Abstract

The 5-nitro-2-furaldehyde diacetate (NFD) single crystals were grown by slow evaporation solution growth technique. By single crystal XRD analysis it was found that, NFD single crystal belongs to monoclinic crystal system. Powder XRD spectrum revealed the crystallinity of the sample. Fourier transform infrared red spectral analysis gave idea regarding the vibrations of functional groups. The transparency of the crystal in the visible region is clearly depicted in the UV–Vis spectrum. Thermo gravimetric/differential scanning calorimetric analysis showed the thermal stability and Vicker’s microhardness test showed the mechanical stability of the crystal. From the scanning electron microscopic images, the crystal morphology was analysed. By Kurtz–Perry powder technique, the second harmonic generation efficiency of the NFD crystal is obtained as 15 times greater than that of standard potassium dihydrogen phosphate (KDP) and the laser damage threshold value of the crystal is 4.2 GW/cm2, which implies that the sample has got better laser damage withstanding capacity. The studies revealed that, the title compound is a potential candidate for opto-electronic applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Organic nonlinear optical materials with larger optical susceptibility, capability to withstand laser damage, ultrafast response etc., captured constant attention of the researchers because of their wide range of application in electro-optic modulation, optical switching, optical parametric oscillation, high speed information processing and optical data storage [1,2,3,4]. Scientists have been working in this area for the last few decades, in search of photonic materials with notable nonlinear response. In addition to this, wider transparency range, higher laser damage threshold, lower absorption cutoff etc. are some other requirements for better NLO response. The presence of extended \(\pi \) bond system attached to the aromatic groups with strong donor and acceptor groups causes delocalization of electrons [5]. The modern world urges highly capable gadgets. The NLO materials with enhanced second harmonic generation (SHG) efficiency is an inevitable component of such devices. Hence the demand for the synthesis and growth of new potential NLO materials is increasing day by day.

It was reported that certain aromatic heterocyclic compounds with delocalized π electrons are exhibiting good second order nonlinearity [5,6,7,8]. In the present work, single crystals of an aromatic heterocyclic organic compound 5-nitro-2-furaldehyde diacetate (NFD) were grown by conventional method with ethanol as the solvent. For the better understanding of the structure and properties of the crystal single crystal XRD, powder XRD, UV–Vis, FTIR, thermal analysis, microhardness, SEM, laser damage threshold and SHG efficiency were studied and discussed.

2 Materials and methods

2.1 Crystal growth

The powder NFD (AR grade) was dissolved in ethanol to grow NFD single crystals and stirred continuously for 4 h at room temperature to ensure homogeneity of the solution. In order to remove impurities the solution was filtered using Whatmann filter paper and transferred to a crystal growth vessel allowing the crystal to grow by slow evaporation, at room temperature. The mouth of the vessel was covered with porous polythene sheet, for controlling the rate of evaporation. Optically good quality NFD crystals (4 × 2 × 2 mm) were formed within two weeks by slow evaporation solution growth technique (Fig. 1).

2.2 Characterisation techniques

Single crystal XRD analysis was done using Bruker Kappa Apex II diffractometer and the powder crystal XRD using BRUKER AXS-D 8 advance X-ray diffractometer (wavelength = 1.54 Å) with copper target. The Varian, Carry 5000 spectrometer enabled the UV–Vis spectral analysis in the range 200–1000 nm. Perkin Elmer, Diamond TG/DTA analyzer was used for the thermal analysis. The FTIR spectral analysis was carried out with the help of Thermo Nicolet, Avatar 370. JEOL Model JSM-6390LV was the instrument used to record SEM images. In order to do the hardness studies, CLEMEX Microhardness Tester was made use of.

3 Results and discussion

3.1 Single crystal XRD

The crystal structure and lattice parameters of the sample were confirmed with the help of single crystal X-ray diffraction. They are in good agreement with the reported values [9]. Figure 2 represents the molecular structure of NFD. The data obtained from the analysis are shown in Table 1.

3.2 Powder XRD

The powder XRD pattern of the NFD crystals is depicted in the Fig. 3. The razor sharp and well designated peaks at certain \(2\theta \) values, that are distinctive property of the XRD spectrum, reveal the crystalline nature of the sample.

