Abstract

The microstructure, strain behavior, and piezoelectric properties of Bi0.5(Na0.8K0.2)0.5TiO3 (BNKT-Sn) piezoelectric ceramics modified with Sn4+ ions were systematically studied. The experimental results indicated that the Sn4+ ion doping was a viable and effective method to promote the electromechanical properties and the strain behavior of the BNKT ceramics. When the Sn content was 0.02 mol, the resultant BNKT ceramics exhibited excellent electrical properties with a density of 5.92 g.cm–3, a dielectric constant (εr) of 1235, a dielectric loss (tanδ) of 0.048, the electromechanical coupling factors of 0.36 (kp) and 0.39 (kt), a piezoelectric coefficient (d33) of 171 pC/N, and a mechanical quality factor (Qm) of 125. Moreover, a large unipolar strain of 0.45% and a high normalized strain of 865 pm/V were achieved at 50 °C. The main achievement of this study was the large normalized strain (d33*) of 876 pm/V at the SnO2 content of 0.04 mol.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Lead-free piezoelectric materials with high strains exhibit an interconversion of electrical and mechanical energies that can be utilized in a wide range of applications, such as sensors, actuators, and electrical devices [1,2,3,4]. Therefore, multifarious piezoelectric ceramics, such as KxNa(1−x)NbO3-based ceramics [5,6,7,8], Bi0.5(Na(1−x)Kx)0.5TiO3-based piezoelectric ceramics [1, 2, 9,10,11], and (Ba1-xCax)(Zr1-yTiy)O3-based piezoelectric ceramics [12,13,14] have been synthesized. Among the lead-free materials, Bi0.5(Na(1−x)Kx)0.5TiO3 (BNKT)-based ceramics are the most promising candidates for replacing the PZT-based piezoelectric ceramics due to the former’s large piezoelectric coefficients, large field-induced strains, good ferroelectricity, and high Curie temperatures [15]. Furthermore, modification of the elements at A-and/or B-sites to obtain a modified BNKT solid solution is a viable approach to enhance the dielectric, ferroelectric, and piezoelectric properties or reduce the sintering temperature [16]. Zhang et al. [17] reported that the Sn4+ cations could enter the B-sites of a perovskite structure to replace the Ti4+ ions and enhance the energy storage density. It was also pointed out that 1% mol SnO2-doped Sr0.6(Na0.5Bi0.5)0.4TiO3 ceramics yielded a high energy storage efficiency (η) of 80%. Recently, in our research, it was discovered that optimal Sn doping could effectively reduce the sintering temperature of the BNKT ceramics by generating a eutectic liquid phase at 170 °C [18]. Moreover, it was found that isovalent Sn substitution at Ti-sites could induce a ferroelectric-to-nonpolar pseudocubic phase transition and a giant strain at the phase boundary [19, 20]. Recently, several novel BNKT-based ceramics exhibiting high strain under a low electric field have been discovered. In a research reported by Khaliq et al. [21], Bi0.5Na0.5TiO3 seed-modified 0.96Bi0.5(Na0.78K0.22)0.5TiO3–0.04Bi(Mg0.5Ti0.5)O3 exhibited considerably high Smax/Emax values of 725 pm/V at 3 kV/mm and 560 pm/V at 2.5 kV/mm. Gupta et al. [22] recently reported that Sr(Hf0.5Zr0.5)O3-doped Bi0.5(Na0.8K0.2)0.5TiO3 ceramics display excellent piezoelectric properties. The ceramics with Sr(Hf0.5Zr0.5)O3 content of 2% mol showed the Smax/Emax value of 663 pm/V under the field of 5 kV/mm, indicating its potential as a lead-free replacement material for actuating applications. Huo et al. [23] reported obtaining a large normalized strain of 600 pm/V in the BNKT ceramics in complex with Cs2Nb4O11 tungsten bronze phase. Zhang et al. [24] also demonstrated that (Bi0.5Na0.5)TiO3-based ceramics exhibited a large strain of 0.38% (d33* = Smax/Emax = 638 pm/V) under a field of 60 kV/cm. In another report by Zhang et al. [25], d33* = Smax/Emax = 720 was achieved for the NKBT-0.05FN ceramic at 50 kV/cm. In the present study, Sn-modified Bi0.5(Na0.8K0.2)0.5TiO3 (BNKT) lead-free ceramics were synthesized using a conventional solid-state reaction method, with the main objective of improving the strain behavior and the piezoelectric properties of BNKT ceramics by adding a suitable amount of Sn4+ ions.

