Abstract

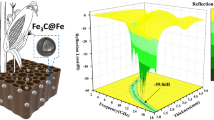

Biomass transformation is being considered as a green and sustainable strategy for carbon-based functional materials in many fields. To produce porous structure favorable for microwave absorption, we demonstrate herein the successful synthesis of macroporous carbon materials with cornstalk as a biomass precursor. It is found that two kinds of typical biological structures in cornstalk, linear vascular bundles and parenchyma cells, can be well preserved during high-temperature pyrolysis. Mercury intrusion porosimetry and N2 adsorption indicate that these cornstalk-derived carbon materials have very high porosity, which is mainly from desirable macroporous structure rather than conventional micro/mesopores. Electromagnetic (EM) analysis reveals that dielectric loss is the only pathway for the consumption of EM energy, and high pyrolysis temperature favors strong dielectric loss through conductive loss and interfacial polarization loss. Meanwhile, pyrolysis temperature also affects the matching degree of characteristic impedance. When the pyrolysis temperature reaches 750 °C, good dielectric loss and impedance matching endow the sample (CSC-750) with excellent microwave absorption performance, including strong reflection loss, broad response bandwidth, and relatively thin absorber thickness. The advantages of macroporous structure are further highlighted in impedance matching and multiple reflection by comparing with a macropore-free counterpart.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Microwave absorption is emerging as a promising strategy for the precaution of electromagnetic (EM) pollution, because it provides a more sustainable pathway to fundamentally eliminate incident EM waves as compared with conventional shielding strategy [1,2,3]. As a medium for energy dissipation, microwave absorbing materials (MAMs) can convert EM energy into heat or energy in other forms, and determine the efficiency of EM attenuation to a great extent [4, 5]. Magnetic materials, especially magnetic metals, were used to be typical MAMs in the past decades, whereas some intrinsic drawbacks, such as high density, easy corrosion, and low Curie temperature, make them incapable of being the next generation of MAMs [6, 7].

Carbon materials, e.g., carbon nanotubes (CNTs), carbon nanofibers (CNFs), reduced graphene oxide (rGO), are undoubtedly one of the most promising candidates due to their low density, good corrosion resistance, designable microstructure, and tunable dielectric property [8,9,10]. However, single carbon materials may suffer from unsatisfactory microwave absorption performance, for the fact of poor characteristic impedance matching, which can account for strong reflection of incident EM waves at the interface between free space and MAMs [11, 12]. Recently, it has been demonstrated that the introduction of some porous microstructure could be an effective way to improve characteristic impedance matching and reflection loss (RL) characteristics [13,14,15]. For example, Huang et al. validated that solid-void interfaces in mesoporous carbon materials could regulate complex permittivity and increase impedance matching degree effectively [16]; Xu et al. designed porous carbon particles derived for bi-metal organic framework, and proved the great contribution of micro/mesoporous structure to characteristic impedance matching, as well as a remarkable enhancement in RL characteristics [17]. Nevertheless, some groups revealed that such microporous or mesoporous microstructure only worked for optimizing impedance matching, but is incapable of inducing intensive multiple reflection or scattering of incident EM waves, a considerable pathway for EM energy dissipation, due to the gap of several orders of magnitudes between pore size and wavelength [18, 19]. Recent progress indicates that there are great interests to construct macroporous carbon materials as a kind of promising MAMs, including carbon foams [20], graphene aerogels [21], CNTs scaffolds [22]. Although macroporous carbon materials significantly reinforce microwave absorption properties, the formation of macroporous structure is complicated, where some hard templates (e.g., SiO2 and polystyrene microspheres) or unconventional techniques (e.g., catalytic decomposition and freeze-drying) are usually necessary [23, 24]. Therefore, it still remains a challenge to produce macroporous carbon materials in a simple way.