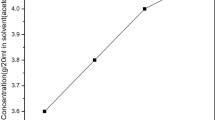

Using Hall-Williamson relation, \(\beta cos\theta =\frac{{K\lambda }}{\tau }+~\eta sin\theta \) (where \(\beta \) is the full width of the half maximum, \(\theta \) is the Bragg diffraction angle, \(~K\) is the Scherrer constant, \(~\lambda \) is the X-ray wavelength and \(\tau \) is the crystal size), the strain developed in the crystal lattice can be calculated from the graph drawn between sinθ and βcosθ (Fig. 4). The value of strain implies the kind of point defect in the crystal.

The strain is found to be 4.70511 which is a positive value. The larger positive value of strain indicates the presence of interstitial type of defect in the NFD crystal. Due to this kind of defect, the lattice around the defect core contracts and hence strain is developed in the crystal lattice [10, 11]. From the Scherrer’s formula, particle size = Kλ/βcosθ where λ is the X-ray wavelength, grain size is calculated as 38.12 nm.

3.3 UV–Vis–NIR spectroscopy

UV–Vis spectrum is capable of giving ideas regarding the nonlinear response of the crystals. Here NFD crystals do have a wider transparency region from 350 to 800 nm (Fig. 5) that includes the whole visible region. This shows that the material can be made use in the optoelectronic device fabrication and second harmonic generation. The optical band gap energy of the crystal can be calculated from UV–Vis spectrum, by using the equation \({E_g}=hC/{\lambda _{max}}\) where h is the Planck’s constant, C is the velocity of light and \({\lambda _{max}}\) is the wavelength corresponding to the maximum absorption. The calculated value of \({E_g}\) is 4.37 eV for the NFD crystals.

3.4 FTIR spectrum

The FTIR spectrum (Fig. 6) obtained is compared with that of the reported standard spectra of functional groups [12]. The Table 2 shows the tentative assignments corresponding to different wave numbers.

3.5 Thermal analysis

The Fig. 7 illustrates the TGA and DSC curves of the NFD crystals. Up to 180 °C the material is found to be thermally stable and also lacks phase transition. The large weight loss between 180 and 280 °C in the TGA curve indicates the decomposition of the sample. The endothermic peak in the DSC curve at 278.64 °C corresponds to the melting point of the crystal. The sharpness of the peak denotes the good crystalline nature of NFD [13]. The endothermic peak in the DSC curve coincides with the fall in the TGA curve at 250 °C which shows that, the sample melts while decomposing.

3.6 Microhardness studies

A well polished surface of the NFD single crystal is selected for the indentation. The microhardness test is carried out using Vicker’s microhardness tester with diamond pyramidal indenter at room temperature with an indentation time 10 s for loads 10, 25, 50,100 and 150 g. When a load of 100 g was applied, microcracks appeared on the surface of the crystal due to the mechanical stress developed in it (Fig. 8) [14].

Vicker’s hardness number \({H_v}=1.854P/{d^2}\;{\text{kg}}/{\text{m}}{{\text{m}}^2}\) is a kind of hardness measure, where P is the applied load in gram and d is the diagonal length of indentation in mm [15]. From Fig. 9 it is evident that, the VHN value increases with load. This verdict is in agreement with the reverse indentation size effect(ISE) [16].

Figure 10 represents the Mayer’s plot, from which the work hardening coefficient or Mayer’s index ‘n’ is calculated by finding the slope of the graph. It has got a value 2.48.

Onistch [17] and Haneman proposed that, if \(1<n<1.6\) the materials are moderately hard and if \(n>1.6\) the materials are soft. So the NFD crystals belong to softer material category.

3.7 SEM

The Fig. 11 shows the SEM images of the NFD crystals that has smoother morphology. Distinct grain boundaries and some valleys are visible in the images.

