Abstract

Over the last decades, a considerable attention has been drawn on the cerium dioxide (ceria, CeO2) due to promising changes in physical and chemical properties in nanoscale. The researches on CeO2 and its structural and morphological modifications have brought about remarkable applications as optical devices, sensors, medical equipments and luminescent materials. For instance, rare earth (RE) ion-doped cerium oxides have exhibited enhanced peculiar optical, catalytic and magnetic properties with respect to the dopant-free CeO2 nanoparticles. Herein we aimed to compare characteristics of undoped (CeO2) and europium (Eu3+) doped ceria (CeO2:Eu3+) nanoparticles synthesized by sol–gel (SG) and one-step flame spray pyrolysis (FSP) methods. In this work, fabricated nanoparticles were evaluated in terms of the structural, morphological, chemical and optical properties by using X-ray diffraction (XRD), scanning electron microscopy (SEM), X-ray photoelectron (XPS) and photoluminescence spectroscopy (PL), respectively. Nanoparticles in the intended crystalline CeO2 structure were obtained for both methods. Spherical particles in nanoscale (particle size < 100 nm) and sharp edged blocky particles in sub-micron size (particles size range 200–1000 nm) were produced through FSP and SG, respectively. Nevertheless, no significant difference due to the difference in particle size was observed in optical properties. On the other hand, Eu3+ doped particles of both methods exhibited longer decay time than the undoped particles.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, there has been considerable interest in preparation, characterization and applications of metal oxide nanoparticles that play a key role in several technologies. The metal oxide nanoparticles that used in the piezoelectric, optoelectronic and sensor applications show excellent chemical and physical specifications because of having limited size and high edge surface sites. There are many types of metal oxide nanoparticles as MgO, Al2O3, CeO2, ZrO2, AgO, NiO and TiO2 oxide. Al2O3 material has importance as a catalyst component; MgO has wide application for as a scrubber for air pollutant gases; ZrO2 has application as a solid electrolyte, gas sensor as well as a catalyst; TiO2 is one of the most common oxide material used for various kinds of industrial applications about catalysis, photocatalysis, organic synthesis and etc. [1]. Among them, cerium dioxide (ceria, CeO2) nanoparticles particularly plays a major role in a wide variety of technological applications as; catalysis, luminescence-based optical sensors, biology and medical applications thanks to distinct physical, chemical and optical properties [2, 3]. Today, pristine ceria and its metal incorporated modifications have also been attracted attention owing to their strong optical properties and the excitation of the activator ions by energy transfer. Moreover, incorporation of rare earth ions into cerium dioxide, led to act as luminescent activators due to the strong emission lines based on their sharp 4–4f intra-shell transitions [4].

As a rare earth, europium (Eu3+) have been incorporated of into cerium dioxide structure by several groups. Li and co-workers reported that Eu3+ concentration in CeO2 crystal lattice up to 1.0 wt% resulted in the observation of red shifts at the excitation spectrum. However, for the concentrations 5 and 10 wt% they recorded blue shifts. Eu3+ ions with the low concentrations (< 1.0 wt%) no distortion in the cubic fluorite structure of CeO2 was observed while in higher concentrations (> 1.0 wt%), the sites of Eu3+ ions are strongly affected by the oxygen vacancies [5]. In another study, Vimal et al. declared the optimum doping concentration of Eu3+ as 1.5 wt% since an emission quenching was observed at 617 nm for the concentrations up to 2.0 wt% [6].

