Abstract

Polymer blends of polyaniline (PANI) and polyvinyl chloride (PVC) were fabricated using thermally reduced graphene oxide (TRGO) as nano-level reinforcement to enhance the electromagnetic interference (EMI) shielding effectiveness. The initial assessment of polymer blends of PVC and PANI and hybrid nanocomposites of PVC, PANI and TRGO were done with cyclic voltammetry and the results showed improved electrical conductivity of 1.0 × 10−15 S/cm, 1.5 × 10−6 S/cm and 4.2 × 10−5 S/cm respectively. The capacitive effect of this blend and hybrid nanocomposites were evaluated as an initial assessment at frequency region (100 Hz–5 MHz). EMI-shielding effectiveness of PVC, PVC/PANI blend and PVC/PANI/TRGO hybrid nanocomposites were measured in the microwave frequency region of 11–20 GHz. Almost 29 dB shielding effectiveness was observed in case of PVC–PANI blend. The shielding effectiveness was enhanced to ~ 56 dB as 5 wt% of TRGO was added. The dispersion state, interaction of filler with the polymer matrix and the nature of fillers are the main reasons to the enhance EMI shielding of these hybrid nanocomposites.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The electronic devices operating in the vicinity are surrounded by electromagnetic waves that disrupt the performance of the devices. The electromagnetic interference reduces the life and performance of these devices. A layer of EMI shielding material works as a protective layer on electronic devices to enhance their performance. Characterization of EMI shielding materials is done by electrical conductivity, dielectric permittivity and magnetic permeability [1,2,3,4,5]. Conducting polymer materials were preferred over conventional metals i.e. aluminum, copper, and steel because of flexibility, lightweight, corrosion resistance and ease of processability in EMI shielding application. Moreover, conductive polymers were found easy for blending with other polymers with more flexible and robust thermoplastics. Intrinsically conducting polymers are mostly used as conductive materials like polyaniline (PANI), polypyrrole, and polythiophene [6]. A blend of Poly ethyl methacrylate (PEMA) and polyvinyl chloride (PVC) was prepared using LiClO4 as salt and propylene carbonate (PC) as a plasticizer by solvent casting technique. The blend exhibited a significant conductivity even at room temperature. Highest conductivity (3.454 × 10−3 S/cm) at room temperature having good mechanical stability was observed for composition (PVC: 5, PEMA: 20, PC: 67, LiClO4: 8 wt%) among the various compositions of blends studied [7]. The blends of polyaniline (PANI)/styrene acrylonitrile (SAN) were prepared and the dielectric and EMI shielding behaviors of these blends were studied. Thin films of 150 µm of PANI/SAN blends were used to check the total shielding effectiveness (SET). SET was highest for PANI/SAN blends at 40 wt% [5]. PVA–PANI based conducting hydrogels were prepared by high-pressure induced gelation process. SEM images of the blended hydrogels showed that the in situ polymerization of aniline in PVA hydrogels formed a 3D nano-network structure. A nano-composite was prepared by adding graphene nanoflakes in PVC matrix. These prepared nano-composite based thin films were mechanical and thermally studied. 2 wt% loading of graphene in PVC exhibited 58% increase in Young’s modulus and a 130% increment of ultimate tensile strength. Glass transition temperature (Tg) of the composite was increased in comparison to pure PVC which showed high thermal stability [8]. Various researchers used either one or combinations of PVC and graphene and characterized them for EMI shielding applications [1,2,3,4,5, 9,10,11,12,13,14,15,16,17,18,19,20]. The above studies confirmed that nanocomposites based on graphene and PANI provide the high potential to be employed in several electronics applications. Special features of insulative and conductive polymeric hybrid nanocomposite with graphene nanoflakes revealed that it can be utilized as EMI shielding material which will have the advantages of high protection against EM radiations, ease of fabrication, lower concentration of filler nanoparticles, ease of fabrication and it will also be cost-effective. PANI and graphene were separately used in various application and proved to be very effective and in EMI shielding also. It is believed that using both materials together in a single composite as reinforcement, extraordinary EMI shielding properties can be achieved.