More recently, biomass conversion has been considered as a popular method for porous carbon materials, because some biological structures can be well preserved during high-temperature pyrolysis [25, 26]. Such a situation means one can easily obtain desirable macroporous carbon materials by choosing suitable biomass precursors. For example, Wang et al. prepared macroporous carbon with large specific surface area of 1075 m2g−1 and a broad pore size distribution between 25 and 60 μm with kenaf stem as the precursor [27]. Chen et al. also demonstrated a biomass-derived carbon anode by pyrolysis of bass wood, where natural macroporous structures were retained perfectly [28]. To date, various biomass-derived macroporous carbon materials have been investigated in the fields of supercapacitors, lithium-ion batteries, and biosensors, etc. [29, 30]. Several researchers also paid some attention to microwave absorption of biomass-derived carbon materials, while the microstructures therein are mainly established on micropores/mesopores [31, 32], and the contribution of macropores is still less discussed. In this article, cornstalk is selected as a new biomass precursor due to its abundant honeycomb-like parenchyma tissues and vascular bundles, which offers a good conversion platform for macroporous carbon materials. As we expected, the as-obtained carbon materials inherit the biological structure features of cornstalk. The effects of pyrolysis temperature and porous structure on EM properties and RL characteristics are investigated and discussed in detail. It is found that when cornstalk is pyrolyzed at 750 °C, there will be good microwave absorption performance with the strongest RL value of − 70.6 dB and a broad effective absorption bandwidth of 5.7 GHz, which is comparable to those of the best carbonaceous carbon materials in previous studies. By considering the advantages of biomass conversion, these results may enlighten the synthesis of high-performance carbon-based MAMs in the future.

2 Experimental

2.1 Synthesis of macroporous carbon materials

A typical procedure for cornstalk-derived macroporous carbon materials was illustrated in Scheme 1. Raw cornstalk collected from our own experimental plot was peeled, cut into sheets, and then washed with deionized water at room temperature for 12 h to remove impurities. After being dried at 80 °C in a vacuum oven, the cornstalk sheets were pyrolyzed in a tubular furnace under nitrogen atmosphere at a designated temperature for 2 h. The final products were denoted as CSC-x, where x was the corresponding pyrolysis temperature.

For comparison, a control sample (CSC-750A) was also prepared through KOH activation [32]. Specifically, the cornstalk was pre-pyrolyzed at 400 °C, and then 0.2 g of the as-obtained CSC-400 was immersed in 15 mL of KOH aqueous solution for 4 h at room temperature, where the mass ratio of C and KOH was 1:6. After being dried at 80 °C, the mixture was treated in the same procedure of CSC-750 and repeatedly washed with dilute HCl solution and deionized water.

2.2 Characterization

Powder X-ray diffraction (XRD, D/MAXRC, Rigaku, Japan) patterns were recorded with a Cu Kα radiation source (40 kV, 40 mA). Porous morphologies were observed by a FEI Sirion 200 scanning electron microscopy (SEM). An AutoPore IV 9510 porosimetry was used to carry out mercury injection porosimetry (MIP) measurement. Nitrogen adsorption–desorption isotherms were recorded at – 196 °C on an ASAP2020M micropore physisorption analyzer. Samples were degassed at 120 °C before measurement. Brunauer-Emmet-Teller (BET) method was used to calculate the specific surface area within the relative pressure range of 0.05 to 0.20. Pore size distributions were derived from the adsorption branches of the isotherms using the Barrett-Joyner-Halenda (BJH) method and collected from pores between 1 and 1000 Å diameter. Raman spectra were performed on a confocal Raman spectroscopic system (Renishaw, InVia) at 532 nm. The relative complex permittivity and complex permeability were calculated using an Agilent N5234A vector network analyzer in the frequency of 2.0–18.0 GHz for the calculation of RL characteristics. The samples containing 20 wt% of the obtained composites and 80 wt% of the paraffin wax. Before measurement, the samples were pressed into a ring with an outer diameter of 7.0 mm, an inner diameter of 3.0 mm and a thickness of 2.0 mm.