There are many different approaches applied for the production of both, CeO2 and CeO2:Eu3+ nanoparticles such as flame spray pyrolysis, sol–gel, micro-emulsion, hydrothermal, radio frequency magnetron sputtering solid-reaction, and electrodeposition [5, 7,8,9,10,11,12,13]. In the present study, Eu3+ doped and un-doped ceria nanocrystals were synthesized using both of the SG and the FSP methods. As stated in previous literatures [5, 6] the optimum Eu3+ ratio in CeO2 was determined as 1.5 wt% for both methods. Many advantages including rapid growth, increased reaction rate and shortened reaction time, make the FSP technique as the mostly preferred method for synthesizing many nanocrystals. The capacity to disperse the precursor immediately in the fuel, the simplicity of the introduction of the precursor into the hot reaction area and the flexibility in using the high-velocity spray jet for rapid quenching of aerosol formation are the advantages of FSP [14]. Therefore the FSP technique has been used many times in the production of a wide variety of compositions as metal oxides, complex oxides, and nanocomposites used in a number of emerging applications such as photo-catalysis, sensors, batteries and solar cells [15, 16]. On the other hand, the SG process can be easily controlled in terms of the effect of a diversity of synthesis parameters as gelation time, the temperature of calcination and dwell time on chemical composition and crystallite size during the synthesis of nanoparticles.

In the literature, there is no other sample of work about the comparison of two methods for the synthesis of the CeO2 and Eu3+-doped CeO2 nanoparticles to the best of our knowledge. With this motivation, in this work, we studied the structural characterization and optical properties of the nanoparticles synthesized by SG and FSP methods. The fabricated nanoparticles were characterized by using X-ray diffractometer (XRD), X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM) photoluminescence (PL) and decay time measurements.

2 Experimental studies

In order to produce nano-powders by both FSP and SG, cerium(III) acetylacetonate hydrate [Ce(C5H7O2)3·xH2O, anhydrous basis] and europium(III) nitrate pentahydrate [Eu(NO3)3·5H2O, 99.99%] were utilized as initial and dopant precursors, respectively. In all of the samples, the undoped and Eu3+-doped precursors were prepared by dissolving an inappropriate amount of pure methanol (99.8 vol%). Optimum Eu3+ ratio was determined as 1.5 wt% to obtain strongest emission intensity [6, 17]. Glacial acetic acid (≥ 99.7 vol%) was added to the solution as a chelating agent for adjusting pH level, increasing the solubility of Ce and Eu in methanol, and obtaining a homogenous solution. All solutions were stirred under magnetic stirring for 30 min until attaining transparent solutions. The same solutions were used in both sol–gel and flame spray production. For the sol–gel production, sol to gel transformation was obtained after keeping at 80 °C for 30 min. Then, the drying process was carried out at 280 °C for 2 h. Subsequently, dried powder was annealed at 600 °C for 2 h to attain crystalline structures. For then FSP synthesis, flame spray pyrolysis equipment (Tethis Nps10) was used to obtain nanoparticles following the same procedure of our previous study [14] with by feeding these solutions into the precursor syringe. All chemicals and solvents were purchased from Sigma Aldrich and used without any further purification.

Determination of phase and crystal structures of the undoped and Eu3+-doped powders was carried out by an X-ray diffractometer (XRD, Thermo Scientific ARL) which operates with 45 kV voltage and 44 mA current settings, and uses Cu-Kα radiation (1.5405 Å). XRD data were recorded with a scanning speed of 2º/min in the range of 20º ≤ 2θ ≤ 80º. Rietveld refinement by Maud (V2.71) program was used for obtaining structural parameters. X-Ray photoelectron spectroscopy (XPS, Thermo Scientific K-Alpha) with a monochromatic Al-Kα (1486.7 eV) X-ray source and a beam size of 400 nm diameter was carried out to determine elemental composition and surface chemistry for all samples. The instrument was calibrated in accordance with gold; 4f7/2. The pressure of the system was kept at below 5 × 10−10 mbar for the period of data acquisition. The XPS data of the survey scan was performed from − 10 to 1350 eV with a scanning speed of 1 eV applying pass energy of 150 eV. Whole samples were scanned 20 times from a single point. XPS spectra showed up binding energies of Ce3d, O1s, C1s, and Eu3d. For high-resolution elemental spectra, the pass energy and the scan numbers were 30 eV and 15, respectively. Binding energies and deconvoluted spectra were achieved using the curve fitting application (Thermo Advantage V5.65). Microstructure images of particles were captured at different magnification by scanning electron microscope (SEM, Zeiss Sigma 300 VP) with 20 kV accelerating voltage.