In this study, hybrid nanocomposites were prepared based on polyvinyl chloride matrix (PVC), polyaniline (PANI) and thermally reduced graphene oxide (TRGO) with different wt% loadings. The prepared samples were evaluated for the EMI shielding behavior. Dielectric properties were assessed in the frequency region of 100 Hz–5 MHz that used as an initial assessment for the prediction of EMI shielding. Lower frequency region deals with the magnetic attenuation while hybrid nanocomposite prepared was percolative system meant for the attenuation of an electric part electromagnetic wave in GHz frequency. So, hybrid nanocomposites for EMI shielding in 11–20 GHz frequency range were experimentally analyzed. Using vector network analyzer (VNA) coaxial cable method, calculations using real and imaginary parts of scattering parameters, it was observed that attenuation was more than 29 dB for PVC/PANI blend and 56 dB for of hybrid nanocomposites. Cyclic voltammetry has also helped to understand the formation of electrically conductive network structure.

2 Materials and methods

2.1 Materials

Ammonium persulfate (APS) was purchased from DAU-JUNG-Korea. Aniline was used as a monomer for the polymerization of polyaniline with 99% purity and graphite powder of 45 µm particle size with 99% purity were obtained from Sigma-Aldrich. Tetrahydrofuran (THF) with 96% purity was purchased from Fisher chemicals the UK and formic acid with 85% purity was acquired from Merck Schuchardt, Germany. Commercial grade polyvinylchloride (PVC) was donated by Engro group of companies, Pakistan.

2.2 Preparation of polyaniline

Chemical oxidative method was used for the fabrication of polyaniline (PANI) [21]. In this method, two separate solutions of APS (4.88 g) and aniline (2 ml) in formic acid (50 ml) each were prepared at 50 °C with continuous stirring. The solutions were then placed in an ice bath to achieve a temperature of 0–5 °C. APS solution was then added in a dropwise manner (1 drop/s) to aniline solution. The dark greenish color of PANI started to appear as APS solution was added. The solution was then kept at 0–5 °C for 4 h with homogeneous stirring, to achieve complete polymerization. Formic acid doped PANI precipitates were prepared. Excess Formic acid was then evaporated at 100 °C and at the bottom of the beaker, dark greenish PANI powder was obtained. Polymer precipitates were washed with ethanol and water, dried in a vacuum oven at 90 °C and 300 mbar pressure overnight.

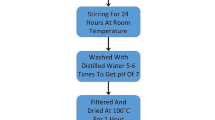

2.3 Preparation of thermally reduced graphene oxide (TRGO)

Graphene oxide (GO) was prepared by modified hammer’s method and reduced at elevated temperature to make it thermally reduced graphene oxide (TRGO) [22, 23]. 3 g of graphite and 18 g of KMnO4 were taken in a beaker. Four hundred millilitre solution of sulfuric acid and phosphoric acid (9:1) was poured on it. Maintain the temperature at 50 °C with continuous stirring for 1 h to initialize the reaction. Heating was then turned off and left the solution for the reaction to complete for 24 h at room temperature with continuous stirring. After the formation of GO, stirring was turned off and left the GO particles to settle down, 2 phases were formed after 8–10 h, GO was present in the bottom phase of the beaker. Extra liquid from above was poured out and the remaining GO solution was washed with ethanol and water 4–5 times and then dry at 50 °C. After the formation of graphene oxide (GO), it was reduced at 200 °C in a muffle furnace for 72 h. X-ray diffraction was used to identify the formation of TRGO and particle size measurement.

