Abstract

The effects of oxidation/nitridation for 15 min at different temperatures (300–800 °C) on metal–oxide–semiconductor characteristics of sputtered Zr thin film based on Ge substrate in N2O ambient have been systematically investigated. The crystallinity of the film were evaluated by X-ray diffraction analysis, Raman analysis, and X-ray photoelectron spectrometer. The crystallite size and microstrain of film were estimated by Williamson–Hall plot analysis. Optical microscope was used to examine samples surface condition and high-resolution transmission electron microscopy was carried out to investigate the cross-sectional morphology. GeO2 was detected in samples with oxidation/nitridation temperature above 700 °C. A possible mechanism of Ge atomic diffusion and its rearrangement in ZrO2 has been proposed and explicated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

SiO2/Si material structure has dominated the semiconductor industries for complementary metal oxide (CMOS) process for decades. The reason being SiO2 has excellent insulating properties and low interface trap level density around the order of approximately 1010 cm−2 eV−1 with Si surface [1,2,3,4]. To improve device performance, the geometry of device has been shrank continuously for past few decades. Besides dimensions shrinkage, alternative material structures were also studied intensively [5, 6]. The paragraph below will give an in-depth explanation.

Looking at current Si substrate, to improve device performance, besides shrinking the channel length, another option is changing the material which has higher mobility than silicon. Comparing both essential devices which comprise p-MOSFET and n-MOSFET, the mobility of majority carrier of p-MOSFET is lower than its majority carrier of n-MOSFET. Hence, it is more essential to improve from p-MOSFET aspect [7]. Ge was selected in this study because it has the highest hole mobility in all of the known semiconductor materials [8]. The hole mobility of Ge is 1900 cm2 eV−1 s−1, more than 4 times compared with Si [9].

As newer-generation chip dimensions are shrinking, gate oxide thickness is reducing. However, SiO2 encounters physical limitation with tunneling effect when thickness is down to 1.2 nm [10]. Therefore, alternative high κ materials were widely study as SiO2 replacement, such as HfO2, ZrO2 [11], Sm2O3 [12], Nd2O3 [13], TiO2 [14], Ta2O5 [15], Al2O3 [16], Y2O3 [17], and other. In this study, ZrO2 have been selected for its high κ value, large-energy bandgap, and its stability in the form of cubic or tetragonal polymorphs [18]. Another benefit is the interfacial layer (IL) free between ZrO2 gate dielectric and Ge wafer during thermal treatment [9] which will prevent electrical breakdown prematurely [19]. The phenomenon of IL free may due to the Ge diffusion into ZrO2 dielectric [9]. The details of the behavior still remains an open question. A possible mechanism of Ge atomic diffusion and its rearrangement in ZrO2 has been proposed and explicated in this paper.

Compared with the counterpart Si, Ge is considerably unstable at high-temperature process. As studied previously [20], it is observed that Zr/Ge was unstable at oxidation temperature above 600 °C at O2 ambient. On the other hand, NO and N2O are common gases used for oxidation and nitridation process in semiconductor industries [21]. N2O is the preferred gas because it is less toxic as compared with NO [22]. Another reason for NO was not selected in this study because of its activation energies are lower than O2. This study will focus on changing to N2O ambient conditions where activation energies are higher than O2 [23] and study the stability under different temperature.

2 Experimental procedures

To prepare impurity-free samples, germanium wafer [n-type, (100)-oriented, 0.01–0.05 Ω cm, 1 cm × 1 cm] were dipped cleaned by hydrofluoric acid (HF) solution (1:50 HF:H2O) and DI water. By using TF 450 physical vapor deposition (PVD) radio frequency (RF) sputtering system, metallic zirconium (Zr) film was sputtered from a Zr target (Kurt J. Lesker, USA, 99.999% purity) at room temperature. Pressure, RF power, and argon gas flow rate were set at 3 × 10−5 mbar, 170 W, and 25 cm3 min−1, respectively. Experimental oxidation/nitridation temperatures were set at 300, 400, 500, 600, 700, and 800 °C using Carbolite CTF tube furnace. Samples of sputtered Zr on Ge wafer were placed into the tube furnace with N2O flow rate of 150 mL min−1 at each experimental temperature for 15 min. The oxidized/nitrided samples were cooled down in the tube furnace before removal.

