Abstract

The harvesting of renewable energy storage has prompted extensive study on the energy storage devices, chiefly batteries and supercapacitors. Electrodes made up of nano-architecture arrays are promising candidate to strengthen the electrochemical performance of the energy storage devices. In this work, nano-sized Co3O4 materials have been prepared by facile coprecipitate technique. The materials were characterized by XRD, FTIR, SEM, EDAX, HR-TEM and XPS. The TEM studies confirmed the existence of nano-rods of length ranges from 50 to 160 nm. The electrochemical studies were carried out using three-electrode system. The Co3O4 electrode material exhibited prominent specific capacitance of 373.84 F g−1 at the current density of 1.5 A g−1 with superior cyclic stability of 92% after 1000 cycles. The Co3O4 nanorods are attributed to high surface to volume ratio which results in more provisions for active sites and in turn enhance the redox reactions. Also the EIS studies reveal the diffusive charge transfer mechanism that enhances the accumulation of charges. The results imply that Co3O4 nanoparticles would be a promising material for electrodes in supercapacitors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the past two decades, there is a huge increase in use of electrical energy storage devices such as mobile phones, laptops, uninterruptible power supplies, portable electrical and electronic devices [1, 2]. In this regard, lot of interest has been aroused in developing the energy storage devices and high power density electrochemical capacitors. Meanwhile the supercapacitor is considered as suitable device, as they possess high power density, fast charging rate and outstanding cyclic behavior [3]. The foremost part of the supercapacitor is the electrode material which greatly influences its performance of energy storage. Among the electrode materials, Co3O4 is found to be one of the better alternate material due to high surface area, good conductivity, redox property, controllable size and shape, structural identities and charge storage mechanism. The promising electrode materials for supercapacitors are carbon materials [4], transition metal oxides [5] polymers (conductive) [6], and their derivatives [7].

A recent report in the literature reveals better electrochemical performance of layered Co3O4. However, such materials exhibit lower capacitance value and rate capability due to the short-range structures which suffer internal resistance and structural modification/degradation under rigorous reaction conditions. Among them cobalt oxide (Co3O4) pays much focus due to its high theoretical capacity (890 mAh g−1), high specific capacitance [8], less energy band gap, cheaper and more abundance in nature [9, 10].

As reported earlier, Co3O4 nanoparticles with different morphology were synthesized by many methods such as micro wave route method [11], polymer combustion [12], sol–gel method [13], hydro-thermal synthesis [14] and spray pyrolysis [15]. Therefore, an efficient strategy to achieve high energy density without sacrificing the power density is to develop the composite materials that combine high conductivity of carbon materials with high specific capacitance of metal oxides. Then, structure–property relationships of the cobalt oxide-based nanomaterials and current challenges in both supercapacitor and their applications in electrochemical energy devices are proposed, and an outlook on future research of this family of materials in electrochemical energy applications is brought forward. This understanding on the relationships of synthesis-nano/microstructure-property-performance of cobalt oxide-based nanomaterials is expected to lay a good foundation for pushing this promising class of materials to the practical application in energy conversion and storage devices and to provide a good reference for the readers in the fields of materials, chemistry, sustainable energy, and nanotechnology.

In the present work, Co3O4 nanoparticles were prepared by facile, inexpensive coprecipitate technique. The morphological, structural, elemental studies and its electrochemical behavior were carried out. The Co3O4 exhibited a better specific capacitance of 373.84 F g−1 and good stability of retention even after 1000 cycles. Due to the unique properties of these core–shell nanoarrays, such as high surface areas, crystallinity, and good conductivity and direct growth on conductive substrates, they have potential applications in chemical sensing, lithium-ion batteries, electrochemical or photocatalysis, electrochromic devices, field emission, and energy conversion storage.

2 Experimental details

2.1 Materials

All the chemicals with AR grade (Sigma-Aldrich) only were used for synthesis of the samples without any further purification.

2.2 Material synthesis

The dataset covers a supercapacitors of Co3O4 nanorods that are prepared through different synthesis methods and doped with various metals [16,17,18,19]. The experimental data already done by many researchers and it is listed in Table 1 [20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49]. In order to prepare the nanostructured cobalt oxide particles, 5.86 gm of cobalt nitrate hexa hydrate (Co(No3)2⋅6H2O) was dissolved in 100 ml of deionized water at 27 °C for 30 min. Subsequently 1.6 gm of sodium hydroxide (NaOH) was dissolved in 100 ml of deionized water at 27 °C for 30 min. Later the sodium hydroxide solution was added in drop-wise to the cobalt nitrate solution with continuous stirring for 120 min. Consequently a dark greenish blue precipitate was obtained. Later the precipitate was allowed to settled, filtered and washed several times with water and ethanol. The filtered samples are kept in hot air oven at 110 °C to remove water molecules for 8 h. The obtained samples were annealed using muffle furnace at temperature 600 °C for 3 h and grounded.