3.8 SHG studies

SHG efficiency of the NFD crystal was analysed by Kurtz and Perry powder technique [18]. It has an SHG output 15 times greater than that of standard KDP. Nonlinear response of a sample depends up on its structural properties. If the charge transfer across the NLO chromosphere of a material is larger, larger will be the SHG output [19]. The electrostatic and directed nature of H-bonds also can improve the SHG efficiency of a material [20, 21]. The polarizability of π electrons is another factor that can affect nonlinearity. Here the larger SHG output of NFD is due to the presence of delocalized π electrons and intermolecular H-bonding.

3.9 Structure–property relationship

NFD consists of a furan ring which is a heterocyclic organic compound with five membered aromatic ring of four carbon atoms and one oxygen atom. It also contains two acetoxy groups. NO2 attached to the furan ring acts as electron acceptor group and CH3 in the acetoxy group acts as an electron donor. Delocalisation of π electrons between the donor and acceptor occurs through the heterocyclic ring furan similarly as in benzene ring and this delocalization causes the optical nonlinearity of the molecule [5, 22, 23].

3.10 Laser damage threshold

It is very important to understand the laser damage withstanding capacity of an NLO material, since the nonlinear optics always deals with the interaction of intense light with matter. A continuous pulse of Nd:YAG laser (1064 nm) with pulse width 20 ns was allowed to fall on one of the smoother surfaces of the NFD crystal of thickness 4 mm. Above 350 mJ, the crystal surface got damaged. That energy was noted and the surface power density was calculated using the relation,

E is the input energy density in mJ, \(\tau \) is the pulse width in ns and r is the radius of the circular spot on the crystal in mm [24,25,26]. The laser damage threshold value thus obtained is 4.2 GW/cm2.

4 Conclusion

Good quality NFD single crystals grown by slow evaporation solution growth technique have excellent crystalline nature, broader transparency range and belong to softer material category with hardness coefficient 2.48. The presence of different functional groups in the sample were confirmed by the FTIR studies. The thermal analysis proves that, the sample is stable up to 220 °C, and it melts at 278.64 °C. The SEM images show the smoother morphology of the crystal. Second harmonic generation efficiency of the sample is found to be 15 times higher than that of standard KDP and it has the capacity to withstand laser damages with an LDT value 4.2 GW/cm2. The studies revealed that, the title compound is a potential candidate for opto-electronic applications.

References

V.G. Dmitriev, G.G. Gurzadyan, D.N. Nicogosyan, Handbook of Nonlinear Optical Crystals (Springer, New York, 1999)

M.S. Wong, C. Bosshard, F. Pan, P. Gunter, Non-classical donor–acceptor chromophores for second order nonlinear optics. Adv. Mater. 8(8), 677 (1996)

E. Ishow, C. Bellaı¨che, L. Bouteiller, K. Nakatani, J.A. Delaire, Versatile synthesis of small NLO-active molecules forming amorphous materials with spontaneous second-order NLO response. J. Am. Chem. Soc. 125(51), 15744 (2003)

D. Wang, T. Li, S. Wang, J. Wang, Z.Wang,Jianxu Ding, W. Li, C. Shen, G. Liu, P. Huang, Effect of Fe3+ on third-order optical nonlinearity of KDP single crystals. CrystEngComm 18, 9292 (2016)

S.R. Prabhu, A. Jayarama, V. Upadhyaya, K.S. Bhat, S.W. Ng, Structure and characterization of a novel chalcone crystal having nitro as an acceptor group. Mol. Cryst. Liq. Cryst. 607, 200 (2015)

H.S. Shubhalaxmi, C.A. Zschille, A. Jayarama, K.S. Bhat, Chem. Sci. Trans. 2.3, 829 (2013)

H.S. Nalwa, S. Miyata, Nonlinear Optics of Organic Molecules and Polymers (CRC Press, Boca Raton, 1997)

S. Manivannan, S. Dhanuskodi, ‘Synthesis, crystal growth, structural and optical properties of an organic NLO material’. J. Cryst. Growth 262, 1–4 (2004) 473

A.F. Mishnev, K.K. Venters, Molecular and crystalline structure of furfural diacetate nitration intermediate. Tetrahedron 36(12), 1817 (1980)

B. Riscob, R. Bhatt, N. Vijayan, I. Bhaumik, S. Ganesamoorthy, M.A. Wahab, G. Rashmi, Bhagavannarayana, Structural, optical and thermal properties of Zr–Fe co-doped congruent LiNbO3 single crystals. J. Appl. Cryst. 46, 601 (2013)