3 Results and discussion

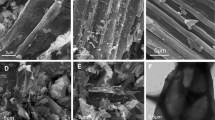

Figure 1a–c shows SEM images of raw cornstalk. It is clear that raw cornstalk contains two different microstructures (Fig. 1a), linear vascular bundles of cornstalk (marked by red rectangle) and parenchyma cells surrounding those vascular bundles (marked by blue rectangle). When the red marked rectangle is substantially enlarged, one can find that these linear vascular bundles are along with the axial direction of the cornstalk and composed of numerous macroporous channels ranging from several to tens of microns (Fig. 1b). As for those parenchyma cells, they are mostly distributed along the radial direction and present typical honeycomb microstructure with the size of ca. 100 μm (Fig. 1c). Very interestingly, both of two microstructures are well preserved after high-temperature pyrolysis at 750 °C except a slight shrinkage due to the removal of water and some volatile small molecules (Fig. 1d and e). The samples obtained at other temperatures (650, 700 and 800 °C) exhibit pretty much close microstructures (Fig. S1). These results indicate that cornstalk may be an ideal biomass precursor for macroporous carbon materials, and its microstructure has very good thermal stability that can survive from high-temperature pyrolysis. However, CSC-750A displays quite a different microstructure (Fig. S2), because the reaction between carbon and KOH at high temperature induces the collapse of macroporous microstructure [33].

Mercury intrusion porosimetry and N2 adsorption are employed to accurately evaluate the change of microstructure at different pyrolysis temperature. As shown in Fig. 2a, all these samples present similar variations in mercury intrusion-extrusion isotherms, where the intrusion volume is slightly increased in the low-pressure region, then drastically raises between 10 and 1000 psia, and finally become stable in the high-pressure region. In general, the external pressure is inversely proportional to pore size, because most solid materials are not wettable by mercury easily, and thus a high external pressure is always necessary to squeeze mercury into their pores [34]. Therefore, the feature of these intrusion curves confirms that CSC-x herein contains abundant macropores. The pore size analysis confirms that the most probable distributions of these macropores are about 5.0–20.0 μm (Fig. 2b). It is worth noting that the saturated intrusion volumes for CSC-650, CSC-700, CSC-750, and CSC-800 are 22.81, 20.30, 15.15, and 11.14 mL/g, respectively. Their corresponding porosities are 95.24%, 94.59%, 92.52%, and 81.14%, respectively. These results suggest that high pyrolysis temperature more or less impacts on the macroporous microstructure negatively. Although CSC-650, CSC-700, CSC-750, and CSC-800 present obvious mercury intrusion under high pressure, their N2 adsorption amounts are very poor as compared with those conventional microporous/mesoporous carbon materials (Fig. S3) [35, 36]. Their BET surface areas and pore volumes calculated from adsorption–desorption isotherms are 13.43 m2/g and 0.010 cm3/g, 15.08 m2/g and 0.011 cm3/g, 14.27 m2/g and 0.008 cm3/g, and 25.05 m2/g and 0.011 cm3/g, respectively. All these results clearly witness that CSC-x is absolutely macroporous carbon materials with negligible micropores and mesopores. In contrast, CSC-750A displays a characteristic IV-type isotherm (Fig. S4), whose maximum N2 adsorption amount can reach up to 573 cm3/g, indicating that CSC-750A has quite different microstructure from CSC-750. Moreover, CSC-750A also has high BET surface area (1587 m2/g) and large pore volume (0.837 cm3/g). It is undoubted that KOH activation should be responsible for the transformation from those inherent macropores to hierarchical micropores and mesopores. The mechanism of this process is suggested as the reaction between amorphous carbon and KOH, where K2CO3 is firstly generated and then decompose into CO2 and K2O at higher temperature [32, 37], and thus the overall activation procedure can be described as 6KOH + 2C → 2 K + 3H2 +2K2O + 2CO2.

