Abstract

Ce doped MgO nanoparticles with various doping concentrations of cerium ion were prepared by the sol–gel method. Both pure and Ce doped MgO nanoparticles were characterized by powder X-ray diffraction (XRD), Scanning electron microscope (SEM), Field emission scanning electron microscope, Energy-dispersive X-ray spectroscopy, UV–Vis diffuse reflectance spectroscopy, and Photoluminescence spectra analysis. XRD and SEM results suggest that both pristine and Ce doped MgO nanoparticles were in face centered cubic structure with individual spherical shaped nanoparticles with average particles sizes in the range of 20–30 nm. The band gap energy of pure MgO was significantly reduced from 3.81 eV to 3.22 eV. The Ce doped MgO catalyst showed outstanding photocatalytic degradation activity such as high efficiency (95%) and high stability (only loss 3.5%) towards phenol dye under visible light irradiation. The improved photocatalytic mechanism of MgO by Ce doping is also discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Environmental pollution has many facets, and the resultant health risks include diseases in almost all organ systems. Of particular interest is water pollution, which has become a global challenge, developing nations being highly affected due to their drive for development. The prevention of toxic chemical and biological contamination through environmentally green techniques is an important issue. In recent decades, semiconductor photocatalysis has been intensively studied for water and air treatment [1]. Generally, most of solar radiation is within the region of visible light, and hence it is significant and basic to explore photocatalysts with accessible visible light adsorption and exceedingly efficient activity [2,3,4,5]. Recently, metal oxide semiconductor materials such as TiO2, SnO2, WO3, CeO2 and ZnO have pulled in broad consideration within the recent years due to their photocatalytic capacity within the degradation of natural pollutant in water and air. Moreover, oxide semiconductors are most reasonable candidate for broad natural applications due to their organic and chemical inactivity, solid oxidation control and cost adequacy and long-term stability against photo- and chemical corrosion [6,7,8,9,10].

Among the different metal oxide nanoparticles utilized for photocatalytic applications, MgO has significant interests. Magnesium oxide (MgO) is one of the foremost important functional metal oxides which have been to a great extent utilized in numerous areas such as catalysis, poisonous waste remediation, material industry, paints and superconductors [11]. Even though, the band gap (4.2 eV) and absorption of visible light is the major concern for MgO to utilize the photocatalytic activity. In addition, the performance on electron–hole separation of the MgO based photocatalyst still need to be improved. Generally, dopant is a suitable method to increase the surface area and reducing the band gap of host material, which enhance the absorption property of visible light as well as increasing the photocatalytic ability. Hence, this work we choose cerium (Ce) dopant to enhance the photocatalytic performance of bare MgO. Ce3+ possesses shielded 4f levels, which allow various well-defined narrow optical transitions between the spin–orbit levels and thus split the bandgap of MgO and increase the performance on electron–hole separation. One of the rare earth metal elements that commonly known as the lanthanide group of the periodic system is cerium. Ce that showed strong absorption and emission in a visible region of UV–Vis and PL spectra. Cerium is a particular lanthanide element and it has two stable oxidation states, Ce3+ and Ce4+ (a noble gas configuration with r = 0.90 Å). Due to the high ionic radius Ce4+ ions are easily replaced the Mg2+ ions in the MgO crystal system, which enhancing the crystalline size. Owing to the increase in the size the band gap energy was also significantly reduced. Hence, we report a systematic study on the effect of Ce ion as a dopant in MgO nanoparticles. The effect of Ce doping on the electronic states, structural and optical properties and the photocatalytic activity was evaluated. The Ce dopant has positive influence in the optical and photocatalytic properties. To the best of our knowledge, this is the first report on structural, optical and photocatalytic properties of pure and Ce doped MgO nanoparticles synthesized by simple sol–gel route.

2 Experimental procedure

2.1 Materials

Cerium (IV) nitrate sulfate (CeSO4·4H2O), Magnesium (IV) sulfate (MgSO4·4H2O), NaOH, Congo-red and phenol solutions were purchased from Sigma-Aldrich Company with purity of 99.99%. The chemical used in the present work was analytical grade without use of sny further purification.

2.2 Synthesis of pure and Ce doped MgO nanoparticles

In a typical synthesis, 2.5 g of magnesium (II) sulfate was mixed with 50 mL of ethanol under magnetic stirring to build 0.1 M solution. Then cerium (IV) sulfate was dissolved in the above solution with a molar ratio of Ce is varied from 0.00, 0.01, 0.02 to 0.05 respectively. After that NaOH solution was drop wise and again stirring with half an hour until the pH was reaches to 8.

