Abstract

In this paper, a plasmonic sensor consists of a bimetallic layer of Ag and Au, a nano-thin layer of two-dimensional material MXene and a thin layer of Magnesium oxide (MgO) is proposed to operate in a visible region. Using Kretschmann configuration-based structure and transfer matrix method, the change in the refractive index of liquid Biosample have been observed at a fixed incident wavelength. Using the distinctive properties of Ti3C2Tx MXene and MgO, we have investigated the performance of Surface Plasmon Resonance (SPR) biosensor. Significant performance parameters such as Sensitivity, Figure of Merit (FoM) and Detection Accuracy (DA) calculated for different cases to prove the capability of proposed sensing structure. We also compared the sensitivity and sharpness of SPR curve obtained when using conventional adhesion layers such as titanium (Ti), chromium (Cr), and tantalum (Ta). A detailed investigation is carried out to observe the role of polymer as an adhesion layer and its thickness impact on FoM and resonance angle sharpness. The concept of Long range SPR (LR-SPR) and Short range SPR (SR-SPR) are also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

A Surface Plasmon Resonance (SPR) [1] sensor is a kind of plasmonic sensor having numerous applications such as use in biosensing application [2], gas sensing [3], chemical sensing [4] and many more but from 1990 it’s the most wide technique for biomolecular interaction. The SPR biosensor detects the change in refractive index, takes place due to the adsorption of biomolecules such as DNA, Bacteria, ligand, enzymes, virus etc. on a metal layer surface. In this paper, we are concerned of the biosensing of a liquid sample. A metal layer has negative permittivity which contributes in SPR excitation because of having plenty of free electrons. The interaction of free electrons with incident light causes SPR phenomenon. In comparison to other metal layers such as Cu, Al thin film of Au and Ag have numerous advantages, it gets less oxidized due to aging effect, absorbs biomolecules strongly, has twenty times less value of imaginary part in complex refractive index which causes less damping (it result to high detection accuracy), lower d-electron energy conduction which is sufficient to design a plasmonic operation in the visible region [5,6,7]. As a biosensor, their performance parameters such as sensitivity, FoM must be ultra-high for accurate detection, using various approach this can be modulated [8]. The surface plasmons excited strongly at metal dielectric interface, because Au and Ag metal layers are less adhesive towards glass substrate, so it’s the key requirement for sensor that metal thin layer must be tightly bounded with glass substrate because it affected the stability and performance of sensor directly [9]. Previously some of research work done in this direction. In 2013, Sui et al. [10] presented that by using Bi2O3 adhesion layer the adhesive strength between metal and prism is improved more than three times. In 2015, Maurya et al. [11] presented an SPR biosensor in which the low RI over high RI (SiO2 over TiO2) composite layer used as an adhesion layer. They concluded that composite layer works better than individual layers because plasmonic effect occurs near TiO2–SiO2 interface. In year 2016 Agarwal et al. [12] concluded that titanium as an adhesion layer works better than chromium. They also concluded that higher thickness increases the roughness of the top layer which eventually degrades the sensor performance. In the year 2017, Todeschini et al. [13] experimentally investigated how Cr and Ti adhesion layers influence the nanostructure of 2−20 nm thin Au films by means of high-resolution electron microscopy, complemented with atomic force microscopy and X-ray photoelectron spectroscopy. This group recommended the use of Ti adhesion layers for nano-optics applications because of its low diffusion, time stability. Thus, one can say that from above studies, dielectric layer or buffer layer applicable as an adhesive layer between metal thin layer and prism substrate [14] and a thin metal layers (≈ 2–5 nm thick) of chromium (Cr), titanium (Ti), and tantalum (Ta) [15, 16] used as a adhesion layer in most of research papers. As these are metal layers and have complex refractive index (n + ik) where the imaginary part also called as extinction coefficient (k) adversely affected the sensing performance. Due to the complex part in metal refractive index, significant damping takes place, as damping proportional to FWHM, thus as a result a shallow and broad resonance angle obtained this situation decreases the signal to noise ratio of sensor. Some papers have suggested very important solutions to overcome the issue such as to introduce organic adhesion layers, oxides adhesion layers such as indium tin oxide (ITO), TiO2, and Cr2O3, or a molecular linker, which are all low-loss materials at optical wavelengths. These oxide materials provide a light-trapping behavior causing more absorption of light hence to allow enhanced plasmon generation [17], finally more shift in SPR angle (\(\Delta \theta\)) and sensitivity at same change in bio-sample refractive index (\(\Delta n\)). In this manuscript, magnesium oxide (MgO) applied as an oxide adhesion layer and its effect on the biosensor performance parameter has also analyzed. Refractive index of prism and metal layer Au and Ag can be determined by Sellmeier equation and Drude-Lorentz model, respectively [18]. The wavelength-dependent RI of FK51A glass-prism can be calculated using Eq. 1 as:

The parameters of the oxide used in the proposed sensing device are given by the Eq. 2.

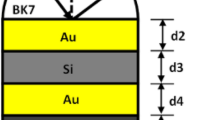

where u = 0.02195770, \(\upsilon\) = 0.0142832, A = 0.01062387, B = 0.0000204969, λ is the wavelength in μm. As a dielectric material, FK51A glass-based prism have low refractive index, shows excellent performance when used in visible region like negligible dispersion and outstanding transmission Characteristics [19]. The schematic diagram of the proposed sensing device is given in Fig. 1.

Using Kretschmann configuration and by following angle interrogation theoretical concept of the proposed setup elaborated. A 633 nm operation wavelength taken due to less optical nonlinearity and Kerr effect. MATLAB software has been utilized throughout this study in order to analysis the available results in this area as well as to propose additional conditions. In the year 2020, Moshkenani et al. [20] fabricated a plasmonic nanostructure, the results given in this paper shows that MgO is a lossless alternative adhesion layer that provides a sharp and narrow resonance angle and to avoid magnitude decrement caused by previously mentioned adhesive layers. The adhesive capacity of MgO is performed experimentally, shows its strong adhesiveness. A comparison analysis of plasmonic resonance using MgO adhesion layer with different nanostructures have Cr, Ti, Ta, and ITO as a adhesion layers done via. FEM analysis. The results show that MgO is a promising candidate because of negligible resonance angle broadening in compare to other adhesive materials. Bimetallic layer have been taken to take the advantage of the properties of both metallic layers, as silver gives a narrow and sharp SPR angle (helps to reduce signal to noise ratio value) and gold provides a large shift in SPR angle moreover a stable layer in ambient environment to work as a shield for silver layer. As a Bio Recognition Element (BRE) a continuous monolayer of MXene [21,22,23] has been used. MXene is two-dimensional materials that belong to transition metal carbide, nitride, or carbonitride family. It's remarkable properties makes it differ and extraordinary from other existing 2D materials e.g. graphene, black phosphorus etc. like bandgap tenability (0.3–1 eV) and work function, chemical and physical stability and larger surface area to attach biomolecules, hydrophilic nature (rare in other 2D materials like graphene, black phosphorus, MoS2 etc.) etc. Exploiting these novel properties of MXene make it is a suitable candidate to use as a BRE layer. Some of the previous work already did using MXene to modulate SPR biosensor performance works in visible region, Like Wu et al. [22] used MXene as a BRE layer, optimized the thickness by varying the number of MXene layers and estimate the value of sensitivity at different metallic layers, but the maximum sensitivity obtained was not up to the mark. Pandey [23] suggested performance enhancement of a SPR sensor by utilizing the properties of BP and Ti3C2Tx MXene layer, A CaF2 glass prism is considered as the coupling substrate and 2D Ti3C2Tx MXene as analyte interacting layer. Gas sensing and bio-sensing perspectives of proposed sensor configuration explored in this paper. In all of these papers only a fix span of the refractive index of sensing medium is given which specify the detection behaviour/capacity of sensor but not any particular object detection. In present study we have focused to enhance the performance parameter including Sensitivity, FoM and DA using MXene as a BRE layer as well as theoretical study to detect the sugar content concentration variation in a liquid sample using proposed biosensor. Physical and optical parameters of each layer are given in Table 1.