2.4 Blend and hybrid nano-composite preparation

Solution casting method was employed to prepare polymer blend and hybrid nanocomposites of various compositions that are shown in Table 1. PVC, PANI, and TRGO were dissolved in THF separately and sonicated for 2 h. All the solutions were then mixed together to get the desired composition of each component and sonicated again for 2 h and magnetic stirring afterward for 24 h. The solutions were poured in a glass Petri dish, first dried at room temperature for 24 h and then in a vacuum oven at 300 mbar pressure and 50 °C overnight. Three different compositions of PVC/PANI blend were fabricated of 5, 15 and 30 wt% of PANI. 5 wt% PANI film didn’t exhibit any prominent increase in electrical conductivity value whereas 30 wt% PANI film possess very high electrical conductivity but also very fragile, brittle and hard to handle. 15 wt% PANI film have an acceptable value of electrical conductivity and also not as brittle and fragile as 30 wt% PANI film was. So, PVC with 15 wt% of PANI film was selected for the incorporation of TRGO.

The thickness of prepared samples of PVC, PVC/PANI, and HNCs is ranging between 100 and 130 µm measured by scanning electron microscope (Fig. 1).

2.5 Characterization

The polymer blend and hybrid nanocomposites were characterized using X-ray diffraction (XRD) using Cu Kα radiations for the confirmation of PANI. Scanning Electron Microscope (SEM) (JEOL-instrument JSM-6490A) for morphological analysis, Impedance analysis for dielectric properties, Cyclic Voltammetry for DC conductivity and Vector Network Analyzer (VNA) for EMI shielding effectiveness measurements of hybrid nanocomposites.

3 Results and discussion

3.1 X-ray diffraction

Conductive “Emeraldine Salt” Structure of PANI was prepared directly and confirmed by XRD. The conductive structure of PANI is semi-crystalline and have two characteristic peaks in the XRD spectrum at 2θ = 19° and 2θ = 27° as shown in Fig. 2. PANI is being prepared in different ways and its properties vary from method to method and also depend on the nature of dopant. The electrical conductivity of PANI–HCOOH was reported up to 500 S/cm highest ever achieved by a scientist using formic acid as dopant [21]. PVC showed amorphous nature as shown in the figure. TRGO has its characteristic peak at 2θ = 26°. These XRD patterns of PANI and PANI/Graphene was also crosschecked by literature [20, 24].

3.2 Fourier transform infrared spectroscopy

PVC, PANI and their blend were evaluated with FTIR to analyzer their interaction in the range of 400 to 4000 cm−1 and the obtained graph is shown in Fig. 3. PANI characteristic peaks appear at 1100 cm−1 and 3500 cm−1 corresponds to –C–N and –N–H stretching respectively. Moreover, the characteristic peak of PVC corresponds to –C–Cl stretching appear at 650 cm−1. A similar pattern of PANI was also found in the literature [25]. The all three above-mentioned peaks are present in PVC/PANI blend. As there is no disappearance and appearance of a new peak in FTIR pattern of the blend clearly shows that there is no chemical interaction between both polymer and it’s just a physical blend. The peaks configurations in blend clearly indicate that polyvinylchloride and polyaniline are well mixed physically and both exist as separate phases and have small physical intermolecular forces indicated by a small shift in C–N stretching peak of PANI. If bond length decreases the peak wavenumber shift to higher values. If it decreases the bond length increases. Bond length changes may occur due to the change in electronegativity of the neighboring atom. As clear from DSC graphs that with the addition of PANI Tg increases because PANI is restricted the chain movement and confined itself in small empty spaces present in amorphous PVC structure. The C–N bond length decreases and its peak shift to a slightly higher value. There is no chemical interaction and structure change in both polymers they are only physical mixed.