The properties of the samples were characterized by various measurement methods which are as follows: film crystallinity was characterized using a PANalytical Empyrean X-ray diffractometer (XRD) system in the 2\(\theta\) scan range from 10° to 80°. Copper radiation (Cu Kα) with wavelength (λ) of 0.15406 nm was used as X-ray source. The chemical compositions of the films were analyzed by X-ray photoelectron spectrometer (XPS) on AXIS ULTRA DLD (Al-Ka radiation). The X-ray tube was operated at 80 W. The analyzed area had a diameter of 300 µm. During XPS measurements, the pressure in UHV chamber was about 3 × 10− 9 Torr. Survey scan was measured at 160 eV (energy resolution 1 eV per step) pass energy, this was for elemental analysis. Narrow scan (with high resolution) was measured at 20 eV (energy resolution 0.1 eV per step) pass energy, and it was for chemical states analysis. All data were recorded at a 45° take-off angle. To study geometry structure, film samples were sent for deposition of platinum (Pt) on the surface for protection from ion bombardment damage caused by the focused ion beam during lamella preparation. Followed by cross-sectioning using TECNAI G2 F20 high-resolution transmission electron microscope (HRTEM), the interplanar spacing (d) of the polycrystalline structure was measured from HRTEM images using ImageJ software. Olympus BX61 optical microscope were used to examine samples surface and the picture capture by Color view (soft imaging system).

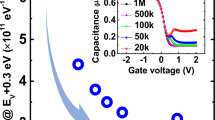

To study the electrical properties of the films, MOS capacitor test structures with area of 300 µm × 300 µm were fabricated. Aluminum (Al 99.9995% purity, 100 nm; Kurt J. Lesker, USA) was sputtered through a mask using a TF 450 PVD RF sputtering system. The back side of the Ge was also sputtered with 100-nm-thick Al film to form an Ohmic back contact. BPW-800 8″ probe station with a Keithley 4200 semiconductor characterization system (SCS) were used to measure current–voltage (I–V).

3 Results and discussion

3.1 J–E and J–V characteristics

The J–E and J–V characteristics were used to study the effects of oxidation/nitridation temperature on the electrical properties of the samples. Figure 1 shows the J–E and J–V characteristics of samples oxidized/nitridation at various temperatures. For samples of 300, 400, 500, and 600 °C, the thickness of the dielectric will be discussed in Sect. 3.6, the J–E curve using left axis and bottom axis at which the arrows pointing indicates. In the results, all the samples shows typical J–E curve. The electrical breakdown fields were 6.0, 6.9, 5.7, and 5.7 MV cm−1, respectively. Electrical characterization revealed that 400 °C samples yielded the highest electrical breakdown fields. For samples of 700 and 800 °C, due to lack of values of dielectric thickness, the J–V curve were shown in Fig. 1. The J–V curve using right axis and top axis at which the arrows pointing indicates. The 700 °C samples shows an almost short circuit in the J–V curve, and the 800 °C samples shows an almost open circuit in J–V curve measurement results. For further study, a physical analysis will be performed in next section.

3.2 Optical microscope analysis

Optical microscope was used to examine samples surface condition at various temperatures as shown in Fig. 2. Figure 2a shows the 300–600 °C samples, the surfaces were found to be smooth and free from defects. Figure 2b shows the 700 °C samples with scattered blisters. Figure 2c shows the 800 °C samples. For indication of surface roughness, another lower magnification for sample 800 °C is shown in Fig. 2d.

Comparing 600 °C samples between N2O ambient and O2 ambient, the N2O ambient samples were smooth and defect-free. This might be because the activation energies of N2O is higher than O2. For the 700 °C samples, the surface was similar for both N2O and O2 ambient. This could be results of similar reaction where N2O or O2 atoms diffused through the ZrO2 layer, forming GeO2 under N2O or O2 ambient. For 800 °C, Rough surface with uneven thick films on the sample were observed. There have been lack of literatures on the liquid state of Ge3N4. It has been reported that the Ge3N4 will decompose around 700–900 °C [24, 25]. In this study, based on the on the J–V result and the OM analysis, it is assumed that some form of liquidation occurred during oxidized/nitridation at 800 °C and trapping GeO2 in a form of solid powder on sample surface. These mixtures of liquid and powder further solidified on sample surface after cooling to room temperature. It was not observed at O2 ambient. Hence, Ge3N4 was the possible material based on this assumption. Thus, explaining the difference between J–V curve results where short circuits were observed for samples under O2 ambient, and open circuits were observed for samples under N2O ambient, all under 800 °C.