The pH value was 6.8 before adding NaOH. Where NaOH is strong precipitate agent than KOH and NH4OH. When NaOH is added in the precursor solution, it mixed well with the precursor solution and increased the pH of the solution as well as increased in reaction rate. Then dried at 80 °C at 24 h. The as prepared sample was further annealed at 500 °C for 3 h in air atmosphere in order to improve the crystalline nature of the samples. The pure MgO was prepared followed the similar experimental procedure without adding cerium source. The final products were named as M, CM1, CM2 and CM5 for pure, 0.01, 0.02 and 0.05% Ce doped MgO respectively.

2.3 Characterization techniques

X-ray powder diffraction (XRD) pattern of the samples were collected on a Bruker D8 Advance X-ray diffractometer using Cu Kα radiation source (wavelength: 1.54056 Å) in the 2θ range of 10°–80°. Transmission electron microscope (JEOL JEM 2100F Tecnai G-20, USA) operated at 200 kV, combining with Energy Dispersive X-ray spectroscopy (EDX) for the identication of morphology and elemental composition of the samples. The fundamental vibration modes of the samples were measured by using Raman spectra of the samples were recorded using BRUKER RFS 27: Stand alone FT-Raman Spectrometer at a resolution of 0.2 cm−1. The specific surface areas and porous nature of materials were further investigated by nitrogen adsorption/desorption measurements on nova 2200e. The UV–Vis absorption spectrum was recorded on a Perkin–Elmer lambda 950 UV–Vis–NIR spectrophotometer.

3 Results and discussion

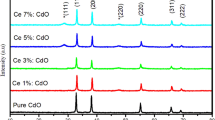

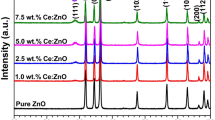

The X-ray diffraction patterns of undoped MgO and Ce doped MgO nanoparticles (NPs) are shown in Fig. 1a. The diffraction peaks and their relative intensities of both pure and Ce doped MgO NPs were match well with those given by JCPDS card no. 89-7746 of MgO which indicated that all the samples had typical face centered cubic structure with space group Fm-3 m. In addition, no diffraction peaks of Ce or other impurity phases were found, hence we assume that the Ce ions have evenly substituted into the Mg2+ sites or interstitial sites in the MgO lattice site [12,13,14]. The average grain size was calculated using Scherrer’s equation [15] and found to be 35, 31, 27 and 23 nm for M, CM1, CM2 and CM3 samples respectively. Malvern particle size analyzer (Model, Micro-P) was used to measure the size of nanoparticles. The average size obtained by the DLS distribution graph was around 25 to 45 nm (Fig. 1b). The dimension of both pure and doped MgO form of an equivalent sphere and sizes were found to be 40 and 25 nm for M and CM3 samples respectively. The morphology of the catalysts was analyzed via SEM and Field emission scanning electron microscope (FESEM) and the corresponding images are shown in Fig. 2. It was clear evident that both SEM and FESEM images illustrates that individual spherical shaped nanoparticles with average particles sizes in the range of 20–30 nm, which is good agreement with the XRD results. Further elemental composition of the CM3 sample was analyzed by using EDS and the related graph is shown in Fig. 2e. The sample is mainly composed of Ce, Mg and O elements. Figure 3a, b shows the N2 adsorption–desorption isotherms and pore size distribution curve of M and CM3 samples respectively. It was clear evident that both sample showed a typical IV isotherm with a clear H3 type hysteresis loop, which is typical characteristics of mesoporous materials [16]. The surface area and pore size was found to be 112 m2 g−1 and 24 nm for pure MgO sample, which is higher than that of CM3 sample (surface area 62 = m2 g−1 and pore size = 37 nm). Figure 4a shows the UV-DRS analysis of all the catalyst powders. From Fig. 4a, the curve dropped sharply in a range of 325 nm then slightly shifted to 385 nm for cerium doped. In the sample of 5% Ce doped MgO, the shift is followed by an increase in the UV absorption intensity. It is well known that the absorption edge relating to band gap energy of MgO. Based on the absorption edge, the band gap energy was calculated using Kubelka–Munk (K–M) relation [17, 18] and the band gap energy was establish to be 3.81, 3.61, 3.43 and 3.22 eV for M, CM1, CM2 and CM3 samples respectively (Fig. 4b). The crystallographic information of the catalyst was further evaluated by Raman spectra and the relevant spectra are shown in Fig. 5a. The Raman spectra of bare MgO are observed for two prominent modes of 710 and 805 cm−1, which is related to MgO. In Ce doped MgO, the intensity of the Raman modes are decreased and shifted to smaller wavenumber side. This may due to the size variation of both pure and Ce doped MgO samples, respectively. Figure 5b displays the room temperature PL spectra of the samples with an excitation wavelength of 270 nm in the range of 200–800 nm. A broad emission band appeared around at 430 nm, which is exceptionally feasible for device applications such as UV laser innovation, scintillators and phosphors. The detailed photocatalytic set up was described below and schematic representation was shown in Fig. 6. For photocatalytic process, the dye solution was prepared by adding a particular concentration (for example 200 mL, C0 = 10 mg L−1) and a particular amount of synthesized material poured into the dye solution. In the experimental set up, 250 mL of water cooled cylindrical glass reactor with 125 W high pressure mercury lamp was used as a light source. The samples/dye solution was irradiated in the horizontal direction and the distance between the mercury lamp and the glass/dye solution was kept within 20 cm. Then the solution was kept in the dark room and well stirred with the magnetic stirrer for more than 30 min to attain the equilibrium condition throughout the solution. The concentration of the aqueous suspensions (phenol and CR) in each sample was analyzed using UV–Vis spectrophotometer at a wavelength of 270 and 495 nm. The photocatalytic efficiency was calculated from the expression η = (1 − C/C0) × 100, where C0 is the concentration of dyes (phenol and CR) before illumination and C is the concentration of dyes after a certain irradiation time. Figure 7 shows the decline of the characteristic absorption band of phenol and CR dyes using M and CM3 samples under visible light irradiation. The absorption peaks of both dyes were completely diminished after 100 min testing. After 100 min of visible light irradiation, the percentage of the photodegradation of both dyes was measured for the four samples. The result is shown in Fig. 8a, b. The maximum photocatalytic degradation efficiency was observed for CM3 and found to be 95 and 87% for phenol and CR dyes respectively. The improved photocatalytic efficiency of Ce doped MgO is due to Ce dopant promoted the transfer and separation of photogenerated electrons and holes in the bare MgO. Figure 8c, d shows the plot of ln(C0/C) versus the irradiation time which indicates the kinetics of the reaction [19,20,21,22,−23]. First order decay kinetics according to the following formula.