2 Experiment

The general chemical formula of the investigated material was Bi0.5(Na0.8K0.2)0.5(Ti1-xSnx)O3 (BNKTS) (x = 0.0, 0.01, 0.02, 0.03, and 0.04). Reagent grade oxide powders (purity ≥ 99.5%) of Bi2O3, TiO2, Na2CO3, K2CO3, and SnO2 were used as starting materials. The oxide powders of Bi2O3, TiO2, Na2CO3, K2CO3, and SnO2 were weighed and milled for 20 h. The powders were calcined at 850 °C for 2 h, producing the BNKTS compound. The production of the BNKTS compound was confirmed through thermogravimetric analysis (TGA) and differential thermal analysis (DTA) [20]. The calcined BNKTS powder was then milled for 20 h. Next, the ground materials were pressed at 150 MPa into pellets of diameter 1.2 cm and thickness 1.5 mm by steel mold of the corresponding diameter, which was then sintered at 1100 °C for 3 h in the air at a heating/cooling rate of 5 °C/min.

The crystalline phase of the sintered ceramics was examined by X-ray diffraction (XRD, D8 Advance) under Cu-Kα radiation at a wavelength of 1.5405 Å, in the 2θ range of 20°–70°, and with a step size of 0.02°, at room temperature (RT). Scanning electron microscopy (SEM, Hitachi S_4800) was employed to examine the surface morphologies. In addition, the energy-dispersive spectrometry (EDS) of the sintered ceramic was performed. Furthermore, Rietveld refinements were performed using the FullProf software, and the grain size was determined using the mean linear intercept method. The sintered samples were coated with silver paint at 550 °C for 15 min and then polarized in silicone oil at 25–125 °C for 25 min under 3.5 kV/mm to measure their piezoelectric properties. The piezoelectric properties of the Sn-modified BNKT ceramics were determined from their resonant vibration spectra collected at room temperature using an impedance analyzer (HP 4193A and RLC Hioki 3532). The piezoelectric constant, d33, was determined using a d33 meter (YE2730A, Sinocera).

3 Results and discussion

3.1 The structure and microstructure characteristics

In order to clarify the morphological evolutions and the elemental distributions of the ceramic samples, the EDS spectra of the Sn-doped BNKT ceramics were obtained and are shown in Fig. 1a. It is clear from the EDS spectra that Bi, Na, K, Ti, and O elements were present in the synthesized ceramics, similar to the findings reported by Wang et al. [26]. In our recent research, the sintering temperature of the Sn-doped BNKT ceramics was determined to be 1100 °C [18]. In comparison to the green pellets without sintering that had a diameter of 12 mm and a thickness of 1.5 mm, after sintering at 1100 °C for 3 h, the Sn-doped BNKT ceramics exhibited good shrinkage with a diameter of 10.3 mm and a thickness of 1.0 mm [inset of Fig. 1a]. Therefore, based on preliminary observation and the testing for sample homogeneity using the EDS surface method, it could be confirmed that the chemical composition of the Sn-doped BNKT ceramics was considerably good qualitatively as well as quantitatively.

