Abstract

In this work, we examined the influence of In doping on the morphological and structural characteristics of ZnO active layers grown by the spin coating and the electrical performance of ZnO-based thin film transistors. XRD results indicated that the active layers were amorphous due to the absence of any sharp peaks. XPS analysis was carried out to determine indium amounts as an atomic percentage in ZnO and oxidation state of In. AFM images indicated that the roughness of the active layers decreased with increasing indium concentration in ZnO. The indium doping has dramatically improved the electrical parameters of ZnO-based transistors. The field-effect mobility of undoped TFT increased ~ 157 times by adding %3 In content. The highest field-effect mobility (μsat) of 12.9 cm2V−1 s−1 was obtained for %3 In-doped ZnO TFT (IZO3). Also IZO3 has a 6.96 V threshold voltage (Vth), 106Ion/Ioff ratio, 1.98 V/dec subthreshold slope (SS), and a high on-current of 4.6 mA. We ascribed the performance enhancement of devices with In doping due to increasing carrier concentration of channel. These results show that the low concentration of indium incorporation is very crucial to change the morphological properties of ZnO active layers and to obtain high-performance solution-processed TFTs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, amorphous metal oxide semiconductors, which are utilized as the active layer of TFTs (thin film transistors), have drawn great attention owing to their high field effective mobility (μFET), wide optical bandgap, and high transparency in comparison with traditional amorphous silicon [1,2,3]. These amorphous-based TFTs with high field-effect mobility allow them to be used as pixel drivers for the active-matrix organic LED display (AMOLED) backplanes and active-matrix LCD display (AMLCDs) [4, 5]. Among many inorganic metal oxide active materials, ZnO has been widely investigated and turned into an attractive because of its excellent optoelectronic properties [6, 7]. ZnO is richly abundant and environmentally friendly. It has n-type semiconductor nature, superior carrier mobility and high optical bandgap energy (3.4 eV) at room temperature. ZnO TFT can be a promising candidate for transparent electronic because of its transparency [8]. The electrical characteristic of ZnO can be controlled a wide range of conductivity from insulating to metallic by the methods of preparation active layer, the type, and the concentration of doping materials [9,10,11]. Recent researches exhibited that the resistivity of ZnO active layer can be decreased with increasing donor concentration by doping IIIB elements such as In, Ga, Al, and B when they are replaced with Zn sites. Because these elements behave as shallow donors in ZnO due to their weakly bounded outer p electron, it is considered as the source of more free electrons that contribute to the increase of electrical conductivity [12,13,14]. So, the indium-doped ZnO (IZO) thin film can be considered as a promising semiconductor layer for achieving high-performance TFTs. IZO has excellent properties such as high optical transparency, high electrical conductivity, and good chemical–physical stability in comparison with undoped ZnO active layers [15,16,17]. Also, since the difference between the ionic radii of the In3+ (~ 80 pm) and Zn2+ (~ 74 pm) is small, the In can be a promising candidate for substitutionary replacing Zinc in the ZnO crystal structure [18, 19]. As an active layer of transistors, IZO thin films can be deposited with different techniques such as magnetron sputtering [1], electron beam evaporation [20], and plasma-enhanced chemical vapor deposition (AP-PECVD) [21]. Semiconductor active layers having excellent electrical properties can be obtained using these methods requiring a high vacuum [22]. But most of these methods have some disadvantages such as requiring expensive instruments, limited deposition area, and long processing times [23]. On the other hand, the sol–gel technique offers several advantages such as simplicity, applicability to a large area, low fabrication cost, and easy controlling of chemical composition with homogeneity [17, 24]. Taking all these advantages into account, there are very few studies [12, 25] reported on ZnO with different indium content deposited by sol–gel methods to fabricate thin film transistor. Therefore, the ZnO and IZO active layers were prepared via a solution-processed sol–gel spin coating technique on SiO2 gate insulators. The aim of this study is to examine the influence of In doping on morphological, structural characteristics of ZnO films and electrical performances of TFTs when used as transistor active layers. We also recommend the optimal composition for a channel layer from which the best performance is achieved.

