Abstract

To optimize the comprehensive electrical performances of lead-free piezoelectric ceramics, (1-x)(Ba0.85Ca0.15)(Ti0.9Zr0.1)O3-xLiTaO3-0.3 mol% GeO2 (abbreviated as (1-x)BCZT-xLT-0.3 mol%G, 0 ≤ x ≤ 0.5) ceramics were prepared by conventional solid-state sintering method. The structures and electric properties of ceramics were systemically studied through XRD, Raman spectra, εr-T, SEM, and P–E, respectively. The results show that the piezoelectric properties can be affected by phase coexistences for different doping contents. Thereinto, the phase coexistences change from R-O at x = 0 to R-O/O-T at 0.1 ≤ x ≤ 0.2 and O-T at x = 0.3, respectively, while the R single phase is detected with x further increasing to 0.5. Correspondingly, the ceramics with multiphase coexistences at 0 ≤ x ≤ 0.3 obtain more excellent electrical properties than the ones with single phase at x = 0.5. In addition, the outstanding electric properties especially including the piezoelectric response are achieved at x = 0.2 mol% (e.g., d33 = 570 pC/N, kp = 0.61, εr = 14,887, tanδ = 0.007, Pr = 8.51 µC/cm2, Ec = 0.18 kV/cm, respectively).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Piezoelectric ceramics possess the characteristic of morphotropic phase boundary (MPB) and have been used in many electronic devices including transducers and actuators, etc., because of their desirable piezoelectric properties and superior temperature stability [1,2,3,4,5,6,7]. Lead-based piezoelectric ceramics (PZT) are extensively utilized among them up to now. However, the nocuous lead is easy to volatilize at high temperature and harmful to people’s health and the environment. Hence, more and more researchers are tending to study lead-free piezoelectric materials like BaTiO3(BT) ceramics to replace lead-based materials [8,9,10]. Over the past few years, BT-based ceramics have been extensively studied and many progresses are obtained [1, 11,12,13]. A most significant breakthrough is 0.5(BaZr0.2Ti0.8O3)-0.5(Ba0.7Ca0.3TiO3) (BCZT) ceramics discovered by Ren et al. which piezoelectric properties(d33) reached ~ 620 pC/N [11]. After that, many researchers begin to conduct researches about BCZT-based ceramics to replace PZT ceramics [11,12,13,14,15].

It is well known that the MPB plays a key role in improving electric properties of piezoceramics. Three kinds of phase transitions (TR−O, TO−T, TC) exist in BT-based ceramics with temperature increasing [11]. The coexistence of multiphases is achieved by adjusting the TR−O and TO−T through equivalent ions doping and replacing near room temperature, which is helpful to enhance piezoelectric performance. Thereafter, many researchers begin to utilize ionic doping to build phase boundaries and improve piezoelectric properties of BCZT-based ceramics.

In terms of doped modification, some researchers add single ions [16,17,18], while some researchers use composite ions [19,20,21,22]. For example, Chen et al. utilized Ge4+ to improve the sintering and properties of (K0.5Na0.5)NbO3 Ceramics [23]; Chen [24], Zhang [25] and Liu [26] improved piezoelectric properties through doping Li+ in BCZT-based ceramics; Zeng et al. used Ge4+ to enhance the piezoceramics’ electric properties and adjusted piezoelectric properties and the Curie temperature with Ta5+ & Li [17, 21]. Most of them discussed the relationship between electrical performances and ion replacements in their studies. However, few researchers studied the effects of multiphase coexistence on high piezoelectric properties by adjusting the composite doping of Li+, Ta5+ and Ge4+.

According to previous work about Ge4+ doping in BCZT [17] in our group and the doping experiments of GeO2 in BCZT before starting the research of the (1-x) BCZT - xLT − 0.3 mol%G (0 ≤ x ≤ 0.5) system, we choose the quantitative 0.3 mol%GeO2 to study Li+ and Ta5+ doping based on the piezoelectric properties. Hence, the Li+, Ta5+ and Ge4+ are doped together in BCZT-based ceramics to improve piezoelectric properties by conventional sintering route in the paper. The results show that these elements facilitate to enhance piezoelectric performance and a high piezoelectric constant (d33 = 570 pC/N) at x = 0.2 mol% is obtained. Furthermore, we discuss the composition dependence of phase structures and explore the reasons of high piezoelectric properties of ceramics by XRD, Raman spectra and εr-T. We firmly believe that the piezoelectric performances of BaTiO3-based ceramics can be improved by adjusting compositions and driving phase structures.

