Abstract

This work reports on the thermoelectric properties of bulk SnS2, which shows a similar composition and layered crystal structure to the extensively studied SnS and SnSe. The synthesis process for mechanical alloying (MA) SnS2 was also investigated. The SnS2 compound was formed in the reaction between SnS and S, after the formation of SnS using Sn and S as raw materials. However, single-phase SnS2 appears to be difficult to obtain by MA because Sn2S3 is produced when milling times are extended. Nevertheless, a pure-phase SnS2 bulk is achieved by further spark plasma sintering. The pristine SnS2 bulk shows an n-type conductive characteristic and a moderate absolute Seebeck coefficient between 100 and 700 μV/K. However, with a low figure of merit value ZT, the thermoelectric property is poor because of the low electrical conductivity of below 0.2 S/cm and the relatively high thermal conductivity of above 1.5 W/mK. Further, the electrical conductivity is enhanced and the thermal conductivity decreases significantly after Ag doping. An enhanced ZT value of 0.01 is achieved which is two times higher than pristine one.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

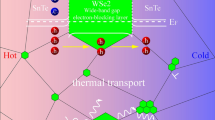

Thermoelectric (TE) solid-state energy conversion technology [1,2,3] has attracted great attention in reducing the energy consumption and enhancing the energy utilization efficiency because of their capability to convert waste heat directly into electricity according to the Seebeck effect—a phenomenon by which a voltage is produced when a material is exposed to a temperature gradient [4, 5]. The TE efficiency of a material used in TE devices is determined by the dimensionless figure of merit, ZT = S2σT/κ, where S denotes the Seebeck coefficient, σ the electrical conductivity, κ the thermal conductivity, and T the absolute temperature, respectively. Thus, a large Seebeck coefficient, a high electrical conductivity, and a low thermal conductivity are needed to realize high ZT values. However, as these three transport coefficients are interdependent, searching for practical materials with good TE performance is challenging [6, 7].

Natural superlattice materials typically consist of two or more periodically stacked sublattices, which often exhibit special physical properties. There remains the possibility that the thermal and electrical properties of these materials may be adjusted independently. Therefore, the idea of a natural superlattice as a means to develop new TE materials has received much interest. Actually, some of the layered materials, such as CaAl2Si2-type Zintl compounds [8], SnS [9] WoS2 [10], and layered Co oxides [11,12,13], with excellent TE properties, have been developed in recent years. As a typical example, the layered and anisotropic crystal structure of SnSe single crystal brings about an extremely low thermal conductivity, which results in a much higher ZT value of over 2.0 along the b- and c-axis directions [14] and establishes it as a very promising material. Moreover, layered metal dichalcogenides MX2 (M = W, Ti; X = S, Se), the constituent elements of which are abundant and non-toxic, are also supposed to be good TE materials because of its acceptable Seebeck coefficient and comparatively low cross-section thermal conductivity [15, 16]. Among them, Guilmeau and collaborators reported that TiS2 shows a high-power factor of 1.7 mW/mK2 at 325 K [17]. Here, the power factor (PF) is PF = σS2, which is always primarily evaluated from the TE potential of the material. Recently, Nunna and collaborators further optimized the TE properties of TiS2 and reported a maximum ZT of 0.54 at 700 K for Cu0.05TiS1.5–Se0.5.[18] Moreover, WS2 was also found to be a good TE material at high temperatures. N-type WS2 can achieve a maximum ZT value of 0.90 at 1500 K, which is comparable to the best TE materials presently used in devices [19]. As a member of the metal dichalcogenides, tin bisulfide (SnS2) also crystallizes in hexagonal close-packed CdI2-type structure [20]. It has attracted much attention because it is the thinnest two-dimensional crystal structure in the field of energy storage. However, although many promising TE materials have been found in metal dichalcogenides, the experimental reports on the TE properties of SnS2 are scarce. In fact, according to theoretical calculation, the PF of SnS2 reaches as high as 11.89 × 10−4 and 15.50 × 10−4 W/mK2 along the a-axis direction at 800 K, suggesting that SnS2 might be a very promising TE candidate. Furthermore, bulk SnS2 shows a similar composition and layered crystal structure as the extensively studied SnS and SnSe, which also indicates that SnS2 may be a good TE material.

In this work, the TE properties of pure SnS2, which was prepared by combining mechanical alloying (MA) with spark plasma sintering (SPS), have been investigated. The synthesis process was also studied considering the results of X-ray diffraction (XRD) patterns and Raman spectrum. With an aim to further improve its TE property, Ag-doped SnS2 has been prepared. Benefiting from the enhanced electrical conductivity compared with that for a pristine sample, an optimal TE property has been achieved.