2 Experimental

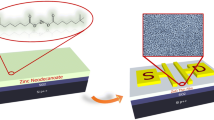

In this study, the amorphous ZnO and IZO active layers were deposited by sol–gel spin coating method. The experimental details for deposition active layers and fabrication of TFTs can be found in a previously published work in our group [26]. Only in this experiment, Indium chloride (InCl3) was used as a dopant source. Also, the nominal volume ratio of the In/Zn was arranged at 0%, 1%, 3%, 5%, and 10%. Each device has four active layers deposited by spin coater on 100 nm SiO2 coated Si (highly doped) layer (University wafer, USA). Each sample was annealed at fixed 750 °C into a furnace for 2 h. After the annealing, to form source and drain electrodes, high-purity aluminum metal was evaporated on top of the active layers with the help of a shadow mask having an interdigitated-finger geometry (channel length 50 μm, width 1000 μm) at a pressure of 10−6 mbar. At the end of this process, 60 nm thick aluminum source and drain contacts were obtained. The device structure and its interdigitated electrodes are shown in Fig. 1. Finally, the silver paste was used as gate contact for the last process of fabrication of TFTs. The transistors are labeled ZnO, IZO1 (%1), IZO3 (%3), IZO5 (%5), and IZO10 (%10), respectively. The flow chart depicting the device fabrication step by step is illustrated in Fig. 1. The surface morphology of TFTs was investigated with NT-MDT Nanoeducator II model atomic force microscopy (AFM) in non-conduct mode and in acoustic enclosure. AFM image analysis was carried out with Image Analysis P9 Program. The structural characterization of active layers and electrical performances of TFTs were performed by BRUKER D2 Phaser X-ray diffractometer and Keithley 4200 SCS with connected Signatone Probe Station, respectively. X-ray photoelectron spectroscopy (XPS) (SPECS) was used to determine the oxidation stage of In and the atomic percentage of In in ZnO and before this analysis, the calibration according to the C 1s peak at 284.6 eV was carried out.

3 Result and discussion

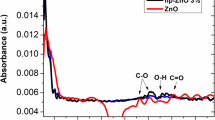

XPS analysis of (a) full spectrum of In-doped ZnO films with the associated binding energies of the elements and (b) In 3d spectrum of IZO films is shown in Fig. 2. The related elements in the films are shown in Fig. 2a, and also the intensity of characteristic 3d two peaks associated with In between 440 and 460 eV increases as the amount of indium in ZnO increases. The atomic percentages (at.%) of In obtained from these spectra are 0.741, 1.329, 1.978, and 3.801 for IZO1, IZO3, IZO5, and IZO10, respectively. Figure 2b shows the oxidation state of In and the spectra having the binding energies of 3d5/2 and 3d3/2 at around 444.5 eV and 452 eV separated by 7.6 eV from each other indicate that indium has 3 + oxidation state in ZnO. The investigation of surface morphology of the active layer for TFT is crucial to improve their performances. Therefore, the effect of In doping on ZnO morphology was examined by AFM. Figure 3a and b illustrates AFM images and the roughness of IZO active layers as a function of the In concentrations, respectively. It is observed that the dopant concentration strongly affects the surface morphology of the active layers. The change of surface roughness values of active layers with In doping is given in Table 1. The root-mean-square (RMS) roughness value of thin films decreases from 16.45 nm (ZnO) to 10.75 nm (IZO10) as the In concentration increases. The effect of a metal dopant on the decreasing of the surface roughness of ZnO has been reported many times [26, 27]. The difference between the ionic radii of Zn2+ (~ 74 pm) and In3+ (~ 80 pm) causes compression stresses and can limit grain growth in the c-axis direction of the structure. Therefore, the smoothness of films may increase with the doping of In [28]. A smoother surface of the semiconductor thin film can help transport the charge along the channel as it suppresses the interface traps and the scattering center, which leads to higher carrier mobility [29]. The similar surface variations of ZnO with different doping metals have also been reported in the literature [30,31,32]. However, it can easily be seen from Fig. 3 that the surface homogeneity of IZO3 is better than the others. Figure 4 shows XRD spectra of the ZnO and IZO films. All films indicate an amorphous nature due to the absence of any sharp peaks. The amorphous structure can occur in many multicomponent complex oxide films where the thermal energy is considerably lower than crystallization energy at room temperature [26, 33].