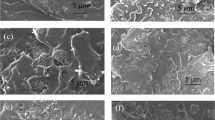

3.3 Scanning electron microscopy

Surface morphology was analyzed using scanning electron microscope (JEOL-instrument JSM-6490A) at various magnifications. SEM images of PVC, PVC–PANI, HNC-1, and HNC-2 are shown in Fig. 4. It was observed that PVC shows amorphous nature. A network structure was formed with the addition of 15 wt% PANI as clearly visible in Fig. 4b. With the addition of 1 and 5 wt% TRGO in polymer blend, interconnected network structure become more and denser. TRGO and PANI both form their own network in PVC matrix and their size and shapes are identical, therefore, it is impossible to differentiate the structure formed by PANI with the structure formed by TRGO but it is clear that both PANI and TRGO form 3D network structure that becomes more and denser as wt% of TRGO is increased clearly indicated as the no of white phase is becoming more and more as PANI and TRGO is being added in PVC.

Figure 5a and b shows the the structure of 15 wt% PANI in PVC and 1% TRGO in PVC. It is clear the structure formed by these 2 nano level particles are exactly the same.

3.4 Cyclic voltammetry

DC conductivities (σdc) of PVC–PANI and HNCs were analyzed using “BioLogic VSP electrochemical workstation”. As PVC is completely insulator by nature and its conductivity was reported 1 × 10−16 S/cm [26]. A three-electrode cell with and the composite film (1 × 1 cm2) as the working electrode, platinum wire as the counter electrode and a Saturated Calomel Electrode as reference was used in the electrolyte of 1 M solution of sodium sulfate (Na2SO4). The I–V plots, shown in Fig. 6a representing current (I) in milliamperes (mA) on the y-axis and potential difference of working electrode (Ewe) in voltage difference (V) on the x-axis. Following relations was used to calculate the DC conductivities of samples after getting I–V plots.

where R is resistance, I and V are current and voltage passing through sample respectively, ρ is resistivity, L and A are the length and area of films respectively. DC conductivity found to be increased as PANI was added in PVC and TRGO 1 wt% and 5 wt% added in PVC/PANI-15 wt% blend. DC conductivity calculated to be 1.5 × 10−6 S/cm for PVC/PANI, 2.5 × 10−6 for HNC-1 and 4.2 × 10−5 for HNC-2. The increase in DC conductivity was due to an electrically conductive network structure formed by both PANI and TRGO in PVC matrix as described in SEM results.

3.5 Dielectric measurements

Dielectric data is expressed first in real (ɛ′) and imaginary part (ɛ″) of dielectric permittivity that was obtained from the following Eq.

The dielectric constant of a material is the ability to store electrical energy when exposed to an electric field that can be calculated as

where d and A are thickness and area of the sample respectively. ε° is permittivity of free space and C is the observed capacitance of the sample.

Using dielectric tangent loss (tanδ) and dielectric constant (ɛ′), dielectric loss (ɛ″) can be calculated using this formula:

By using some of these parameters, AC conductivity can be calculated as follow:

100 Hz to 5 MHz frequency was used to analyze these parameters as the function of frequency.

Dielectric properties of neat PVC, PVC–PANI and HNCs were analyzed using “Wayne kerr 6500B”. It was observed that \(\varepsilon^{\prime}\) increased from 2 to 3 and 6.5 for pure PVC, PVC–PANI and HNC-2 respectively. Dielectric Loss and AC Conductivity also seemed to increase 5 times with the addition of 15% PANI and 5% TRGO in PVC. This increase in AC Conductivity confirmed that both PANI and TRGO was well dispersed in PVC matrix and form a 3D interconnected network structure that provide enhance electrical conductivity and capacitive properties i.e. dielectric loss and dielectric constant. Dielectric parameters are shown in Fig. 7. It was observed that both ε′, ε″ were high at low frequency (100 Hz–1 kHz) and then decreased to a constant value because of dipoles didn’t have enough time to reorient with the changing electric field at this high frequency. With the addition of PANI 15 wt% and TRGO 1 wt% and 5 wt%, both ε′, ε″ seemed to be increased due to the high surface charge density at the filler–matrix interfaces as the filler is electrically conductive because of free electrons in its structure that come to the surface/interface with the changing electric-field. As the AC conductivity directly dependent on the number of the frequency-induced dipole. In lower frequency region, σac showed relatively smaller values and higher vales at high frequency region. Because of high relaxation time at lower frequency region, frequency induced dipoles orient well along the external applied field, while at high frequency region, relaxation time is very less and so the dipoles couldn’t reorient. The hoping mechanism is the key for the excitement of charges with the frequency, and responsible for the enhancement in the electrical conductivity. The increase in the concentration of conductive fillers, further enhance the electrical conductivity [27].