Figure 3a exhibits XRD patterns of CSC-x. All four samples exhibit a broad peak centered at about 23.0°, suggestive of their amorphous nature [38]. Through a careful observation, one can also find that the intensity of a weak peak at about 43.2° slightly increases from CSC-650 to CSC-800. This phenomenon is attributed to the formation of tiny stacked crystalline graphite domains with the increase of pyrolysis temperature [39]. That is to say, the relative graphitization degree of these samples is gradually enhanced. To support this view point, Raman spectra, a sensitive tool for the bonding state of carbon atoms, is further utilized to identify the difference among these carbon materials. As shown in Fig. 3b, although all of them give two similar bands at 1342 cm−1 and 1592 cm−1, the intensity ratios (ID/IG) of these two bands are quite different. In general, the band at 1342 cm−1 is described as D band, originating from the disordered arrangement of carbon atoms, and the band at 1592 cm−1 is always denoted as G band, which is related to sp2-hybridization sites of carbon materials [40, 41]. Ferrari and Robertson ever reinterpreted the change of ID/IG value in different stages systematically [42]. For amorphous carbon materials, when tiny graphite domains appear in the carbon frameworks, the relative intensity of D band will be increased due to the decreases in bond-angle and bond-bending disorder, as well as the tightened vibrational density of states. Therefore, the incremental ID/IG value from CSC-650 to CSC-800 means that the relative graphitization degree is gradually enhanced, in good agreement with XRD results. It is very interesting that CSC-750A has quite similar XRD pattern and Raman spectrum to CSC-750 (Fig. S5), and thus one can infer that the differences in EM parameters and RL characteristics between CSC-750A and CSC-750 are more dependent on their microstructure rather than their own physicochemical properties.

It is well known that relative complex permittivity (εr = εr’ − jεr’’) and complex permeability (μr = μr’ − jμr’’) are two very important parameters to determine the performance of MAMs [43, 44]. For these macroporous carbon materials derived from cornstalk, their real parts (μr’) and imaginary parts (μr’’) of relative complex permeability are almost constant at 1 and 0 in the frequency range of 2.0–18.0 GHz (Fig. S6), suggesting their magnetic loss abilities are negligible. The difference of their EM functions is mainly embodied in dielectric property. Figure 4 shows frequency-dependent real parts (εr’) and imaginary parts (εr’’) of relative complex permittivity of CSC-x. As observed, CSC-650 has the lowest εr’ and εr’’ values among these samples. With increasing the pyrolysis temperature, both εr’ and εr’’ values are significantly increased, and meanwhile, frequency dispersion in these samples also become obvious. Dielectric loss tangent (tanδe = εr’’/εr’) reveals that their dielectric loss ability is in the order of CSC-650 < CSC-700 < CSC-750 < CSC-800 (Fig. S7). Generally speaking, dielectric loss is from two aspects, namely conductive loss and polarization loss, and the latter can be further divided into dipole orientation polarization and interfacial polarization in gigahertz range [45]. In our case, high pyrolysis temperature promotes the relative graphitization degree of these carbon materials (Fig. 3b), and thus the intrinsic conductivities of these carbon materials will be subsequently reinforced. According to free electron theory, high conductivity is favorable for large εr’’ value and further contributes to strong conductive loss [46,47,48]. Dipole orientation polarization in these carbon materials comes from the bound charges at some defective sites and surface functional groups, whose hysteretic reorientation under the applied EM field will be responsible for energy consumption [49]. Interfacial polarization is primarily attributed to the uneven distribution of space charges at the interfaces between carbon materials and wax matrix, and the electric moment therein may also dissipate EM energy to some extent [50]. Debye relaxation theory points out that εr’’ vs. εr’ curve can describe various polarization relaxations in MAMs, where one semicircle usually represents one Debye relaxation process [51,52,53]. There are at least three semicircles in εr’’ vs. εr’ curves of CSC-x (Fig. S8), which confirm the presence of multiple polarization relaxations according to Debye theory. As we discussed above, carbon materials from higher pyrolysis temperature have more crystalline graphite domains (i.e., less defective sites and surface functional groups), and thus the contribution from dipole orientation polarization will be gradually weakened from CSC-650 to CSC-800. However, high pyrolysis temperature also results in relatively large BET surface area, which means interfacial polarization is gradually consolidated. After checking the overall dielectric loss ability (Fig. S7), one can conclude that conductive loss and interfacial polarization may play two important roles for the consumption of EM energy in these carbon materials. Although CSC-750A has quite similar graphitization degree to CSC-750, the activation process induces the increase of BET surface area by at least 60 times and contains more solid-vacant interfaces, which can act as polarization center and enhance the interfacial polarization, leading to the remarkable enhancement in both relative complex permittivity and dielectric loss tangent [51] (Fig. S9).

