Abstract

The aim of this study is to prepare a non-toxic, light, flexible and low-cost radiation shielding material that protects against gamma ray (γ-ray). So, flexible and lead-free gamma-ray-shielding composites based on room temperature vulcanizing silicone rubber matrix with 37.5% weight of tungsten (W) and bismuth oxide (Bi2O3) as filler materials were prepared by using a simple and well-established open mould cast technique. The shielding properties of the composites [linear attenuation coefficient (µ), transmittance, half value layer (HVL) and tenth value layer (TVL)] have been evaluated using 152Eu radioactive source in the energy range (122–964 keV). The prepared composites show high performance in gamma-ray-shielding in comparison with commercial composite (76% Pb). The sample that was treated with 18.75 wt% W + 18.75 wt% Bi2O3 shows the lowest values of HVL and TVL in high energy levels and is the best-attenuating shielding for γ-ray compared to the other investigated samples. Morphological observations showed that increasing of Bi2O3 in samples can prevent from the accumulation of fillers. For this reason, the tensile strength and elongation at break improved with increasing of Bi2O3 in composites.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The use of X and gamma rays is increasing due to development of science and technology. In other words, the use of these radiations in various industries is inevitable. Recent developments have been reported on their versatile application in medicine, industry and agriculture [1, 2]. The increasing use of these radiations in hospitals (diagnostics and radiotherapy) or research centers makes it possible for people to be exposed to these rays. This continuous exposure with the high energy radiations result in harmful effects and this can damage human cells [3, 4]. Hence, an appropriate shielding material is essential to minimize the radiation dose received by the personnel working in the radiation environment [5]. Numerous researches on the use of various shielding materials have been reported. Among them, the polymer composites are interesting materials that can be used as shielding materials due to lightness, environmental-friendliness, non-toxicity and flexibility. Generally, metallic lead (Pb) has been used for high energy radiation shielding due to low cost and effective shielding against penetrative gamma radiation [6,7,8,9]. For example, ultra-high molecular weight polyethylene (UHMWPE) fiber reinforced nano-epoxy composites were fabricated by Zhong et al. The authors reinforced epoxy matrix with reactive nanofibers of graphite to form a nano-epoxy composite and showed that the high radiation shielding performance associated with UHMWPE was not degraded by the addition of graphitic nanofibers in the matrix [10]. A new fast-curing shielding composite based on two-component polyurethane was fabricated with lead oxide (PbO) as the filler through a one-step, laboratory-scale method [11]. The authors confirmed with increasing of the filler, the curing time decreased while gamma-ray shielding properties increased. Unsaturated polyester resin reinforced with the lead monoxide composites were fabricated by Nagaiah et al. They found that the linear attenuation coefficient of the composites enhanced with increase filler content in the composites [12]. However, lead is known for its toxicity, environmental pollution and conventional lead aprons made from these materials are very heavy and bulky for personal shielding. Therefore, many researchers have been concentrated on development of lead-free radiation shielding materials [13,14,15,16,17,18,19,20,21,22,23,24,25]. Lead-free rubber composites are very much considered due to their high flexibility and ease of use. Tang et al. prepared new flexible lead-free X-ray radiation-shielding based on high-functional methyl vinyl silicone rubber (VMQ) containing tungsten and bismuth(III) oxide [26]. With the X-ray energy ranging from 48 to 185 keV, the W/Bi2O3/VMQ composites exhibited higher X-ray-shielding properties. Radiation cross-linked polydimethylsiloxane (PDMS)/Bi2O3 composites were fabricated by Dubey et al. Their study revealed that gamma radiation can be effectively used to crosslink the composites containing large amounts of high-atomic-number fillers, and such composites have the potential to be used as a flexible radiation shielding for Am-241 gamma radiation [27]. PDMS nanocomposites with different weight percentages (wt %) of bismuth oxide nano-powder were fabricated by Yeow et al. They confirmed that PDMS/bismuth oxide nanocomposite (44.44 wt% of bismuth oxide and 3.73-mm thick) was capable of attenuating all the scattered X-rays generated at a tube potential of 60 kV, which is the beam energy commonly employed in interventional radiology (IVR) procedures [28]. Better heat resistance, chemical stability, low density and high flexibility of PDMS causes that lead-free PDMS composites have been excellent candidates for radiation shielding materials. In respect of economic and cost concepts, the use of both low fillers amount and ease of preparation method for fabricating of more effective radiation shielding materials can be important. Therefore, in this research, flexible shielding materials with lower filler content and thickness have been fabricated by using the room temperature vulcanizing (RTV) silicone rubber along with W and Bi2O3 as functional powder fillers through simple method. These composites were investigated for their γ-radiation shielding from 122 to 964 keV, mechanical properties and compared with a commercial sample containing lead filler.