2 Excitation of surface plasmons mathematical overview

Surface plasmons can get excite by mainly of three methods prism coupling, grating coupling [24], Waveguide coupling [25] where the most common approach for excitation of surface plasmons is by means of a prism coupler. Otto [26], Kretschmann with Reather [27] developed prism-coupling configurations for SPR excitation based on concepts involving attenuated total reflectance. The Kretschmann configuration (Fig. 1) is most common approach for sensing application where a metal layer is in immediate contact on top of the Total internal reflection (TIR) surface, which makes it an efficient plasmon generator configuration. Excitation of free electrons takes when excite with P polarized (or TM polarized) incident light under total internal reflection (TIR) condition. This phenomenon gives rise to evanescent wave [28] which is the strongest at metal dielectric interface. The resonance of free electrons (plasmon) realized in terms of minimum reflectance where SPR angle reaches to its lowest value of reflection intensity. The mathematical expression of SPR generation is given in Eq. 3.

where \(\varepsilon _{m} ~and~\varepsilon _{s}\) the dielectric constants of the metal and the sensing are layer respectively, and \(k_{0} = {\raise0.7ex\hbox{${2\pi }$} \!\mathord{\left/ {\vphantom {{2\pi } {\lambda _{0} }}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{${\lambda _{0} }$}}\) is the wavenumber of the incident light in free space,\(~n_{{prism}}\) is refractive index of dielectric material (prism). Equation 3 is the condition of wavevector matching. Prism is a key element for an angle interrogation based SPR sensor which increases the wavevector of incident light to match the wavevector of surface plasmon. In general it contributes in to match the wavevector of surface plasmon wave with wavevector of incident light. So to get excellent performance parameter and maximum electromagnetic wave absorption prism selection must be done carefully. Equation 3 shows the relation between surface plasmons wavelength and incident wavelength and wavevector matching condition.wave vector in x direction is given by -

Reflection and transmission of light in multi-layered structure is not easy to calculate from Fresnels equation so transfer matrix method play a significant role here. The tangential field between the boundaries is related by-

Here, \(A_{1} ,~A_{2} ,~A_{3} \ldots ..A_{{N - 1}}\) and \(B_{1} ,~B_{2} ,~B_{3} \ldots ..B_{{N - 1}}\) are the tangential components of electric and magnetic field respectively. M is the characteristic transfer matrix of N-Layered structure, given by-

where,

In Eq. 7\(q_{k} ~and~\beta _{k} ~\) are defined as-

\(q_{k} = \left( {\frac{{\mu _{k} }}{{\varepsilon _{k} }}} \right)^{{{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 2}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$2$}}}} \cos \theta _{k}\) and

Finally the total reflection coefficient (r) as well as reflectivity (R) obtained by-

3 Design consideration and performance parameters

Sensitivity [29] of a SPR biosensor defines the minimum change in refractive index of an analyte \((\delta n_{a}\)) with respect to shift in resonance angle \(~\left( {\delta \theta _{{res}} } \right)\). Mathematically, it defines as-

FoM value responsible to the resolution capacity of sensor can be calculated by-

where FWHM is treat as a usual term of full width half maximum and its must as least as possible because of high FoM and detection accuracy (DA = \(\frac{1}{{FWHM}}\)).

4 Result and discussion

4.1 Effect of oxide adhesion layer

Figure 2a Includes a comparison analysis that has been given for SPR angles. It clearly appeared in figure that when a 5-nm-thick MgO oxide layer used as a adhesion layer it shows a sharp, smooth angle with minimum value of reflectance (Rmin), while when metallic layer used for same purposed with same thickness the resonance angle gets wider or shallow. To clarify our results more. we have analyzed the shift in SPR angle and corresponding sensitivity of sensor by varying the refractive index of liquid sample in sensing medium from 1.33 to 1.36. Fortunately we have got almost the same position of SPR angle and almost same sensitivity of about 190°/RIU for proposed sensor with and without oxide adhesion layer, refer to Fig. 2b.