Microwave absorption performance is usually evaluated by RL characteristic, which can be calculated with the following equations [54, 55],

The parameters of c and f are the velocity and frequency of EM waves, respectively, and d refers to the coating thickness of MAMs. Figure 5 shows three-dimensional RL maps of CSC-x in the frequency range of 2.0–18.0 GHz by varying d value from 1.0 to 5.0 mm. The minimum value of RL intensity (RLmin) in Fig. 5 is cut off by − 40.0 dB for a clear comparison, and the curves corresponding to the strongest absorption are displayed in Fig. S10. As observed, CSC-650 is nearly ineffective for the attenuation of EM waves in 2.0–18.0 GHz (Fig. 5a), whose RLmin is only − 4.2 dB (f = 10.0 GHz and d = 5.00 mm, Fig. S10a). This is because both dielectric loss and magnetic loss of CSC-650 are negligible. With the improvement of dielectric loss ability, CSC-700 and CSC-750 present significantly enhanced RL characteristics (Fig. 5b and Fig. 5c), and their RLmin intensities are − 32.8 dB (f = 6.7 GHz and d = 4.99 mm, Fig. S10b) and − 70.6 dB (f = 13.0 GHz and d = 2.47 mm, Fig. S10c), respectively. It is unfortunate that CSC-800 with better dielectric loss ability fails to promise larger RL intensity, and its RLmin intensity drastically falls back to − 13.1 dB (f = 18.0 GHz and d = 1.19 mm, Fig. 5d and Fig. S10d). In addition to RL intensity, another and even more important evaluation index is effective absorption bandwidth (EAB), generally defined as the frequency range with RLmin intensity less than − 10.0 dB. Such a situation means that the absorption efficiency of EM waves is over 90% [56, 57]. In the studied frequency interval, the integrated EABs for CSC-650, CSC-700, CSC-750, and CSC-800 are 0, 12.5 GHz (5.5–18.0 GHz), 13.5 GHz (4.5–18.0 GHz) and 9.6 GHz (8.4–18.0 GHz), respectively. The detailed comparison between CSC-700 and CSC-750 are further carried out in Table S1. It is clear that CSC-750 cannot only produce stronger reflection loss than CSC-700, but also realize similar single-point EAB with less absorber thickness. These features confirm that CSC-750 is indeed the best candidate among these carbon materials. CSC-750A, as a control sample, has richer porous structure and larger surface area, as well as more powerful dielectric loss, while it produces much inferior performance to CSC-750 (Fig. S11), suggesting that macroporous structure is more favorable for microwave absorption. Table 1 summarizes RL characteristics of CSC-750 and some pure carbonaceous MAMs reported in recent years [14,15,16, 32, 53, 56, 58,59,60,61,62,63,64,65]. Both RL intensity and EAB value further validate the advantages of CSC-750 as a promising MAM in a wide frequency range, which even generates a comparable performance to some of the best pure carbonaceous MAMs ever reported. Undoubtedly, this low-cost and simple biomass-derived strategy will provide a very good platform for the practical application of CSC-750.