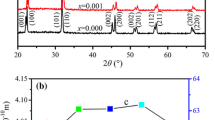

Figure 1b displays the crystalline phases of the Sn-doped BNKT ceramics over a 2θ range of 20°–70°. All samples possessed a typical perovskite structure. In order to clearly illustrate the effect of SnO2 on the structural properties of the BNKT ceramics, a magnified view of the peaks in the region between 46.2° and 47.1° is presented in Fig. 1c. The tetragonal phase concentration was quite low and was observed only in the ceramic samples without Sn4+ ions or those with an extremely small concentration of Sn4+ ions. The Lorentz curves could be used to theoretically fit the partial intensity profile of ceramics as presented in Fig. 1c. This was consistent with the report by Han et al. [27] for Sn-doped Bi1/2(Na0.82K0.18)1/2TiO3. Moreover, the presence of rhombohedral crystal symmetries (R3c) in the Bi0.5(Na0.8K0.2)0.5(Ti0.98Sn0.02)O3 sample was confirmed using the Rietveld refinement technique (Fig. 1d). The fitting analysis of the peak shape, peak position, structure, and background was performed by considering the rhombohedral (R3c) space group symmetry. In our previous report, the coexistence of two different structural phases occurred, and hence, the morphotropic phase boundary (MPB) was confirmed at Sn4+ ion content of 0–0.01 mol, along with the rhombohedral phase fraction (R3c) of greater than 60% [20]. On further refinement (the content of Sn4+ ions was higher than 0.01 mol), the rhombohedral symmetry was observed to fit well (MR = 100%). It is well known that the Bi0.5Na0.5TiO3 ceramic is rhombohedral, while the Bi0.5K0.5TiO3 ceramic is tetragonal at room temperature [28]. The split (002)T and (200)T peaks indicate the ferroelectric tetragonal phase (T), while the single (200)R peak represents the ferroelectric rhombohedral phase (R). Thus, doping could increase the tetragonal or rhombohedral phases of the BNKT ceramic system. According to Pradhan et al. [29], the structure of the Bi0,5(Na0.8K0.2)0,5TiO3 ceramics can be described by the P4mm space group with the lattice parameters of a = 3.893 Å and c = 3.908 Å and a c/a ratio of 1.004. However, in our work, a pure Bi0,5(Na0.8K0.2)0,5TiO3 with both R phase (space group R3c ~ 60%) and T phase (space group P4mm ~ 40%) was observed [20]. Similar observations were reported by Ullah et al. [28], who observed that the relative amount of the tetragonal phases was 58.6% for the Bi0.5(Na0.78K0.22)0.5TiO3 ceramic samples sintered at 1100 °C. The overall effect of Sn4+ ions on the XRD patterns of Bi0,5(Na0.8K0.2)0,5TiO3 ceramics was the slight shift in the intensity of the peaks toward lower angles and the enhancement of the rhombohedral phase (R) structure, as depicted in Fig. 1c. This result implies that the Sn4+ ions (0.69 Å) replaced the similar-sized Ti4+ ions (0.61 Å) at the B-site rather than the bigger cations at the A-site, such as K+, Na+, and Bi3+ [18]. Similar results were observed by Yan et al. [30] in Sn-doped Ba0.5Sr0.5TiO3 ceramics as well as by Zhang et al. [17] in Sn-doped Sr0.6(Na0.5Bi0.5)0.4TiO3 ceramics. It is evident that the Goldschmidt’s tolerance factor [16], t(BNKT/Sn) ≤ tBNKT when rTi = 0.61 Å < rSn = 0.69 Å, and the corresponding atom radii are rBi3+ = 1.17 Å, rNa+ = 1.39 Å, rK+ = 1.64 Å, and rO2– = 1.42 Å [31, 32]. Therefore, the tolerance factor of pure BNKT was tBNKT = 0.9492 when tBNKT/Sn ≤ tBNKT < 1.

Figure 2 presents the scanning electron microscopy images of the fracture surfaces (SEM) of the Sn-doped BNKT ceramics with different Sn contents. In our previous research [18], the perovskite structure of the ceramic samples was formed in the temperature range of 745–883 °C. In order to ensure the single perovskite phase formation in high-volume samples, the calcination of the Sn-doped BNKT ceramics was carried out at 850 °C for two hours (Fig. 2a). The average grain size of the calcined BNKT compounds was about 0.33 µm (Fig. 2a). However, the mechanism underlying the effects of the preliminary calcination temperature on the microstructures of the Sn-doped BNKT samples remains unknown so far and requires further investigation. In order to better understand the influences of different Sn contents on the microstructure of the Sn-doped BNKT ceramics, the samples were sintered at 1100 °C for three hours (Fig. 2b–f). In all samples, the grains had a dense microstructure and a clear grain boundary. At low Sn doping levels (x ≤ 0.03), the grain size increased with the increasing Sn content and reached the maximum value of 1.62 µm at the Sn content of 0.03 mol (Fig. 3e). The increase in the grain size may be due to a reaction between Bi and Sn elements, which produced some molten compounds [33, 34]. Similar behaviors of increase in the grain size and change in the morphology have also been observed in Zn-modified BNKT ceramics [35]. Muhsen et al. [36] suggested that the increase in the grain size could be related to the differences in the ionic radii of Sn4+ and Ti4+ at the B-sites, due to which the interdiffusion movement occurred via the grain boundary through the formation of necks between the grains, and its growth accelerated the grain growth. As the Sn content further increased, the grain size decreased (Fig. 3f). This could be because during sintering to produce the Sn-modified BNKT ceramics, a portion of Sn4+ ions may accumulate near the grain boundaries and reduce their densification mobility. The reduction in the mobility of the grain boundary weakens the mass transport and thus inhibits the grain growth to a certain extent [37]. It is reported that a large grain size is essential to obtain ceramics with good piezoelectric properties [16, 18, 36]. Sn4+ ions diffused into the BNKT lattice until the Sn doping content was less than 4%.