1.1 Experimental section

In a typical experiment, commercial powders of Sn (99.99%), S (99.95%), and Ag (99.9%) were used as raw materials to synthesize the pristine SnS2 and Ag-doped SnS2 samples. They were weighed according to the nominal composition of SnS2-X%Ag (x = 0,3) and then milled at 425 rpm for 5–11 h in an atmosphere of high-purity argon (99.99%), using a planetary ball milling machine (QM-2SP2, Nanjing University, China). Stainless steel vessels and balls were used, and the weight ratio of the ball to powders was kept at 30:1. After that, the precursor powders were charged into column graphite dies with diameters of 15 mm and sintered in vacuum environment by a spark plasma sintering system (SPS, LABOX-325, Japan) under a uniaxial pressure of 50 MPa at 723 K for 5 min to obtain the final samples.

The phase structures and compositions of SnS2-X%Ag (x = 0,3) powders and bulk samples were analyzed in X-ray diffraction (XRD, Rigaku, Japan) with a CuKα radiation and Raman spectrum (Raman inVia, China). The morphology, elementary composition ratio, and element mappings of the SnS2 sample were observed using a scanning electron microscope and an energy-dispersive spectrometer (SEM, EDS, Supra 55 Sapphire, Germany). The Seebeck coefficient and electrical resistivity were measured from 323 to 723 K in a helium atmosphere using a Seebeck coefficient/electrical resistance measuring system (Seebeck, Seebeck 458, Germany). The density was measured using Archimedes’ method. The thermal conductivity is calculated from the relation κ = DCPρ, where D is the thermal diffusivity measured using laser flash method (LFA467, Netzsch, Germany), CP—the specific heat capacity—is calculated using the empirical formula: \(C_{P } = A_{1} + A_{2} \times 10^{ - 3} T + A_{3} \times 10^{5} T^{ - 2} + A_{4} \times 10^{ - 6} T^{2} + A_{5} \times 10^{8} T^{ - 3}\) [21], and ρ is the density.

2 Results and discussion

Figure 1a shows the XRD patterns of precursor powders with different milling times (5–11 h). The standard diffraction patterns of SnS2 (PDF#23–0677), Sn2S3 (PDF#72–0031), SnS (PDF#75–0925), Sn (PDF#04–0673), and S (PDF#99–0066) were plotted for comparison (Fig. 1a). They show that with increasing ball milling time, Sn and S elements reacted and formed the SnS phase initially, and then the SnS2 phase was synthesized via the reaction between SnS and S. When the ball milling time was prolonged to 10 h, the precursor powder was a mixture mainly composed of SnS2, SnS, and Sn. However, when the ball milling time exceeded 10 h and 30 min, a new Sn2S3 phase appeared in the XRD pattern of the precursor powder. This indicates that with the extension of ball milling time, the formed SnS2 might react with the redundant SnS to form Sn2S3. As the ball milling time was further extended to 11 h, the full width at half-maximum of Sn2S3 peaked and gradually became narrower, indicating that its crystallinity was gradually enhanced. Thus, this result suggests that the pure phase of SnS2 is difficult to obtain directly by MA using Sn and S as raw materials because of the production of intermediate compounds SnS and Sn2S3. In addition, the morphologies of the precursor powders with different milling times were observed (Fig. 2). The result indicates that the precursor obtained from a 5 h milling time is mainly composed of coarse grains of 1–5 μm diameter (Fig. 2a). With increasing milling time, grain size decreases with the precursor mostly having grain diameters between 200 nm and 1 μm with ball milling times of 8 h, 10 h, and 11 h (Fig. 2b–d). The grain size is also uniform compared with the powder with a 5 h milling times. Combined with the XRD results, the indication is that the constant accumulation of energy by the MA triggers the reaction to produce the compound. Meanwhile, the crushing and extrusion of the MA also reduces the grain sizes of precursor powders after milling over 5 h. Spark plasma sintering is a flash sintering approach combining high electrical current and high pressures at the beginning of sintering process; the generated pulsed current can clean the precursor’s surfaces form absorb species and create surface defects at the same time, therefore, activating the surface of precursor powders [22]. The activation energy is then significantly reduced, which assists densification as diffusion, in the form of grain boundary diffusion, lattice diffusion, and volume diffusion, can be accelerated. The sample may also be recrystallized during sintering because of diffusion. Therefore, the precursor powder obtained from a 10 h milling time without the impure Sn2S3 phase was selected for spark plasma sintering to possibly synthesize pure SnS2 bulk through re-reaction during sintering at high temperature. The XRD pattern for the sintered bulk is exhibited in Fig. 1b. All the peaks can be indexed to the standard diffraction pattern of SnS2 (PDF# 23–0677); no secondary phase was found, indicating a pure-phase SnS2 was obtained after sintering. However, it is also found that the relative intensity of the peak (001) is slightly stronger than that of the standard diffraction peak suggesting the existence of anisotropy. Generally, the Lotgering method is used to calculate the ab degree of orientation for the (00 l) crystal planes in bulk specimen using the following equations, which are referred to as F(00 l),