Although relative complex permittivity and complex permeability have great effects on the performance of MAMs, one can find that RL characteristics of CSC-x are not monotonously dependent on their dielectric loss (Fig. 5). Actually, there are two additional factors associated with microwave absorption performance, namely, attenuation constant (α) and impedance matching [66]. The former elucidates the theoretical amplitude attenuation of EM waves inside MAMs induced by the joint action of dielectric loss and magnetic loss [67]. In our case, these macroporous carbon materials are single dielectric loss media, and thus their α values are in the same order as dielectric loss tangents (Fig. S12). The latter usually determines the transmission of EM waves at the front interface of MAMs [68]. If the impedance matching is good, most EM waves can enter MAMs and EM energy can be consumed therein; once the impedance of MAMs is poorly matched with that of free space, most EM waves will be reflected off at the interface rather than being penetrated into MAMs, and thus no matter how powerful theoretical attenuation is, there will be poor microwave absorption. A delta-function method was previously proposed to represent the impedance matching degree between MAMs and free space, which could be expressed by the following equations [40],

Although |∆| = 0 means that all EM waves can penetrate into MAMs (i.e., zero-reflection state), it is impossible to achieve this condition in reality. Some previous studies point out that |∆| ≤ 0.4 may be a threshold for acceptable impedance matching degree that can satisfy the prerequisite condition of good microwave absorption [6, 69]. Figure 6 shows two-dimensional delta maps of CSC-700, CSC-750, and CSC-800 with different d values in the frequency range of 2.0–18.0 GHz. It is very clear that CSC-750 has larger region with smaller delta values (|∆| ≤ 0.4) than CSC-700 and CSC-800. Therefore, the enhancement of microwave absorption performance from CSC-700 to CSC-750 benefits from the improvements of intrinsic attenuation ability and impedance matching, while the regressive performance of CSC-800 should be attributed to its unfavorable impedance matching. Although micropores/mesopores are proved to be effective to improve impedance matching, CSC-750A is still incapable of creating good impedance matching comparable to that of CSC-750 (Fig. S13), even inferior to those of CSC-700 and CSC-800, which in turn suppresses its microwave absorption performance. These results again verify the advantages of macroporous structure in microwave absorption, not only for the facilitation of multiple reflection which lengthens the attenuation path of EM energy [70], but also for its positive effect on impedance matching.

4 Conclusions

With cornstalk as a biomass precursor, a series of electromagnetic functionalized carbon materials have been prepared through a direct high-temperature pyrolysis. The as-obtained carbon materials have abundant macroporous structure and extremely high porosity. High pyrolysis temperature favors strong dielectric loss, because conductive loss and interfacial polarization will be gradually enhanced with the pyrolysis temperature. The sample pyrolyzed at 750 °C (CSC-750) shows the best microwave absorption performance among these macroporous carbon materials due to its decent attenuation ability and good impedance matching. More importantly, its performance is comparable to those of the best pure carbonaceous microwave absorbing materials in previous studies. By comparing with a control sample rich in micropores and mesopores, the advantages of macroporous structure can be clearly established in impedance matching and multiple reflection. These results suggest that macroporous carbon materials derived from cornstalk can not only produce desirable microwave absorption performance, but also provide a good platform for the design of various carbon-based composites with upgraded absorption efficiency.

References

X.X. Wang, T. Ma, J.C. Shu et al., Chem. Eng. J. 332, 321–330 (2018)

Y.C. Yin, X.F. Liu, X.J. Wei et al., ACS Appl. Mater. Interfaces. 9, 30850–30861 (2017)

X.M. Zhang, G.B. Ji, W. Liu et al., Nanoscale 7, 12932–12942 (2015)

J.W. Liu, R.C. Che, H.J. Chen et al., Small 8, 1214–1221 (2012)

Z. Xu, Y.C. Du, D.W. Liu et al., ACS Appl. Mater. Interfaces. 11, 4268–4277 (2019)

L.R. Cui, C.H. Tian, L.L. Tang et al., ACS Appl. Mater. Interfaces. 11, 31182–31190 (2019)

X.P. Li, Z.M. Deng, Y. Li et al., Carbon 147, 172–181 (2019)

R. Qiang, Y.C. Du, Y. Wang et al., Carbon 98, 599–606 (2016)

W.Q. Cao, X.X. Wang, J. Yuan et al., J. Mater. Chem. C 3, 10017–10022 (2015)

S.K. Singh, M.J. Akhtar, K.K. Kar, ACS Appl. Mater. Interfaces 10, 24816–24828 (2018)