3.3 Raman spectroscopy analysis

Figure 3 shows the Raman analysis of oxidized/nitridation samples at various temperatures. The background noise for 700 and 800 °C samples were observed to be higher than the other samples during measurement. As a result, an extra Y-axis was added in Fig. 3 right hand sites. The peak that belonged to Ge was detected at 300 cm−1 for all samples. The peak that belonged to monoclinic ZrO2 was detected at 181 and 346 cm−1 [26,27,28]. The peaks that belonged to tetragonal ZrO2 were detected at 404 and 460 cm−1 [29]. The peak that belonged to Orthorhombic ZrO2 was detected at 415 cm−1 [30]. The peaks that belonged to cubic ZrO2 were detected at 454 cm−1 [29]. The peak that belonged to GeO2 were detected at 167 cm−1 for 700 and 800 °C samples. The numbers of GeO2 peak increased as the oxidation/nitridation temperature increased. Extra GeO2 peaks found in 800 °C samples were 263, 444, and 515 cm−1 [31, 32]. Ge3N4 peaks were detected at 202 and 455 cm−1 for 800 °C samples [33, 34]. These results were in conformity with the J–V characteristics where GeO2 was detected for the samples oxidized/nitridation above 700 °C and Ge3N4 was detected in 800 °C samples.

3.4 XRD analysis

Figure 4 shows XRD patterns of samples oxidized/nitridation at various temperatures, from 49° to 56°. Several structures of ZrO2 were detected. The orthorhombic ZrO2 was found at around 51.21°, 52.71°, and 52.87°, corresponding to (151), (020), and (142) planes, respectively. These peaks are matched by ICSD with reference code 98-017-3960 and 98-005-6696. The tetragonal ZrO2 was found at around 51.91° and 52.04° corresponding to (112) and (020) planes, respectively. These peaks are matched by ICSD with reference code 98-009-2092. The cubic ZrO2 was found at around 51.32° corresponding to (022) planes. This peak is matched by ICSD with reference code 98-018-5123. The monoclinic ZrO2 was found at around 51.03° corresponding to \({\text{(12}}\overline {\text{2}} {\text{)}}\) planes. This peak is matched by ICSD with reference code 98-065-9226. On the other hand, the hexagonal O0.27Zr was found at around 51.41° corresponding to (026) planes. This peak is matched by ICSD with reference code 98-004-2986. The tetragonal GeO8Zr3 was found at around 51.61° corresponding to (220) planes. This peak is matched by ICSD with reference code 98-002-9263. The tetragonal Ge4Zr5 was found at around 51.78°, corresponding to (117) planes. This peak is matched by ICSD with reference code 98-063-8154.

Figure 5 shows XRD patterns of samples oxidized/nitridation at various temperatures, from 10° to 80°. The peaks of hexagonal GeO2, h-GeO2 that were found in the 700 and 800 °C samples were around 20.55°, 25.94°, 35.99°, 38.02°, 39.47°, 41.80°, 44.90°, 48.27°, 48.66°, 53.35°, 56.31°, 58.84°, 61.65°, 66.04°, 67.03°, 73.81°, 76.32°, 77.27°, and 78.50° corresponding to (010), (011), (110), (102), (111), (020), (021), (003), (112), (202), (210), (211), (113), (122), (031), (302), (220), (213), and (221) planes, respectively. These peaks are matched by ICSD with reference code 98-001-6577. The peaks of orthorhombic Ge3N4, o-Ge3N4 that were found in the 700 and 800 °C samples were around 20.30°, 23.84°, 25.34°, 35.27°, 41.27°, 41.39°, 58.79°, 65.54°, 65.99°, 66.93°, 70.70°, and 73.89° corresponding to (101), (011), (111), (311), (202), (112), (430), (701), (313), (123), (413), and (721) planes, respectively. These peaks are matched by ICSD with reference code 98-015-6339. The GeO2 and Ge3N4 were observed for sample 700 and 800 °C. It could be contributed to the diffusion of N2O through ZrO2 layer, which reacted with Ge and formed crystallization of GeO2 and Ge3N4. These results were in conformity with the J-V characteristics, Raman spectroscopy analysis and OM analysis.