where P and P0 are the ratios of the integrated intensities of all (00 l) crystal planes to those of all (hkl) planes for preferentially and randomly oriented samples, respectively. The calculated F value will be 1 when the grain grows exactly in the direction of the pressure. In the present work, P and P0 were calculated from the XRD data of a block specimen and the standard card (PDF#23–0677). The calculated result of F(00 l) is around 0.2, which reveals that the axial plane is weakly oriented.

To further confirm the phase composition of the bulk, Raman spectra have been obtained (Fig. 3). The Raman bands appear at 140.5, 205, 315 cm−1, which is in agreement with the result obtained by Smith and collaborators [23]. These characteristic bands indicate that the phase composition of the bulk is 2H-SnS2, which belongs to space group D33d-P3m1 and agrees with the standard PDF card (PDF#23–0677), see Fig. 1. Meanwhile, there is no SnS spectrum suggesting that the impure SnS phase in the precursor powder may have successfully reacted with S and was converted into SnS2 during sintering.

Figure 4 shows an SEM image, the average elementary composition ratio and the mappings of Sn, S elements for polished surface of SnS2 bulk, respectively. Figure 4a exhibits the morphology of the fresh fracture surface of the bulk. The bulk is seen to be almost composed of lamellar grains of diameter 10–40 μm and thickness 80–100 nm. In addition, some obvious oriented grains can be found in certain regions in the image, indicating a slight orientation in the block, which is consistent with the calculation of the orientation above. Moreover, the ratio of Sn and S elements (Fig. 4b) is nearly 1:2. The slightly higher Sn content in the composition may arise from sublimation of some S elements during sintering. During the sintering process in the present study, the vacuum is lower than 6 Pa. According to the vapor pressure calculation formula (\(\log P = A - \frac{B}{t + C},\) where \(P\) stands for vapor pressure in millimeters of mercury; t is for temperature in degrees Celsius; A, B and C are constants, respectively), the temperature required for the vapor pressure of S to reach 6 Pa is 129 °C, which is much lower than the sintering temperature of 450 °C. In addition, the melting point of S element with 115.2 °C is much lower than that of Sn with 231.89 °C. Thus, these would cause the more serious deficiency of S than Sn element. Furthermore, the element mappings of Sn and S for the bulk (Fig. 4c and d) suggest that the elements are distributed homogeneously without obvious enrichment. Therefore, these results reveal that MA combining SPS is an effective and simple way to synthesize SnS2 with a pure phase and an appropriate composition. Indeed, SnS2 is mainly prepared by chemical vapor transport, successive ionic layer absorption and reaction, as well as other reported methods [24,25,26]. Compared with these methods, the two-step method used in this experiment is simpler and faster.

Figure 5 shows the TE transport properties of the SnS2 bulk as function of temperature in the range of 300–750 K. The electrical conductivity (Fig. 5a) increases with temperature rising within the entire measured temperature range, suggesting a typical semiconductor behavior. The value increases from 0.006 S/cm at 323 K to 0.18 S/cm at 723 K, which follows the result of Lee and collaborators that the value of electrical conductivity of SnS2 crystals is in the range of 10−12–10−2 S/cm [27], and is also comparable with reported values for SnSe2 [28]. However, compared with the electrical conductivity of SnS [28] and SnSe [13], SnS2 is a poor conductor. From the expression for electrical conductivity σ = nµe, where e, n, and µ are the unit charge, the carrier concentration, and the carrier mobility, the low electrical conductivity of SnS2 stems from the low carrier concentration or carrier mobility. In addition, with increasing temperature, the carrier concentration increases because of the impact of thermal excitation, which enhances electrical conductivity with temperature rises. The Seebeck coefficient of bulk SnS2 is negative (Fig. 5b), indicating an n-type semiconductor. The absolute value of the Seebeck coefficient also increases with temperature increases. Combined with the behavior in electrical conductivity, this anomaly may be due to the low intrinsic carrier concentration in bulk SnS2. Numerically, the absolute value of the Seebeck coefficient rises rapidly with temperature from 75 μV/K at 323 K to a relatively high value of 652 μV/K at 723 K.