W. Liu, Q.W. Shao, G.B. Ji et al., Chem. Eng. J. 313, 734–744 (2017)

L. Huang, J.J. Li, Z.J. Wang et al., Carbon 143, 507–516 (2019)

Y. Cheng, Z.Y. Li, Y. Li et al., Carbon 127, 643–652 (2017)

H.L. Xu, X.W. Yin, M. Zhu et al., ACS Appl. Mater. Interfaces. 9, 6332–6341 (2017)

Y.C. Du, T. Liu, B. Yu et al., Mater. Chem. Phys. 135, 884–891 (2012)

Y.X. Huang, Y. Wang, Z.M. Li et al., J. Phys. Chem. C 118, 26027–26032 (2014)

H.L. Xu, X.W. Yin, M. Zhu et al., Carbon 142, 346–353 (2019)

T. Huang, Z.C. Wu, Q. Yu et al., Chem. Eng. J. 359, 69–78 (2019)

Z.C. Wu, W. Hu, T. Huang et al., J. Mater. Chem. C 6, 8839–8845 (2018)

S. Wang, N. Xiao, Y. Zhou et al., Carbon 105, 224–226 (2016)

Z.C. Wang, R.B. Wei, J.W. Gu et al., Carbon 139, 1126–1135 (2018)

M. González, J. Baselga, J. Pozuelo, J. Mater. Chem. C 4, 8575–8582 (2016)

Z.Y. Huang, H.H. Chen, Y. Huang et al., Adv. Funct. Mater. 28, 1704363 (2018)

X.C. Gui, J.Q. Wei, K.L. Wang et al., Adv. Mater. 22, 617–621 (2010)

S.Y. Lu, M. Jin, Y. Zhang et al., Adv. Energy Mater. 8, 1702545 (2018)

J.X. Jiang, Q.H. Zhang, X.L. Zhan et al., ACS Sustainable Chem. Eng. 5, 10307–10316 (2017)

L. Wang, Q.Y. Zhang, S.L. Chen et al., Anal. Chem. 86, 1414–1421 (2014)

C.J. Chen, Y. Zhang, Y.J. Li et al., Energy Environ. Sci. 10, 538–545 (2017)

L. Estevez, R. Dua, N. Bhandari et al., Energy Environ. Sci. 6, 1785–1790 (2013)

H.Y. Song, S.M. Xu, Y.J. Li et al., Adv. Energy Mater. 8, 1701203 (2018)

X.F. Zhou, Z.R. Jia, A.L. Feng et al., Carbon 152, 827–836 (2019)

X. Qiu, L.X. Wang, H.L. Zhu et al., Nanoscale 9, 7408–7418 (2017)

W.J. Ma, N. Wang, Y.C. Du et al., ACS Sustainable Chem. Eng. 7, 2718–2727 (2018)

S. Diamond, Cement Concrete Res. 30, 1517–1525 (2000)

L.N. Han, X. Wei, Q.C. Zhu et al., J. Mater. Chem. A 4, 16698–16705 (2016)

W. Liu, L. Liu, Z.H. Yang et al., ACS Appl. Mater. Interfaces. 10, 8965–8975 (2018)

G.Y. Xu, J.P. Han, B. Ding et al., Green Chem. 17, 1668–1674 (2015)

Y.C. Du, J.Y. Wang, C.K. Cui et al., Synthetic Met. 160, 2191–2196 (2010)

K.X. Wang, Y.G. Wang, Y.R. Wang et al., J. Phys. Chem. C 113, 1093–1097 (2009)

Y.H. Wang, C.L. Li, X.J. Han et al., ACS Appl. Nano. Mater. 1, 5366–5376 (2018)

D.W. Liu, R. Qiang, Y.C. Du et al., J. Colloid Interf. Sci. 514, 10–20 (2018)

A.C. Ferrari, J. Robertson, Phys. Rev. B 61, 14095–14107 (2000)

C.H. Tian, Y.C. Du, C.S. Cui et al., J. Mater. Sci. 52, 6349–6361 (2017)