The output characteristics of the TFTs are shown in Fig. 5a. All transistors show typical n-channel nature because of increasing the current of the channel with increasing positive gate voltage. Also, the kink current in the linear/saturation region and crowding current in the low Vgs region were not observed in TFTs. This case indicates that the metal source/drain contacts deposited on the semiconductor have good ohmic character [34]. In order to examine the influence of In dopant on the electrical performance of the ZnO TFTs, the transfer characteristics of TFTs were measured at room temperature, under dark conditions with a constant source-to-drain voltage (Vds) of 25 V and given in Fig. 5b. The key parameters for transistors such as mobility (μsat), Ion/Ioff rate, the threshold voltage (Vth), subthreshold swing (SS), and the maximum interface trap states (\({N}_{max}^{SS}\)) need to be analyzed to evaluate the performance of the TFTs. The field-effect mobility in the saturation region of drain current and the threshold voltage can be extracted from a linear fitting to (Ids)1/2–Vgs plot using the following relation (1):

where Vgs is gate-source voltage, Ids is drain-source current, Ci is the gate capacitance per unit area, W is the width of the channel, and L is the length of the channel. The electrical performance of the transistors is influenced by the trap density in the active layers and the channel/gate insulator interface, which are dependent on the subthreshold swing (SS) value [22]. The SS can be obtained from Eq. (2):

The interface trap density for the transistor can be extracted from the following relation [35]:

where kT is the thermal energy and q is the electronic charge. The electrical parameters of transistors are shown as graphically in Fig. 5b. In addition, as seen in Table 1, It is clear that the electrical properties of IZO TFTs are very sensitive to the concentration of In in ZnO active layers. The SS value provides information about the total of the interface trap density between semiconductor/insulator and trap density of the bulk active layer [36]. The SS values and \({N}_{\max}^{\text{SS}}\) for the transistors show a decrease from ZnO to IZO3 than an increase from IZO3 to IZO10. A similar trend of variation in the SS values has been reported for the lithium-doped ZnO transistor [37]. The increase in SS value was attributed to the excess carrier concentration after optimum doping, which deteriorated conductivity in the channel. In addition, the decrease in the SS value indicates that the interface between the semiconductor and the insulator is improved [38]. The density and roughness of the active layers are generally directly related to \({N}_{\max}^{\text{SS}}\). The decreasing of the roughness value reduces the number of carriers to fall into the trap in defect sites [32]. Thus, an increase in mobility can be obtained. Also, It is seen that the SS and \({N}_{\max}^{\text{SS}}\) values are consistent with the trend of mobility change. The Ion/Ioff switching ratio of transistors is a crucial parameter, especially for active-matrix TFT applications. It is important to have a sufficiently high conductivity in the channel to obtain good drive currents. However, the conductivity must be low enough to achieve a high on/off ratio and pinch off [39, 40]. when the transfer characteristics are examined, it is clearly seen that the off current (Ioff) increases with increasing In doping. A high off current is an indication of many mobile charge carriers (extra electrons) in the active layer, which is due to the fact that trivalent In acts as a donor in ZnO [25, 32]. As a result, IZO1 TFT showed the highest Ion/Ioff ratio of ~ 107 in this study. It was clear that Vth decreased from 15.66 to 6.33 V as the In concentration increased in ZnO. The decreasing Vth is due to the increased electron concentrations in the active layers related to the continuously increasing In dopants. Also, the mobility values of all doped transistors were higher than undoped ZnO. The highest mobility value of 12.90 cm2/Vs was obtained from IZO3 and this value is 157 times higher than the mobility of undoped ZnO transistor. Similar results are observed by Kumar et al. [41] for spin-coated undoped ZnO, In-doped ZnO, and Ag nanowires (AgNWs) embedded indium-doped ZnO thin films. They have reported that doping In and In with AgNWs to ZnO gave rise to increase mobility and decrease the Vth and the SS values according to undoped ZnO-based transistor. They expressed that the improvement of these parameters referred to reduction of hydroxyl groups and increase in charge carriers due to doping In and In-AgNWs. Zhu et al. [42] fabricated undoped and In-doped ZnO horizontal nanorod array-based thin film transistors. The field-effect mobility, Vth, and on/off values of undoped ZnO and In-doped ZnO TFTs were obtained as 1.06 cm2 V−1 s−1, 10.99 V, 103 and 26.3cm2 V−1 s−1, − 3.32 V, 103, respectively. This variation was attributed that the In doping could lead to an increase in the concentration of oxygen vacancy and carrier density. Kim et al. [25] reported the effect of Indium doping on the electrical properties of ZnO-based TFT. The highest mobility of 5.22 cm2 V−1 s−1 and on/off rate of 4.54 × 104 were achieved from 60 μL Indium solution-doped ZnO TFT. Although the carrier concentration of thin films increased with In doping, the conductivity of films increased to only 60 µL In-doped film, then decreased. As an explanation of this case, they stated that increasing scattering centers and microcracks in the film structure led to this variation. This variation trend was reflected to their mobility value of TFTs, similar to our study. Also, they reported that Vth and SS values decreased with increasing In doping. Similar results have been reported by other researchers for In-doped ZnO-based TFTs [38, 43]. The highest mobility value for this study is higher than the mobility of previously published ZnO-based TFTs [2, 5, 12, 22, 25, 32, 39, 44, 45]. For this purpose, in the literature, the electrical parameters of In-doped ZnO-based TFTs previously published are listed in the Table 2 to make better comparison. Considering the studies carried out in the literature, the improved ZnO-based TFT performance should be evaluated with regard to increasing the carrier concentration and the conductivity of the active layers due to In doping [12, 22]. Also, a smoother surface of the IZO films can support transport the charge, which ensures higher carrier mobility. However, it is observed that the mobility of transistors first increases and then decreases with increasing In doping. The highest mobility value (IZO3) indicates that the In dopant in ZnO lattice has reached the optimum concentration for this study. The addition of further In doping in ZnO can degrade the electrical performance of transistors as dopants act as an impurity scattering center [25, 46]. Therefore, this degradation of mobility can be ascribed to this additional carrier scattering. Of course, the increase in the interface trap density after 3% In doping may have also led to this degradation. These results indicate that optimized doping concentration in metal oxide active layers can be a very efficient way of enhancement device performance. Similar results have been also observed in a few studies on the fabrication of In-doped ZnO TFTs by sol–gel method in the literature. In one of these studies, Zhang et al. [12] have investigated the influence of low-concentration indium (In) doping on ZnO TFTs. In this study, they obtained the highest mobility value of 0.16 cm2/Vs for the 7% In-doped ZnO TFT. Similarly, Choi et al. [23] deposited InZnO semiconductors by sol–gel spin coating method to use as the active layers of TFTs. They investigated the photo-response characteristics of these TFTs. They achieved the highest mobility value of 2.30 cm2/Vs from the TFT with the composition of the I0.5Z0.5O + I0.7Z0.3O active layer in the dark state. Finally, the mobility value obtained in this work is higher than those fabricated by the same method.

4 Conclusion

In summary, the ZnO and IZO thin films were deposited by sol–gel spin coating method to use as the active layers of TFTs. Then, we examined the effect of In doping on the morphological and structural characteristics of ZnO thin films and the electrical performance of TFTs. XPS analysis revealed that the incorporated indium in ZnO has 3 + oxidation state and showed us the atomic ratios of indium in ZnO. The results of X-ray diffraction indicated that the active layers were amorphous due to the absence of any sharp peaks. The atomic force microscope (AFM) images displayed that the roughness of the active layers decreased with increasing In concentration. Depending on the increasing indium doping concentration, the off current increased while the Vth decreased. TFT performance was remarkably enhanced with optimized In doping. The highest mobility value of 12.90 cm2/Vs was obtained from IZO3. This mobility value is 157 times higher than the mobility of the undoped ZnO transistor. The performance enhancement of TFTs was ascribed due to increasing the electron concentration and the conductivity of the channel because of In doping. Thus, we have indicated that the performance of TFTs can be improved with optimized In concentration in sol–gel-processed ZnO active layers.