2.3 Electrochemical studies

To analyse the supercapattery performances, the three-electrode cell was constructed by using Co3O4 electrode (coated on nickel foam) as working electrode, Ag–Agcl as reference electrode and platinum coil with few turns as counter electrode. The working electrode was constructed by uniformly mixing 70 wt% of Co3O4, 20 wt% of acetylene black and 10 wt% of polyvinylidene fluoride with two drops of N-methyl-2-pyrolidone (NMP) as binder. The obtained slurry was collected and coated uniformly on a nickel foam substrate of 1 × 1 cm2. The coated Ni foam was heated in oven at 90 °C for 10 h [50]. The active mass of the coated samples was found as 2 mg cm−2. The cyclic voltammetry (CV), galvanostatic charge–discharge studies (GCD) and electrochemical impedance spectroscopy (EIS) were carried out in 1 M KOH using the workstation (PGSTAT204- Metroohmautolab).

2.4 Characterization techniques

The XRD analysis of the prepared samples was carried out by using the Bruker AXS D8 Advance instrument diffractometer with CuKα radiation. The structural morphology and the elemental analysis were done by using field emission scanning electron microscopy (FESEM; GEMINI SUPRA 55VP Zeiss). The FTIR studies were carried out using Nicolet 5DX FTIR spectrometer. The TEM studies and SAED were analysed using HETEM: joel/JEM 2100. The electrochemical performance of the prepared sample was carried out on a three-electrode cell which was connected to a potentiostat (PGSTAT204- Metroohmautolab).

3 Result and discussion

3.1 Structural and morphological characterizations

The structural and morphological studies of Co3O4 nano-particles were carried out by XRD, FTIR, SEM and TEM analysis.

The Powder XRD pattern of cobalt oxide nanoparticles is shown in Fig. 1. It is evident that, the diffraction peaks appeared are correspond to (111), (220), (311), (222), (400), (511) and (440) planes. These reflections from the Co3O4 nano-particles matched with the stable spinel cubic structured crystalline (JCPDF-00-042-1467) [51, 52]. The average crystallite size of the Co3O4 was found using the Scherrer’s formula as (Eq. 1).

where λ is the wavelength of the X-ray source (1.54 Å), θ is the half of the Bragg angle (in radians), K is the shape factor (for spherical shape, K = 0. 9), and β is the full width at half maximum (FWHM) obtained from diffraction peak. Using Eq. (1), the average crystallite size of Co3O4 particles was found as 24 nm.

Figure 2 shows the FTIR spectra of Co3O4 nanoparticles. The absorption peaks at 575 cm−1 and 666 cm−1 are attributed to Co3+–O and Co2+–O vibrations of Co3O4 respectively [53]. Here the Co3+ lies in the tetrahedral sites and the Co2+ lies in the octahedral sites, herewith confirms the formation of the spinel cubic Co3O4 nanoparticles. The peaks at 1635 cm−1 and 3426 cm.−1 are due to the cause of amalgamation of the water molecules from humidity [54, 55]

The XPS studies were carried out to evaluate the elemental composition and electronic states of Co3O4 nano-materials. Figure 3a represents the survey spectrum of Co3O4 evaluated in the range of 0–1000 eV. Three peaks can be assigned to Co 2p, O 1s and C 1s, respectively. From Fig. 3a, the binding energies of the C 1s spectrum at 284.73, 286.37 and 288.75 eV correspond to C–C/ C=C, C–N, and C = O, respectively [56,57,58]. Figure 3b shows XPS resolution peak of O 1s. Furthermore the 1 s peak is de-convoluted into two peaks of binding energy 530.18 eV and 531.18 eV, attributed to Co–O bonds and the hydroxyl groups, respectively [59, 60]. Figure 3c depicts the high-resolution spectrum of Co 2p consists of two sharp peaks corresponding to 780.3 eV and 795.07 eV. The two main broad peaks correspond to 2 p1/2 and 2p3/2 spin orbit lines along with two shakeup satellite peaks at peaks at 790 eV and 804.3 eV. The energy gap between the twin peaks is 15.04 eV which confirms the existence of Co2+ and Co3+ oxidation states. This is in good agreement with the FTIR studies and previously reported Co3O4 materials [61].

The surface morphology of the Co3O4 nanoparticles was investigated by SEM analysis. The SEM images of Co3O4 nanoparticles are shown in Fig. 4a, b and c. The SEM images showed irregular plates-shaped grains associated with array of nanorods of diameter range from 40 to 45 nm. The structures are well defined and separated from one another with clear distinct boundaries [62, 63] and few agglomeration caused due to nucleation and crystal growth when annealed at 600 °C [64, 65]. These nanorods play a vital role in the electrochemical performance.

Energy-dispersive X-ray analysis (EDAX) was performed to analyze the elemental mapping of the nano-materials and it is depicted in Fig. 5 It shows ‘Co’ and ‘O’ peaks alone without any additional impurities. The percentage amount of ‘Co’ and ‘O’ were found to be 64.31 wt% and 35.69 wt%, respectively. The EDAX analysis confirms the presence of cobalt and oxygen in the prepared Co3O4 nanoparticles.

