Abstract

Magnetic recoverable MnFe2O4/rGO nanocomposites were synthesized via a facile one-pot hydrothermal method. The microstructure, morphology, optical and magnetic property were characterized by X-ray diffraction, high-resolution transmission electron microscope, ultraviolet–visible spectroscopy, N2 adsorption–desorption technique, photoluminescence spectroscopy and vibrating sample magnetometer. The photo-Fenton degradation activity of the MnFe2O4/rGO composites was investigated using the methylene blue (MB) in aqueous solution under the simulated sunlight. The results show that MnFe2O4 nanoparticles with cubic spinel structure were loaded on the surface of rGO, possessing irregular ellipsoid with uniform particle size and good dispersion. The band gap of MnFe2O4/rGO is narrower than that of pure MnFe2O4 and exhibits redshift. The weak luminescence of MnFe2O4/rGO nanocomposites indicates the efficient separation of photoexcited electron/hole pairs. MnFe2O4/rGO nanocomposites display superior photo-Fenton degradation efficiency of MB, exhibit obvious room temperature ferromagnetism and can be readily recovered by external magnetic field. MnFe2O4/rGO nanocomposites exhibit the best degradation efficiency under the condition of pH 9, 0.5 mL H2O2 and 0.06 g mass fraction in photo-Fenton degradation of MB dye. The radical scavenger tests demonstrate that ·OH, e− and h+ are the main active species and play a decisive role, and rGO plays a vital role in synergistic enhancement of photo-Fenton degradation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent decades, environmental pollution and energy shortage have become global problem facing mankind due to the rapid growth of population and the development of modern industry [1,2,3]. Meanwhile, it is difficult to degrade the toxic, chromatic and organic dye wastewater under natural conditions. Up to now, various physicochemical methods including adsorption membrane filtration, biodegradation, chemical oxidation and photocatalytic degradation have been developed to eliminate toxic pollutants in wastewater [4,5,6,7,8]. Among them, the photocatalytic degradation technology widely spread in the removal of organic matter under mild reaction conditions, which is considered to be one of the most promising approaches because it is efficient, low cost and friendly environment, especially the conversion of light energy into chemical energy [9,10,11]. Moreover, the process of photocatalytic degradation requires no additional additives and equipment, except light that is inexhaustible in nature [12,13,14]. Therefore, it is urgent to develop more ideal photocatalytic materials to degrade organic pollutants in wastewater and meet the sustainable development of human society.

MnFe2O4 as a kind of bimetal oxide semiconductor nanomaterial shows excellent photocatalytic performance in photocatalytic degradation of organic synthetic dyes and pigments in wastewater, which have been extensively investigated due to its unique spinel crystal, narrow band gap, visible light response, high chemical and thermal stabilities [15,16,17]. The electrical transport of MnFe2O4 accelerates the effect of Verway hopping: Mn2++ Fe3+↔ Mn3+ + Fe2+, and the electron transfer between a mixed valance Mn2+ and Fe3+ on octahedral sites to enhance the photo-Fenton activity [18, 19]. In addition, MnFe2O4 can be effectively separated and recovered by external magnetic field with high recycling efficiency due to room temperature ferromagnetism [20,21,22,23]. However, the photocatalytic performance of pure MnFe2O4 is not high enough due to the fast recombination of photogenerated electron–hole pairs, which seriously affects it difficult to further promote and apply in photocatalysis [24,25,26]. Therefore, the photocatalytic activity of MnFe2O4 are needed to improve by surface modification and hybridization to solve the recombination of photogenerated electron–hole pairs.