4.2 Sensitivity analysis with respect to change in analyte refractive index

Sensitivity analysis by taking the surrounding materials as a reference medium discussed in Fig. 3. The step size of refractive index variation is Δn = 0.0025 start to vary from pure water refractive index 1.33 to 1.36.the \(\theta _{{SPR}}\) values for discrete values of analyte refractive index are 73.69 (ns = 1.33), 74.1 (ns = 1.3325), 74.51 (ns = 1.335), 74.94 (ns = 1.3375), 75.37 (ns = 1.34), 75.82 (ns = 1.3425), 76.28 (ns = 1.345), 76.75 (ns = 1.3475), 77.24 (ns = 1.35), 77.75 (ns = 1.3525), 78.28 (ns = 1.355), 78.82 (ns = 1.3575), 79.4 (ns = 1.36). Thus, for a small \(\Delta n_{s}\) = 0.0025 (1.3575–1.36) the shift in SPR (i.e. \(\Delta \theta _{{SPR}}\)) is 0.58°. A significantly high value of sensitivity of 236°/RIU (0.58°/0.0025) obtained at this observation. The variation of sensitivity with respect to analyte refractive index is shown in Fig. 3.

Application of designed sensor for liquid sample concentration variation deduction.

We have given a theoretical study to detect the concentration variation of a liquid sample using proposed biosensor. We have varied the sugar concentration in water (g/ml) from 0 to 30% and corresponding shift in SPR angle also observed. The refractive index change for each concentration variation of liquid sample is taken directly from the paper by Belay A* and Assefa G [30]. The limit of detection with variation in sugar concentration variation shown in Fig. 4.

Limit of detection (LOD) is a key term that indicates the smallest sugar concentration in water that can be measured under the Angular interrogation method (AIM) by using Eq. (11) [29].

From the result shown in the Fig. 4 its concluded that at sugar concentration of 20% the LoD value is highest while its tends to decrease sharply on higher concentration values. The sensitivity of sensor observed 224.18°/RIU for this analysis. This kind of analysis is very helpful to estimate the concentration of sugar in soft drinks, shakes and beverages which are in liquid form. Table 2 includes the value of SPR angle at each variation in sugar content, corresponding refractive index and at each shift value of LoD.

4.3 Polymers as an adhesion layer

Polymeric materials (somewhere buffer layer) are also a good option as an adhesive material due to their flexible processing, chemically resist behavior and less fabrication costs, although their influence was not thoroughly investigated. They are sometimes treating as organic glasses because of amorphous structures while in contrast of them traditional optical glasses are inorganic glass materials. The most common and existing polymer materials for optical applications are poly (methyl methacrylate) (PMMA, acrylic), polycarbonate (PC), polystyrene, liquid silicone. Most commonly the refractive indices of optical polymer materials lies between 1.4 and 1.7 which are almost similar to typical optical glasses. In the previous sections, we have used a type of Classical surface plasmon resonance (C-SPR) sensor where it’s shown that a thin oxide layer is more effective as an adhesion layer in compare to metal adhesion layer. In this segment we have given a theoretical insight about the effect of polymer adhesion layer and its thickness on SPR based sensors performance parameter in terms of Figure of Merit (FoM), Detection Accuracy (DA) by focusing on FWHM. When a thin film of polymer whose refractive index approximately matched to glass substrate introduced between metal and glass substrate, such films support a long-range surface plasmon polariton (LRSPP) [31, 32] mode where propagation loss is expected to decrease rapidly with decreasing metal thickness. More generally in insulator metal insulator (IMI) type structure arranged with enough thick layer of polymer the interaction between SPP at two metal-dielectric interfaces as shown in Fig. 5 gives rise to two modes symmetric (SM) as well as asymmetric modes (ASM) respectively. As the thickness of central metal decreases the confinement of ASM close to metal surface increase, gives rise to reduction of propagation length. While SM exhibits opposite behavior, the confinement of SM decreases, the field spreads deeply into dielectric medium causes a significant enhancement in propagation length. Thickness of metal kept 30 nm to provide strong coupling between SPWs. To more generalized the concept a pictorial diagram shown in Fig. 5.