3.6 Differential scanning calorimetry

Differential scanning calorimetry (DSC) results are shown in Fig. 8. For PVC, Tg appears at almost 69 °C. After the incorporation of 15 wt% PANI in PVC, the Tg step increased to 79 °C due to the strong interaction of matrix and filler and chain restriction of the matrix. As TRGO was added in PVC–PANI blend, TRGO showed “intercalation” phenomena and thus gives more space to PVC chains to move and so the Tg decreased as 1 wt% to 5 wt% TRGO was added. On the other hand, TRGO does not affect the crystalline portion of PANI because it is tightly packed and cannot disturbed, so the melting of PANI appear at exact 138 °C. Almost a similar trend was also found in the literature [22, 25].

DSC and SEM results confirm the formation of heterogeneous phase morphology for PVC–PANI polymer blend and HNCs. PANI and TRGO form the interconnected network structure that affects the conductivity, dielectric and mechanical properties.

3.7 Mechanical properties

The tensile test was performed with a universal testing machine using ASTM standard (D3039). Sample size and shape of rectangular strips are (10 mm width, 20 mm gauge length). Stress–strain graphs of samples are shown in Fig. 9.

It is clear from the graph that maximum strength is achieved with the incorporation of 15 wt% of PANI due to complete dispersion and strong matrix filler interaction and also load transfer. As TRGO is added in PVC/PANI blend, all parameters like strength, elongation, and modulus decrease because of its small size and intercalation phenomena. Thermally reduced graphene oxide goes between the polymer chains creating its own network structure that break the connecting path and open up the natural structure of PVC matrix and so the mechanical properties decrease with the addition of TRGO in PVC–PANI polymer blend as similar observation was also found in the literature [28].

3.8 EMI shielding properties

EMI Shielding characteristics were measured by Vector Network Analyzer (VNA) using a disc shape sample of 7 mm outer diameter and 3 mm inner diameter in the frequency range of 11–20 GHz. According to EMI theory, whenever electromagnetic radiation interacts with material, it reflects, absorbs and transmit EM wave [18]. The EMI shielding effectiveness was measured and calculated in decibels (dB), expressed as the logarithmic ratio of incoming to transmitted energy as expressed below:

The scattering parameters S11, S12, S21, and S22 obtained from VNA and the following relations were used to calculate SER, SEA and SET [18].

Both SER and SEA are expressed as:

The above mention equations were used to calculate SER, SEA and SET and shown in Fig. 10.

PVC is insulator in nature, it didn’t exhibit any attenuation of EM radiations and EMI value was close to zero. Most polymers are insulator in nature and don’t exhibit EMI shielding properties. With the addition of 15 wt% PANI in PVC matrix, the electrically conductive structure was formed and the blend was no more electrically insulator and so the attenuation increased to 29 dB. It is clear from Fig. 10a and b that PANI possesses the absorbing nature of EM radiations and shows SEA ≈ 23 dB and SER ≈ 4 dB. With the addition of 1 wt% TRGO there was a small increase in all SEA, SER and SET values but as the TRGO concentration increased to 5 wt%, huge increase in attenuation of EM radiations from 29 to 56 dB was observed. Modak prepared a composite with 5 wt% of graphene and 95 wt% of PANI achieved shielding effectiveness of 47 dB [3]. The benefit of using this hybrid nanocomposite is that at higher frequency region it exhibits SET more than 45 dB in a broad range of frequency, while other shields are effective in only one or two specific frequencies and don’t show any protection at any other frequencies [29,30,31].