Williamson–Hall (W–H) plot analysis is used for evaluating the crystallite size (D) and microstrain (ɛ) [35,36,37]. The W–H as Eq. (1):

where λ is the wavelength of the radiation; K is a constant, which is equal to 0.9; \(\theta\) is the peak position; βD is the peak width at half-maximum intensity; and βS is the peak width at half-maximum intensity. Based on Eq. (1), one plots a graph of (βD + βS) cos\({\text{~}}\theta\) versus 4 sin \(\theta\). Microstrain is the gradient, whereas \(K\lambda\)/D is the intercept of the graph, from which D can be calculated as Eq. (2):

Crystallite sizes of ZrO2, O0.27Zr, Ge4Zr5, and GeO8Zr3 were not calculated by using W–H plot because the number of peaks was insufficient for study purposes. Figure 6 shows the W–H plot of h-GeO2 and O-Ge3N4 for 700 °C and 800 °C samples. According to Fig. 6, the points were well distributed in the four groups.

The crystallite size of h-GeO2 (type 1) of 700 and 800 °C samples were 26.15 and 26.21 nm, respectively. The microstrain of h-GeO2 (type 1) of the 700 and 800 °C samples were − 0.0036 and − 0.0034, respectively. The crystallite size of h-GeO2 (type 2) of the 700 and 800 °C samples were 19.30 and 20.02 nm, respectively. The microstrain of h-GeO2 (type 2) of the 700 and 800 °C samples were − 0.0089 and − 0.0076, respectively. These results were similar with the O2 ambient.

The crystallite size of O-Ge3N4 for sample of 700 °C was not calculated by using W–H plot because the number of peaks was insufficient for study purposes. The crystallite size of O-Ge3N4 (type 1) of the 800 °C samples were 17.55 nm. The microstrain of O-Ge3N4 (type 1) of the 800 °C samples were − 0.0048. The crystallite size of O-Ge3N4 (type 2) of the 800 °C samples were 13.29 nm. The microstrain of O-Ge3N4 (type 2) of the 800 °C samples was − 0.012.

Two type of GeO2 and Ge3N4 crystallite size and microstrain were found indicates that two generating sources for GeO2 and Ge3N4. This inference will be verified and discussed in a later section.

3.5 Thermal oxidation/nitridation mechanism

Figure 7a shows the schematic diagram of sputtered Zr film on Ge wafer before thermal oxidation. For the 300, 400, 500, and 600 °C samples, the N2O directly reacted with the Zr film which was deposit by sputtering according to Eqs. (3) and (4) [38] and formed the ZrO2 dielectric as shown in Fig. 7b.

For the 700 and 800 °C samples, the samples thermally oxidized/nitridation according to the 3-step reactions, as shown in Fig. 7c. In high-temperature ambient, the N2O received enough energy to diffuse through ZrO2 dielectric layer and reacted with the Ge wafer. GeO2 film formed on the surface of Ge wafer was assumed as equation Eqs. (5) and (6). After the GeO2 formed, GeO2 will react with Ge wafer, and GeO gas was generated according to Eq. (7) [9, 39]. The GeO gas diffused outward and reacted with N2O in atmosphere. After that, another GeO2 film was formed on the ZrO2 assumed to be according to Eq. (8).

Because the Ge3N4 was found at Raman and XRD measurements, the reactive equation were assumes to be Eqs. (9) and (10).

From the analysis of the two layers of GeO2 and the two layers of Ge3N4, which are similar with the O2 ambient, the absolute value of microstrain for the top layer will be less than the bottom layer. Therefore, h-GeO2 (type 1) and O-Ge3N4 (type 1) at Fig. 6 were assumed to be the top layers, and the h-GeO2 (type 2) and O-Ge3N4 (type 2) as the bottom layers.

3.6 HRTEM analysis

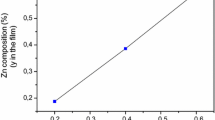

HRTEM analysis was performed to study the cross-section of the samples. Figure 8 shows the cross-section of the HRTEM images of the 400 and 500 °C samples. The thicknesses of ZrO2 dielectric for the 400 and 500 °C samples were 5.6 and 6.8 nm, respectively. Assuming the thicknesses are in linear relationship with oxidation temperatures [40], by using 400 and 500 °C thicknesses, a regression line was shown at Fig. 9. Therefore, the thicknesses of the oxidized Zr thin films were approximately ranging from 4.4 to 8 nm from the 300 to 600 °C samples. The thicknesses for 700 and 800 °C will not be analyzed here because the film conditions were not appropriate for analysis. The ZrO2 dielectric layer exhibits mainly an amorphous state with partial crystallized structure, and no IL was found between Ge wafer and ZrO2 dielectric layer. The phenomenon of IL free will be discussed at Sect. 3.8.

