou, J. Zhu, J. Wu, F. Li, L. Jiang, D. Xiao, Microstructure and electrical properties of (1−x)K0.5Na0.5NbO3–xBi0.5Na0.5Zr0.85Sn0.15O3 lead-free ceramics. J. Alloys Compd. 730, 311 (2018)

X. Wang, J. Wu, X. Lv, H. Tao, X. Cheng, T. Zheng, B. Zhang, D. Xiao, J. Zhu, Phase structure, piezoelectric properties, and stability of new K0.48Na0.52NbO3–Bi0.5Ag0.5ZrO3 lead-free ceramics. J. Mater. Sci.: Mater. Electron. 25, 3219 (2014)

Q. Gou, D.-Q. Xiao, B. Wu, M. Xiao, S.-S. Feng, D.-D. Ma Zhao, J.-G. Wu, J.-G. Zhu, New (1-x)K0.5Na0.5NbO3–x(0.15Bi0.5Na0.5TiO3–0.85Bi0.5Na0.5ZrO3) ternary lead-free ceramics: microstructure and electrical properties. RSC Adv. 5, 30660 (2015)

Funding

Authors gratefully acknowledge the supports of Anhui Huachen Testing Technology Research Institute Co., Ltd (Study on the modification of high-performance piezoelectric ceramics), Provincial Quality Engineering Project of Colleges and Universities of Anhui Province (Grant No. 2019jyxm1161), National grade Undergraduate Innovation and Entrepreneurship Training Project in 2022 (Grant Nos. 202211059050 and 202211059069), Natural Science Foundation of Anhui Provincial Department of Education (Grant No. 2022AH010096), and Graduate innovation and entrepreneurship project of Hefei University in 2021 (Grant No. 21YCXL47).

Author information

Authors and Affiliations

Contributions

RZ performed the experiment and the data analyses and wrote the manuscript. QY contributed to the conception of the study. HC contributed to data curation. XZ contributed to data curation. FL contributed to data curation. YZ contributed to data curation. SW contributed significantly to analysis and manuscript preparation. ZZ contributed significantly to analysis and manuscript preparation. KH helped perform the analysis with constructive discussions. QZ helped perform the analysis with constructive discussions.

Corresponding author

Ethics declarations

Competing interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zheng, R., Yin, Q., Cheng, H. et al. The effect of (Bi0.5Li0.5)0.9Sr0.1ZrO3 substitution on the construction of polymorphic phase boundary and high curie temperature of K0.45Na0.55NbO3 piezoelectric ceramics. J Mater Sci: Mater Electron 34, 954 (2023). https://doi.org/10.1007/s10854-023-10305-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10305-0