2 Experimental procedure

(1-x)(Ba0.85Ca0.15)(Ti0.9Zr0.1)O3-xLiTaO3-0.3 mol%GeO2 (0 ≤ x ≤ 0.5) solid solution ceramics were prepared by conventional ceramic processing route. The raw materials including BaCO3 (≥ 99.8%, AR), CaCO3 (≥ 99.5%, AR), TiO2 (≥ 99%, AR), ZrO2 (AR), Li2CO3 (AR), Ta2O5 (≥ 99.9%, AR), GeO2 (≥ 99.9%, AR), and ethanol were used as medium in this work. These raw materials were ball-milled with the medium for 12 h in Planetary and dried in oven, then we calcined them at 1150°C for 3 h and made these resulting powder in ball-mill for 12 h again. The dried powders were granulated with paraffin as the binder and pressed into disks of 12 mm in diameter and 1 mm in thickness under 30 MPa. Finally, such pellets were sintered at 1450°C for 3 h in air.

The crystalline phase structures of ceramics were detected by X-ray diffraction (Bruker D8 advance, Germany) with Cu-Ka radiation (λ = 1.5406 Å). The molecular structures were confirmed by Raman spectrometer (Horiba Scientific LabRAM HR Evolution, France). The morphologies of ceramics were scanned using SEM (ZEISS MERLIN Compact, China).

To explore electrical properties, the ceramic samples were fired at ~ 750°C for 30 min after coating the silver pastes on both surfaces of them. The samples were polarized at 25°C in the silicone oil bath by applying direct current electric field of 3.0 kV/mm for 30 min, and after 24 h to release remnant stress and charge, the piezoelectric coefficient (d33) values were measured by a quasi-static d33 meter (ZJ-3AN, Institute of acoustics, Chinese Academy of Sciences). In addition, dielectric properties were measured by LCR meter (HP4294, America Agilent Corporation) at 10 kHz and in the temperature range of −50 °C, 200 °C. Ferroelectric hysteresis loops (P-E) were measured at 0.5 kV, 1 kV, 1.5 kV, 2 kV, 2.5 kV, 3 kV and 10 Hz by tester (Radiant Technologies Inc., Albuquerque, NM).

3 Results and discussion

3.1 Phase structures

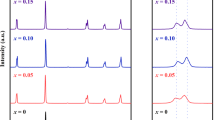

Figure 1 shows the room temperature XRD patterns of (1-x)BCZT-xLT-0.3 mol%GeO2 (0 ≤ x ≤ 0.5) ceramics which measured at 2θ range of 20 ~ 70 degree. It can be seen that all testing samples with different compositions have pure phase perovskite structures (ABO3) without second phases, indicating that the doping ions (Li1+, Ta5+, Ge4+) have diffused into BCZT lattices to form a stable solid solution. To analyze the dependence of phase structures on different compositions, the enlarged XRD pattern of 2θ = 44 ~ 46° is shown in Fig. 1b. The standard diffraction peaks are cited from BaTiO3 with rhombohedral(R) (PDF#85-1797), orthorhombic(O) (PDF#81-2200) and tetragonal(T) (PDF#05-0626) phases, which are plotted by vertical lines at the bottom of Fig. 1a and b. These phase structures are highly dependent on doping components. According to the comparison of these standard patterns and changes of the characteristic diffraction peak shapes at the position, the R-O phase coexistence occurs at x = 0, the R-O/O-T phase coexistence exists at 0.1 ≤ x ≤ 0.2, the O-T phase coexistence is found at x = 0.3 and single R phase is discovered at x = 0.5. Because of the coexistence of R, O and T phases, the piezoelectric properties of these ceramics have been improved significantly.

Moreover, the phase structures are proved through Lorentz fitting, Raman spectra and the temperature-dependent dielectric constant further.