As a new two-dimensional carbon material, graphene is composed of single-layer carbon atoms with two-dimensional planar structure, exhibiting many remarkable properties, such as large surface area, excellent electrical and mechanical properties [27,28,29,30,31]. Based on these unique properties, many researchers have attempted to modify metal oxide with graphene owing to fact that the composite materials can decrease the band gap and promote the separation and transfer of electrons and holes [32,33,34,35]. In addition, graphene coupling with good electrical conductivity can reduce the recombination probability of electrons and holes, improving its photocatalytic efficiency [20, 36,37,38]. Mishra et al. prepared rGO/MnFe2O4 nanocomposites by hydrothermal method with a different weight ratio of GO sheets, and studied the effect of the content of the GO sheets on the structural, optical, magnetic and microwave magnetic properties of MnFe2O4 nanoparticles [36]. Huang et al. reported solvothermal synthesis of magnetically separable rGO/MnFe2O4 hybrids as efficient photocatalysts for degradation of MB under visible light, and found with the increasing weight ratio of rGO content in the rGO/MnFe2O4 hybrids, the particle size of MnFe2O4 was gradually reduced but the visible light adsorption increased, and 10% rGO/MnFe2O4 hybrid exhibited the best photocatalytic activity [35]. Peng et al. synthesized magnetic recoverable graphene/MnFe2O4 hybrids for efficient decomposition of methylene blue, and found that rGO /MnFe2O4 catalyst shows exceptional performance towards the MB decomposition in the presence of H2O2, and the catalysts can be magnetically recycled [23]. The better catalytic performance of rGO/MnFe2O4 hybrid is mainly related to the synergetic effects of rGO, MnFe2O4, H2O2 and MB molecules, and it is also attributed to the redox couples of Fe/Mn ions in the reaction process. Unfortunately, to the best of our knowledge, up to now, most of the studies were focused on the photocatalytic activity, optical and magnetic property of the spinel structure mix-metal-oxide semiconductor, and there are few studies on the influence of pH value, dosage of photocatalyst and volume of H2O2 in the solution on the photo-Fenton degradation of organic synthetic dyes under simulated solar irradiation. From the perspective of industrial applications, it is necessary to evaluate the photo-Fenton degradation rate by controlling the pH value, amount of photocatalyst and volume of H2O2, in order to explore the photo-Fenton degradation mechanism and obtain the optimal photo-Fenton condition.

In this paper, magnetic recoverable MnFe2O4/rGO nanocomposites were successfully fabricated via a facile one-pot hydrothermal method, and the microstructure, morphology, optical and magnetic property of the samples were characterized by X-ray diffraction (XRD), high-resolution transmission electron microscopy (HRTEM), ultraviolet–visible spectroscopy, N2 adsorption–desorption technique, photoluminescence spectra (PL) and vibrating sample magnetometer (VSM). The photo-Fenton activity of the samples was evaluated by the photodegradation of methylene blue (MB) in aqueous solution under the simulated sunlight, the effects of pH value, dosage of photocatalyst and volume of H2O2 on the photo-Fenton degradation were studied, and the possible photo-Fenton mechanism was further proposed.

2 Experimental

2.1 Preparation of MnFe2O4–rGO nanocomposites

All chemicals were analytical grade without any further purification. Graphene oxide (GO) was synthesized from natural graphite powder via a modified Hummers method [39]. Firstly, 1 g of graphite powder was weighed and 23 mL concentrated H2SO4 was added to a 500 mL three-necked round bottom bottle; the mixture was kept in an ice-water bath to ensure the temperature remained below 5 ℃. Then, 5 g KMnO4 was slowly added into the mixed solution under constant magnetic stirring for 2 h in order to make concentrated H2SO4 fully inserted into the graphite layer. The mixture was oxidized for 1 h at 35 ± 5 °C, and 150 mL deionized water was added and then stirred at 98 °C for 15 min. Finally, 5 mL of 30% hydrogen peroxide was added in the mixed solution to terminate the reaction mixture. Then, the mixed solution was filtered and washed by adding 200 mL 5% hydrochloric acid solution. After repeated centrifugation to neutral, ultrasonication was carried out for 4 h to finally obtain graphene oxide.

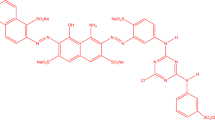

MnFe2O4 nanoparticles were synthesized by one-step hydrothermal method. In a typical procedure, 2.5 mmol MnCl2·4H2O and 5 mmol FeCl3·6H2O were weighed as precursors, and dissolved in ethylene glycol to obtain 0.05 mol/L mixed metal salt solution by magnetic stirring at room temperature. Meanwhile, NaOH solution (0.5 mol/L) was added dropwise into the above solution to regulate the pH value of the mixed solution to 12. Subsequently, 1 g PVP slowly was added to the above mixed solution under constant magnetic stirring. The resultant mixture was then transferred to seal into a 100 mL Teflon-lined stainless-steel autoclave and kept at 200 °C for 24 h. After the reaction was completed, the autoclave was naturally cooled down to room temperature. Thereafter, the resulting precipitate was separated centrifugally and washed several times with distilled water and absolute alcohol to remove excess surfactants and impurities, respectively, and dried at 60 ℃ in a vacuum oven for 12 h. For comparison, MnFe2O4/rGO (with weight percent of GO to the total mass ratio of 10%) was prepared under the same hydrothermal condition of MnFe2O4 sample, as shown in Fig. 1, except that GO slurry was added dropwise to the mixed solution under ultrasonic treatment to obtain a uniform mixture.