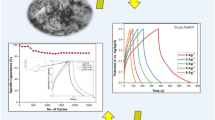

To observe the nano-structure and crystalline nature of the as-prepared materials transmission electron microscopy (TEM) studies were carried. The TEM morphology of the samples is depicted in Fig. 6a, b, c which clearly shows a mixture of irregular shaped Co3O4 nanoparticles and a large portion of Co3O4 nano-rods of length ranges from 50 to 160 nm. The average crystallite size is found as 43.41 nm. Figure 6d shows the TEM profile of single grain in Co3O4 nanoparticles (see Fig. 6). Here all atomic planes are arranged in uniform manner with the d-spacing of 0.246 nm. The SAED pattern of Co3O4 is shown in Fig. 7. The SAED pattern shows bright spots with diffused concentric circular rings indicating polycrystalline nature of Co3O4 nanoparticles [66]. The Co3O4 nano-rods are attributed to high surface to volume ratio which results in more provisions for active sites and in turn enhance the redox reactions for better electrochemical performances [67]. The SAED pattern showed a typical ring structure characteristic for polycrystalline in nature of the materials and agrees well with the spinel structure of Co3O4.

3.2 Electrochemical performance

3.2.1 Cyclic voltammetry studies (CV)

Initially, the electrochemical activity of the prepared Co3O4 sample was investigated by using cyclic voltammetry studies carried out in the presence of 1 M of KOH in a three-electrode system. The specific capacitance was calculated from the following equation [67].

where A is the integral area of the CV loop, ΔV is the sweep potential window, v is the scan rate and ‘m’ is the mass of the electrode materials. The CV profiles recorded at the scan rates of 5 mV s−1, 10 mV s−1, 20 mV s−1, 50 mV s−1 and 100 mV s−1 respectively are shown in Fig. 8. It is clearly seen that all the curves showed a pair of redox peaks conforming the pseudocapacitive behavior. The anodic peak occurs at 0.5 V is due to the transition of Co2+ to Co3+ and the cathodic peak appears at 0.15 V is due to the reduction to Co3+ with the separation of peak potential of 0.35 V at the scan rate of 50 mV s−1. As the scan rate increases from 5 mV s−1 to 100 mV s−1 the reduction peaks shifts towards the low negative potential and the oxidation peaks are shift towards the higher positive potential, this may occurs due to various resistive phenomena occurring at the interface of the electrode/electrolyte [30, 67,68,69]. Also it is observed that the CV curves are symmetric in nature in the entire scan rate showing that the prepared material possesses good rate capability which is the basic need for practical applications in supercapacitor. The possible reaction mechanism for the redox peaks is shown below [66, 70, 71]:

3.2.2 Galvanostatic charge–discharge studies (GCD)

Furthermore, the galvanostatic charge–discharge (GCD) studies were carried out at different current densities. The specific capacitance of the Co3O4 electrode was calculated from the GCD profiles using the following formula [73]

where, C (F g−1) is the specific capacitance, I is the discharge current (A), m(g) is the mass of the active materials, (and discharging process, and (dV) is the potential window. Factor of 2 was used because the series capacitance was formed in a two-electrode system.

The energy density was expressed for the following equation as [72]

where C is the specific capacitance calculated from the charge–discharge curves. Figure 9 shows the GCD curves at current densities of 1.5 A g−1, 3 A g−1, 6 A g−1, and 9 A g−1 in the potential window of 0 V to 0.525 V. All the curves show almost symmetric mirror images representing that the Faradaic reactions are reversible in nature. The plateau region is observed in the potential range of 0.35 V–0.525 V which represents that the Faradaic process behaves as a typical battery-type electrode [73] (see Fig. 9). The specific capacitance at the current densities of 1.5 A g−1, 3 A g−1, 6 A g−1, and 9 A g−1, respectively, are found as 373.84F g−1, 317.37F g−1, 295.49F g−1 and 238.83F g−1 respectively. Figure 10 shows the better visualization of dependence of specific capacitance with respect to current density. It is seen that the specific capacity decreases with the increase in current density. At extreme current there was a poor usage of active material during the rapid charge–discharge phenomena. Despite this, the Co3O4 possesses high specific capacity of 373.84 F g−1 at 1.5 A g−1. Also it is seen that even at a higher current density of 9 A g−1 the Co3O4 electrode exhibits good specific capacity of 127.77 F g−1 and hence implying the Co3O4 electrode as a potential electrode for supercapacitor applications. The behavior of capacitance retention of Co3O4 electrode is shown in Fig. 11. It showed a better stability of 92% retention even after 1000 cycles.