Steady-state PL emission spectra were measured using Edinburgh instruments FLSP 920 fluorescence spectrometer. Fluorescence decay time measurements were performed by single photon counting technique (TCSPC) of the FLSP 920. The instrument was equipped with a standard 15 W xenon lamp and a micro-second flash lamp for steady-state and lifetime measurements, respectively. The decay time parameters were recovered by iterative convolution with a weighted, nonlinear least squares method using the measured IRF and emission decay data. The reduced chi square values were less than 1.2 and the residuals were symmetrically distributed around the zero axes. Finally, the optical band gap were calculated from the excitation spectra of the samples.

3 Results and discussion

3.1 Phase analysis

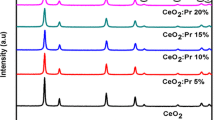

XRD patterns of undoped and Eu3+-doped CeO2 particles produced by different processes are shown in Fig. 1. The XRD patterns show peaks of CeO2, corresponding to the (111), (200), (220), (311), (222), (400), (331), and (420) crystallographic plane cubic fluorite structure [space group Fm3m (225)] according to the standard data JCPDS Card No. 34-0394. The positions of the peaks are in an agreement with the literature. [19,20,21,22,23]. A slight shift observed in the peak (111) is thought to be due to the dopant incorporated structure and low grain size. The XRD pattern of high purity nanoparticles was not observed in any other phase. As the particles become nano-sized, the patterns broaden [21].

The structural and lattice parameters of the nanoparticles were analyzed with the Rietveld refinement using the Maud 2.79 V software and listed in Table 1. The crystallite sizes were calculated from the broadening of the highest peak (111) of the sample using Debye–Scherrer’s formula; D = kλ/βcosθ, where D is the crystallite size (nm), k = 0.94, λCu = 0.15406 nm, β is the full-width at half-maximum of the peak in radians corrected from instrumental broadening, and, θ is the peak angle [18, 24]. The values of lattice parameters are 5.410, 5.406, 5.395, and 5.401 Å for FCO, FCO:Eu, SCO and SCO:Eu samples, respectively. The calculated cell parameter (a) is a little smaller than that of bulk CeO2 (5.411 Å). This may be due to the lattice constriction effect resulting from Eu3+ ions and oxygen vacancies. The crystallite sizes of undoped and Eu3+-doped CeO2 particles were found to be 22.4, 33.3, 43.1 and 46.2 nm for FCO, FCO:Eu, SCO and SCO:Eu, respectively. The enhancement in the crystallite size of the Eu3+ doped particles can be attributed to the radius of Eu3+ (r = 0.1066 nm) which is larger than the radius of Ce4+ (r = 0.097 nm), and consequently, the Eu3+ occupies more site then the Ce4+ [25]. Although the crystal size parameters of the undoped and doped forms were different, the differentiation of the synthesis method did not affect the crystal formation. In addition, the cause of a very small change in the lattice parameters is due to incorporated of the Eu3+ ions that entered as interstitial and substitutional atoms in the CeO2 lattice structure.

3.2 Elemental analysis (XPS)

XPS measurements were carried out to determine the surface chemical composition of all samples whose existing elements, binding energies (BE), and weight concentration (wt%) are summarized in Table 2. The binding energy peaks around 883 eV for the Ce3d, 531 eV for the O1s, and 285 eV for the C1s were in evidence for both undoped and Eu3+-doped CeO2 which were shown in Fig. 2a. The observed C1s peaks for all samples are expected to be derived from the fortuitous hydro-carbon from the external contaminants or XPS instrument itself which are in agreement with the peak positions and values that reported in the literature [26]. Table 2 shows the binding energy of the Ce3d, O1s, C1s, and Eu3d and atomic weight % for all samples titled FCO, FCO:Eu, SCO, and SCO:Eu.

Figure 2b. shows the core level spectra of Ce3d for the FCO, FCO:Eu, SCO, and SCO:Eu, respectively. The deconvoluted fitted lines are related to the valance levels of the Ce which are labeled as u0, u′, u″, u‴ and v0, v′, v″, v‴. While the u0, u′, and v0, v′, are characteristics peaks of the Ce3+ ions the u″, u‴ and v″, v‴ are belonged to the Ce4+ ions [27,28,29,30,31,32,33,34] which means CeO2 has mixed valance states. Because of the presence of both 3+ and 4+ oxidation states besides multiple d-splitting together, the deconvoluted spectra is relatively complex.