3.2 Influence of Sn content on the strain behavior and piezoelectric properties of BNKT ceramics

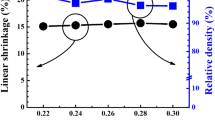

Figure 4a illustrates the dielectric constant (εr) and dielectric loss (tanδ) of the sintered ceramics with different SnO2 contents at 1 kHz. With the increasing Sn content, εr gradually increased, reached the peak value of 1235 at x = 0.02, and then decreased. The variation trend of tanδ was the opposite; tanδ decreased rapidly when the Sn content was less than 0.02 mol, reached the smallest value of 0.048 at the Sn content of 0.02 mol, and then started to increase.

These phenomena are probably related to the density and the increasing grain size. According to Muhsen et al. [36], the movement and growth of the grain boundaries through the formation of necks between the grains increase the grain size of the ceramics. The dielectric properties of the Sn-doped BNKT ceramics were improved with an increase in their density (Fig. 4b). With the increase in the Sn content from 0 to 0.04 mol, the density of the ceramics increased from 5.80 g/cm3 to 5.92 g/cm3, reached the maximum values of 5.92 g/cm3 at x = 0.02 (98.6% of the theoretical density) corresponding to the highest εr value, and then started to decrease again. This could be because the low melting point of the Bi–Sn system is beneficial for the generation of a eutectic liquid phase at 138.4 °C [33, 34], and this phase can work as a lubricant during the sintering process, wetting the solid particles, and providing capillary pressure among them, thereby increasing the sintering capacity of the ceramics [3, 4, 38]. However, when the Sn content exceeded the solubility limit of the Sn4+ ions, the segregation of some Sn4+ ions at the grain boundaries prevented grain boundary movements during sintering and inhibited the grain growth, leading to a decrease in the grain size and a reduction in the density and the dielectric properties of the ceramics [36].

The piezoelectric properties of the Sn-modified BNKT ceramics were determined from their resonant vibration spectra (Fig. 5a, b). It is clear from Fig. 5c that the electromechanical coupling factors (kp, kt) and the piezoelectric factor (d33) varied as a function of the Sn content. With the increase in the Sn content, the values of kp, kt, and d33 were significantly increased. At x = 0.02, the Sn-modified BNKT ceramics exhibited the best piezoelectric properties, with the kp, kt, and d33 values of 0.36, 0.39, and 171 pC/N, respectively, and this could be attributed to the increase in the grain size. Therefore, at small Sn contents, the increase in the grain size was beneficial for the improvement of kp, kt, and d33 as the increasing grain size reduced the volume fraction of the grain boundaries [36]. However, with further increase in the Sn content, the values of kp, kt, and d33 decreased; this happened when the solubility limit of the Sn4+ ions in the Bi0.5(Na0.8K0.2)0.5TiO3 ceramics was 0.02 mol. When the SnO2 content was above 0.02 mol, excess Sn2+ ions accumulated at the grain boundaries and abnormally influenced the piezoelectric properties. Jiang et al. [39] obtained the best piezoelectric properties with kp = 0.3 in 0.2 wt% Mn2+ doped (Na0.5K0.2)0.5Bi0.5TiO3. Zhang et al. [40] reported that 0.3 wt.% Sm3+ substitution in (Na0.82K0.18)Bi0.5TiO3 ceramics exhibited a high planar coupling factor (kp) value of 0.22. Surprisingly, the variation in the mechanical quality factor (Qm) was almost similar to that of d33, and the optimized Sn content was 0.03 mol instead of 0.02 mol, resulting in the highest Qm value of 125 (Fig. 5b). The values of Qm increased when the Sn content increased from 98 to 125, and then decreased with a further increase in the Sn content. It is believed that mechanical loss is typically quantified in terms of the material’s mechanical loss tangent (tanδ) and the dielectric loss is also quantified in terms of the material’s dielectric loss tangent (tanδ), which occur in the material due to the inertia of the charge exchange process [41, 42], which is represented by Q–1 m ~ tanδ. Interestingly, an abrupt drop in the Qm value was observed when 0.04 mol Sn4+ ions were doped on the B-site Ti4+ ions. The accumulation of an excess amount of Sn ions at grain boundaries led to a reduction in the mechanical quality factor (Fig. 3f) [43]. Thus, although the average grain size of the ceramic was the largest when the Sn content reached x = 0.03 (1.62 μm), as depicted in Fig. 3e, the piezoelectric properties of Sn-doped BNKT ceramics reached the highest values of kp, kt, d33, and Qm when Bi0.5(Na0.8K0.2)0.5TiO3 was doped with 2 mol.% of the Sn dopant.