3.2.3 Electrochemical impedance spectroscopy studies (EIS)

The electrochemical impedance spectroscopy (EIS) is one of the techniques to investigate the electrochemical behavior of the materials. The EIS study was carried out on Co3O4 electrode in the presence of 1 M of KOH and the obtained Nyquist plot is shown in Fig. 12. The plot composed of two parts: a depressed semi-circle in the high frequency region and the other is an inclined straight line (Warburg element) in the low frequency region. The equivalent circuit of the obtained Nyquist plot is shown in Fig. 12 (insight). The circuit consists of electrode–electrolyte resistance Rs obtained from the intersection of the EIS curve with the real axis, charge transfer resistance of the faradic reaction Rct, constant phase element Cpe and the Warburg element W [74, 75]. Using the fit and simulation technique, the value of Rs is obtained as 1.57 Ω. The inclination of Warburg element at slightly less than 45° with the real axis indicates the existence of ionic diffusion controlled faradaic reaction [76,77,78,79]. From Table 2, it was found that as prepared Co3O4 nanorod arrays showed a better specific capacitance and suitable for the electrode in supercapacitor applications. The current study suggests that this process has promise to be better electrode materials for supercapacitor applications.

4 Conclusion

In summary, an array of Co3O4 nanorods was synthesized using facile coprecipitate method. The X-ray diffraction analysis, confirmed the formation of spinel cubic Co3O4 nanoparticles and the mean crystallite size, was calculated as 24 nm. The FTIR, EDAX and XPS studies confirm the presence of Co and O species. The TEM image showed an array of nano-rods of length ranges from 50 to 160 nm. It is observed that the Co3O4 electrode materials exhibited superior specific capacitance of 373.84 F g−1 at the current density of 1.5 A g−1 with excellent capacity retention of 92% after 1000 cycles. The simple preparation method and the excellent electrochemical performance provide this Co3O4 material as a promising electrode for practical supercapacitor applications.

Data availability

The data that support the findings of this study are available from the corresponding author, Dr. R. Mariappan, upon reasonable request.

References

D. Guo, X. Song, F. Li, L. Tan, H. Ma, L. Zhang, Y. Zhao, Oriented synthesis of Co3O4 core-shell microspheres for high-performance asymmetric supercapacitor. Colloids Surf., A 546, 1–8 (2018)

X. Chen, C. Li, M. Grätzel, R. Kostecki, S.S. Mao, Nanomaterials for renewable energy production and storage. Chem. Soc. Rev. 41(23), 7909–7937 (2012)

P. Zhang, B.Y. Guan, L. Yu, X.W. Lou, Formation of double-shelled zinc–cobalt sulfide dodecahedral cages from bimetallic zeoliticimidazolate frameworks for hybrid supercapacitors. AngewandteChemie 129(25), 7247–7251 (2017)

Y. Zhu, S. Murali, M.D. Stoller, K.J. Ganesh, W. Cai, P.J. Ferreira, R.S. Ruoff, Carbon-based supercapacitors produced by activation of graphene. Science 332(6037), 1537–1541 (2011)

P. Simon, Y. Gogotsi, Materials for electrochemical capacitors. Nat. Mater. 7(11), 845–854 (2008)

W. Li, H. Lu, N. Zhang, M. Ma, Enhancing the properties of conductive polymer hydrogels by freeze–thaw cycles for high-performance flexible supercapacitors. ACS Appl. Mater. Interfaces 9(23), 20142–20149 (2017)

C. Zhou, Y. Zhang, Y. Li, J. Liu, Construction of high-capacitance 3D CoO@ polypyrrole nanowire array electrode for aqueous asymmetric supercapacitor. Nano Lett. 13(5), 2078–2085 (2013)

B. Wang, Y. Wang, J. Park, H. Ahn, G. Wang, In situ synthesis of Co3O4/graphenenanocomposite material for lithium-ion batteries and supercapacitors with high capacity and supercapacitance. J. Alloy. Compd. 509(29), 7778–7783 (2011)

S. Gupta, S.B. Carrizosa, Graphene–inorganic hybrids with cobalt oxide polymorphs for electrochemical energy systems and electrocatalysis: Synthesis, processing and properties. J. Electron. Mater. 44(11), 4492–4509 (2015)

X. Xie, W. Shen, Morphology control of cobalt oxide nanocrystals for promoting their catalytic performance. Nanoscale 1(1), 50–60 (2009)

R. Al-Tuwirqi, A.A. Al-Ghamdi, N.A. Aal, A. Umar, W.E. Mahmoud, Facile synthesis and optical properties of Co3O4 nanostructures by the microwave route. Superlattices Microstruct. 49(4), 416–421 (2011)

J. Jiu, Y. Ge, X. Li, L. Nie, Preparation of Co3O4 nanoparticles by a polymer combustion route. Mater. Lett. 54(4), 260–263 (2002)

A.B. Vennela, D. Mangalaraj, N. Muthukumarasamy, S. Agilan, K.V. Hemalatha, Structural and optical properties of Co3O4 nanoparticles prepared by sol-gel technique for photocatalytic application. Int. J. Electrochem. Sci 14(4), 3535–3552 (2019)