2.2 Characterization

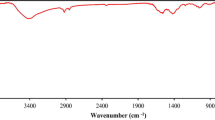

The structural analysis of the as-prepared samples was examined by a powder X-ray diffractometer (Rigaku corporation, Japan, D/Max-2400) with Cu Kα radiation at = 1.54056 Å. The samples were scanned in the angular range from 10° to 70° with scanning rate of 0.005°/s and step size of 0.02°. The morphology and microstructure were characterized by high-resolution transmission electron microscopy (HRTEM, JEM-2010). The recombination rates of electron–hole pairs were characterized by photoluminescence spectra (PL). The band gap energy was characterized by UV–Vis spectrophotometer (PERSEE TU-1901) with an integrating sphere attachment. Magnetic hysteresis loops were investigated at room temperature using a vibrating sample magnetometer (VSM, Lakeshore 7304). The Brunaue–Emmett–Teller (BET) specific surface area and Barrett–Joyner–Halenda (BJH) pore size distribution of the samples were tested by N2 adsorption–desorption technique using an ASAP 2020 analyzer.

2.3 Photo-Fenton experiment

The photo-Fenton degradation experiments were performed in VS-GCH-XE-300 photochemical reaction apparatus at room temperature. The synthesized MnFe2O4/rGO composite was employed as photocatalyst to degrade MB dye under the simulated sunlight irradiation. In a typical experiment, a certain amount of catalyst was dispersed in 100 mL MB solution, and pH of the mixed solution adjusted to a certain value. Meanwhile, the distance between the light source and the catalysts was fixed at 15 cm. The suspension was firstly ultrasonicated for 10 min, and then magnetically stirred in the dark for 30 min before illumination to establish adsorption–desorption equilibrium between photocatalyst and MB dye. Subsequently, 0.5 mL H2O2 was added to the MB dye solution under the simulated sunlight. Among them, the photo-Fenton reaction was carried out for 150 min under 300W xenon lamp irradiation with different masses of catalyst and different pH values. Subsequently, 4 mL of the reaction solution was taken out at given time intervals (30 min). The concentration of MB dye was determined by measuring the absorbance of the solution at a fixed wavelength of λ = 664 nm using a UV–Vis spectrophotometer during the photo-Fenton process. The samples were subjected to stability and cycle tests with magnetically collected and separated.

3 Results and discussion

The typical XRD pattern of GO, MnFe2O4 and MnFe2O4/rGO nanocomposites is shown in Fig. 2. The diffraction peak of GO appeared at 2θ = 11.81° corresponds to the crystal plane of (001) [40]. In the process of graphite powder oxidation, the increase of oxygen functional group leads to the increase of crystal surface spacing of graphite layer. Compared with pure MnFe2O4, the XRD pattern of MnFe2O4/rGO nanocomposite shows obvious diffraction peak of rGO at 2θ = 23.2°, but no characteristic peak of GO was observed. It demonstrated that the decreased graphite layer spacing would result in GO being reduced to rGO due to the removal of some oxygen-containing functional groups in the hydrothermal reaction process [41]. The XRD patterns of MnFe2O4 and MnFe2O4/rGO samples possess similar diffraction peaks at 2θ = 18.077°, 29.789°, 35.034°, 42.505°, 52.907°, 56.246° and 61.799°, completely corresponding to the (111), (220), (311), (400), (422), (511) and (440) crystal planes of spinel structure MnFe2O4 with JPCDS (No. 10-0319), respectively. In addition, the MnFe2O4 (311) peak is much higher than any other peak, which concludes that the as-synthesized MnFe2O4 nanomaterials are well crystallized and grew along the crystal planes (311). The crystallite size is estimated from the most intense diffraction peak (311) based on Scherrer equation to be 70 and 65 nm for pure MnFe2O4 and MnFe2O4/rGO nanocomposites, respectively (shown in Table 1), which is consistent with the HRTEM results.

The morphology and microstructure of the samples were characterized by HRTEM. It can be seen that the morphology of pure MnFe2O4 is mainly irregular ellipsoidal with rough surface and irregular edges as shown in Fig. 3a. MnFe2O4 nanoparticles present different degrees of agglomeration owing to the van der Waals force, Coulomb force or chemical bond cooperation between nanoparticles. The histogram corresponding to the particle size distribution of pure MnFe2O4 is shown in Fig. 3b. It is obvious that the particle size mainly distributed in the range of 60–90 nm with relatively uniform and the average particle size about 75 nm. The selected area electron diffraction (SAED) pattern of pure MnFe2O4 is shown in Fig. 3c, and a series of concentric rings with different radii appear in the diffraction pattern due to the random orientation between grains, indicating that the sample possesses polycrystalline structure. The polycrystalline diffraction ring corresponds to the (111), (220), (311), (400), (422), (511) and (440) crystal plane of MnFe2O4 from inside to outside. The SAED and HRTEM results further show that pure MnFe2O4 is spinel structure, which is consistent with the XRD analysis results. Figure 3d represents the high magnification of the local part of pure MnFe2O4, which reveals that the fringes of MnFe2O4 with an interplanar spacing of about 0.256 nm are well crystallized and grew selectively along the (311) crystal planes of cubic spinel structure.