Reflection and absorption of EM radiation can also be calculated from the following equations.

Here \(\sigma_{T}\), \(\omega ,\varepsilon_{^\circ } ,\mu_{r}\) and t are total electrical conductivity, angular frequency, permittivity of free space, relative permeability and thickness of film respectively. Electrical conductivity and angular frequency are directly proportional to SEA, as angular frequency increases electrical conductivity also increases confirmed in dielectric characterization and thus SEA shows increasing trend. SER is directly proportional to electrical conductivity but inversely proportional to frequency. And so it remain constant as both nominator and denominator increasing but in specific range, the increase in conductivity is more prominent then frequency maybe due to electron energy in that range of frequency that depends on materials intrinsic characteristics like electronegativity, bond energy etc. so in particular range of frequency, SER exhibit a peak, clearly indicating the high change in electrical conductivity with frequency.

A schematic diagram is shown in Fig. 11 that how electromagnetic radiation interacts with shielding material and how it is attenuated.

The electromagnetic theory says that whenever an EM radiation falls on a surface, some of it reflected back and remaining part goes inside the material [16]. In the case of polymeric nanocomposites, there are several interfaces inside the thin composite material and every interface act as reflecting surface for EM radiation. If the thickness of film increased, it will accommodate a greater number of nanoparticles in its transverse direction creating a greater number of reflecting surfaces for EM radiation and hence shielding will enhance.

EMI shielding can also be calculated by the above equation where t, σ, and f are the thickness of the film, the electrical conductivity of film and frequency in MHz respectively. All the films were prepared with the same thickness so the effect on EMI shielding behavior can be compared that was purely due to the reinforcement added and not due to the film thickness.

According to this theory, EMI shielding doesn’t only depend on electrical conductivity, relative permeability, and dielectric permittivity but also depends on the number of reflecting surfaces and thickness of shielding film. The benefit of using hybrid nanocomposites is that due to extremely small size of filler particle, the greater number of particles can accommodate in the smaller thickness of film creating a greater number of interfaces that will attenuate more EM radiation. According to reported data on EMI shielding, 20 dB is a threshold value for a good EMI shielding material, in case of polymer nanocomposites, this value achieved with the film thickness of 1–2 mm [5]. In case of hybrid nanocomposites of the insulator polymer matrix (PVC), conductive polymer (PANI) and conductive nanofiller (TRGO), EMI shielding value achieved was more than twice (56 dB) the threshold value (20 dB) with 8–14 times less thickness of shielding film. SET of 56 dB was measured with SEA is about 38 dB and 18 dB SER. According to EM theory, electrically conductive material reflects the EM radiation and the material that has both electrical conductance and magnetic permeability absorbs the EM radiation. Therefore, SER should be greater than SEA for these hybrid nanocomposite films because they don’t have magnetic permeability. In these hybrid nanocomposites, SEA is far greater than SER because PVC/PANI and PVC/TRGO interfaces are inside the thin film. The small fraction of incident radiation is reflected back through the outer surface of shielding film and remaining radiation goes inside the film and absorbs in it due to multiple reflections through the interfaces of PVC/PANI and PVC/TRGO that exist inside the thin shielding film.