Z. Liu, C. Ma, Q. Cai, T. Hong, K. Guo, L. Yan, Promising cobalt oxide and cobalt oxide/silver photocathodes for photoelectrochemical water splitting. Sol. Energy Mater. Sol. Cells 161, 46–51 (2017)

A. El Bachiri, L. Soussi, O. Karzazi, A. Louardi, A. Rmili, H. Erguig, B. El Idrissi, Electrochromic and photoluminescence properties of cobalt oxide thin films prepared by spray pyrolysis. Spectrosc. Lett. 52(1), 66–73 (2019)

Y. Zhang, X. Xu, Machine learning optical band gaps of doped-ZnO films. Optik 217, 164808 (2020)

Y. Zhang, X. Xu, Machine learning band gaps of doped-TiO2 photocatalysts from structural and morphological parameters. ACS Omega 5(25), 15344–15352 (2020)

Y. Zhang, X. Xu, Machine learning properties of electrolyte additives: A focus on redox potentials. Ind. Eng. Chem. Res. 60(1), 343–354 (2020)

Y. Zhang, X. Xu, Predicting the superconducting transition temperature and relative resistance ratio in YBa2Cu3O7 films. Physica C 592, 1353998 (2022)

E. Duraisamy, S. Archana, A. Prasath, P. Elumalai, High capacity and high stability lithium-ion battery using nanoSn/SnS-decorated carbon leaf anode and LiCoO2 cathode for consumer electronics. ElectrochimicaActa 338, 135863 (2020)

D. Cao, J. Chao, L. Sun, G. Wang, Catalytic behavior of Co3O4 in electroreduction of H2O2. J. Power Sour. 179(1), 87–91 (2008)

H.A. Alalwan, D.M. Cwiertny, V.H. Grassian, Co3O4 nanoparticles as oxygen carriers for chemical looping combustion: A materials characterization approach to understanding oxygen carrier performance. Chem. Eng. J. 319, 279–287 (2017)

R. Bhargava, S. Khan, N. Ahmad, M.M.N. Ansari, Investigation of structural, optical and electrical properties of Co3O4 nanoparticles. AIP Conf. Proc. 1953, 030034 (2018)

S.K. Meher, G.R. Rao, Ultralayered Co3O4 for high-performance supercapacitor applications. J. Phys. Chem. C 115(31), 15646–15654 (2011)

S. Zallouz, B. Rety, L. Vidal, J.M. Le Meins, C. Mate Gihimbeu, Co3O4 nanoparticles embedded in mesoporous carbon for supercapacitor applications. ACS Appl. Nano Mater. 4(5), 5022–5037 (2021)

I. Rabani, J. Yoo, H.S. Kim, S. Hussain, K. Karuppasamy, Y.S. Seo, Highly dispersive Co 3 O 4 nanoparticles incorporated into a cellulose nanofiber for a high-performance flexible supercapacitor. Nanoscale 13(1), 355–370 (2021)

Y. Fan, H. Chen, Y. Li, D. Cui, Z. Fan, C. Xue, PANI- Co3O4 with excellent specific capacitance as an electrode for supercapacitors. Ceram. Int. 47(6), 8433–8440 (2021)

G. Maheshwaran, G. Seethalakshmi, V.K. Devi, L.M. VenkataKrishna, M.R. Prabhu, M.K. Kumar, S. Sudhahar, Synergistic effect of Cr2O3 and Co3O4 nanocomposite electrode for high performance supercapacitor applications. Curr. Appl. Phys. 36, 63–70 (2022)

C.V. Niveditha, R. Aswini, M.J. Fatima, R. Ramanarayan, N. Pullanjiyot, S. Swaminathan, Feather like highly active Co3O4 electrode for supercapacitor application: a potentiodynamic approach. Mater. Res. Express 5(6), 065501 (2018)

H. Xu, L. Gao, Q. Zhang, J. Li, J. Diwu, X. Chou, C. Xue, Preparation method of Co3O4 nanoparticles using degreasing cotton and their electrochemical performances in supercapacitors. J. Nanomater. 2014, 1 (2014)

R. Kumar, A. Soam, V. Sahajwalla, Carbon coated cobalt oxide (CC- Co3O4) as electrode material for supercapacitor applications. Materials Advances 2(9), 2918–2923 (2021)

T. Geng, L. Zhang, H. Wang, K. Zhang, X. Zhou, Facile synthesis of porous Co3O4 nanoplates for supercapacitor applications. Bull. Mater. Sci. 38, 1171–1175 (2015)

X. Wang, J. Fu, Q. Wang, Z. Dong, X. Wang, A. Hu, S. Yang, Preparation and electrochemical properties of Co3O4 supercapacitor electrode materials. Curr. Comput.-Aided Drug Des. 10(9), 720 (2020)

S. Ramesh, K. Karuppasamy, H.S. Kim, J.H. Kim, Hierarchical Flowerlike 3D nanostructure of Co3O4@ MnO2/N-doped Graphene oxide (NGO) hybrid composite for a high-performance supercapacitor. Sci. Rep. 8(1), 16543 (2018)