3.7 XPS analysis

XPS analysis was performed for the evaluations of the structural and chemical properties of the ZrO2 dielectric. Core-level spectra of Zr 3d, Zr 3p, Zr 3s, Ge 3d, Ge 3p, Ge 3s, C 1s, N 1s, and O 1s were detected in the XPS wide scans. Narrow scans on Zr 3d, Ge 3p, and O 1s were also performed as a function of etching time for different oxidation/nitridation temperatures (300–600 °C) as shown in Figs. 10, 11, 12 and 13. Each spectrum was calibrated in respect to the carbon 1s (284.8 eV) state [41].

Figure 10 shows the narrow scan of Zr 3d for samples oxidized/nitridation at various temperatures from 300 to 600 °C. The positions of the peaks that belonged to Zr 3d5/2 were around 182.37–183.25 eV. The positions of peaks that belonged to Zr 3d3/2 were around 184.68–185.55 eV [42,43,44,45]. The peak positions of Zr 3d at the ZrO2 surface were obviously lower than the inside for all samples. The detail mechanism will be discussed later. The peaks that belonged to Ge 3 s were observed for all samples. The peaks’ height increased as etch time increases. As observed, after being etched around 840 s, the peaks that belonged to Zr 3d disappeared and left only Ge 3s peaks.

Figure 11 shows the narrow scan of Ge 3p. The peaks that belonged to GeOX of Ge 3p1/2 and Ge 3p3/2 were around 128.81–127.29 eV and 124.64–123.08 eV, respectively [46, 47], before etch. After being etched for 420–480 s, the peaks of Ge 3p1/2 and Ge 3p3/2 which belong to Ge were around 126 and 122 eV, respectively [44, 47]. After being etched for 420–480 s, a weak peak found at 118–119.7 eV, indicating that Ge-N bonds exist for all samples.

Figure 12 shows the narrow scan of O 1s. The peaks that belonged to GeO2 and ZrO2 were found before etch for all samples at around 531.88–532.29 eV [48] and 530.67–531.12 eV [44, 49], respectively. After a certain level of etching, the peak of GeO2 disappeared and left only the peak that belongs to ZrO2. The details of the mechanism will be discussed in Sect. 3.8.

Figure 13 shows the narrow scan of N 1s, no peak was found at the surface for all samples. After etch, a weak peak was found at around 404 eV which was assumed to be Ge–N. The same peaks were also detected at a deeper level of Ge wafer.

Figure 14 shows Zr 3d3/2 narrow scan peak position of samples oxidized/nitridation at various temperatures at various etching times. The fully oxidized line was plotted at 185.3 eV [45, 50]. The surface of ZrO2 dielectric was under oxidation for all samples, it may be that Ge atom accumulation at the surface and combined with oxygen atom of existing ZrO2 and induced the ZrO2 under oxidation. For the 300 °C sample, mainly ZrO2 under oxidation and the oxidation level increase when the temperature increases except the for 500 °C samples. This phenomenon was similar with the O2 ambient. For the 600 °C sample, the result shows mainly ZrO2 overoxidation. The sample of 400 °C was the sample nearest to the full oxidation line, thus having the highest electrical breakdown fields compared with the other samples. For 300 and 500 °C samples, the ZrO2 overoxidization is near Ge interface region. It could be that the Ge atoms diffused up during the cooling process, leaving excess O atoms causing ZrO2 overoxidation. The details of the mechanism will be discussed at Sect. 3.8.

Figure 15 shows O 1s narrow scan of samples oxidized/nitridation at 400 °C. The back color line shows the original measurement line including noise. The peak position of GeO2 was located at around 532.06 eV which was labeled as a green color line. The peak position of ZrO2 was located at around 531.05 eV which was labeled as a red color line. The blue color shows the peak merge with ZrO2 and GeO2. Hence, when GeO2 increase, the peak will shift to the left and shift to right when the ZrO2 increases. Figure 16a was drawn based on this concept used to monitor the Ge atom arrangement in the ZrO2. The GeO2 and ZrO2 binding energy were assumed to be 532.2 eV [51, 52] and 530.8 eV [53], respectively. As shown in Fig. 16a, the sample of 600 °C has the highest Ge atom in the ZrO2 and sequentially, were 500, 400 and 300 °C. Obviously, the number of Ge atom diffused to ZrO2 increase as the oxidation temperature increases. For the 500 and 600 °C samples, the concentration of Ge atoms increases at the interface of ZrO2 and Ge wafer. Figure 16b shows the 400 °C sample cross-sectional HRTEM images, which correspond with Fig. 16a. A possible of mechanism will be discussed at the next section.