The simulated XRD profiles through Lorentz method are used to further verify phase structures of ceramics, as shown in Fig. 2. Several separated peaks exist in these ceramics. Previous studies have confirmed that they are regarded as O phases which the right peak lower than the left, while they are viewed as T phases if the right one higher than the left [11]. As shown clearly in Fig. 2, the peak intensity of O phases is tending to decrease with x increasing from 0 to 0.2 mol%. In addition, they continuously shift to lower angle and overlap with T phase peaks when x = 0.3 mol% successfully, which suggests that the phase transition of O-T phases exists in ceramics. As a result, the coexistence of R-O/O-T phases at x = 0.1 ~ 0.2 mol% makes their piezoelectric properties better than the ceramics with x other components, as shown in Fig. 7a.

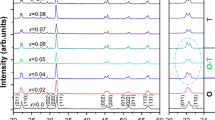

It is well known that the Raman vibrational modes of BaTiO3-based materials are mainly specified to E(LO1), A1(TO1), A1(TO2), E(TO2), A1(TO3) and A1(LO3)/E(LO3) [27]. Similarly, all the modes were observed in (1-x)BCZT-xLT−0.3 mol%G (0 ≤ x ≤ 0.5) ceramics as shown in Fig. 3, which were measured at room temperature and in the range of 100–1000 cm− 1. Because of random distribution of phonon wavevectors and long-range electrostatic force effects in ceramics [28], the A1(TO2) modes at ~ 217 cm− 1 turn to be broader. Moreover, the vibrational modes shift to higher or lower values due to the differences of tension and compression force [28]. For instance, the A1(TO3) modes are supposed to be obtained at ~ 490 cm− 1 in the BT ceramics representative for O phase [29], while are found at ~ 530 cm− 1 here. It can be seen from Fig. 3 that the modes symbolized R phase and O phase, respectively, which are situated at ~ 109 cm− 1 (E(LO1)), ~ 163 cm− 1 (A1(TO1)) and ~ 530 cm− 1 (A1(TO3)) when x = 0. The peaks at ~ 217 cm− 1 (A1(TO2)) and ~ 300 cm− 1 (E(TO2)) become flat with x increasing to 0.3 mol%, indicating that phase transitions occur between O phase and T phase [30]. Meanwhile, the R phases still exist in the ceramics of 0 ≤ x ≤ 0.2 mol%, confirming that the coexistences of R, O and T phases are obtained at the doping ceramics. Furthermore, the phase structure turns into R phase at x = 0.5 mol% with the splitting of the A1(TO3) and A1(LO3)/E(LO3) modes decreasing gradually for the doping contents adding. Hence, the Raman spectra further prove the phase structures of the ceramics.

Here, we continue to identify the phase transitions of ceramics with the curves of temperature dependence of dielectric constant (εr–T). Figure 4a–e respectively shows the εr–T curves of ceramics at x = 0 ~ 0.5 mol% and Fig. 4f displays the composition dependence of TR–O, TO–T, and TC, which are measured at −50 ~ 200 °C and 10 kHz. It is reported that the sequence of phase transitions is rhombohedral (R) → orthorhombic (O) → tetragonal (T) → cubic (C) with temperature increasing [11]. From Fig. 4a–e, we can observe that three dielectric peaks exist in the ceramics to facilitate piezoelectric performance [1, 13]. In addition, the phase transition temperatures (TR–O, TO–T, and TC) are different with the influence of doping components. It can be interpreted that doping ions affect the phase transition temperatures [31, 32]. In this study, the doping ions substitute Ti4+ and occupy B site, leading to TR–O and TO–T increase and TC decrease, while the TR–O, TO–T begin to lower and TC still decreases weakly with doping ions continuously being added (x = 0.3 ~ 0.5 mol%) and taking up A site, as shown in Fig. 4f. At the same time, the three phase transitions are close to each other because of the diffuse phase transition (DPT) behaviors [33]. All of these phenomena reveal that doping the ions is beneficial to form phase coexistence and improve piezoelectric properties of the ceramics.