The group ‘u’ is related to 3d3/2 while group ‘v’ is related to 3d5/2 states and main peaks of these states are shown with ‘u‴’ and ‘v‴’ at 916.58 ± 0.7 eV and 898.6 ± 0.7 eV, respectively. These peaks correspond to 3d104f0 state of the Ce4+ ions [27, 28]. The ‘u″ (907.38 eV), u (900.78 eV)’ and ‘v″ (888.78 eV), v (882.38 eV)’ are two satellite peaks which located lower binding energy positions for each main peaks (u‴ and v‴). On the other hand, the u′ (903.92 eV) and v′ (885.34 eV) are belong to the 3d104f1 configuration of the Ce3+ ions [27, 28]. Similarly the Fig. 2c shows the core level spectra of O1s for the FCO, FCO:Eu, SCO, and SCO:Eu. The fitted line and deconvoluted graph which are labeled as Oa, Ob, and Oc, give peaks at 529.28 ± 0.2 eV, 529.94 ± 0.2 eV and 531.30 ± 0.2 eV, respectively. The Oa and Ob are related to the oxygen bonds to Ce4+ and Ce3+ [28, 31, 35] while the Oc is associated with hydroxyls and/or H2O molecules bond to Ce3+ [28, 31, 36], respectively. The Oa peak with the lowest binding energy of O1s core level spectra is related to O2− ions surrounded by the Ce4+ ions at Ce–O bond in CeO2 and the Ob peak can be attributed to the O2− ions at Ce–O bond which include the Ce as 3+ valance state. The Oc peaks belong to the O2− ions which are proper to the Eu3+–O2− configuration [28, 37]. And, while the Oa is related to the lattice oxygen, the Oc belongs to the oxygen vacancies [30]. The characteristic peaks of Eu3d5/2 (1134.19 eV) which is shown in Fig. 2d indicated that the Eu is in the trivalent state at Eu doped samples [28, 33].

3.3 Particle morphology (SEM)

The SEM images of undoped CeO2 and Eu3+ doped CeO2 powders produced through SG and FSP are depicted in Fig. 3. Eu3+ doped CeO2 powders fabricated by SG method were found to be agglomerated within a wide size range between Fig. 3a, b. However, the FSP based powders exhibited agglomerates in nanoscale (size) that are formed by spherical particles in a uniform distribution. As can be seen from the images in SG based powders complex geometries with sharp edges were observed. The SEM images of both SG and FSP based powders are in a good agreement with the literature [29, 38] for, in which they observed similar behavior.

3.4 Photoluminescence properties

As far as it is known, the luminescence properties of the CeO2 arise from its cubic fluorite-type crystal structure and the Ce4+ is not possessed of the 4f electrons. However, the Eu3+ ion-doped ceria become a remarkable luminescent material. Herein, the room temperature PL analysis of undoped and the Eu3+-doped CeO2 nano-powders, which is fabricated, by the SG and FSP methods has been carried out.

Figure 4 shows excitation-emission spectrum of CeO2 and CeO2:Eu3+ that synthesized by both of the FSP and the SG. When we compare the CeO2:Eu3+ and the CeO2, the emission maxima of the fabricated nano-powders have significant variations in consequence of the dopant ion.

When both Eu3+-doped and undoped CeO2 material excited at approximately 355 nm, we observed the emission peak maximum at 536 nm for undoped form, behind this there is a significant change for Eu3+-doped CeO2 which resulted with 12–14 nm red-shifted in emission maxima.