M. Mirzaeian, N. Akhanova, M. Gabdullin, Z. Kalkozova, A. Tulegenova, S. Nurbolat, K. Abdullin, Improvement of the pseudocapacitive performance of cobalt oxide-based electrodes for electrochemical capacitors. Energies 13(19), 5228 (2020)

S.M. Jogade, D.S. Sutrave, Electrochemical performance of Mn doped Co3O4 supercapacitor: effect of aqueous electrolytes. J. Mater. Sci. Eng. 6, 351 (2017)

C. Guo, M. Yin, C. Wu, J. Li, C. Sun, C. Jia, Y. Wei, Highly stable gully-network Co3O4 nanowire arrays as battery-type electrode for outstanding supercapacitor performance. Front. Chem. 6, 636 (2018)

L. Tao, L. Shengjun, Z. Bowen, W. Bei, N. Dayong, C. Zeng, Z. Weifeng, Supercapacitor electrode with a homogeneously Co3O4-coated multiwalled carbon nanotube for a high capacitance. Nanoscale Res. Lett. 10(1), 1–7 (2015)

C. Xiang, M. Li, M. Zhi, A. Manivannan, N. Wu, A reduced graphene oxide/ Co3O4 composite for supercapacitor electrode. J. Power Sour. 226, 65–70 (2013)

H. Liu, X. Gou, Y. Wang, X. Du, C. Quan, T. Qi, Cauliflower-like Co3O4/three-dimensional graphene composite for high performance supercapacitor applications. J. Nanomater. 2015, 11–11 (2015)

M. Kalyani, R.N. Emerson, High-performance supercapacitor cobalt oxide thin films by the influence of copper substrate. Int. J. Pure Appl. Phys. 14, 115–124 (2018)

F. Zhang, L. Hao, L. Zhang, X. Zhang, Solid-state thermolysis preparation of Co3O4 nano/micro superstructures from metal-organic framework for supercapacitors. Int. J. Electrochem. Sci 6, 2943–2954 (2011)

Z. Yu, Z. Cheng, Z. Tai, X. Wang, C.M. Subramaniyam, C. Fang, S. Dou, Tuning the morphology of Co3O4 on Ni foam for supercapacitor application. RSC Adv. 6(51), 45783–45790 (2016)

C. Guan, X. Qian, X. Wang, Y. Cao, Q. Zhang, A. Li, J. Wang, Atomic layer deposition of Co3O4 on carbon nanotubes/carbon cloth for high-capacitance and ultrastable supercapacitor electrode. Nanotechnology 26(9), 094001 (2015)

R.B. Rakhi, W. Chen, M.N. Hedhili, D. Cha, H.N. Alshareef, Enhanced rate performance of mesoporous Co3O4 nanosheet supercapacitor electrodes by hydrous RuO2 nanoparticle decoration. ACS Appl. Mater. Interfaces 6(6), 4196–4206 (2014)

K. Chopngam, M. Luengchavanon, M. Khangkhamano, K. Chetpattananondh, W. Limbut, Coating activated carbon from coconut shells with Co3O4/CeO2 for high-performance supercapacitor applications: an experimental study. Bio Resources 16(4), 8022–8037 (2021)

Q. Hu, Z. Gu, X. Zheng, X. Zhang, Three-dimensional Co3O4@NiO hierarchical nanowire arrays for solid-state symmetric supercapacitor with enhanced electrochemical performances. Chem. Eng. J. 304, 223–231 (2016)

M. Wang, J. Zhang, X. Yi, B. Liu, X. Zhao, X. Liu, High-performance asymmetric supercapacitor made of NiMoO4 nanorods@Co3O4 on a cellulose-based carbon aerogel. Beilstein J. Nanotechnol. 11(1), 240–251 (2020)

Z. Wang, S. Pan, B. Wang, J. Qi, L. Tang, L. Liu, Asymmetric supercapacitors based on Co3O4@ MnO2@ PPy porous pattern core-shell structure cathode materials. J. Electrochem. Sci. Technol. 12(3), 346–357 (2021)

R. Miao, B. Tao, F. Miao, Y. Zang, C. Shi, L. Zhu, P.K. Chu, Co3O4 and Co (OH)2 loaded graphene on Ni foam for high-performance supercapacitor electrode. Ionics 25, 1783–1792 (2019)

C.P. Lee, B.T. Murti, P.K. Yang, F. Rossi, C. Carraro, R. Maboudian, Cobalt oxide-decorated silicon carbide nano-tree array electrode for micro-supercapacitor application. Materials 14(16), 4514 (2021)

M. Khalaj, A. Sedghi, H.N. Miankushki, S.Z. Golkhatmi, Synthesis of novel graphene/Co3O4/polypyrrole ternary nanocomposites as electrochemically enhanced supercapacitor electrodes. Energy 188, 116088 (2019)