Figure 4a shows the HRTEM image of GO. Obviously, the prepared GO possesses transparent two-dimensional planar structure with single or few layers about tens of micrometers in area. There are some folds and wrinkles presented on the surface of GO film. It is seen that MnFe2O4 particles with irregular particle morphology are partially wrapped or completely covered by graphene, indicating that the surface activity and agglomeration between MnFe2O4 nanoparticles are inhibited by graphene coating. The good dispersion and no obvious agglomeration of MnFe2O4 nanoparticles are beneficial to the transfer photocarrier and improve the photocatalytic activity.

The band gap and absorption coefficient of the synthesized samples are the critical parameters for the photocatalytic degradation of pollutants, which was studied by UV–Vis absorption spectra. Figure 5a shows the UV–Vis absorption spectra of MnFe2O4 and MnFe2O4/rGO recorded in range 200–850 nm. Compared with pure MnFe2O4 nanoparticles, MnFe2O4/rGO nanocomposites reveal much higher absorption band in visible light region, manifesting that nanocomposites have strong absorption property in the visible region. For direct band gap, the absorption coefficient and band gap of the samples can be calculated according to Tauc formula [42]: [αhν]2=A(hν–Eg), where α, hν, A and Eg represent the absorption coefficient, the photon energy, constant dependent on the effective masses of electron–hole pairs and material refractive index and the band gap of materials, respectively. The relationship between (αhν)2 and hν is represented in the inset of Fig. 5b. The band gap values (Eg) are obtained by extrapolating the linear region of the curve on hν axis at (αhν)2= 0 [43]. The estimated optical band gap Eg of pure MnFe2O4 and MnFe2O4/rGO nanocomposites are 2.44 eV and 2.13 eV, respectively. It is obvious that the band gap of MnFe2O4/rGO nanocomposites is smaller than that of pure MnFe2O4, and red shift occurs. This result is because MnFe2O4 nanoparticles are encased in graphene and trapped in a very small space in the core–shell structure, and the surface effect of nanocrystals causes electron transition, narrowing the energy gap, and the light absorption band moves to the direction of long wave, thus widening the absorption intensity of MnFe2O4, which promotes the generation of more photoinduced electron–hole pairs, thereby increasing the photocatalytic activity.

The hysteresis loop of MnFe2O4 and MnFe2O4/rGO samples at room temperature with a magnetic field of − 20,000 Oe−20,000 Oe is shown in Fig. 6. The M–H curve shows that obvious hysteresis loops at room temperature, demonstrating MnFe2O4 and MnFe2O4/rGO nanomaterials possess room temperature ferromagnetism. The general formula of MnFe2O4 normal spinel structure is AB2O4, and the A position represents the tetrahedral position occupied by the divalent metal ion (Mn2+) and the tetrahedral gap formed by the surrounding of four oxygen ions. Position B represents the octahedral space occupied by the trivalent metal ions (Fe3+), which is surrounded by six oxygen ions. When the particle size reaches the nanoscale scale, the cation distribution in MnFe2O4 nanocrystals changes significantly, some Fe3+ enters the A position of tetrahedron, and Mn2+ enters the B position of octahedron, leading to the generation of ion logarithm of super exchange between A and B, which weakened spin coupling and ferromagnetism [44]. The magnetization intensity reaches saturation with the increase of magnetic field, which can effectively separate the catalyst for improving the recycling efficiency (inset of Fig. 6).

Figure 7a presents the N2 adsorption–desorption isotherm of pure MnFe2O4 and MnFe2O4/rGO nanocomposites. The isotherms of all the samples in this work can be classified as type IV with H3 hysteresis loop at higher relative pressure according to the IUPAC classification, which indicates the obvious mesoporous structure characteristics. The BJH pore size distribution plot of pure MnFe2O4 and MnFe2O4/rGO nanocomposites is shown in Fig. 7b, which demonstrated that the pore diameter primarily distributed in the range of 3–50 nm within the typical mesoporous region for all the samples. The accumulated pore volume (VPore) and the average pore size of the samples are obtained from N2 adsorption branch by the BJH method. The BET specific surface area (SBET) of the samples is estimated from the linear region of the plot ranging from P/P0 = 0.07 to P/P0 = 0.30, and the specific surface area, total pore volume and pore width data are summarized in Table 1. The specific surface areas of MnFe2O4/rGO nanocomposites are larger than that of pure MnFe2O4, which partly attributed to MnFe2O4/rGO nanoparticles that are evenly wrapped in thin graphene sheets. The increase of specific surface areas of MnFe2O4/rGO nanocomposites is beneficial to the photocatalytic performance of the photocatalyst.