When Eu3+ is doped to the ceria, the transitions between 4f levels depends on as a cumulative effect of the magnetic and electrical dipole interactions cause the observation of the emission peaks between 590 and 660 nm [28, 39]. In order to achieve an effective energy transfer, optimal spectral overlap of CeO2 and Eu3+ is important. The strong and intense red light in the emission spectrum shows that the energy levels of Eu3+ are suitable to receive energy from Ce4+. Although the Eu-doped ceria has sharp peaks observed at around 590, 610, 630 and 650 nm, which is the specific 4–4f, transitions for Eu3+ in for both synthesis, the pure ceria does not show any peaks stated emission band. The emission spectrum showed the characteristic peaks of the Eu3+ that related to the various transitions of 5D0–7FJ (J = 0, 1, 2, etc.) which shows off more information about the environment and symmetry of the Eu3+ ions [40, 41]. The Eu3+-doped CeO2 nanocrystals showed remarkable enhancement at a wavelength between 590 and 655 nm in the emission spectrum, because of the increased oxygen vacancies, the charge compensation effect and the improvement of crystallinity. The crystallite size of Eu3+-doped CeO2 synthesized by the SG method have bigger when compared with the obtained Eu3+-doped ceria nanocrystals by the FSP. Therefore, the increment with the crystallite size of ceria caused the improvement of the emission intensities of the plural peaks in the red emission band. It can be attributed to the enhancement of crystallinity as well as charge compensation.

The specific emission peak depends on the symmetry of Eu-substituted CeO2 crystal sites. For CeO2:Eu, Eu3+ ions replaced in highly symmetric Ce4+sites. In Fig. 4, for both FSP and SG synthesis techniques, the dominant red emission band of Eu3+, which is situated at around 590 nm, is due to magnetic dipole transition of 5D0 → 7F1 of inside Eu3+ ion with 4f configurations. On the contrary, the electric dipole transitions, 5D0 → 7F2 (~ 614 nm), 5D0 → 7F3 (~ 634 nm) and 5D0 → 7F4 (~ 653 nm) transitions are allowed when Eu3+ ions are in the sites without the inversion symmetry. These situations show that Eu3+ ions are actually doped into the CeO2 crystal lattice by both the FSP and the SG synthesis methods.

According to the excitation/absorption peak electrons absorb the energy at a certain specific wavelength and so energy absorbing electrons are going to excited state from ground state. This means that related material is having a band gap that can be determined by absorption or excitation wavelength. The optical band gap of both undoped and Eu3+-doped CeO2 nanoparticles synthesized by FSP and SG was found using the formula [6].

in which ‘λg’ is the maximum wavelength of the excitation spectra (See Eq. 1). The optical band gap values of for both undoped and Eu3+-doped CeO2 material excited at 354 nm, 358 nm for FSP and 362 nm, 350 nm for SG methods are found 3.50, 3.46, 3.42, 3.54, respectively. Our results are in good agreement with the study of literature [17, 42,43,44], in which they measured the approximately the same optical band gap values for un-doped and doped CeO2 nanoparticles.

Figure 5 shows decay curves of the CeO2 and CeO2:Eu3+ fabricated by both FSP and SG methods respectively. The synthesized nanoscale powders were excited with a microsecond flash lamb at 536 nm, 550 nm, 536 nm, and 548 nm, respectively. All of the composites exhibited three-exponential decays. Table 3 reveals the results of the decay time measurements of the free form and the Eu3+ doped ceria nano-powders along with the standard deviation and percentage distribution. The average decay times of 88.20 and 102.06 µs have been calculated for the sol–gel synthesized SCO and SCO:Eu3+, respectively. Similarly, the flame spray synthesized forms exhibited average decay times of 53.11 and 92.00 µs for the Eu3+-free and Eu3+-doped forms. In both cases, the presence of the Eu3+ enhanced the decay time 16 and 73% respectively which was evidenced in our previous work [45]. Decay times of the Eu3+-free sol–gel synthesized particles were longer with respect to the flame spray-synthesized ones. The observation of the three exponential decay times can be attributed to the structural properties of the host matrix (CeO2) and the formation of three different microenvironments for the Eu3+ dopant.