3.8 Ge diffused and rearrange mechanism

When Ge atoms diffuse to ZrO2 region, it should be travelling in random thermal motion [54]. However, the XPS result has shown that the Ge atoms were accumulating at both sides of ZrO2, indicating that another factor does exist to influence the way the Ge atom behaves. The factor could be the thermal gradient during cooling appear to make Ge rearrange. As ZrO2 has low thermal conductivity of less than 4 W m−1 K−1 above 500 °C [55], high thermal gradient formed during the cooling process. Figure 17a shows the schematic diagram during thermal process, the Ge atoms diffuse to ZrO2 film with Ge concentration being highest near Ge surface and lowest Ge concentration at ZrO2 surface [56]. Figure 17b shows the schematic diagram of Ge distribution during cooling process. The Ge atom at the center region was at random thermal motion due to higher temperature at the center of ZrO2. The atoms diffused near the edge of the ZrO2 which stayed stagnant due to the high thermal gradient. Hence, the Ge atoms accumulate at both sides of ZrO2 eventually. As explained above, the thermal motion of Ge atoms during cooling will result in an IL-free phenomenon.

4 Conclusions

The activation energies of N2O are higher than O2, thus explaining the stable film performance at N2O ambient than O2 ambient at temperature above 600 °C. The ZrO2 dielectric film was unstable for temperatures above 700 °C on Ge wafer in N2O ambient. Ge diffusion was observed during oxidation process. A possible mechanism of Ge atomic diffusion and its rearrangement in ZrO2 has been proposed and explicated. The sample of 400 °C was closest to the full oxidation, and electrical characterization has shown that the 400 °C sample has the highest electrical breakdown fields.

References

X.R. Wang et al., Annealing effect on the metal gate effective work function modulation for the Al/TiN/SiO2/p-Si structure. Microelectron. Eng. 88(5), 573–577 (2011)

V.E. Vamvakas et al., Correlation between infrared transmission spectra and the interface trap density of SiO2 films. Microelectron. Reliab. 47(4–5), 834–837 (2007)

D.G. Park, T.K. Kim, Effects of fluorine and chlorine on the gate oxide integrity of W/TiN/SiO2/Si metal-oxide-semiconductor structure. Thin Solid Films 483(1–2), 232–238 (2005)

T. Sakurai et al., Electrical properties of the silicon oxide/Si structure formed with perchloric acid at 203 °C. Solid State Commun. 118(8), 391–394 (2001)

C.A. Mack, Fifty years of Moore’s law. IEEE Trans. Semicond. Manuf. 24(2), 202–207 (2011)

S.E. Thompson, S. Parthasarathy, Moore’s law: the future of Si microelectronics. Mater. Today 9(6), 20–25 (2006)

V.K. Arora, D.C.Y. Chek, M.L.P. Tan, The Role of Ballistic Mobility and Saturation Velocity in Performance Evaluation of a Nano-CMOS Circuit. 2009 International Conference on Emerging Trends in Electronic and Photonic Devices and Systems (Electro-2009) (2009), p. 14

R. Pillarisetty, Academic and industry research progress in germanium nanodevices. Nature 479(7373), 324–328 (2011)

Y. Kamata, High-k/Ge MOSFETs for future nanoelectronics. Mater. Today 11(1–2), 30–38 (2008)

Y.H. Lee et al., Prediction of Logic Product Failure Due to Thin-Gate Oxide Breakdown. 2006 IEEE International Reliability Physics Symposium Proceedings—44th Annual (2006), p. 18

P.W. Peacock, J. Robertson, Bonding, energies, and band offsets of Si–ZrO2 and HfO2 gate oxide interfaces. Phys. Rev. Lett. 92(5), (2004)

K.H. Goh, A.S.M.A. Haseeb, Y.H. Wong, Physical and electrical properties of thermal oxidized Sm2O3 gate oxide thin film on Si substrate: influence of oxidation durations. Thin Solid Films 606, 80–86 (2016)

K. Hetherin, S. Ramesh, Y.H. Wong, Formation of neodymium oxide by thermal oxidation of sputtered Nd thin film on Si substrate. J. Mater. Sci: Mater. Electron. 28(16), 11994–12003 (2017)