The calculated PF as a function of temperature (Fig. 5c) shows an increase in value with temperature. The PF improves from 0.003 μW/mK2 at 323 K to 7.9 μW/mK2 at 723 K, benefiting from increases in both electrical conductivity and Seebeck coefficient. However, the PF of pristine SnS2 within the entire tested temperature range is much lower compared with those for the extensively studied SnS and SnSe because of its poor electrical conductivity. Further improvements can be had by optimizing its carrier concentration.

The temperature dependence of the total thermal conductivity (κtotal) of SnS2 bulk (Fig. 5d) shows that at room temperature, the κtotal is 3.6 W/mK which is comparable to the reported value of 3.45 W/mK of SnS2 but slightly higher than that of SnSe2.[27, 28] With increasing temperature, the value decreases from 3.6 W/mK at 323 K to 1.7 W/mK at 723 K. In general, κtotal has two contributions,

in which κlat denotes the lattice thermal conductivity and κel the electronic thermal conductivity calculated using the Wiedemann–Franz–Lorenz relation κel = LσT. Reduced Fermi energy was used to calculate the Lorenz number (L) (Eq. (5)) which varies as the Seebeck value changes (Eq. (5)) with temperature or composition. The Lorenz number L is estimated in a traditional single parabolic band model using

where η denotes the reduced chemical potential, r the scattering factor, and kB the Boltzmann constant. The calculated value of L shows a deviation of less than 10% compared with those from a more rigorous single non-parabolic band and multiple band model calculations.

The contribution κlat was obtained by subtracting κel from κtotal. The plot κlat as a function of temperature in the range from 300 to 723 K (Fig. 5e) shows κlat decreases with rising temperature. Moreover, κlat contributes over 90% to κtotal for the pristine sample, indicating heat transport in SnS2 is dominated by phonons. However, the value of κlat is significantly higher than that of SnSe2 [28], which has a similar-layered crystal structure and composition. Usually, thermal conductivity for different materials shows a strong dependence on the speed of sound, which is mainly associated with atomic bonding strength and scales with Young’s modulus. Phonons are transported faster if the chemical bonding strength between atoms is stronger. Therefore, to verify this higher value in thermal conductivity, the speed of sound associated with longitudinal (vl) and shear (vs) waves in SnS2 were measured via ultrasonic pulse echo measurements. Young’s modulus was also calculated using

where ρ denotes the density, and Vl and Vs denote the speeds associated with longitudinal and shear sound waves. The average speed \((\nu_{a} )\) is obtained from

However, the calculated result shows that this average speed of sound for SnS2 is 1869 m/s, giving Young’s modulus of 32.1 Gpa, which is slightly lower than that of SnSe2 (38.5 Gpa). Therefore, this does not seem to explain the higher thermal conductivity of SnS2. Generally, a layered structure subject to van der Waals interactions does support a low thermal conductivity as phonon scattering may be enhanced between weakly bonded layers. Thus, further study combined with theoretical calculations needs to be undertaken to clarify the higher thermal conductivity of SnS2. Combined with the electrical and thermal conductivity, the calculated ZT values of SnS2 block was plotted (Fig. 5f). The ZT value increases with increasing temperature mainly because of the enhanced electrical transport. However, because of the low PF and high thermal conductivity, the maximum ZT only reaches 0.003 at 723 K.