Modes of surface plasmon in Insulator metal insulator (IMI) type structure [33]

Its seen in this figure that there are two surface plasmon modes generates at two interfaces in a IMI type structure moreover at both of the interfaces electric field generates. In symmetric case Electric fields are in phase and they superimpose to each other or overlapped and are treat as plasmonic supermodes.

This overall phenomenon is responsible to enhance EM field at interface, wavevectors adding to each other in phase so larger wavevector than Conventional SPR(C-SPR) and causes large penetration depth. In its opposite if electric field at both the interface are out of phase they are called as anti-symmetric mode and they are responsible for short range surface plasmon waves (SR-SPR) provides short penetration depth. One of the limitation of standard SPR sensor also called as classical SPR(C-SPR) is its low penetration depth and high width of SPR angle, e.g. at 633 nm incident light wavelength penetration depth in order of nm (≈200 nm) and FWHM≈3° Although those SPR sensor which provides small penetration depth have specific application toward biomolecules or analytes which are of very tiny bio-entity but when the analyte is a bio-entity of size equal to or larger than the penetration depth such as cells the sensing device get failure towards biosensing. The use of IR light may be a good alternative to overcome the issue however the detector and light source are very expensive in IR. To overcome the issue LR-SPR is very effective and cost-effective option. The LR-SPR use to sense large particles, bacteria and other cells. In visible region they give penetration depth in µm order. Figure 6 shows the LRSPR curve for proposed biosensor when a thick enough polymer layer applied between prism and metal layer. In this manuscript, as a polymer adhesion layer, we have taken optical liquid silicone rubber (OLSR) [34] because of its advancement over well-known optical polymers like Polycarbonate (PC) and acralyte (PMMA). Silicone has light transmission capacity upto 94% which is significantly high (Very low surface roughness), Moreover, OLSR has low refractive index of 1.42 in compare to PC, PMMA. From Fig. 7a it’s observed that the SPR angle is polymer thickness dependent which get sharper and sharper by varying the thickness of polymer because of LR-SPR. The least value of FWHM or most narrow SPR angle observed when OSLR polymer thickness opt as 1400 nm, bimetallic layer thickness 30 nm and MXene monolayer used as BRE layer. When polymer thickness opts as 5 nm as taken in oxide case and remain physical parameters of other layer kept same the resonance angle gets extremely shallow. In previous section two as we have discussed that FOM depends on FWHM and its inversely proportional. From Fig. 7b we observed that at polymer thickness of 1400 nm the FoM value is highest at the least value of FWHM, while below 600 nm thickness the minimum reflectance (Rmin) value get enhanced much and it’s not possible to estimate the value of FoM below to this value. So we come on the conclusion that by increasing the polymer adhesion layer thickness sufficiently FoM value increases appreciably but at the same time Sensitivity get reduced. The theoretical concept given in this manuscript is expected to realized experimentally because its already reviewed that 2D layer of MXene can be experimentally realized [35] and to obtain nano thin bimetallic layer most frequent method like thermal evaporation is in existence and by spin coting adhesion layer can be apply on glass substrate earlier.

5 Conclusion

In this manuscript, we have given a detailed concept of SPR-based biosensor, its mathematical concept and various parameters that directly affect the performance of the sensor. Oxide adhesion layer have various advantage over metallic adhesion layer, it’s shown in the manuscript with suitable diagram. As an oxide layer, the resonance angle of Mgo adhesion layer-based sensor compared with resonance angle of metal layer-based SPR angle. A brief study of polymer adhesion layer is also described and it’s shown that Resonance angle is polymer thickness-dependent. When polymer thickness is thick enough it will cause to generate LR-SPR which is a key term to significantly increase the value of FoM. Application of proposed sensing device is shown and it’s claimed that device can be worked to detect the sugar concentration in a liquid sample.