C.K. Maiti et al., Electrical characterization of TiO2 gate oxides on strained-Si. Microelectron. Eng. 72(1–4), 253–256 (2004)

M. Tapajna et al., Gate oxide thickness dependence of the leakage current mechanism in Ru/Ta2O5/SiON/Si structures. Semicond. Sci. Technol. 25(7), 075007 (2010)

C. Lee et al., The electrical and physical analysis of Pt gate/Al2O3/p-Si (100) with dual high-k gate oxide thickness for deep submicron complementary metal-oxide-semiconductor device with low-power and high reliability. J. Electron. Mater. 34(8), 1104–1109 (2005)

B.W. Busch et al., Interface reactions of high-kappa Y2O3 gate oxides with Si. Appl. Phys. Lett. 79(15), 2447–2449 (2001)

Y.H. Wong, K.Y. Cheong, ZrO2 thin films on Si substrate. J. Mater. Sci: Mater. Electron. 21(10), 980–993 (2010)

C.C. Li et al., Improved electrical characteristics of Ge pMOSFETs with ZrO2/HfO2 stack gate dielectric. IEEE Electron. Device Lett. 37(1), 12–15 (2016)

Z.C. Lei et al., Effect of oxidation temperature on physical and electrical properties of ZrO2 thin-film gate oxide on Ge substrate. Thin Solid Films 642, 352–358 (2017)

R. De Almeida, I.J.R. Baumvol, Reaction–diffusion in high-k dielectrics on Si. Surf. Sci. Rep. 49(1–3), 1–114 (2003)

S. Dimitrijev et al., in Recent Major Advances in SiC, ed. by W.J. Choyke, H. Matsunami, G. Pensl (Taylor & Francis, New York, 2003)

M.L. Campbell, R.E. Mcclean, Kinetics of Neutral transition-metal atoms in the gas-phase—oxidation reactions of Ti(a(3)F) from 300-K to 600-K. J. Phys. Chem. 97(30), 7942–7946 (1993)

K. Maeda et al., Dependence of activity and stability of germanium nitride powder for photocatalytic overall water splitting on structural properties. Chem. Mater. 19(16), 4092–4097 (2007)

Y.G. Lee et al., Effect of high-pressure ammonia treatment on the activity of Ge3N4 photocatalyst for overall water splitting. J. Phys. Chem. B 110(35), 17563–17569 (2006)

Y. Leng, Materials Characterization: Introduction to Microscopic and Spectroscopic Methods (Wiley, New York, 2009)

Q. Tong et al., Rhenium-promoted Pt/WO3/ZrO2: an efficient catalyst for aqueous glycerol hydrogenolysis under reduced H-2 pressure. RSC Adv. 6(89), 86663–86672 (2016)

M. Rawat et al., Micro-Raman and electronic structure study on kinetics of electronic excitations induced monoclinic-to-tetragonal phase transition in zirconium oxide films. RSC Adv. 6(106), 104425–104432 (2016)

S. Vasanthavel, S. Kannan, Structural investigations on the tetragonal to cubic phase transformations in zirconia induced by progressive yttrium additions. J. Phys. Chem. Solids 112, 100–105 (2018)

G. Sponchia et al., Orthorhombic phase stabilization and transformation phase process in zirconia tantalum-doped powders and spark plasma sintering systems. J. Eur. Ceram. Soc. 37(10), 3393–3401 (2017)

A. Lignie et al., Raman study of alpha-quartz-type Ge1-xSixO2 (0 < x < = 0.067) single crystals for piezoelectric applications. RSC Adv. 5(69), 55795–55800 (2015)

G. Kartopu et al., On the origin of the 2.2–2.3 eV photoluminescence from chemically etched germanium. J. Lumin. 101(4), 275–283 (2003)

P. Kroll, Pathways to metastable nitride structures. J. Solid State Chem. 176(2), 530–537 (2003)

S.K. Deb et al., The Raman spectra of the hexagonal and cubic (spinel) forms of Ge3N4: an experimental and theoretical study. Solid State Commun. 114(3), 137–142 (2000)

X. Fan, H. Liu, X. Zhang, Identification of optimal ALD process conditions of Nd2O3 on Si by spectroscopic ellipsometry. Appl. Phys. A 114(2), 545–550 (2014)

A. Laha et al., Epitaxial multi-component rare earth oxide for high-K application. Thin Solid Films 515(16), 6512–6517 (2007)