Figure 8a shows the photo-Fenton degradation experiment of pure MnFe2O4 and MnFe2O4/rGO nanocomposite with 0.04 g catalysts, 0.5 mL H2O2 and normal conditions under simulated solar irradiation within 150 min. The blank experiment without any photocatalysts show that the self-degradation of MB is negligible, revealing that MB exhibits good stability without catalyst. The degradation percentage of the dye is defined as (C0 − Ct)/C0 × 100%, where C0 and Ct represent the dye concentrations before and after t min of photocatalysis, respectively. Notably, the adsorption percentage of MnFe2O4/rGO nanocomposite (15%) exhibits a slightly increased adsorption compared to that of pure MnFe2O4 (6%) treatment in dark for 30 min. However, the degradation rate of MB increased with the increase of degradation time under simulated solar irradiation and catalyst acted together, implying that the continuous decrease of MB concentration was mainly caused by photocatalysis. It can be seen that the photo-Fenton degradation for MnFe2O4/rGO nanocomposite to MB solution under normal conditions is about 62% within 150 min. In contrast, the pure MnFe2O4 only removed about 36% of the initial concentration of MB solution. The improved photocatalytic performance of MnFe2O4/rGO composite significantly is mainly attributed to the high dispersibility of the high specific surface area of MnFe2O4 nanoparticles. Meanwhile, MnFe2O4 nanoparticles are on the rGO surface to facilitate separation and transfer of electron and holes. Figure 8b shows plots of ln (Ct/C0) vs irradiation time t for the photo-Fenton degradation of MnFe2O4 and MnFe2O4/rGO composites corresponding to Fig. 8a. The kinetics of the photo-Fenton degradation to MB solution are conformed by first-order kinetic equation [7]: ln (Ct/C0) = kt of MnFe2O4 and MnFe2O4/rGO composites, where k is reaction rate constant, t represents time, and C0 and Ct represent the initial concentration and reaction concentration of MB, respectively. The rate constant k of MnFe2O4 and MnFe2O4/rGO is 0.00271/min and 0.00526/min, respectively. The MnFe2O4/rGO composites exhibit a photocatalytic activity about 2 times higher than that of bare MnFe2O4 under normal conditions, which suggests that MnFe2O4/rGO is an excellent photocatalyst. In addition, the photogenerated electrons of MnFe2O4 would transfer from the conduction band of MnFe2O4 to rGO film, while rGO can reduce the optical band gap of MnFe2O4, enhancing sunlight absorption and the generation of electron–hole pair. Also, rGO acts as electron acceptor can inhibit the recombination of electron–hole pairs, thus accelerating redox reactions and promoting photodegradation of MB.

For the photo-Fenton degradation of MB dye, the amount of photocatalyst in the solution is an important factor. The effect of different amounts of MnFe2O4/rGO for the degradation of MB dye under simulated solar irradiation at pH 9 and 0.5 mL H2O2 within 150 min is shown in Fig. 9a. The degradation rates of MB were 62%, 69%, 73%, 76%, 80% and 78% by adding 0.040, 0.045, 0.050, 0.055, 0.060 and 0.065 g photocatalyst, respectively. It can be seen that the degradation rate of MB increased significantly when the photocatalyst dosage increased from 0.040 to 0.06 g, while the degradation rate decreased gradually when the photocatalyst dosage increased from 0.060 to 0.065 g, and the degradation rate increased to its maximum at 0.06 g. This results because more active centers are added on the catalyst surface with the increase of photocatalyst consumption. However, as the amount of photocatalyst continues to increase, the turbidity of the reaction solution will also increase, thus reducing the utilization of visible light in photocatalytic reaction, which is unfavorable to photocatalytic degradation.

In the experiment, pH value also is a key factor to affect the photo-Fenton degradation of the catalyst. 0.06 g MnFe2O4/rGO with 0.5 mL H2O2 is chosen to measure the photo-Fenton degradation rate at different pH values within 60 min as shown in Fig. 9b. The degradation rates of MB were 93%, 88%, 45%, 95% and 91% when the pH values were 3, 5, 7, 9 and 11, respectively. It can be seen that the photo-Fenton degradation at pH 9 is the best. Under alkaline conditions, the photo-Fenton degradation rate of MnFe2O4/rGO composite is more efficient than neutral conditions, which maybe owing to H2O2 and NaOH have a slight reaction to produce O2; O2 is more likely to react with h+ and generate·O2−, speeding up the photocatalytic effect.