S.K. Kushwaha, K.K. Maurya, N. Vijayan, B. Kumar, R. Bhatt, S. Ganesamoorthy, G. Bhagavannarayana, Crystalline perfection, Raman, UV-VIS-NIR and prism coupler investigations on Cz-grown pure and Zn-doped LiNbO3 single crystals. CrystEngComm 14, 3297 (2012)

G. Socrates, Infrared Characteristic Group Frequencies (Wiley, Chichester, 1980)

A. Stanculescu, F. Stanculescu, H. Alexandru, Melt growth and characterization of pure and doped meta-dinitrobenzene crystals. J. Cryst. Growth 198, 572 (1999)

K. Naseema, V. Rao, K.V. Sujith, B. Kalluraya, Crystal growth and characterization of an NLO organic crystal: N’-[(Z)-(4-methylphenyl)methylidene]-4-nitrobenzohydrazide. Curr. Appl. Phys. 10, 1236–1241 (2010)

K. Sangwal, M. Hordyjewicz, B. Surowaska, J. Opt. Adv.Mater. 4, 875 (2002)

A.R. Mariadassa, S.S. John Xavier, P.A. Devarajana, Crystal growth and characterizations of an efficient semiorganic nonlinear optical (Nlo) single crystal: 2-amino 5-nitropyridinium chloride (2a5npcl) by assembled temperature reduction apparatus (Atr) method. Mater. Res. Innov. 0, 1–6 (2017)

E.M. Onitsch, Bulk growth and characterization of d-(–)-alanine single crystals. Mikroskopie 95(15), 12 (1956)

S.K. Kurtz, T.T. Perry, A powder technique for the evaluation of nonlinear optical materials. J. Appl. Phys. 39, 3798 (1968)

S.A. Martin Britto Dhas, G. Bhagavannarayana, S. Natarajan, Growth and characterization of a new potential NLO material from the amino acid family—L-prolinium picrate. J. Cryst. Growth 310, 3535 (2008)

J.L. Oudar, Optical nonlinearities of conjugated molecules. Stilbene derivatives and highly polar aromatic compounds. J. Chem. Phys. 67, 446 (1977)

J.L. Oudar, Relations between microscopic and macroscopic lowest-order optical nonlinearities of molecular crystals with one- or two-dimensional units. J. Zyss Phys. Rev. A 26, 2028 (1982)

M.I. Baig, M. Anis, G.G. Muley, ‘Influence of tartaric acid on linear-nonlinear optical and electrical properties of KH2PO4 crystal’. Opt. Mater. 72, 1 (2017)

S. Shashidhar Bharadwaj, B. Poojary, S. Madan Kumar, K. Byrappa, Synthesis, characterization, thermal analysis, crystal structure and Hirshfeld surface analysis of 2-(3, 5-difluorophenyl)quinoline-4- carboxylic acid. Chem Data Collections 9–10, 134 (2017)

R. Krishnamurthy, R. Rajasekaran, B.S. Samuel, Growth and characterization of KDP crystals doped with l-aspartic acid. Spectrochim. Acta A 104, 310 (2013)

N. Rani, N. Vijayan, B. Riscob, S.K. Jat, A. Krishna, S. Dhas, G. Bhagvannarayana, B. Rathi, M.A. Wahab, Single crystal growth of ninhydrin by unidirectional Sankaranarayanan–Ramasamy (SR) method by using a glass ampoule for nonlinear optical applications. CrystEngComm 15, 2127 (2013)

S.A.M.B. Dhas, G. Bhagavannarayana, S. Natarajan, Growth, HRXRD, microhardness and dielectric studies on the NLO material L-alaninium maleate. Open Crystallogr. J. 1, 42 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naseema, K., Athira, K.M., Sujith, K.V. et al. Growth and characterisation of 5-nitro-2-furaldehyde diacetate single crystals. J Mater Sci: Mater Electron 29, 16074–16079 (2018). https://doi.org/10.1007/s10854-018-9696-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9696-6