Figure 6 demonstrates the bipolar strain curves of the BNKT ceramics as a function of the Sn content [44]. A slight decrease in the maximum strain (Smax) occurred initially at x = 0.01; then, the Smax value increased with a further increase in the Sn content (Fig. 7a). The value of Sneg increased with the increasing Sn content and reached the maximum value of 0.16% at x = 0.02. Negative strains in ferroelectric materials manifest as the switching back point of domain reorientation under cyclic fields; hence, the highest values of kp and d33 were obtained at x = 0.02. However, with further increase in the Sn content, the Sneg value decreased and tended to zero because the relaxor of the Sn-doped BNKT ceramics was enhanced [44]. The normalized strains (d33*) of the sintered ceramics were calculated (Fig. 7a) and compared with those of the other BNKT-based piezoceramics (Fig. 7b). It is evident from Fig. 7a that the normalized strain reached the maximum value of 876 pm/V at x = 0.04 and then decreased. Therefore, the variation of the normalized strain with the Sn content was almost similar to that of Smax, and the optimized Sn content of 0.04 mol led to the largest d33* value of 876 pm/V (Fig. 7a). Among all the BNKT-based ceramics reported to date, the BNKT-0.04Sn ceramic has the largest d33* value of 876 pm/V (Fig. 7b) [45,46,47,48,49,50].

3.3 Influence of temperature on the strain behavior and piezoelectric properties of BNKT ceramics

For practical applications of piezoelectric materials, the temperature stability of their electromechanical properties (poling temperature and operating temperature) is crucial. In order to determine the optimum poling temperature for the Sn-doped BNKT ceramics to enhance their piezoelectric responses, their poling temperatures were measured in silicone oil under 3.5 kV/mm for 25 min (Fig. 8). At the poling temperature of 75 °C, BNKT-0.02Sn exhibited the best piezoelectric properties with d33 = 171 pC/N and kp = 0.36. The effect of temperature allowed the flexible domains to easily move in the field direction and resulted in improved piezoelectric properties. The suitable polarization of the Sn-doped BNKT ceramics was noticed in the temperature range of 50–100 °C, which then decreased quickly upon further increasing the temperature [51,52,53]. With a further increase in the temperature, the rise of the leakage current caused a reduction in d33 and kp [12], which proves that the piezoelectric responses of the ceramics were dependent on the poling temperature.

Figure 9 displays the temperature-dependent strain hysteresis loops of the Bi0.5(Na0.8K0.2)0.5(Ti0.98Sn0.02)O3 ceramics (x = 0.02). A typical ferroelectric behavior was noticed until 100 °C. However, when the temperature exceeded TF-R (Fig. 10) and reached 125 °C, a little negative strain was observed [48]. Several researchers have suggested that the shift of TF-R in various lead-free BNKT ceramics could be related to the loss of Bi, K, and/or Na during the processing [20]. It is believed that the origin of the large strain in Bi-based ceramics is associated with the reversible electric field-induced phase transition from a nonpolar ergodic relaxor to the polar ferroelectric state [22]. Therefore, the temperature dependence of the polarization and the strain hysteresis are the maximum at the boundary where the ferroelectric state transforms into the relaxor state.