In order to evaluate the cyclic stability of the photocatalyst, the cycling stability of MnFe2O4/rGO photocatalyst for the degradation of MB dye under normal conditions with 0.04 g catalysts and 0.5 mL H2O2 for 5 successive cycles is shown in Fig. 10a. There is no obvious decrease of degradation rate after 5 cycles, indicating that the MnFe2O4/rGO photocatalyst exhibits higher stability and repeatability. Figure 10b shows the supernatant obtained by magnetite separation every 30 min in the first cycle. It can be clearly seen that the color of supernatant gradually becomes lighter with the increasing degradation time. Especially, MB dye becomes almost transparent after 150 min irradiation.

The active species are investigated to reveal the possible reaction mechanism. Here, we use 10 mL iso-propyl alcohol (IPA), 0.1 mmol AgNO3, 10 mL methanol and 0.1 mmol parabenzoquinone (PBQ) to capture for hydroxyl radical (·OH), photogenic electron (e−), hole (h+) and superoxide radical (·O2−), respectively [45]. Figure 11 shows the effects of different capture agents IPA, AgNO3, methanol and PBQ on the photo-Fenton degradation of MB dye over MnFe2O4/rGO photocatalyst under simulated sunlight irradiation. It is noted that the photo-Fenton degradation rates of MnFe2O4/rGO decreased from 73 to 32%, 35%, 40% and 64% after adding the capture agents of IPA, AgNO3, methanol and PBQ, respectively. It demonstrates that ·OH, e− and h+ are the main active species and play decisive role in MnFe2O4/rGO composite. While the photo-Fenton degradation rates of the dye are still 64% by adding the PBQ, which illustrates that ·O2− is not the active species.

Photoluminescence spectrum (PL) of photocatalysts is an effective means to study the recombination probability of photogenic electron–holes. Figure 12 shows a representative PL spectrum of pure MnFe2O4 and MnFe2O4/rGO with excitation wavelength is 300 nm. A strong emission peak is centered at 450–500 nm in MnFe2O4/rGO, which is basically consistent with pure MnFe2O4. The luminescence intensity of MnFe2O4/rGO is weaker than that of MnFe2O4, which corresponds to a low recombination probability of photogenic charge [13]. Graphene can effectively inhibit the recombination of electron–hole pairs, which improves the photo-Fenton performance of the MnFe2O4/rGO nanocomposite.

Figure 13 shows the possible photo-Fenton mechanism of MnFe2O4/rGO nanocomposite degradation of MB based on the above experimental results. The energy band edge position of EVB and ECB for MnFe2O4/rGO can be determined by the following two equations:

where EVB and ECB are the valence band and conduction band energy, Ee= 4.5 eV represents the free electron energy, X represents the electronegativity of semiconductor materials and Eg is the band gap of sample. The values of CB and VB for MnFe2O4/rGO by calculation are − 0.01 and + 2.43 eV, respectively.

The possible photo-Fenton mechanism of MnFe2O4/rGO nanocomposite degradation of MB under visible irradiation can be explained in two ways. On the one hand, electron (e−) are excited to the conduction band (CB), while holes (h+) are generated in valence band (VB) of MnFe2O4 under visible light irradiation. However, only a few photogenerated electron–hole pairs can transfer to the surface of the catalyst to participate in the redox reaction. In contrast, most of electron–hole pairs recombine rapidly for pure MnFe2O4. Notably, the combinations of electrons and holes are greatly inhibited for MnFe2O4/rGO composites due to the excellent electron transfer ability of rGO and the chemical bonding of M–O–C on the MnFe2O4/graphene interface [23]. High-energy electrons (e−) can react with H2O to produce hydroxyl radical (·OH), and oxygen (O2) absorbed on the surface of catalysts can react with electrons to produce superoxide-free radical (·O2−). Moreover, the holes (h+) can react with H2O2 to produce ·OH, which further degrades the pollutants into the harmless mineral materials, such as CO2 and H2O. On the other hand, the electrical transport of MnFe2O4/rGO nanocomposites accelerates the effect of Verway hopping (Mn2+ + Fe3+ ↔ Mn3+ + Fe2+), and Fe2+ and Mn3+ are oxidized or reduced to Fe3+ and Mn2+ by adding H2O2, respectively [18, 19]; especially, a large amount of ·OH is produced in the process of adding H2O2, indicating that the electron transfer between the mixed valance Mn2+ and Fe3+ on octahedral sites for MnFe2O4/rGO nanocomposites is essential to prevent the recombination of photogenerated electron–hole pairs and enhance the photo-Fenton performance.