References

J. Homola, M. Piliarik, Surface Plasmon Resonance Based Sensors, vol. 4 (Springer, Berlin, 2006), pp. 46–47

Md.N. Hossena, Md. Ferdousa et al., Design and analysis of biosensor based on surface plasmon resonance. Sens. Bio-Sens. Res. 21, 1–6 (2018)

T. Srivastava, R. Jha, Black phosphorus: a new platform for gaseous sensing based on surface plasmon resonance. IEEE Photon. Technol. Lett. 30(4), 319–322 (2018)

J. Homola, Surface plasmon resonance sensors for detection of chemical and biological species. Chem. Rev. 108, 462–493 (2008)

C. Rhodes, M. Merruti et al., Dependence of plasmon polaritons on the thickness of indium tin oxide thin films dependence of plasmon polaritons on the thickness of indium tin oxide. J. Appl. Phys. 103(9), 093108 (2008)

C. Rhodes, S. Franzen, Surface plasmon resonance in conducting metal oxides. J. Appl. Phys. 100(5), 054905 (2006)

H. Khamh, E. Sachet, K. Kelly, J.-P. Maria, S. Frazen, As good as gold and better: conducting metal oxide materials for midinfrared plasmonic applications. J. Mater. Chem. C 6, 8326–8342 (2018)

A. Shalabney, I. Abdulhalim, Sensitivity-enhancement methods for surface plasmon sensors. Laser Photonics Rev. 5(4), 571–606 (2011)

T.G. Habteyes, S. Dhuey, E. Wood, D. Gargas, S. Cabrini et al., Metallic adhesion layer induced plasmon damping and molecular linker as a nondamping alternative. ACS Nano 6, 5702–5709 (2012)

C. Sui, Z. Lu, B. Yan et al., ‘Enhanced stability in surface plasmon resonance sensor using prism coupler based on Au/Bi2O3 bilayer film. Res J. Appl. Sci. Eng. Technol. 5(23), 5391–5395 (2013)

J.B. Maurya, Y.K. Prajapati, V. Singh et al., Sensitivity enhancement of surface plasmon resonance sensor based on graphene – MoS2 hybrid structure with TiO2–SiO2 composite layer. Appl. Phys. A 121(2), 525–533 (2015)

S. Agarwal, Y.K. Prajapati, J.B. Maurya, Effect of metallic adhesion layer thickness on surface roughness for sensing application. IEEE Photon. Technol. Lett. 28(21), 2415–2418 (2016)

M. Todeschini, A.B.S. da Fanta, F. Jensen, J.B. Wagner, A. Han, Influence of Ti and Cr adhesion layers on ultrathin Au films. ACS Appl. Mater. Interfaces 9(42), 37374–37385 (2017)

D.T. Debu, P.K. Ghosh, D. French et al., Surface plasmon damping effects due to Ti adhesion layer in individual gold nanodisks. Opt. Mater. Express 7(1), 73–84 (2017)

C.M. Chow, J.A. Bain, Effect of thin Cr and Cu adhesion layers on surface plasmon resonance at Au/SiO2 interfaces. IEEE Trans. Magn. 52(7), 1–4 (2016)

T. Aubert, O. Elmazria, B. Assouar, L. Bouvot, Z. Bournebe, M. Hehn, S. Weber, M. Oudich, P. Alnot, Study of tantalum and iridium as adhesion layers for Pt/LGS high temperature SAW devices. IEEE Int. Ultrason. Symp. (2009). https://doi.org/10.1109/ULTSYM.2009.5441517

R. Malureanu, A. Lavrinenko, Ultra-thin films for plasmonics: a technology overview. Nanotechnol. Rev. 4(3), 259–275 (2015)

A.D. Rakic, A.B. Djurišić, J.M. Elazar, M.L. Majewski, Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt. 37, 5271–5283 (1998)

J. Wang, Z. Zhu, A. Munir, H.S. Zhou, Fe3O4 nanoparticles-enhanced SPR sensing for ultrasensitive sandwich bio-assay. Talanta 84(3), 783–788 (2011)

P. Sadri Moshkenani, M.W. Khan, M. Shafiqul-Islam, E. Montoya, I. Krivorotov, N. Bagherzadeh, O. Boyraz, Effect of magnesium oxide adhesion layer on resonance behavior of plasmonic nanostructures. Appl. Phys. Lett. 116(24), 241601 (2020)