In order to elucidate the variation trend of temperature-dependent strains, strain values were plotted against temperatures ranging from 25 °C to 125 °C (Fig. 11). The temperature-induced phase transition of the ceramics was verified by the strain–electric field (S–E) hysteresis measurements. The positive maximum strain (Smax) gradually increased with temperature, reached the highest value of 0.45% at 50 °C, and then gradually decreased (Fig. 11). With further increase in temperature, lattice softening occurred when the temperature approached the phase transition temperature; hence, the Smax value decreased [54]. When the sintering temperature was higher than TF-R, a notable increase in the usable strain occurred due to the reduction in the remanent strain (Fig. 9). According to Yin et al. [55], Smax reached the maximum value and Sneg dropped to almost zero at around TF-R, indicating that the field-induced long-range ferroelectric order disappeared around this temperature.

It is evident from Fig. 11b that Bi0.5(Na0.8K0.2)0.5(Ti0.98Sn0.02)O3 ceramic presented the highest d33* value of 865 pm/V at 50 °C. The positive maximum strain (Smax) gradually increased with increasing temperature and promoted the increase in d33* according to the following formula: d33* = Smax/Emax [45, 51]. The obtained d33* and Smax values in this research are higher than those reported previously for lead-free ceramics [19]. The large Smax value can be attributed to the reversible electric field-induced transition between the ergodic relaxor and the ferroelectric status around the TF-R temperature [48]. Due to the shift of TF-R below the room temperature (RT), a large d33* was obtained at RT.

4 Conclusions

In this work, Bi0,5(Na0.8K0.2)0,5(Ti1-x)Snx)O3 lead-free ceramics were synthesized using a conventional mixed-oxide approach. The experimental results revealed that the doping of Sn4+ ions into the BNKT ceramics significantly improved their dielectric and piezoelectric properties as well as their strain behavior. The resultant ceramics exhibited excellent dielectric properties with a density of 5.92 g.cm–3, a dielectric constant (εr) of 1235, and a dielectric loss (tanδ) of 0.048. Under the optimized poling temperature, the sintered ceramics had the best piezoelectric constant (d33) of 171 pC/N, while the electromechanical coupling factors were 36% (kp) and 39% (kt) at 75 °C. In particular, the electric field-induced unipolar strain was increased from 0.17% for the pure BNKT (x = 0.00) to 0.45% (x = 0.02) at an electric field of 50 kV/cm, with a corresponding increase in the large normalized strain (d33*) from 400 to 876 pm/V for 4 mol. % Sn-modified BNKT ceramic, which is relevant for the actuator applications of this material.

References

L.D. Vuong, D.A. Quang, P. Van Quan, N. Truong-Tho, J. Electron. Mater. 49(11), 6465–6473 (2020)

L.D. Vuong, D.A. Quang, V.T. Tung, N.H. Chuc, N.N. Trac, J. Mater. Sci.: Mater. Electron. 31(20), 18056–18069 (2020)

L.D. Vuong, P.D. Gio, N.D.V. Quang, T.D. Hieu, T.P. Nam, J. Electron. Mater. 47(10), 5944–5951 (2018)

L.D. Vuong, V.T. Tung, P.D. Gio, The Investigation on the Fabrication and Characterization of the Multicomponent Ceramics Based on PZT and the Relaxor PZN-PMnN Ferroelectric Materials, Ceramic Materials, IntechOpen2020

X. Lv, J. Wu, X.-X. Zhang, Chem. Eng. J. 402, 126215 (2020)

W. Wu, J. Ma, B. Wu, Q. Gou, M. Chen, J. Alloys Compds. 822, 153585 (2020)

Y. Pan, X. Dai, J. Li, Y. Yi, Y. Yu, C. He, Y. Liu, Y. Xiang, Y. Chen, Phys. Scr. 95(6), 065802 (2020)

P.D. Gio, H.Q. Viet, L.D. Vuong, Int. J. Mater. Res. 109(11), 1071–1076 (2018)

D.V. Le, A.Q. Dao, J. Electroceram. 44(1), 68–77 (2020)