K. Singh, A. Ohlan, V.H. Pham et al., Nanoscale 5, 2411–2420 (2013)

G.L. Wu, Y.H. Cheng, Z.H. Yang et al., Chem. Eng. J. 333, 519–528 (2018)

W.L. Hu, L.D. Wang, Q.F. Wu, H.J. Wu, J. Mater. Sci. Mater. Electron. 25, 5302–5308 (2014)

H. Hu, L.D. Wang, H.J. Wu, Q. Lian, Appl. Phys. A 115, 1299–1307 (2014)

P. Chamoli, S.K. Singh, M.J. Akhtar et al., Physica E 103, 25–34 (2018)

A. Ohlan, K. Singh, A. Chandra et al., ACS Appl. Mater. Interfaces. 2, 927–933 (2010)

Y. Wang, Y.C. Du, P. Xu, Polymers 9, 1–28 (2017)

S.K. Singh, M.J. Akhtar, K.K. Kar, Compos. Part B 167, 135–146 (2019)

S.K. Singh, H. Prakash, M.J. Akhtar et al., ACS Sustain. Chem. Eng. 6, 5381–5393 (2018)

Y.J. Ding, J.Q. Zhu, S.S. Wang, J. Colloid Interf. Sci. 552, 196–203 (2019)

W.L. Chu, Y. Wang, Y.C. Du et al., J. Mater. Sci. 52, 13636–13649 (2017)

Y.Y. Shi, L.J. Yu, K. Li et al., Compos. Sci. Technol. 197, 180246 (2020)

W.W. Liu, H. Li, Q.P. Zeng et al., J. Mater. Chem. A 3, 3739–3747 (2015)

Q.X. Yang, Y.Y. Shi, Y. Fang et al., Compos. Sci. Technol. 174, 176–183 (2019)

X.S. Qi, Y. Yang, W. Zhong et al., J. Solid State Chem. 182, 2691–2697 (2009)

L. Liu, K.C. Zhou, P.G. He, Mater. Lett. 110, 76–79 (2013)

X.S. Qi, J.L. Xu, W. Zhong et al., RSC Adv. 5, 16010–16016 (2015)

N.J. Tang, W. Zhong, C.T. Au et al., J. Phys. Chem. C 112, 19316–19323 (2008)

N.N. Wang, F. Wu, A.M. Xie et al., RSC Adv. 5, 40531–40535 (2015)

S. Fang, D.Q. Huang, R.T. Lv et al., RSC Adv. 7, 25773–25779 (2017)

W.L. Song, M.S. Cao, L.Z. Fan et al., Carbon 77, 130–142 (2014)

Q.S. Li, J.J. Zhu, S. Wang et al., Carbon 161, 639–646 (2020)

X. Li, L.M. Yu, W.K. Zhao et al., Chem. Eng. J. 379, 122393 (2020)

P.J. Liu, Z.J. Yao, J.T. Zhou et al., J. Mater. Chem. C 4, 9738–9749 (2016)

Y.C. Du, W.W. Liu, R. Qiang et al., ACS Appl. Mater. Interfaces. 6, 12997–13006 (2014)

Z. Ma, Y. Zhang, C.T. Cao et al., Phys. B 406, 4620–4624 (2011)

S.K. Singh, M.J. Akhtar, K.K. Kar, Ind. Eng. Chem. Res. 59, 9076–9084 (2020)

Acknowledgements

This work was supported by the Youth Innovation Foundation of Heilongjiang Academy of Science (CXJQ2019WL02), the Natural Science Foundation of Heilongjiang Province (LH2019A023), Special Research Project on Basic Applied Technology of Heilongjiang Province (ZNBZ2020WL01), Science Research Foundation of Heilongjiang Academy of Science (KY2020WL02), and National Natural Science Foundation of China (21676065).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, J., Zhang, N., Zhao, H. et al. Cornstalk-derived macroporous carbon materials with enhanced microwave absorption. J Mater Sci: Mater Electron 32, 25758–25768 (2021). https://doi.org/10.1007/s10854-020-04571-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04571-5