4 Conclusions

MnFe2O4/rGO nanocomposites were synthesized via a facile one-pot hydrothermal method. MnFe2O4 nanoparticles are cubic spinel structure with uniform particle size and good dispersion, which are loaded on the surface of rGO, partially coated with graphene. The band gap of MnFe2O4/rGO is narrower than that of pure MnFe2O4, with redshift phenomenon. The weak luminescence of MnFe2O4/rGO nanocomposites indicates that the efficient separation of photoexcited electron/hole pairs can improve the photo-Fenton performance. MnFe2O4/rGO nanocomposites display superior photo-Fenton degradation efficiency of MB under the simulated sunlight, show obvious room temperature ferromagnetism and can be readily recovered by external magnetic field. Meanwhile, MnFe2O4/rGO nanocomposites possess the best degradation efficiency under the condition of pH 9, 0.5 mL H2O2 and with 0.06 g mass fraction for the degradation of MB dye under simulated solar irradiation. The radical scavenger tests demonstrate that ·OH, e− and h+ are the main active species and play a decisive role in photo-Fenton degradation of MB for MnFe2O4/rGO nanocomposites.

References

K.E. Sickafus, J.M. Wills, N.W. Grimes, J. Am. Ceram. Soc. 82, 3279 (2010)

G. Gao, W. Feng, W. Su, S. Wang, L. Chen, M. Li, C. Song, Int. J. Electrochem. Sci. 15, 1426 (2020)

M. Li, W. Feng, X. Wang, Int. J. Electrochem. Sci. 15, 526 (2020)

D.B. Miklos, C. Remy, M. Jekel, K.G. Linden, J.E. Drewes, Water. Res. 139, 118 (2018)

W.H. Zhao, Z.Q. Wei, X.J. Wu, X. Wang, Mater. Sci. Semicond. Proc. 88, 173 (2018)

A. Sudhaik, P. Raizada, P. Shandilya, D.Y. Jeong, J.H. Lim, P. Singh, J. Ind. Eng. Chem. 67, 28 (2018)

W.H. Zhao, Z.Q. Wei, L. Zhang, X.J. Wu, X. Wang, Materials. 582, 1 (2019)

M. Mahendiran, J.J. Mathen, K.M. Racik, J. Madhavan, M.V.A. Raj, J. Mater. Sci. 30, 16099 (2019)

T. Hisatomi, J. Kubota, K. Domen, Chem. Soc. Rev. 43, 7520 (2014)

Y. Ma, X.L. Wang, Y.S. Jia, X.B. Chen, H.X. Han, C. Li, Chem. Rev. 114, 9987 (2014)

R.C. Sripriya, M. Mahendiran, J. Madahavan, M.V.A. Raj, Mater. Today 8, 310 (2019)

X. Li, J.G. Yu, J. Low, Y.P. Fang, J. Xiao, X.B. Chen, J. Mater. Chem. A. 3, 2485 (2015)

Y.X. Yan, H. Yang, Z. Yi, T. Xian, X.X. Wang, Environ. Sci. Pollut. Res. 26, 29020 (2019)

N. Sreelekha, K. Subramanyam, D. Amaranatha Reddy, G. Murali, K. Rahul Varma, R.P. Vijayalakshmi, Solid State Sci. 62, 71 (2016)

W.H. Zhao, Z.Q. Wei, X.D. Zhang, M.J. Ding, S.P. Huang, Mater. Res. Bull. 124, 110749 (2020)

Z.M. Wang, H. Ma, C. Zhang, J. Feng, S.Y. Pu, Y.M. Ren, Y. Wang, Chem. Eng. J. 34, 711 (2017)

S.P. Huang, Z.Q. Wei, X.J. Wu, J.W. Shi, Mater. Res. Express 7, 015025 (2020)

F.K. Lotgering, J. Phys.Chem. Solids. 25, 95 (1964)

H. Xu, X. Quan, L. Chen, Chemosphere. 217, 800 (2019)

S. Gautam, P. Shandilya, B. Priya, V. Singh, P. Raizada, R. Rai, M.A. Valente, P. Singh, Sep. Purif. Technol. 172, 498 (2017)

Z.M. Sun, G.Y. Yao, M.Y. Liu, S.L. Zheng, J. Taiwan. Inst. Chem. E. 71, 501 (2017)

V.T. Tran, D.T. Vu, Appl. Phys. A. 124, 675 (2018)