4 Conclusion

Polyaniline was successfully prepared with a chemical oxidative method using formic acid as a dopant that gives maximum electrical conductivity. Polymer blend (PVC/PANI) and Hybrid nanocomposites were prepared by solution casting method using thermally Reduced Graphene Oxide and polyaniline as fillers. 100–130 micron thick film were obtained and evaluated for mechanical properties, dielectric characteristics, thermal properties, DC Conductivity, and EMI shielding. Dielectric properties were evaluated in 100 Hz–5 MHz frequency region that provided a basic prediction for the EMI shielding measurements. The dielectric constant increased up to 7 for HNC-2 as compared to only 2 for PVC. By using cyclic voltammetry, it was confirmed that AC conductivity increased to 6 × 10−5 S/cm for the 5% addition of TRGO in 100 Hz– 5 MHz frequency range. EMI shielding effectiveness was measured by VNA in the frequency range of 11–20 GHz, maximum attenuation of ~ 55 dB and 40 + dB in a broad range of 11–20 GHz frequency rather than having EMI shielding properties only on specific frequencies. These hybrid polymer composites will be a future prospect for applications in a broad range frequency spectrum.

References

A. Saboor, A.N. Khan, H.M. Cheema, K. Yaqoob, A. Shafqat, Effect of polyaniline on the dielectric and EMI shielding behaviors of styrene acrylonitrile. J. Mater. Sci. 27(9), 9634–9641 (2016)

T. Zia, A.N. Khan, M. Hussain, I. Hassan, I.H. Gul, Enhancing dielectric and mechanical behaviors of hybrid polymer nanocomposites based on polystyrene, polyaniline and carbon nanotubes coated with polyaniline. Chin. J. Polym. Sci. 34(12), 1500–1509 (2016)

P. Modak, S.B. Kondawar, D.V. Nandanwar, Synthesis and characterization of conducting polyaniline/graphene nanocomposites for electromagnetic interference shielding. Proc. Mater. Sci. 10, 588–594 (2015)

C.B. Hatter et al., Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 353(6304), 1137–1140 (2016)

R. Jan, A. Saboor, A. Khan, I. Ahmad, Estimating EMI shielding effectiveness of graphene–polymer composites at elevated temperatures. Mater. Res. Express 4, 8565 (2017)

I.A. Rashid et al., Stretchable strain sensors based on polyaniline/thermoplastic polyurethane blends. Polym. Bull. (2019). https://doi.org/10.1007/s00289-019-02796-x

S. Rajendran, M. Ramesh Prabhu, M. Usha Rani, Characterization of PVC/PEMA based polymer blend electrolytes. Int. J. Electrochem. Sci. 3(3), 282–290 (2008)

S. Vadukumpully, J. Paul, N. Mahanta, S. Valiyaveettil, Flexible conductive graphene/poly (vinyl chloride) composite thin films with high mechanical strength and thermal stability. Carbon N. Y. 49(1), 198–205 (2010)

M. Arjmand, T. Apperley, M. Okoniewski, U. Sundararaj, Comparative study of electromagnetic interference shielding properties of injection molded versus compression molded multi-walled carbon nanotube/polystyrene composites. Carbon N. Y. 50(14), 5126–5134 (2012)

K. Lakshmi, H. John, K.T. Mathew, R. Joseph, K.E. George, Microwave absorption, reflection and EMI shielding of PU-PANI composite. Acta Mater. 57(2), 371–375 (2009)

T. Mäkelä, S. Pienimaa, T. Taka, S. Jussila, H. Isotalo, Thin polyaniline films in EMI shielding. Synth. Met. 85(1–3), 1335–1336 (1997)

S. Koul, R. Chandra, S. Dhawan, Conducting polyaniline composite for ESD and EMI at 101 GHz. Polymer (Guildf) 41(26), 9305–9310 (2000)

C. Tian et al., Constructing uniform core-shell PPy@PANI composites with tunable shell thickness toward enhancement in microwave absorption. ACS Appl. Mater. Interfaces 7(36), 20090–20099 (2015)

J. Wojkiewicz, Dielectric behavior and shielding properties of polyanilinie. pp. 46–49, 2001

H. Baniasadi, A. Ramazani, S. Mashayekhan, F. Ghaderinezhad, Preparation of conductive polyaniline/graphene nanocomposites via in situ emulsion polymerization and product characterization. Synth. Met. 196, 199–205 (2014)