R. Pai, V. Kalra, High performance aqueous asymmetric supercapacitor based on iron oxide anode and cobalt oxide cathode. J. Mater. Res. 33(9), 1199–1210 (2018)

N. Padmanathan, S. Selladurai, K.M. Razeeb, Ultra-fast rate capability of a symmetric supercapacitor with a hierarchical Co3O4 nanowire/nanoflower hybrid structure in non-aqueous electrolyte. RSC Adv. 5(17), 12700–12709 (2015)

W. Jia, J. Li, Z. Lu, Y. Juan, Y. Jiang, Synthesis of Honeycomb-like Co3O4 Nanosheets with Excellent Supercapacitive Performance by morphological controlling derived from the alkaline source ratio. Materials 11(9), 1560 (2018)

Z. Yin, K. Allado, A.T. Sheardy, Z. Ji, D. Arvapalli, M. Liu, J. Wei, Mingled MnO2 and Co3O4 Binary nanostructures on well-aligned electrospun carbon nanofibers for nonenzymatic glucose oxidation and sensing. Cryst. Growth Des. 21(3), 1527–1539 (2021)

L. Xing, Y. Dong, F. Hu, X. Wu, A. Umar, Co3O4 nanowire@ NiO nanosheet arrays for high performance asymmetric supercapacitors. Dalton Trans. 47(16), 5687–5694 (2018)

N.O.M. Dewi, Y. Yulizar, D.O.B. Apriandanu, Green synthesis of Co3O4 nanoparticles using Euphorbia heterophylla L. leaves extract: characterization and photocatalytic activity. IOP Conf. Series: Mater. Sci. Eng. 509, 012105 (2019)

S. Nallusamy, K. Sujatha, Experimental analysis of nanoparticles with cobalt oxide synthesized by coprecipitation method on electrochemical biosensor using FTIR and TEM. Mater. Today Proc. 37, 728–732 (2021)

T.F. Yi, L.Y. Qiu, J. Mei, S.Y. Qi, P. Cui, S. Luo, Y.B. He, Porous spherical NiO@NiMoO4@PPy nanoarchitectures as advanced electrochemical pseudocapacitor materials. Sci. Bull. 65(7), 546–556 (2020)

T.F. Yi, L. Shi, X. Han, F. Wang, Y. Zhu, Y. Xie, Approaching high-performance lithium storage materials by constructing hierarchical CoNiO2@CeO2 nanosheets. Energy Environ. Mater. 4(4), 586–595 (2021)

T.T. Wei, P. Peng, Y.R. Ji, Y.R. Zhu, T.F. Yi, Y. Xie, Rational construction and decoration of Li5Cr7Ti6O25@C nanofibers as stable lithium storage materials. J. Energy Chem. 71, 400–410 (2022)

S.Y. Zhang, T.T. Li, H.L. Zhu, Y.Q. Zheng, Co3O4 polyhedrons with enhanced electric conductivity as efficient water oxidation electrocatalysts in alkaline medium. J. Mater. Sci. 53(6), 4323–4333 (2018)

X.M. Yue, Z.J. Liu, C.C. Xiao, M. Ye, Z.P. Ge, C. Peng, S.Q. Zhang, Synthesis of Co3O4/reduced graphene oxide by one step-hydrothermal and calcination method for high-performance supercapacitors. Ionics 27(1), 339–349 (2021)

M. Cheng, S. Duan, H. Fan, X. Su, Y. Cui, R. Wang, Core@ shell CoO@Co3O4 nanocrystals assembling mesoporous microspheres for high performance asymmetric supercapacitors. Chem. Eng. J. 327, 100–108 (2017)

P. Wen, P. Gong, J. Sun, J. Wang, S. Yang, Design and synthesis of Ni-MOF/CNT composites and rGO/carbon nitride composites for an asymmetric supercapacitor with high energy and power density. J. Mater. Chem. A 3(26), 13874–13883 (2015)

A. Hosseinian, A. Amjad, R. Hosseinzadeh-Khanmiri, E. Ghorbani-Kalhor, M. Babazadeh, E. Vessally, Nanocomposite of ZIF-67 metal–organic framework with reduced graphene oxide nanosheets for high-performance supercapacitor applications. J. Mater. Sci.: Mater. Electron. 28(23), 18040–18048 (2017)

E.U. Ikhuoria, S.O. Omorogbe, B.T. Sone, M. Maaza, Bioinspired shape controlled antiferromagnetic Co3O4 with prism like-anchored octahedron morphology: A facile green synthesis using Manihot esculenta Crantz extract. Sci. Technol. Mater. 30(2), 92–98 (2018)

J. Wang, X. Zhang, Q. Wei, H. Lv, Y. Tian, Z. Tong, L. Mai, 3D self-supported nanopine forest-like Co3O4@CoMoO4 core–shell architectures for high-energy solid state supercapacitors. Nano Energy 19, 222–233 (2016)

R. Ahmed, G. Nabi, Enhanced electrochemical performance of Cr-doped NiO nanorods for supercapacitor application. Journal of Energy Storage 33, 102115 (2021)