A. Srivastava, A. Verma, R. Das, Y.K. Prajapati, A Theoretical Approach to Improve the Performance of SPR Biosensor using MXene and Black Phosphorus. Optik Int. J. Light Electron Opt. 203, 1–9 (2020)

L. Wu, Q. You, Y. Shan, S. Gan, Y. Zhao, X. Dai, Y. Xiang, Few-layer Ti3C2Tx MXene: a promising surface plasmon resonance biosensing material to enhance the sensitivity. Sens. Actuators B Chem. 277, 210–215 (2018)

A.K. Pandey, Plasmonic sensor utilizing Ti3C2Tx MXene layer and fluoride glass substrate for bio- and gas-sensing applications: performance evaluation. Photonics Nanostruct. Fundam. Appl. 42, 100863 (2020)

S. Long, J. Cao, Y. Wang, S. Gao, N. Xu, J. Gao, W. Wan, “Grating coupled SPR sensors using off the shelf compact discs and sensitivity dependence on grating period. Sens. Actuators Rep. 2(1), 1–2 (2020)

P. Zhang, L. Liu, Y. He, X. Chen et al., Waveguide-coupled surface plasmon resonance sensor using an Au-MgF2-Au structure. Plasmonics 14(1), 187–195 (2018)

A. Otto, Excitation of nonradiative surface plasma waves in silver by the method of frustrated total reflection. Z. für Phys. A 216(4), 398–410 (1968)

E. Kretschmann, H. Raether, Radiative decay of non-radiative surface plasmons excited by light. Z. für Nat. A 23, 2135–2136 (1968)

Y. Zenga et al., Recent advances in surface plasmon resonance imaging: detection speed, sensitivity, and portability. Nanophotonics 6(5), 1017–1030 (2017)

A.K. Pandey, A.K. Sharma, C. Marques, On the application of SiO2/SiC grating on Ag for high-performance fiber optic plasmonic sensing of cortisol concentration. Materials 13(7), 1–13 (2020)

A. Belay, G. Assefa, Concentration, wavelength and temperature dependent refractive index of sugar solutions and methods of determination contents of sugar in soft drink beverages using laser lights. J. Laser Opt. Photonics 5(2), 187 (2018)

W. Alastair, J.L. Hye, M.C. Robert, Long-range surface plasmon resonance imaging for bioaffinity sensors. Anal. Chem. 77, 3904–3907 (2005)

A. Srivastava, Y.K. Prajapati, Effect of sulfosalt and polymers on performance parameter of SPR biosensor. Opt. Quantum Electron. 52(10), 1–14 (2020)

A.M. Heikal, M.F.O. Hameed, S.S.A. Obayya, Basic principles of surface plasmon resonance, in Computational Photonic Sensors. ed. by M. Hameed, S. Obayya (Springer, Cham, 2018), pp. 53–72. https://doi.org/10.1007/978-3-319-76556-3_3

V. Bhardwaj, R.K. Gangwar, V.K. Singh, Silicone rubber-coated highly sensitive optical fiber sensor for temperature measurement. Opt. Eng. 55(12), 126107 (2016)

F. Wang, C. Yang, M. Duan, Y. Tang, J. Zhu, TiO2 nanoparticle modified organ like Ti3C2 MXene nanocomposite encapsulating hemoglobin for a mediator free biosensor with excellent performances. Biosens. Bioelectron. 74, 1022–1028 (2015)

Acknowledgements

We are grateful to Indian Government funding agency BRNS, Department of Atomic Energy to provide research fund for Project No. 34/14/10/2017-BRNS/34285 entitled “Role of Graphene and MoS2 on Performance of Surface Plasmon Resonance Based Sensors: An Application to Biosensing”

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Srivastava, A., Prajapati, Y.K. Surface plasmon resonance (SPR)-based biosensor using MXene as a BRE layer and magnesium oxide (MgO) as an adhesion layer. J Mater Sci: Mater Electron 33, 8519–8528 (2022). https://doi.org/10.1007/s10854-021-06436-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06436-x