References

J.Y. Won, Y.H. Han, H.J. Seol, K.J. Lee, R. Choi, J.K. Jeong, Transport property improvements of amorphous In-Zn-O transistors with printed Cu contacts via rapid temperature annealing. Thin Solid Films 603, 268–271 (2016)

T.S. Jung, S.J. Kim, C.H. Kim, J. Jung, J. Na, M.M. Sabri, H.J. Kim, Replacement and rearrangement of an oxide lattice by germanium doping in solution-processed indium-zinc-oxide thin-film. IEEE Trans. Electron Dev. 62, 2888–2893 (2015)

B. Du Ahn, H.J. Jeon, J. Sheng, J. Park, J.S. Park, A review on the recent developments of solution processes for oxide thin film transistors. Semicond. Sci. Technol. 30, 064001 (2015)

R.A. Street, T.N. Ng, R.A. Lujan, I. Son, M. Smith, S. Kim, T. Lee, Y. Moon, S. Cho, Sol-gel solution-deposited InGaZnO thin film transistors. ACS Appl. Mater. Interfaces. 6, 4428–4437 (2014)

X. Li, E. Xin, J. Zhang, Effects of Hf incorporation on indium zinc oxide thin-film transistors using solution process. Electron. Mater. Lett. 11, 143–148 (2015)

M.A. Islam, K.S. Rahman, F. Haque, N.A. Khan, M. Akhtaruzzaman, M.M. Alam, H. Ruslan, K. Sopian, N. Amin, Effect of Sn doping on the properties of nano-structured ZnO thin films deposited by Co-sputtering technique. J. Nanosci. Nanotechnol. 15, 9184–9191 (2015)

C.-Y. Tsay, K.-S. Fan, Optimization of Zr-doped ZnO thin films prepared by sol–gel method. Mater. Trans. 49(8), 1900–1904 (2008)

R.L. Hoffman, B.J. Norris, J.F. Wager, ZnO-based transparent thin-film transistors. Appl. Phys. Lett. 82, 733–735 (2003)

C.H. Ahn, S.H. Kim, Y.K. Kim, H.S. Lee, H.K. Cho, Effect of post-annealing temperatures on thin-film transistors with ZnO/Al2O3 superlattice channels. Thin solid flims (Elsevier, Amsterdam, 2015), pp. 336–340

L. Tian, D. Zhou, Y. Ma, X. Zhang, Y. Wang, Effects of annealing temperature on the electrical characteristics of Li–N co-doped polycrystalline ZnO thin film transistors. Superlatt. Microstruct. 109, 279–285 (2017)

S.Y. Park, B.J. Kim, K. Kim, M.S. Kang, K.-H. Lim, T. Il Lee, J.M. Myoung, H.K. Baik, J.H. Cho, Y.S. Kim, Low-temperature, solution-processed and alkali metal doped ZnO for high-performance thin-film transistors. Adv. Mater. 24, 834–838 (2012)

X. Zhang, H. Lee, J.-H. Kwon, E.-J. Kim, J. Park, Low-concentration indium doping in solution-processed zinc oxide films for thin-film transistors. Materials (Basel). 10, 880 (2017)

C. Klingshirn, ZnO: material, physics and applications. ChemPhysChem 8, 782–803 (2007)

R. Biswal, A. Maldonado, J. Vega-Pérez, D. Acosta, M. De La Luz Olvera, Indium doped zinc oxide thin films deposited by ultrasonic chemical spray technique, starting from zinc acetylacetonate and indium chloride. Materials (Basel). 7, 5038–5046 (2014)

S. Major, K.L. Chopra, Indium-doped zinc oxide films as transparent electrodes for solar cells. Sol. Energy Mater. 17, 319–327 (1988)

C. Zhang, D. Xiong, S. Xu, W. Ouyang, L. Wang, P.K. Chu, Highly efficient field emission from indium-doped ZnO nanostructure on nanographene/macroporous electric conductive network. Mater. Lett. 222, 25–28 (2018)