3.2 Microstructure

The SEM of (1-x)BCZT-xLT-0.3 mol%G (0 ≤ x ≤ 0.5) ceramics and the corresponding grain size varied with x are displayed in Fig. 5a–f. It is found that all the ceramics have similar microstructures but own different compactness and grain sizes because of the differences of doping contents. Figure 5a–e shows the compactness lowers due to more and more pores among grains. The grain sizes tend to decrease gradually from 10.09 µm to 4.01 µm with x increasing, as shown in Fig. 5f. These phenomena are caused by ions partially storing in the crystal boundaries, resulting in suppressing grain growth, such as Ta5+ here [34]. What’s more, they are also attributed to the loss of Li at high-temperature sintering because Li2CO3 has a low melting point of 723 °C [35]. In addition, the electrical performances of ceramics are influenced tightly by grain sizes. As reported before, the Pr value would decrease because of grain size refinement, which is attributed to the deepened clamping effect of domain walls with the enhancement of grain boundaries [36, 37]. Similarly, the Pr of (1-x)BCZT-xLT-0.3 mol%G ceramics decrease gradually with x increasing for the reason, as shown in Fig. 6f.

3.3 Electrical properties

Figure 6 shows the polarization–electric field loops (P–E) of (1-x)BCZT-xLT-0.3 mol%G (0 ≤ x ≤ 0.5) ceramics measured at room temperature and 10 Hz. It can be observed that all samples have typical ferroelectric polarization hysteresis loops but possess different Pr and Ec values. It can be seen from Fig. 6f that the Pr of samples decreases with x increasing, which closely relates to the decrease of grain size of the ceramics mentioned above. The higher internal stress exists in fine grain ceramics, the more difficult of the domain reorientation and the domain wall motion between grain boundaries and domain walls, resulting in the decrease of Pr and the increase of Ec [38,39,40,41]. Ec also has a slight change and gets minimum value (Ec = 0.18 kV/cm) at x = 0.2 mol%, which may be because of the low energy barriers of the multiphase coexistence.

Figure 7 plots the diagrams of electrical properties about (1-x)BCZT-xLT-0.3 mol%G (0 ≤ x ≤ 0.5) ceramics. From Fig. 7a, the ceramics obtain the best piezoelectric properties of d33 = 570 pC/N at x = 0.2 mol%, which can be strengthened by the multiphase coexistence. In addition, the planar electromechanical coupling coefficient (kp) of ceramics has similar change tendency with d33 and achieves the greatest value of kp = 0.61. The curves of dielectric constants (εr) and dielectric loss (tanδ) values varying with x are shown in Fig. 7b, both of them are sensitive to the compositions and the maximum εr of 14,887 and minimum tanδ of 0.007 are gained at x = 0.2 mol%. Furthermore, the acquisition of high piezoelectric properties is also related to ferroelectric and dielectric performances of ceramics [42, 43]. The equation of d33 ∼ αεrPr can be quoted and Fig. 7c is plotted to discuss the relationship among dielectric, ferroelectric, and piezoelectric properties. As shown in Fig. 7c, εrPr and d33 have similar variation patterns with the change of doping components and obtain optimal electrical performance under the same doping components. Moreover, the piezoelectric properties are more highly influenced by dielectric performances than ferroelectric properties compared with Fig. 6f and Fig. 7b: indicating that the enhancement of dielectric properties is more beneficial to improve piezoelectric performances.

Table 1 lists the relationship of phase structures and piezoelectric properties for the analogous BCZT-based ceramic systems. It can be seen that phase structures play a key role in piezoelectric properties and we obtain better performances because of R-O/O-T phase coexistence compared with other similar systems which are also listed in Table 1.

4 Conclusions

In this work, (1-x)(Ba0.85Ca0.15)(Ti0.9Zr0.1)O3-xLiTaO3-0.3 mol% GeO2 (0 ≤ x ≤ 0.5) ceramics were successfully synthesized by conventional solid-state reaction method. We systematically discussed the influence of doping component on phase structures, microstructures and electrical properties. We observe that the coexistence of multiphase structures can influence electrical performances of ceramics especially the piezoelectric properties. The ceramics possess optimal electrical properties at x = 0.2 mol% (e.g., d33 ~ 570 pC/N, kp ~ 0.61, εr ~ 14,887, tanδ ~ 0.007, Pr ~ 8.51 µC/cm2, Ec ~ 0.18 kV/cm). We believe that our work can strengthen the understanding of the role of multiphase coexistences in electrical properties of BCZT lead-free piezoceramics.