T.-M. Pan, J.-D. Lee, W.-W. Yeh, Influence of oxygen content on the structural and electrical characteristics of thin neodymium oxide gate dielectrics. J. Appl. Phys. 101(2), 024110 (2007)

J. Moureau et al., High accuracy measurements of Mo isotopes by MC-ICPMS with in situ Mo/Zr separation using N2O in a collision reaction cell. J. Anal. At. Spectrom. 23(11), 1538–1544 (2008)

L. Khomenkova et al., Effect of Ge content on the formation of Ge nanoclusters in magnetron-sputtered GeZrOx-based structures. Nanoscale Res. Lett. 12. (2017)

S.K. Sahari et al., Kinetics of Thermally Oxidation of Ge(100) Surface. 15th International Conference on Thin Films (Ictf-15). (2013), p. 417

Y.H. Wong, K.Y. Cheong, Thermal oxidation and nitridation of sputtered Zr thin film on Si via N2O gas. J. Alloys Compd. 509(35), 8728–8737 (2011)

E. Marin et al., Wear and surface degradation of commercial ZTA femoral heads under boundary lubrication conditions. J. Mech. Behav. Biomed. Mater. 65, 616–626 (2017)

F.M. John et al., Handbook of X-ray Photoelectron Spectroscopy (Perkin-Elmer Corporation Physical Electronics Division, Eden Prairie, 1992)

S. Sinha, S. Badrinarayanan, A. Sinha, Interaction of oxygen with Zr76Fe24 metglass: an X-ray photoelectron spectroscopy study. J. Less Common Met. 125, 85–95 (1986)

O. Bethge et al., Stability of La2O3 and GeO2 passivated Ge surfaces during ALD of ZrO2 high-k dielectric. Appl. Surf. Sci. 258(8), 3444–3449 (2012)

Q. Xie et al., Germanium surface passivation and atomic layer deposition of high-k dielectrics-a tutorial review on Ge-based MOS capacitors. Semicond. Sci. Technol. 27(7), (2012)

F. Wei, H.L. Tu, J. Du, Twin-free (111)-oriented epitaxial Nd2Hf2O7 thin films on Ge(111) for high-k dielectrics. J. Phys. D 42(18), 185301 (2009)

L.G. Kim et al., Enhanced electrooptical characteristics of twisted nematic liquid crystal display with ZrO2 thin films. IEEE Electron. Device Lett. 33(8), 1153–1155 (2012)

Q.C. Zhang et al., Preparation and characterization of polymer-derived Zr/Si/C multiphase ceramics and microspheres with electromagnetic wave absorbing capabilities. J. Eur. Ceram. Soc. 37(5), 1909–1916 (2017)

M.K. Bera et al., TiO2/GeOxNy stacked gate dielectrics for Ge-MOSFETs. Semicond. Sci. Technol. 22(12), 1352–1361 (2007)

R.T. Kouzes, Z. Zhu, M.H. Engelhard, Germanium-76 Sample Analysis: Revision 3. 2011, Pacific Northwest National Laboratory (PNNL), Richland, WA (US), Environmental Molecular Sciences Laboratory (EMSL)

X. Guo, Y.-Q. Sun, K. Cui, Darkening of zirconia: a problem arising from oxygen sensors in practice. Sens. Actuators B 31(3), 139–145 (1996)

S.M. Sze, Semiconductor Devices: Physics and Technology (Wiley, New York, 2008)

Q. Mistarihi et al., Fabrication of ZrO2-based nanocomposites for transuranic element-burning inert matrix fuel. Nuclear Eng. Technol. 47(5), 617–623 (2015)

F. Boucard et al., A Model for Boron TED in Silicon: Full Couplings of Dopant with Free and Clustered Interstitials. MRS Online Proceedings Library Archive. (2002), p. 717

Acknowledgements

This project is financially supported by Frontier Research Grant (FRG) (Grant No.: FG008-17AFR) and Postgraduate Research Grant (PPP) (Grant Nos.: PG221-2015B and PG031-2016A) via University of Malaya (UM) and ScienceFund (Grant No.: 03-01-03-SF1083) via Ministry of Science, Technology and Innovation (MOSTI), Malaysia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lei, Z.C., Zainal Abidin, N.I. & Wong, Y.H. Structural, chemical, and electrical properties of ZrO2/Ge system formed via oxidation/nitridation in N2O gas ambient. J Mater Sci: Mater Electron 29, 12888–12898 (2018). https://doi.org/10.1007/s10854-018-9408-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9408-2