R. Hadj-Tahar, A.B. Mohamed, Sol–gel processed indium-doped zinc oxide thin films and their electrical and optical properties. New J. Glas. Ceram. 4, 55–65 (2014)

C.Y. Tsay, H.C. Cheng, Y.T. Tung, W.H. Tuan, C.K. Lin, Effect of Sn-doped on microstructural and optical properties of ZnO thin films deposited by sol–gel method. Thin Solid Films 517, 1032–1036 (2008)

S. Krehula, M. Ristić, M. Reissner, S. Kubuki, S. Musić, Synthesis and properties of indium-doped hematite. J. Alloys Compd. 695, 1900–1907 (2017)

J.-S. Hong, B.-R. Rhee, J.-J. Kim, S.-H. Park, H.-M. Kim, J.-S. Ahn, Highly transparent and conducting In$_2$O$_3$-ZnO thin films prepared by electron-beam evaporation technique. J. Korean Phys. Soc. 45, 712–715 (2004)

C.-H. Wu, K.-M. Chang, Y.-M. Chen, B.-W. Huang, Y.-X. Zhang, S.-J. Wang, Using KrF ELA to improve gate-stacked LaAlO3/ZrO2 indium gallium zinc oxide thin-film transistors with novel atmospheric pressure plasma-enhanced chemical vapor deposition technique. J. Nanosci. Nanotechnol. 18, 1917–1921 (2017)

J. Park, T.-J. Ha, W.-J. Cho, Improvement of air stability on solution-processed InZnO thin-film transistors by microwave irradiation and Zn composition ration. Phys. Status Solidi. 212, 1719–1724 (2015)

J. Choi, J. Park, K.H. Lim, N.K. Cho, J. Lee, S. Jeon, Y.S. Kim, Photosensitivity of InZnO thin-film transistors using a solution process. Appl. Phys. Lett. 109, 132105 (2016)

Y. Caglar, M. Caglar, S. Ilican, XRD, SEM, XPS studies of Sb doped ZnO films and electrical properties of its based Schottky diodes. Optik (Stuttg). 164, 424–432 (2018)

J. Kim, J.H. Choi, H. Chae, H. Kim, Effect of indium doping on low-voltage ZnO nanocrystal field-effect transistors with ion-gel gate dielectric. Jpn. J. Appl. Phys. 53, 071101 (2014)

S. Ruzgar, M. Caglar, The effect of Sn on electrical performance of zinc oxide based thin film transistor. J. Mater. Sci. Mater. Electron. 30, 485–490 (2019)

G. Singh, S.B. Shrivastava, D. Jain, S. Pandya, T. Shripathi, V. Ganesan, Effect of indium dop ing on zinc oxide films prepared by chemical spray pyrolysis technique. Bull. Mater. Sci. 33, 581–587 (2010)

J.H. Lee, B.O. Park, Transparent conducting ZnO:Al, and Sn thin films deposited by the sol-gel method. Thin Solid Films 426, 94–99 (2003)

F. Liu, C. Qian, J. Sun, P. Liu, Y. Huang, Y. Gao, J. Yang, Solution-processed lithium-doped zinc oxide thin-film transistors at low temperatures between 100 and 300 °C. Appl. Phys. A 122, 311 (2016)

J. Yang, Y. Jiang, L. Li, M. Gao, Structural, morphological, optical and electrical properties of Ga-doped ZnO transparent conducting thin films. Appl. Surf. Sci. 421, 446–452 (2017)

S.H. Jeong, B.N. Park, S.B. Lee, J.H. Boo, Study on the doping effect of Li-doped ZnO film. Thin Solid Films 516, 5586–5589 (2008)

G.H. Kim, B. Du Ahn, H.S. Shin, W.H. Jeong, H.J. Kim, H.J. Kim, Effect of indium composition ratio on solution-processed nanocrystalline InGaZnO thin film transistors. Appl. Phys. Lett. 94, 233501 (2009)

I. Noviyana, A.D. Lestari, M. Putri, M.-S. Won, J.-S. Bae, Y.-W. Heo, H.Y. Lee, High mobility thin film transistors based on amorphous indium zinc tin oxide. Materials (Basel). 10, 702 (2017)