X. Zhao, W. Bai, Y. Ding, L. Wang, S. Wu, P. Zheng, P. Li, J. Zhai, J. Eur. Ceram. Soc. 40(13), 4475–4486 (2020)

W. Kang, Y. Li, Z. Zheng, R. Zhao, Ceram. Int. 46(11 Part A), 18089–18095 (2020)

D.A. Tuan, V.T. Tung, L.D. Vuong, N.H. Yen, L.T.U. Tu, Journal of Elec Materi 47(10), 6297–6301 (2018)

D.A. Tuan, L.D. Vuong, V.T. Tung, N.N. Tuan, N.T. Duong, J. Ceram. Process. Res. 19(1), 32–36 (2018)

S. Shi, H. Hashimoto, T. Sekino, Ceram. Int. 47(3), 3272–3278 (2020)

J. Rödel, W. Jo, K.T.P. Seifert, E.M. Anton, T. Granzow, D. Damjanovic, J. Am. Ceram. Soc. 92(6), 1153–1177 (2009)

L.D. Vuong, P.D. Gio, J. Alloys Compds. 817, 152790 (2020)

L. Zhang, Z. Wang, Y. Li, P. Chen, J. Cai, Y. Yan, Y. Zhou, D. Wang, G. Liu, J. Eur. Ceram. Soc. 39(10), 3057–3063 (2019)

N. Truong-Tho, L.D. Vuong, J. Adv. Dielectr. 10(04), 2050011 (2020)

J.-S. Lee, K.-N. Pham, H.-S. Han, H.-B. Lee, V.D.N. Tran, J. Korean Phys. Soc. 60(2), 212–215 (2012)

N. Truong-Tho, J. Electroceram. (2020). https://doi.org/10.1007/s10832-020-00224-5

A. Khaliq, M. Sheeraz, A. Ullah, J.S. Lee, C.W. Ahn, I.W. Kim, Sens. Actuators A 258, 174–181 (2017)

S.K. Gupta, R. McQuade, B. Gibbons, P. Mardilovich, D.P. Cann, J. Appl. Phys. 127(7), 074104 (2020)

Z. Huo, H. Wang, J. Xu, G. Rao, J. Wang, C. Zhou, C. Yuan, Ceram. Int. 46(8), 10067–10074 (2020)

H. Zhang, P. Xu, E. Patterson, J. Zang, S. Jiang, J. Rödel, J. Eur. Ceram. Soc. 35(9), 2501–2512 (2015)

Y. Zhang, P. Fan, H. Fan, B. Ye, G. Zhang, S. Jiang, H. Zhang, J. Electroceram. 44(1), 32–40 (2020)

T. Wang, X.-M. Chen, Y.-Z. Qiu, Ferroelectrics 510(1), 161–169 (2017)

H.-S. Han, W. Jo, J.-K. Kang, C.-W. Ahn, I. Won Kim, K.-K. Ahn, J.-S. Lee, J. Appl. Phys. 113(15), 154102 (2013)

A. Ullah, C.W. Ahn, A. Hussain, I.W. Kim, Curr. Appl. Phys. 10(6), 1367–1371 (2010)

L.K. Pradhan, R. Pandey, S. Kumar, S. Kumari, M. Kar, J. Mater. Sci.: Mater. Electron. 30(10), 9547–9557 (2019)

Y. Yan, Q. Wu, Y. Yang, L. Zhang, H. Lin, G. Xue, X. Liu, Y. Chen, J. Yang, G. Liu, Ferroelectrics 520(1), 171–176 (2017)

Y. Tsur, T.D. Dunbar, C.A. Randall, J. Electroceram. 7(1), 25–34 (2001)

S.K. Ghosh, V. Chauhan, A. Hussain, S.K. Rout, Ferroelectrics 517(1), 97–103 (2017)

I. Manasijević, L. Balanović, T.H. Grgurić, D. Minić, M. Gorgievski, Mater. Res. (2018). https://doi.org/10.1590/1980-5373-mr-2018-0501

J. Vizdal, M.H. Braga, A. Kroupa, K.W. Richter, D. Soares, L.F. Malheiros, J. Ferreira, Calphad 31(4), 438–448 (2007)

L.D. Vuong, N. Truong-Tho, J. Electron. Mater. 46(11), 6395–6402 (2017)