It was reported that Ag is an effective dopant to improve the electrical conductivity of SnSe2 because of significant increases in carrier concentration [28]. Meanwhile, κlat can be suppressed by the strengthened phonon scattering. Hence, to optimize the TE performance of the SnS2 block, which shows very similar composition and crystal structure with SnSe2, we doped it with Ag, which is an n-type dopant in the interstitial sites in the lattice. From the XRD patterns and the magnified plots of the main peaks of the SnS2 and SnS2–Ag blocks (Fig. 6), there are no second phase peaks in the XRD patterns for the doped sample. They all could be indexed to the standard PDF card of SnS2 (PDF#23–0677). Moreover, the main peak (Fig. 6b) shows that, the crystal plane peak (001) in the XRD pattern of the doped sample gradually shift toward lower 2θ angle. According to the Bragg equation (\(n\lambda =2d\mathrm{sin}\theta )\), the shift of the X-ray diffraction peak to a small angle indicates that the distance of crystal face increases. Thus, the shift of the XRD pattern in the present study suggests the lattice parameter increases after Ag doping. The lattice parameter values were estimated from step-scan XRD measurements with step width of 0.020 using the least-squares method. A smooth surface of the bulk was polished well before taking XRD measurements of doped samples to obtain much more accurate X-ray peaks. The calculated lattice spacings along the a-axis for pure and doped sample are, respectively, 3.6521 and 3.6543 Å, whereas for the c-axis are 5.9136 and 5.9253 Å, which indicates the lattice parameters increased after Ag doping. However, the atomic radius of Ag with 1.44 Å is smaller than that of Sn with 1.58 Å. These results prove that the increase of the lattice parameter of the Ag-doped sample is probably caused by the entry of Ag element into the SnS2 lattice gap. Furthermore, the composition and distribution of Ag were obtained by EDS on the polished surfaces of the Ag-doped sample showing Ag was distributed inhomogeneous. A slight Ag enrichment was observed in some areas. No peaks of the secondary phase appeared in the XRD patterns probably because its content was low.

Furthermore, we have also characterized the TE properties of doped sample (Fig. 7). The conductivities of doped and pristine samples both show trends of increasing with temperature (Fig. 7a). The conductivity of SnS2–Ag is lower than pure phase before 573 K. With the increase of temperature, it crosses with SnS2 at 573 K and increased significantly after that. The maximum conductivity reached 0.49 S/m at 723 K which is about three times that of pure sample. On the other hand, different from SnS2, the absolute value of Seebeck coefficient of SnS2–Ag shows a decreasing trend with temperature rise. The value drops to 664 μV/K at 723 K, which is closed to the SnS2 (Fig. 7b). According to the results of phase characterization, the reason may be that, the lattice distortion caused by Ag interstitial doping increases the scattering of carriers and reduces the conductivity at low temperature. However, Ag doping also increased carrier mobility, making the absolute Seebeck coefficient significantly increased. With the increase of temperature, more activation energy can increase carrier concentration and reduce the influence of scattering on them. At the same time, the defects brought by Ag doping also introduced more carriers at high temperature so that the conductivity of doped samples gradually increased, while the Seebeck coefficient dropped. Further, mainly affected by the change of electrical conductivity, the PF shows a trend of positive correlation with temperature. The optimal value of 22 μW/mk2 was obtained at 723 K, which was about three times of the pure phase (Fig. 7c). The dependence of κe on temperature (Fig. 7d) displays an obviously increase and, after Ag doping, κe shows the same trend as electrical conductivity, which may also affect by carrier concentration. Numerically, κe is far less than κtotal, indicating that the κtotal of samples are mainly composed of κlat. The κtotal of the samples shows a significant trend of decrease with temperature (Fig. 7e). However, influenced by the rise of κe, the decline trend of SnS2–Ag’s κtotal slowed a little after 573 K. After doping, the value at room temperature is reduced from 3.6 W/mK for the SnS2 to 2.7 W/mK for the SnS2–Ag sample. When the temperature rises to 723 K, κtotal has the lowest value of 1.3 W/mK for the SnS2–Ag sample. The calculated κe suggests that the reduced κtotal is mainly caused by the decrease in κlat. Lattice distortions caused by substitutive and interstitial Ag atoms together enhance short-wave phonon scattering, which may be the main reason for the reduced κlat. This indicates that Ag doping can increase phonon scattering effectively and reduce the thermal conductivity of the samples. With the benefit of an enhanced PF and reduced κlat, an improved ZT value was obtained (Fig. 7f). A maximum value of 0.01 at 723 K was achieved for the SnS2–Ag sample and was two times higher than the value for SnS2 at the same temperature. These results indicate that Ag is an effective dopant to enhance the TE property of SnS2. Higher ZT values are expected by further doping experiments.

3 Conclusion

SnS2 was synthesized by combining MA with SPS. The synthesis process and the TE properties over the temperature range 300–723 K were investigated. The results indicate that SnS2 bulk with pure phase is obtained after sintering the precursor powder, although single-phase SnS2 powder seems difficult to obtain by MA because Sn2S3 is produced with prolonged milling times. Pristine SnS2 bulk shows an n-type conductive characteristic and a moderate absolute Seebeck coefficient in the range 100–700 μV/K. However, the electrical conductivity below 0.2 S/cm is poor and the thermal conductivity above 1.5 W/mK is relatively high, resulting in a low ZT value. Nevertheless, after Ag doping, both the electrical resistivity and thermal conductivity have been reduced within the entire measured temperature range. Therefore, an enhanced ZT compared with the pristine sample was obtained.