X. Peng, J. Qu, S. Tian, Y. Ding, X. Hai, B. Jiang, M. Wu, J. Qiu, Rsc. Adv. 6, 104549 (2016)

A. Chaudhary, A. Mohammad, S.M. Mobin, Mater. Sci. Eng. B 227, 136 (2018)

M.Q. Qiu, Z.X. Chen, Z.H. Yang, W.M. Li, Y. Tian, W.X. Zhang, Y.S. Xu, H.S. Cheng, Catal. Sci. Technol. 8, 2557 (2018)

J. Feng, Z.Q. Zhang, M.M. Gao, M.Z. Gu, J.X. Wang, W.J. Zeng, Y.Z. Lv, Y.M. Ren, Z.J. Fan, Mater. Chem. Phys. 223, 758 (2019)

N. Khadgi, Y. Li, A.R. Upreti, C. Zhang, W.L. Zhang, Y.M. Wang, D.W. Wang, Photochem. Photobiol. 92, 238 (2016)

S.N. Xiao, D.L. Pan, R. Liang, W.R. Dai, Q.T. Zhang, G.Q. Zhang, C.L. Su, H.X. Li, W. Chen, Appl. Catal. B 236, 304 (2018)

M. Bagherzadeh, R. Kaveh, Photochem. Photobiol. 94, 1210 (2018)

J.L. Jiang, X.X. He, J.F. Du, X.J. Pang, H. Yang, Z.Q. Wei, Mater. Lett. 220, 178 (2018)

T.T. Bi, H.Q. Fang, J.L. Jiang, X.X. He, X. Zhen, H. Yang, Z.Q. Wei, Z.F. Jia, J. Alloy. Compd. 787, 759 (2019)

Y. Huang, Y.L. Liang, Y.F. Rao, D.D. Zhu, J.J. Cao, Z.X. Shen, W.K. Ho, S.C. Lee, Sci. Technol. 51, 2924 (2017)

Y.D. Lu, Y.P. Feng, F.L. Wang, X.G. Zou, Z.F. Chen, P. Chen, H.J. Liu, Y.H. Su, Q.X. Zhang, G.G. Liu, J. Photochem. Photobiol. A 353, 10 (2018)

Y.L. Guo, L.L. Zhang, X.Y. Liu, B. Li, D. Tang, W.S. Liu, W.W. Qin, J. Mater. Chem. A. 4, 4044 (2016)

X. Huang, L. Liu, Z. Xi, H. Zheng, W. Dong, G. Wang, Mater. Chem. Phys. 231, 68 (2019)

A. Mishra, V. Sharma, T. Mohanty, B.K. Kuanr, J. Alloy. Compd. 790, 983 (2019)

Y. Yao, Y. Cai, F. Lu, F. Wei, X. Wang, S. Wang, J. Hazard. Mater. 270, 61 (2014)

N.U. Yamaguchi, R. Bergamasco, S. Hamoudi, Chem. Eng. J. 295, 391 (2016)

P.H. Luo, X.F. Guan, Y.L. Yu, X.Y. Li, Chem. Phys. Lett. 690, 129 (2017)

M.S. Cuevas, I. Oller, A. Agüera, J. Sánche-Pérez, S. Malato, Chem. Eng. J. 318, 161 (2017)

P.J. Wang, L.Q. Wang, Q. Sun, S.B. Qiu, Y. Liu, X.B. Zhang, X.L. Liu, L.H. Zheng, Mater. Lett. 183, 61 (2016)

X.L. Zhu, Z.Q. Wei, W.H. Zhao, X.D. Zhang, L. Zhang, X. Wang, J. Electron. Mater. 47, 6428 (2018)

W.H. Zhao, Z.Q. Wei, X.L. Zhu, X.D. Zhang, J.L. Jiang, Int. J. Mater. Res. 109, 405 (2018)

X.L. Zhu, Z.Q. Wei, L. Ma, J.H. Liang, X.D. Zhang, Mater. Sci. 43, 1 (2020)

Y.X. Yan, H. Yang, Z. Yi, T. Xian, R.S. Li, X.X. Wang, Desalin. Water Treat. 170, 349 (2019)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51261015), open fund of State Key Laboratory of Silicate Materials for Architectures Wuhan University of Technology (No. SYSJJ2018-20) and Hong Liu First-Class Disciplines Development Program of Lanzhou University of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, Z., Huang, S., Zhang, X. et al. Hydrothermal synthesis and photo-Fenton degradation of magnetic MnFe2O4/rGO nanocomposites. J Mater Sci: Mater Electron 31, 5176–5186 (2020). https://doi.org/10.1007/s10854-020-03077-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03077-4