K.N.D.K. Muhsen, R.A.M. Osman, M.S. Idris, M.H.H. Jumali, N.H.B. Jamil, J. Mater. Sci.: Mater. Electron. 30(23), 20654–20664 (2019)

W. Li, J. Hao, J. Du, P. Fu, W. Sun, C. Chen, Z. Xu, R. Chu, J. Adv. Ceram. 9(1), 72–82 (2020)

P.D. Gio, H.T.T. Hoa, J. Mater. Sci. Chem. Eng. 2(11), 20 (2014)

X.P. Jiang, L.Z. Li, F.L. Jiang, Y.Y. Zheng, L.H. Liu, Effects of Mn-doping on the piezoelectric and ferroelectric properties of (Na0. 8K0. 2) 0.5 Bi0. 5TiO3 ceramics, Trans Tech Publ, pp. 69–71.

Y. Zhang, R. Chu, Z. Xu, J. Hao, Q. Chen, F. Peng, W. Li, G. Li, Q. Yin, J. Alloy. Compd. 502(2), 341–345 (2010)

M.G.S. Ali, N.Z. Elsyed, A.M. Abdel Fattah, G.A. Ali, Journal of Computational Electronics 11(2), 196–202 (2012).

H. Chen, B. Tang, C. Zhong, Y. Yuan, Y. Tan, S. Zhang, Ceram. Int. 43(10), 7383–7386 (2017)

L.D. Vuong, P.D. Gio, J. Mod. Phys. 5(14), 1258–1263 (2014)

Z. Huo, H. Xie, J. Xu, L. Yang, W. Qiu, X. Zhang, C. Zhou, H. Wang, Front. Mater. 7, 8 (2020)

G. Dong, H. Fan, J. Shi, M. Li, J. Am. Ceram. Soc. 98(4), 1150–1155 (2015)

H.T.K. Nguyen, T.A. Duong, F. Erkinov, H. Kang, B.W. Kim, C.W. Ahn, H.-S. Han, J.-S. Lee, J. Korean Ceram. Soc. 57(5), 570–577 (2020)

K.-N. Pham, A. Hussain, C.W. Ahn, W.K. Ill, S.J. Jeong, J.-S. Lee, Mater. Lett. 64(20), 2219–2222 (2010)

K. Wang, A. Hussain, W. Jo, J. Rödel, J. Am. Ceram. Soc. 95(7), 2241–2247 (2012)

A. Ullah, R.A. Malik, A. Ullah, D.S. Lee, S.J. Jeong, J.S. Lee, I.W. Kim, C.W. Ahn, J. Eur. Ceram. Soc. 34(1), 29–35 (2014)

D.S. Lee, D.H. Lim, M.S. Kim, K.H. Kim, S.J. Jeong, Appl. Phys. Lett. 99(6), 062906 (2011)

S.-J. Jeong, D.-S. Lee, M.-S. Kim, S.-M. Jang, I.-S. Kim, S. Mohsin, J.-S. Song, J. Electroceram. 33(3–4), 230–238 (2014)

K. Kumar, B.K. Singh, M.K. Gupta, N. Sinha, B. Kumar, Ceram. Int. 37(8), 2997–3004 (2011)

H. He, W. Lu, J.A.S. Oh, Z. Li, X. Lu, K. Zeng, L. Lu, ACS Appl. Mater. Interfaces 12(27), 30548–30556 (2020)

P. Li, Y. Huan, W. Yang, F. Zhu, X. Li, X. Zhang, B. Shen, J. Zhai, Acta Mater. 165, 486–495 (2019)

J. Yin, Y. Wang, Y. Zhang, B. Wu, J. Wu, Acta Mater. 158, 269–277 (2018)

Acknowledgements

This research was funded by Ministry of Education and Training under grant number B2019-DHH-13

Author information

Authors and Affiliations

Contributions

All persons who meet authorship criteria are listed as authors, and all the authors certify that they have participated sufficiently in the work to take public responsibility for the content, including participation in the concept, design, analysis, writing, or revision of the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Truong-Tho, N., Le Vuong, D. Study on the strain behavior and piezoelectric properties of lead-free Bi0.5(Na0.8K0.2)0.5TiO3 ceramics modified with Sn4+ ions. J Mater Sci: Mater Electron 32, 16601–16611 (2021). https://doi.org/10.1007/s10854-021-06215-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06215-8