References

P. Zong, R. Hanus, M. Dylla, Energ. Environ. Sci. 10, 1 (2017)

M. Ziabari, D. Zebarjadi, Vashaee. Rep. Prog. Phys. 79, 9 (2016)

X. Zhang, L.D. Zhao, J. Materiomics 1(2), 92–105 (2015)

G. Tan, L.D. Zhao, M.G. Kanatzidis, Chem. Rev. 116, 19 (2016)

B. Russ, A. Glaudell, J.J. Urban et al., Nat. Rev. Mater. 1, 10 (2016)

J.R. Sootsman, D.Y. Chung, M.G. Kanatzidis, Angew. Chem. Int. Edit. 48, 46 (2009)

C. Chang, Wu, M. Wu, He, D. He, et al., Science, 360(6390) ,778–783 (2018).

J. Zhang, L. Song, G.K.H. Madsen et al., Nat. Commun. 7, 10892 (2016)

B. Asfandiyar, L.-D. Cai, J.-F. Zhao, J. Li, Materiomics 6(1), 77–85 (2020)

J.N. Coleman, M. Lotya, A. O’Neill, Science 331, 6017 (2011)

M. Lee, L. Viciu, L. Li, Nat. Mater. 5, 7 (2006)

Y. Terasaki, K. Sasago, Uchinokura. Phys. Rev. B 56, 20 (1997)

S. Bresch, B. Mieller, C. Selleng, J. Electroceram. 40, 3 (2018)

L.-D. Zhao, S.-H. Lo, Y. Zhang, H. Tan et al., Nature 508, 7496 (2014)

B. Ouyang, S. Chen, Y. Jing, T. Wei, S. Xiong, D. Donadio, J. Materiomics 4(4), 329–337 (2018)

W. Xie, J. He, H.J. Kang, X. Tang, S. Zhu, M. Laver et al., Nano Lett. 10(9), 3283–3289 (2010)

G. Guélou, P. Vaqueiro, J. Prado-Gonjal, J. Mater. Chem. C. 4, 9 (2016)

E. Guilmeau, Y. Bréard, A. Maignan, Appl. Phys. Lett. 99, 5 (2011)

T.M. Tritt, M.A. Subramanian, MRS Bull. 31, 3 (2006)

R. Nunna, F. Gascoin, E. Guilmeau, J. Alloys Compd. 634, 32–36 (2015)

D. L. Ye, J. H. Hu, Handbook of Practicality Inorganic Thermodynamics. (2002).

Z. Shen, M. Johnsson, Z. Zhao, M. Nygren, J. Am. Ceram. Soc 85(8), 1921–1927 (2002)

J. Smith, P. E. Meek, W. Y. Liang, J. Phys. C: Solid State Phys. 10, 8:1321 (1977).

B.R. Sankapal, R.S. Mane, C.D. Lokhande, Mater. Res. Bull. 35(12), 2027–2035 (2000)

N.G. Deshpande, A.A. Sagade, Y.G. Gudage, J. Alloy. Compd. 469, 1–2 (2009)

M.-J. Lee, J.-H. Ahn, J.H. Sung et al., Nat. Commun. 7, 12011 (2016)

L.E.I.F. Brattas, & A. KJEKSHUS, Acta Cehmica Scandinavica 27, 1290–1298 (1973)

X. He, H. Shen, Phys. B: Condens. Matter 407(7), 1146–1152 (2012)

Acknowledgements

This work was supported by the Fund of Natural Science Foundation of Guangdong Province (No. 2018A030313574) and Shenzhen Science and Technology Plan Project (No. JCYJ20170818142740568), as well as Shenzhen Key Lab Fund (No. ZDSYS20170228105421966). We thank Richard Haase, Ph.D, from Liwen Bianji, Edanz Group China (www.liwenbianji.cn/ac), for editing the English text of a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chang, Y., Ruan, M., Li, F. et al. Synthesis process and thermoelectric properties of the layered crystal structure SnS2. J Mater Sci: Mater Electron 31, 5425–5433 (2020). https://doi.org/10.1007/s10854-020-03105-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03105-3