4 Conclusion

The undoped and Eu3+-doped CeO2 particles were successfully synthesized by flame spray pyrolysis and sol–gel methods. The cubic fluorite structure and the crystallite size between 22 and 46 nm of the obtained powders were determined using XRD. The morphology of the particles synthesized by the sol–gel method was observed to be in a wide range of sizes and shape, while the particles produced by the FSP method were determined to be below 100 nm and spherical shape. XPS analysis showed that Eu element was successfully incorporated into the structure. In this study, in comparison with the two different production techniques, luminescence results played an important role in revealing the presence of the Eu3+ in the lattice. Additionally, the Eu-doped particles exhibited longer decay time than the undoped particles and particle size did not significantly affect luminescence properties within the frame of the study.

References

M. Fernández‐García, J.A. Rodriguez, Encycl. Inorg. Bioinorg. Chem. (2011). https://doi.org/10.1002/9781119951438.eibc0331

F. Charbgoo, M. Bin Ahmad, M. Darroudi, Int. J. Nanomed. 12, 1401 (2017)

G. Wang, Q. Mu, T. Chen, Y. Wang, J. Alloys Compd. 493, 202 (2010)

S. Schmitt-Rink, C.M. Varma, A.F.J. Levi, Phys. Rev. Lett. 66, 2782 (1991)

L. Li, H.K. Yang, B.K. Moon, Z. Fu, C. Guo, J.H. Jeong, S.S. Yi, K. Jang, H.S. Lee, J. Phys. Chem. C 113, 610 (2008)

G. Vimal, K.P. Mani, P.R. Biju, C. Joseph, N.V. Unnikrishnan, M.A. Ittyachen, Appl. Nanosci. 5, 837 (2015)

Q. Yuan, H.-H. Duan, L.-L. Li, L.-D. Sun, Y.-W. Zhang, C.-H. Yan, J. Colloid Interface Sci. 335, 151 (2009)

X.-D. Wang, X.-H. Liu, S.-J. Chen, M. Li, M. Liu, Spectrosc. Spectr. Anal. 27, 2182 (2007)

T. Masui, K. Fujiwara, K. Machida, G. Adachi, T. Sakata, H. Mori, Chem. Mater. 9, 2197 (1997)

I. Yamaguchi, M. Watanabe, T. Shinagawa, M. Chigane, M. Inaba, A. Tasaka, M. Izaki, ACS Appl. Mater. Interfaces, 1, 1070 (2009)

I. Yamaguchi, M. Watanabe, T. Shinagawa, M. Chigane, M. Inaba, A. Tasaka, M. Izaki, ACS Appl. Mater. Interfaces 1, 1070 (2009)

M. Dubau, J. Lavková, I. Khalakhan, S. Haviar, V. Potin, V. Matolín, I. Matolínová, ACS Appl. Mater. Interfaces 6, 1213 (2014)

T. Masui, H. Hirai, N. Imanaka, G. Adachi, T. Sakata, H. Mori, J. Mater. Sci. Lett. 21, 489 (2002)

L. Mädler, H.K. Kammler, R. Mueller, S.E. Pratsinis, J. Aerosol Sci. 33, 369 (2002)

T. Sahm, L. Mädler, A. Gurlo, N. Barsan, S.E. Pratsinis, U. Weimar, Sensor Actuat B-Chem. 98, 148 (2004)

H.Q. Zhou, M. Wang, X. Jiang, G.J. Liu, Q. Gu, S.T. Liu, Adv. Mater. Res. 79, 597 (2009)

M. Oikawa, S. Fujihara, J. Eur. Ceram. Soc. 25, 2921 (2005)

S. Yildirim, E.C. Karsu Asal, K. Ertekin, E. Celik, J. Lumin. 187, 304 (2017)

E. Longo, M. Ramirez, L.S.R. Rocha, A.Z. Simões, J. Cortés, R. Deus, M.A. Ponce, J. Andres, Mater. Res. Bull. 70, 416 (2015)

Z.-L. Wang, G.-R. Li, Y.-N. Ou, Z.-P. Feng, D.-L. Qu, Y.-X. Tong, J. Phys. Chem. C 115, 351 (2011)

A.A. Ansari, J. Semicond. 31, 053001 (2010)

I.V. Zagaynov, S.V. Kutsev, Appl. Nanosci. 4, 339 (2014)