K. Gao, A. Raza, H. Shen, A.A. Haidry, S.A. Muhammad, IR filtering properties of TiAlN/Cu/TiAlN coatings. Mater. Res. Express 6, 5 (2019)

J.M. Thomassin, C. Jerome, T. Pardoen, C. Bailly, I. Huynen, C. Detrembleur, Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. 74(7), 211–232 (2013)

S.P. Pawar, S. Biswas, G.P. Kar, S. Bose, High frequency millimetre wave absorbers derived from polymeric nanocomposites. Polymer (UK) 84, 398–419 (2015)

P. Saini, V. Choudhary, B.P. Singh, R.B. Mathur, S.K. Dhawan, Polyaniline-MWCNT nanocomposites for microwave absorption and EMI shielding. Mater. Chem. Phys. 113(2–3), 919–926 (2009)

V. Panwar, B. Kang, J.O. Park, S. Park, R.M. Mehra, Study of dielectric properties of styrene-acrylonitrile graphite sheets composites in low and high frequency region. Eur. Polym. J. 45(6), 1777–1784 (2009)

E.C. Gomes, M.A.S. Oliveira, Chemical polymerization of aniline in hydrochloric acid (HCl) and formic acid (HCOOH) media. Differences between the two synthesized polyanilines. Am. J. Polym. Sci. 2(2), 5–13 (2012)

G.T.T. Le, J. Manyam, P. Opaprakasit, N. Chanlek, N. Grisdanurak, P. Sreearunothai, Divergent mechanisms for thermal reduction of graphene oxide and their highly different ion affinities. Diam. Relat. Mater. 89, 246–256 (2018)

D.C. Marcano et al., Improved synthesis of graphene oxide. ACS Nano 4(8), 4806–4814 (2010)

M. Fayzan et al., Results in physics EMI shielding properties of polymer blends with inclusion of graphene nano platelets. Results Phys. 14, 102365 (2019)

T. Machappa, M.V.N. Ambika Prasad, AC conductivity and dielectric behavior of polyaniline/sodium metavenadate (PANI/NaVO3) composites. Phys. B Condens. Matter 404, 4168–4172 (2009)

S. Ameen, V. Ali, M. Zulfequar, M. Haq, M. Husain, Electrical and spectroscopic characterization of polyaniline–polyvinyl chloride (PANI–PVC) blends doped with sodium thiosulphate. Phys. B Condens. Matter 403(17), 2861–2866 (2008)

M.-S. Cao, W.-L. Song, Z.-L. Hou, B. Wen, J. Yuan, The effects of temperature and frequency on the dielectric properties, electromagnetic interference shielding and microwave-absorption of short carbon fiber/silica composites. Carbon N. Y. 48, 788 (2009)

Y. Wang, X. Jing, Preparation and characterization of PVC/PANI conductive composite with extremely low percolation threshold. Polym. Adv. Technol. 15(8), 481–484 (2004)

X.G. Liu et al., (Fe, Ni)/C nanocapsules for electromagnetic-wave-absorber in the whole Ku-band. Carbon N. Y. 47(2), 470–474 (2009)

F. Wang, X. Wang, J. Zhu, H. Yang, X. Kong, X. Liu, Lightweight NiFe2O4 with controllable 3D network structure and enhanced microwave absorbing properties. Sci. Rep. 6, 1–8 (2016)

S.P. Pawar, S. Stephen, S. Bose, V. Mittal, Tailored electrical conductivity, electromagnetic shielding and thermal transport in polymeric blends with graphene sheets decorated with nickel nanoparticles. Phys. Chem. Chem. Phys. 17(22), 14922–14930 (2015)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shakir, H.M.F., Tariq, A., Afzal, A. et al. Mechanical, thermal and EMI shielding study of electrically conductive polymeric hybrid nano-composites. J Mater Sci: Mater Electron 30, 17382–17392 (2019). https://doi.org/10.1007/s10854-019-02088-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02088-0