D.Y. Lee, D.V. Shinde, E.K. Kim, W. Lee, I.W. Oh, N.K. Shrestha, S.H. Han, Supercapacitive property of metal–organic-frameworks with different pore dimensions and morphology. Microporous Mesoporous Mater. 171, 53–57 (2013)

Y. Wang, Y. Lei, J. Li, L. Gu, H. Yuan, D. Xiao, Synthesis of 3D-nanonet hollow structured Co3O4 for high capacity supercapacitor. ACS Appl. Mater. Interfaces 6(9), 6739–6747 (2014)

F.B. Ajdari, E. Kowsari, A. Ehsani, Ternary nanocomposites of conductive polymer/functionalized GO/MOFs: synthesis, characterization and electrochemical performance as effective electrode materials in pseudocapacitors. J. Solid State Chem. 265, 155–166 (2018)

T. Meng, P.P. Ma, J.L. Chang, Z.H. Wang, T.Z. Ren, The electrochemical capacitive behaviors of NiO nanoparticles. ElectrochimicaActa 125, 586–592 (2014)

Y. Yin, Y. Xu, Y. Zhou, Y. Yan, K. Zhan, J. Yang, B. Zhao, Millimeter-long vertically aligned carbon-nanotube-supported Co3O4 composite electrode for high-performance asymmetric supercapacitor. ChemElectroChem 5(10), 1394–1400 (2018)

E. Duraisamy, H.T. Das, A.S. Sharma, P. Elumalai, Supercapacitor and photocatalytic performances of hydrothermally-derived Co3O4/CoO@ carbon nanocomposite. New J. Chem 42(8), 6114–6124 (2018)

T. Zhu, J.S. Chen, X.W. Lou, Shape-controlled synthesis of porous Co3O4 nanostructures for application in supercapacitors. J. Mater. Chem. 20(33), 7015–7020 (2010)

W. Deng, W. Lan, Y. Sun, Q. Su, E. Xie, Porous CoO nanostructures grown on three-dimension graphene foams for supercapacitors electrodes. Appl. Surf. Sci. 305, 433–438 (2014)

Y.G. Zhu, Y. Wang, Y. Shi, J.I. Wong, H.Y. Yang, CoO nanoflowers woven by CNT network for high energy density flexible micro-supercapacitor. Nano Energy 3, 46–54 (2014)

I.M. Babu, J.J. William, G. Muralidharan, Ordered mesoporous Co3O4/CMC nanoflakes for superior cyclic life and ultra high energy density supercapacitor. Appl. Surf. Sci. 480, 371–383 (2019)

Y. Liang, Y. Yang, Z. Hu, Y. Zhang, Z. Li, N. An, H. Wu, Three-dimensional cage-like Co3O4 structure constructed by nanowires for supercapacitor. Int. J. Electrochem. Sci 11, 4092–4109 (2016)

R. Selvapriya, M. Alagar, High performance asymmetric supercapacitor based on spinel Co3O4 nanoparticles. Electrochim. Acta 180, 287–294 (2017)

H. Wang, J. Guo, C. Qing, D. Sun, B. Wang, Y. Tang, Novel topotactically transformed carbon–CoO–NiO–NiCo2O4 nanosheet hybrid hetero-structured arrays as ultrahigh performance supercapacitors. Chem. Commun. 50(63), 8697–8700 (2014)

W. Zhou, J. Liu, T. Chen, K.S. Tan, X. Jia, Z. Luo, T. Yu, Fabrication of Co3O4-reduced graphene oxide scrolls for high-performance supercapacitor electrodes. Phys. Chem. Chem. Phys. 13(32), 14462–14465 (2011)

M. Huang, Y. Zhang, F. Li, L. Zhang, Z. Wen, Q. Liu, Facile synthesis of hierarchical Co3O4@MnO2 core–shell arrays on Ni foam for asymmetric supercapacitors. J. Power Sour. 252, 98–106 (2014)

Funding

The author acknowledge the Directorate of Technical Education, Government of Tamilnadu and University Grants Commission, UGC—Q4SERO, Hyderabad (India), for financial support under the project (No. MRP-4892/14 (SERO/UGC)) and Adhiyamaan College of Engineering, Hosur, for providing the research facility to carry out the research work.

Author information

Authors and Affiliations

Contributions

AK: contributed to methodology, formal analysis, resources, and funding acquisition. RM: contributed to conceptualization, methodology, investigation, data curation, and writing—review & editing. RB and EK contributed to conceptualization, methodology, writing—review & editing, supervision, validation, and project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Research involving human and animal participants

This article does not contain any studies involving animals, performed by any of the authors. This article does not contain any studies involving human participants performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Karthikeyan, A., Mariappan, R., Bakkiyaraj, R. et al. High electrochemical performance of Co3O4-PVDF-NMP-based supercapacitor electrode. J Mater Sci: Mater Electron 34, 728 (2023). https://doi.org/10.1007/s10854-023-10147-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10147-w