S. Fujihara, M. Oikawa, J. Appl. Phys. 95, 8002 (2004)

Mİ. Katı, O. Yılmaz, S. Gültekin, E. Çelik, S. Yıldırım, İ.Ç. Keskin, J. Lumin. 206, 59 (2018)

L. Li, H.K. Yang, B.K. Moon, Z. Fu, C. Guo, J.H. Jeong, S.S. Yi, K. Jang, H.S. Lee, J. Phys. Chem. C 113, 610 (2009)

J.F. Moulder, in Handbook of X-ray Photoelectron Spectroscopy: A Reference Book of Standard Spectra for Identification and Interpretation of XPS Data, ed. by J. Chastain, R.C. King Jr (Physical Electronics, Eden Prairie, MN, 1995)

K. Kuntaiah, P. Sudarsanam, B.M. Reddy, A. Vinu, RSC Adv. 3, 7953 (2013)

A. Kumar, S. Babu, A.S. Karakoti, A. Schulte, S. Seal, Langmuir 25, 10998 (2009)

G.B. Della Mea, L.P. Matte, A.S. Thill, F.O. Lobato, E.V. Benvenutti, L.T. Arenas, A. Jürgensen, R. Hergenröder, F. Poletto, F. Bernardi, Appl. Surf. Sci. 422, 1102 (2017)

J.M. López, A.L. Gilbank, T. García, B. Solsona, S. Agouram, L. Torrente-Murciano, Appl. Catal. B 174–175, 403 (2015)

C. Barth, C. Laffon, R. Olbrich, A. Ranguis, P. Parent, M. Reichling, Sci. Rep. 6, 2 (2016)

T. Naganuma, E. Traversa, Biomaterials 35, 4441 (2014)

S. Babu, A. Schulte, S. Seal, Appl. Phys. Lett. 92, 1 (2008)

S. Deshpande, S. Patil, S.V. Kuchibhatla, S. Seal, Appl. Phys. Lett. 87, 1 (2005)

T. Hasegawa, S.M.F. Shahed, Y. Sainoo, A. Beniya, N. Isomura, Y. Watanabe, T. Komeda, J. Chem. Phys. 140, 044711 (2014)

M.A. Henderson, C.L. Perkins, M.H. Engelhard, S. Thevuthasan, C.H.F. Peden, Surf. Sci. 526, 1 (2003)

C.D. Wagner, D.A. Zatko, R.H. Raymond, Anal. Chem. 52, 1445 (1980)

M. Melchionna, P. Fornasiero, Mater. Today 17, 349 (2014)

H. Guo, Y. Qiao, Appl. Surf. Sci. 254, 1961 (2008)

K.Y. Jung, J.C. Lee, D.S. Kim, B.K. Choi, W.J. Kang, J. Lumin. 192, 1313 (2017)

M. Maheshwary, S. Singh, B.P. Singh, P. Singh, R.A. Singh, S.B. Rai, S. Singh, V.K. Sonu, P.V. Ramakrishna, A. Bahadur, RSC Adv. 5, 55977 (2015)

Z.C. Orel, B. Orel, Phys. Status Solidi 186, K33 (1994)

S. Demirci, B. Öztürk, S. Yildirim, F. Bakal, M. Erol, O. Sancakoğlu, R. Yigit, E. Celik, T. Batar, Mater. Sci. Semicond. Process. 34, 154 (2015)

A.V. Emeline, G.N. Kuzmin, D. Purevdorj, V.K. Ryabchuk, N. Serpone, J. Phys. Chem. B 104, 2989 (2000)

S. Yildirim, S. Demirci, K. Ertekin, E. Celik, Z.A. Alicikus, J. Adv. Ceram. 6, 33 (2017)

Acknowledgements

Synthesis and characterization measurements performed at Dokuz Eylul University, Center for Fabrication and Applications of Electronic Materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yildirim, S., Akalin, S.A., Oguzlar, S. et al. Comparison of structural and optical properties of CeO2 and CeO2:Eu3+ nanoparticles synthesized via sol–gel and flame spray pyrolysis methods. J Mater Sci: Mater Electron 30, 13749–13756 (2019). https://doi.org/10.1007/s10854-019-01757-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01757-4