References

W.F. Liu, X.B. Ren, (2009) Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett., 103(25)

B. Wu, H.J. Wu, J.G. Wu, D.Q. Xiao, J.G. Zhu, S.J. Pennycook, Giant piezoelectricity and high Curie temperature in nanostructured alkali niobate lead-free piezoceramics through phase coexistence. J. Am. Chem. Soc. 138(47), 15459–15464 (2016)

J. Rödel, K.G. Webber, R. Dittmer, W. Jo, M. Kimura, D. Damjanovic, Transferring lead-free piezoelectric ceramics into application. J. Eur. Ceram. Soc. 35, 1659–1681 (2015)

V.V. Ajeet Kumar, K.C. Bhanu Prasad, A.R. James Raju, James, Optimization of poling parameters of mechanically processed PLZT 8/60/40 ceramics based on dielectric and piezoelectric studies. Eur. Phys. J. B, 287(88), (2015)

V.V. Ajeet Kumar, K.C. Bhanu Prasad, A.R. James Raju, James, Poling electric field dependent domain switching and piezoelectric properties of mechanically activated (Pb0.92La0.08)(Zr0.60Ti0.40)O3 ceramics. J. Mater. Sci.: Mater. Electron. 26, 3757–3765 (2015)

K.C. Ajeet Kumar, A.R. James Raju, James, Micro-structural, dielectric, ferroelectric and piezoelectric properties of mechanically processed (Pb1-xLax)(Zr0.60Ti0.40)O3 ceramics. J. Mater. Sci.: Mater. Electron. 29, 13483–13494 (2018)

N. Zhang, H. Yokota, A. Glazer et al., The missing boundary in the phase diagram of PbZr1-xTixO3. Nat Commun., 5231(5), (2014)

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Lead- Free Piezoceramics. Nature 432, 84–87 (2004)

J. Rodel, W. Jo, K.T.P. Seifert, E.M. Anton, T. Granzow, D. Damjanovic, Perspective on the development of lead-free piezoceramics. J. Am. Ceram. Soc. 92, 1153–1177 (2009)

Y. Bai, A. Matousek, P. Tofel, V. Bijalwan, B. Nan, H. Hughes, T. Button, (Ba,Ca)(Zr,Ti)O3 lead-free piezoelectric ceramics the critical role of processing on properties. J. Eur. Ceram. Soc. 35, 3445–3456 (2015)

L.F. Zhu, B.P. Zhang, L. Zhao, J.F. Li, High piezoelectricity of BaTiO3–CaTiO3–BaSnO3 lead-free ceramics. J. Mater. Chem. C 2(24), 4764–4771 (2014)

D.Z. Xue, Y.M. Zhou, H.X. Bao, J.H. Gao, C. Zhou, X.B. Ren, Large piezoelectric effect in Pb-free Ba(Ti,Sn)O3-x(Ba,Ca)TiO3 ceramics. Appl. Phys. Lett., 99(12), (2011)

M.C. Ehmke, S.N. Ehrlich, J.E. Blendell, K.J. Bowman, Phase coexistence and ferroelastic texture in high strain (1 – x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 piezoceramics. J. Appl. Phys. 111(12), 110–124 (2012)

Z. Hanani, D. Mezzane, M. Amjoud, S. Fourcade, A.G. Razumnaya, I. Lukyanchuk, M. Goune, Enhancement of dielectric properties of lead-free BCZT ferroelectric ceramics by grain size engineering. Superlattice Microst. 127, 109–117 (2019)

J.G. Wu, D.Q. Xiao, W.J. Wu, J.G. Zhu, J. Wang, Effect of dwell time during sintering on piezoelectric properties of (Ba0.85Ca0.15)(Ti0.90Zr0.10)O3 lead-free ceramics. J. Alloys Compd. 509(41), L359–L361 (2011)

Z.H. Zhao, X.L. Li, H.M. Ji, Y.J. Dai, T. Li, Microstructure and electrical properties in Zn-doped Ba0.85Ca0.15Ti0.90Zr0.10O3 piezoelectric ceramics. J. Alloys Compd. 637, 291–296 (2015)

F.F. Zeng, Q.B. Liu, S.Q. Peng, Y.Y. Wang, E.P. Cai, A. Xue,·SL. Zhou, The (1-x)Ba0.85Ca0.15Zr0.08Ti0.92 - xGe lead-free ceramics with high piezoelectric activity and ultrahigh dielectric constant. Ceram. Int. 45, 1416–1419 (2019)