K.B. Park, J.B. Seon, G.H. Kim, M. Yang, B. Koo, H.J. Kim, M.K. Ryu, S.Y. Lee, High electrical performance of wet-processed indium zinc oxide thin-film transistors. IEEE Electron Device Lett. 31, 311–313 (2010)

Z. Yang, J. Yang, T. Meng, M. Qu, Q. Zhang, Influence of channel layer thickness on the stability of amorphous indium zinc oxide thin film transistors. Mater. Lett. 166, 46–50 (2016)

M. Kumar, H. Jeong, D. Lee, Sol-gel derived Hf- and Mg-doped high-performance ZnO thin film transistors. J. Alloys Compd. 720, 230–238 (2017)

B.Y. Su, S.Y. Chu, Y. Der Juang, Improved electrical and thermal stability of solution-processed Li-doped ZnO thin-film transistors. IEEE Trans. Electron Devices. 59, 700–704 (2012)

A.B. Cheremisin, S.N. Kuznetsov, G.B. Stefanovich, Effect of indium low doping in ZnO based TFTs on electrical parameters and bias stress stability. AIP Adv. 5, 117124 (2015)

J.H. Shim, H. Kim, J.H. Lim, J.H. Choi, C.M. Lee, K. Park, J. Joo, H. Kim, H.-J. Lee, M.R. Moon, D. Jung, Fabrication and comparison of the properties of SnInZnO and InZnO TFTs processed by using the flexible and stretchable electronics view project LG chem view project fabrication and comparison of the properties of SnInZnO and InZnO TFTs processed by using the sol–gel method. Artic. J. Korean Phys. Soc. 57, 1847–1851 (2010)

S. Amano, H. Harada, K. Akimoto, J. Sakata, T. Nishi, K. Moriya, K. Wakimoto, J. Koyama, S. Yamazaki, Y. Oikawa, T. Ikeyama, M. Sakakura, Low power LC display using In-Ga-Zn-oxide TFTs based on variable frame frequency. SID Symp. Dig. Tech. Pap. 41, 626 (2010)

M. Kumar, H. Jeong, D. Lee, Solution-processed undoped and Indium doped ZnO thin film transistors: role of Ag nanowires into InZnO channel layer. Semicond. Sci. Technol. 34, 075019 (2019)

Z. Zhu, B. Li, J. Wen, Z. Chen, Z. Chen, R. Zhang, S. Ye, G. Fang, J. Qian, Indium-doped ZnO horizontal nanorods for high on-current field effect transistors. RSC Adv. 7, 54928–54933 (2017)

Y. Wu, E. Girgis, V. Ström, W. Voit, L. Belova, K.V. Rao, Ultraviolet light sensitive In-doped ZnO thin film field effect transistor printed by inkjet technique. Phys. Status Solidi. 208, 206–209 (2011)

J. Il Song, J.S. Park, H. Kim, Y.W. Heo, J.H. Lee, J.J. Kim, G.M. Kim, B.D. Choi, Transparent amorphous indium zinc oxide thin-film transistors fabricated at room temperature. Appl. Phys. Lett. 90, 022106 (2007)

Z. Yang, N. Wang, M. Qu, H. Pu, Q. Zhang, Preparation and characterization of molybdenum-doped indium-zinc-oxide thin film transistors. Semicond. Sci. Technol. 30(4), 045008 (2015)

R. Xu, J. He, W. Li, D.C. Paine, Performance enhancement of amorphous indium-zinc-oxide thin film transistors by microwave annealing. Appl. Surf. Sci. 357, 1915–1919 (2015)

Acknowledgements

This work was supported by Eskisehir Technical University Commission of Scientific Research Projects under Grant No. 1706F385.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ruzgar, S., Caglar, Y. & Caglar, M. The influence of low indium composition ratio on sol–gel solution-deposited amorphous zinc oxide thin film transistors. J Mater Sci: Mater Electron 31, 11720–11728 (2020). https://doi.org/10.1007/s10854-020-03723-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03723-x