where Co is the initial concentration of dyes, C is the concentration of the dye at various interval times (mol L−1), t is the illumination time (min) and k is the reaction rate constant. The rate constant (k) and the linear co-efficient (R2) values of CR dye were calculated to be 0.1294 min−1 and 0.991 respectively (CM3). Table 1 summarizes the other photocatalytic parameters of all the catalyst powders. In order to verify the high photocatalytic performance of the CM3 catalyst, different mass of (25, 50, 75 and 100 mg) the catalyst was taken and studied the photocatalytic efficiency of both dyes. The results again establish that catalyst showed outstanding photocatalytic performance (Fig. 9a, b). The stability of the catalyst is one of the important parameters to use of practical device applications. Hence, five progressive photocatalytic tests were conducted utilizing the CM3 catalyst and by changing the dye degradation after each cycle. As can be seen in Fig. 9c, d, the photocatalytic efficiency was retain approximately 92 and 84% of its successive five cycles, which shows the great stability of Ce doped MgO catalyst. COD and TOC measurements were further carried out to estimate the toxicity of the photodegraded dye solutions and the corresponding profiles are shown in Fig. 10a, b. In phenol dye solution, it is clearly observed that COD removal (74%) and TOC removal (79%) is achieved using CM3 catalyst. Similarly, in CR was found to be 67% and 71% for COD and TOC respectively. Based on the photocatalytic results, the schematic representation for the present photocatalytic mechanism is shown in Fig. 10c. The overall photocatalytic results demonstrate that Ce doped MgO catalyst showed superior photocatalytic performance than pure MgO. This could be due to the substitution of Ce3+ ions in the MgO crystal system, which can get oxidized to Ce4+ by discharging electrons which can encourage lead to arrangement of superoxide radicals (O2−) by responding with adsorbed O2. The oxidized Ce4+ species can act as electron scavenger or acceptor to trap photoexcited electrons from conduction band (CB) of MgO and subsequently reduced to Ce3+. Hence, the electron (e−)–hole (h+) recombination can be enormously decreased driving to improved photocatalytic performance [24]. Most of the electron–hole pairs are recombined producing heat energy. However, hydroxyl radicals (HO•) are formed in the presence of electron acceptor (dissolved O2) while hole (h+) oxidizes water or MgO surface active ─OH group. Dissolved O2 reacts with the electron (e−) and generates superoxide ion (O2−•). Finally, the HO• reacts with either phenol or phenolic compounds until complete mineralization. In addition, the reduction of band gap energy and gradually diminished the PL spectra intensity for the doped sample demonstrates that suppress the recombination of electron–hole pairs, which results in improving the photocatalytic performance of Ce doped MgO than pure MgO catalyst.