Y. Zhang, H.J. Sun, W. Chen, Li-modified Ba0.99Ca0.01Zr0.02Ti0.98O3 lead-free ceramics with highly improved piezoelectricity. J. Alloys Compd. 694, 745–751 (2017)

X. Liu, Z.H. Chen, B.J. Fang, J.N. Ding, X.Y. Zhao, H.Q. Xu, H.S. Luo, Enhancing piezoelectric properties of BCZT ceramics by Sr and Sn co-doping. J. Alloys Compd. 640, 128–133 (2015)

E.P. Cai, Q.B. Liu, S.L. Zhou, Y.Z. Zhu, A. Xue, Structure, piezoelectric, dielectric and ferroelectric properties of lead-free (1-x)(Ba0.85Ca0.15)(Ti0.93Zr0.07)O3-x(Bi0.5K0.5)TiO3 ceramics. J. Alloys Compd. 726, 1168–1178 (2017)

F.F. Zeng, Q.B. Liu, E.P. Cai, Y.Y. Wang, A. Xue, S.Q. Peng, S.L. Zhou, Y. Zhu, Relaxor phenomenon of (1-x)(Ba.85Ca.15)(Zr.09Ti.91)O3-xTa + 0.6 wt% Li2CO3 ceramics with high piezoelectric constant and Curie temperature. Ceram. Int. 44, 10677–10684 (2018)

X.Q. Huang, Q.B. Liu, C. Zhang, Effect of Sintering Temperature on microstructure and electrical properties of (1-x)BCZT-xBY lead-free ceramics. Adv. Mate., 119–122 (2014)

K.P. Chen, F.L. Zhang, Y.L. Jiao, D.S. Li, J. Tang, F. Gao, L.N. An, Effects of GeO2 addition on sintering and properties of (K0.5Na0.5)NbO3 ceramics. J. Am. Ceram. Soc. 99(5), 1681–1686 (2016)

X.M. Chen, X.Z. Ruan, K.Y. Zhao, X.Q. He, J.T. Zeng, Y.S. Li, L.Y. Zheng, C.H. Park, G.R. Li, Low sintering temperature and high piezoelectric properties of Li-doped (Ba,Ca)(Ti,Zr)O3 lead-free ceramic. J. Alloys Compd., 103–109 (2015)

Y. Zhang, H.J. Sun, W. Chen, Li-modified Ba0.99Ca0.01Zr0.02Ti0.98O3 lead-free ceramics with highly improved piezoelectricity. J. Alloys Compd., 745–751 (2017)

X. Liu, M. Zhu, Z.H. Chen, B.J. Fang, J.N. Ding, X.Y. Zhao, H.Q. Xu, H.S. Luo, Structure and electrical properties of Li-doped BaTiO3-CaTiO3-BaZrO3 lead-free ceramics prepared by citrate method. J. Alloys Compd. 219–225 (2014)

J.G. Wu, D.Q. Xiao, W.J. Wu, Q. Chen, J.G. Zhu, Z.Z. Yang, J. Wang, Composition and poling condition-induced electrical behavior of (Ba0.85Ca0.15)(Ti1 – xZrx)O3 lead-free piezoelectric ceramics. J. Eur. Ceram. Soc. 32(4), 891–898 (2012)

H. Richter, Z.P. Wang, L. Ley, The one phonon Raman spectrum in microcrystalline silico. Solid State Commun. 39(5), 625–629 (1981)

P.S. Dobal, S. Bhaskar, S.B. Majumder, R.S. Katiyar, Micro-Raman investigation of stress variations in lead titanate films on sapphire. J. Appl. Phys. 86(2), 828–834 (1999)

Y. Yang, Y.B. Zhou, J. Ren, Q.J. Zheng, K. Lam, D.M. Lin, Coexistence of three ferroelectric phases and enhanced piezoelectric properties in BaTiO3–CaHfO3 lead-free ceramics. J. Eur. Ceram. Soc. 38(2), 557–566 (2018)

X.S. Wang, H.S. Yamada, C.N. Xu, Large electrostriction near the solubility limit in BaTiO3–CaTiO3 ceramics. Appl. Phys. Lett., 86(2), (2005)

Y.G. Yao, C. Zhou, D.C. Lv, D. Wang, H.J. Wu, Y.D. Yang, X.B. Ren, Large piezoelectricity and dielectric permittivity in BaTiO3-xBaSnO3 system: The role of phase coexisting. EPL, 98(2), (2012)