4 Conclusions

In summary, pure and Ce doped MgO catalysts were synthesized by a facile sol–gel route and study the structural, morphological and optical properties. Powder XRD and FESEM results reveals that both pure and Ce doped MgO nanoparticles were cubic structure with spherical shaped morphology with sizes in the range of 20–30 nm. The UV and PL results exposed that absorption ability was extended to (red-shift) the visible region and reduced the recombination rate of electron–hole pairs in the Ce doped MgO catalyst. The Ce doped MgO catalyst showed outstanding photocatalytic degradation activity such as high efficiency (95%) and high stability (only loss 3.5%) towards phenol dye under visible light irradiation. The present catalysts can be preferable for highly degradation of phenol dye under visible light.

References

A. Fujishima, K. Honda, Nature 238, 37 (1972)

S. Mansingh, D.K. Padhi, K.M. Parida, Catal. Sci. Technol. 7, 2772 (2017)

Y.C. Zhang, Z. Li, L. Zhang, L. Pan, X.W. Zhang, L. Wang, F. Aleem, J.J. Zou, Appl. Catal. B 224, 101 (2018)

S.R. Pouran, M. Mousavi, A. HabibiYangjeh, J. Mater. Sci. Mater. Electron. 29, 1719 (2018)

M. Pirhashemi, A. Habibi-Yangjeh, S.R. Pouran, J. Ind. Eng. Chem. 62, 1 (2018)

O. Carp, C.L. Huisman, A. Reller, Prog. Solid State Chem. 32, 33 (2004)

I.K. Konstantinou, T.A. Albanis, Appl. Catal. B 49, 1 (2004)

S. Tanemura, L. Miao, W. Wunderlich, M. Tanemura, Y. Mori, S. Toh, K. Kaneko, Sci. Technol. Adv. Mater. 6, 11 (2005)

G.K. Mor, O.K. Varghese, M. Paulose, K. Shankar, C.A. Grimes, Sol. Energy Mater. Sol. Cells. 90, 2011 (2006)

M. Ni, M.K.H. Leung, D.Y.C. Leung, K. Sumathy, Renew. Sustain. Energy Rev. 11, 401 (2007)

S. Suresh, D. Arivuoli, J. Nanomater. Biostrut. 6, 1597 (2011)

V.T. Srisuvetha, S.L. Rayar, G. Shanthi, A. DhayalRaj, Int. J. Curr. Eng. Res 5, 1 (2018)

M. Parthibavarman, M. Karthik, S. Prabhakaran, Vacuum 155, 224 (2018)

T. Kato, G. Okada, N. Kawaguchi, T. Yanagida, J. Lumin. 192, 316 (2017)

M. Parthibavarman, K. Vallalperuman, S. Sathishkumar, M. Durairaj, K. Thavamani, J. Mater. Sci. Mater. Electron. 25, 730 (2014)

M. Karthik, M. Parthibavarman, A. Kumaresan, G. Prabhakaran, V. Hariharan, R. Poonguzhali, S. Sathishkumar, J. Mater. Sci.: Mater. Electron. 28, 6635 (2017)

V. Hariharan, S. Radhakrishnan, M. Parthibavarman, R. Dhilipkumar, C. Sekar, Talanta 85, 2166 (2011)

M. Parthibavarman, V. Hariharan, C. Sekar, V.N. Singh, J. Optoelectron. Adv. Mater. 12, 1894 (2010)

B. Chouchene, T.B. Chaabane, L. Balan, E. Girot, K. Mozet, G. Medjahdi, R. Schneider, Beilstein J. Nanotechnol. 7, 1338 (2016)

Y. Hao, G. Meng, C. Ye, X. Zhang, L. Zhang, J. Phys. Chem. B. 109, 11204 (2005)

M. Parthibavarman, S. Sathishkumar, S. Prabhakaran, J. Mater. Sci.: Mater. Electron. 29, 2341 (2018)

M. Parthibavarman, M. Karthik, S. Prabhakaran, J. Clust. Sci. 30, 495 (2019)

M. Parthibavarman, S. Sathishkumar, M. Jayashree, R. BoopathiRaja, J. Clust. Sci. 30, 351 (2019)

S.P. Chaudhari, A.B. Bodade, P.D. Jolhe, S.P. Meshram, G.N. Chaudhari, Am. J. Mater. Synth. Process. 2, 97 (2017)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the research work reported in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Srisuvetha, V.T., Rayar, S.L. & Shanthi, G. Role of cerium (Ce) dopant on structural, optical and photocatalytic properties of MgO nanoparticles by wet chemical route. J Mater Sci: Mater Electron 31, 2799–2808 (2020). https://doi.org/10.1007/s10854-019-02823-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02823-7