D. Hennings, A. Schnell, G. Simon, Diffuse ferroelectric phase transitions in Ba(Ti1-yZry)O3 Ceramics. J. Am. Ceram. Soc. 65(11), 539–544 (1982)

J.F. Ma, X.Y. Liu, W.H. Li, High piezoelectric coefficient and temperature stability of Ga2O3-doped (Ba0.99Ca0.01)(Zr0.02Ti0.98)O3 lead-free ceramics by low-temperature sintering. J. Alloy. Compd. 581, 642–645 (2013)

X.M. Chen, X.Z. Ruan, K.Y. Zhao, X.Q. He, J.T. Zeng, Y.S. Li, Low sintering temperature and high piezoelectric properties of Li-doped (Ba,Ca)(Ti,Zr)O3 lead-free ceramics.. J. Alloy. Compd., 632 (2015)

Z. Zhao, V. Buscaglia, M. Viviani, M.T. Buscaglia, L. Mitoseriu, A. Testino, M. Nygren, M. Johnsson, P. Nanni, Grain-size effects on the ferroelectric behavior of dense nanocrystalline BaTiO3 ceramics. Phys. Rev. B 70, 024107 (2004)

A.D. Dupuy, Y. Kodera, G.P. Carman, J.E. Garay, Effect of phase homogeneity and grain size on ferroelectric properties of 0.5Ba(Zr0.2Ti0.8)O3-0.5(Ba0.7Ca0.3)TiO3 (BXT) lead-free ceramics. Scr. Mater. 159, 13–17 (2019)

H.T. Zhang, H.X. Yan, H.P. Ning, M.J. Reece, M. Eriksson, Z.J. Shen, Y.M. Kan, P.L. Wang, The grain size effect on the properties of Aurivillius phase Bi3.15Nd0.85Ti3O12 ferroelectric ceramics. Nanotechnology 20, 385708 (2009)

M.H. Frey, Z. Xu, P. Han, D.A. Payne, The role of interfaces on an apparent grain size effect on the dielectric properties for ferroelectric barium titanate ceramics. Ferroelectrics 206, 337–353 (1998)

M.H. Frey, D.A. Payne, Grain-size effect on structure and phase transformations for barium titanate. Phys. Rev. B 54, 3158–3168 (1996)

W. Cai, C.L. Fu, J.C. Gao, H.Q. Chen, Effects of Grain Size on Domain Structure and Ferroelectric Properties of Barium Zirconate Titanate Ceramics. Journal of Alloys and Compounds. J. Alloys Comp. 480, 870–873 (2009)

C.L. Zhao, H. Wang, J. Xiong, J.G. Wu, Composition-driven phase boundary and electrical properties in (Ba0.94Ca0.06)(Ti1 – xMx)O3 (M = Sn, Hf, Zr) lead-free ceramics. Dalton Trans. 45(15), 6466–6480 (2016)

T. Zheng, J.G. Wu, D.Q. Xiao, J.G. Zhu, Recent development in lead-free perovskite piezoelectric bulk materials. Prog. Mater Sci. 98, 552–624 (2018)

M.X. Zhou, R.H. Liang, Z.Y. Zhou, C.H. Xu, X. Nie, X.L. Dong, Enhanced Curie temperature and piezoelectric properties of (Ba0.85Ca0.15)(Zr0.10Ti0.90)O3 lead-free ceramics after the addition of LiTaO3. Mater. Res. Bull. 106, 213–219 (2018)

Acknowledgements

The work was supported by High-level Innovative Talents Plan of Guizhou province No.(2015)4009 and Specialized Funds from Industry and Information Technology Department of Guizhou Province No.2016056. The authors also acknowledged the support of the National Natural Science Foundation of China under Project No. 51602066.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mou, F., Xue, A., Liu, Q. et al. The high piezoelectric properties of lead-free (1-x)(Ba0.85Ca0.15)(Ti0.9Zr0.1)O3-xLiTaO3-0.3 mol% GeO2 ceramics driven by multiphase coexistence. J Mater Sci: Mater Electron 32, 2432–2440 (2021). https://doi.org/10.1007/s10854-020-05009-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-05009-8