2 Experimental and methods

2.1 Materials

Bismuth oxide (99%, 5 µm) and tungsten (99%, less than 20 µm) powders were purchased from Merck Chemical Co. RTV silicone rubber and vulcanizing agent (Dibutyltin dilaurate 5%) were purchased from B.K.H. Co.(Canada). Commercial lead-containing sample was supplied by ministry of health and medical education of Islamic Republic of Iran.

2.2 Preparation of composites

A simple open mould cast technique was used to prepare polymer composites. According to Table 1, firstly, suitable weight % of silicone rubber was poured in beaker and stirred mechanically at 400 rpm and then the fillers (up to 37.5 wt%) were added to silicone rubber. The mixture was stirred mechanically at 500 rpm at room temperature for 15 min. Then, the mixture was sonicated for the effective dispersion of the filler within the matrix for 15 min. After addition of curing agent, the mixture was then poured into the mould with dimensions of 100 × 100 × 0.2 and 100 × 100 × 0.5 mm3 for curing at room temperature (Fig. 1). Typical prepared flexible RTV silicone rubber composites and a sample of covers are shown in Fig. 2. According to TGA analysis, lead filler content of commercial sample is 76% (Fig. 3).

2.3 Gamma ray shielding measurements

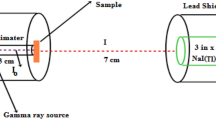

For the study and investigations of gamma radiation properties, the 152Eu as a radioactive source was used. The samples were placed between the gamma point source and the detector, so that the sample spacing was 15 cm from the irradiation point source. The samples were irradiated by photons emitted from 152Eu and the measurement has been done at the photon energies of 122, 344, 779 and 964 keV. Shielding performances of the composite samples with different filler contents were measured using a gamma spectrometer which consists of a NaI (Tl) scintillation detector. The gamma-ray spectrum was recorded as a function of the thickness of the composite. Increasing the thickness of the composite films for attenuation of gamma rays up to 6 mm thickness was obtained by adding multiple films (0.2 and 0.5 mm) with each other. A schematic diagram of the apparatus is shown in Fig. 4.

2.4 Morphology observations

In order to check the distribution of the fillers within the matrix and evaluate the performance of the composites, the morphological features of composites were observed under a scanning electron microscope (SEM, Vega 2TESCAN, Czech Republic). All of the samples were gold-coated by means of a sputtering apparatus before observation.

2.5 Mechanical properties

The mechanical properties of the composites were determined at room temperature using Santam Material Testing Machine (Santam STM-50). The test specimens for the tensile were prepared in the form of square of 100 mm × 100 mm × 0.5 mm dimension and tested at a rate of 500 mm/min until failure due to the application of load.

3 Results and discussion

3.1 Gamma ray shielding properties

To investigate gamma-ray attenuation through the composites, 152Eu as gamma-ray source was used. The number of outgoing rays from the source and the number of passing through the samples are counted by gamma spectrometer. In this way, the linear attenuation coefficient (µ) for samples has been calculated through the Eq. (1):

where yo is initial gamma photon intensity (photon number), y is transmitted gamma photon intensity (photon number), x is the thickness of the prepared composites and µ is the attenuation coefficient of the prepared composites which was then used to evaluate the other parameters such as half value layer (HVL) and tenth value layer (TVL). The number of passing rays through the composites (y) as a function of thickness (x) in different gamma-ray energies is plotted in Figs. 5, 6, 7, 8 and 9 for different prepared composites and commercial lead-containing sample. By using these curves and Eq. (1), the linear attenuation coefficient has been calculated. These figures show that the transmission of γ-ray through the investigated composites decreases with increasing of sheet thickness. In all of the composites, the linear attenuation coefficients depend on the gamma-ray energy which have larger value at lower energies and decrease rapidly toward higher energies. These results are expected because with increasing of gamma-ray energy, the penetrating power of gamma-ray increased so that the linear attenuation coefficient was decreased. According to these graphs, it is noticeable that the increasing of sheet thickness in lower energy levels (122 and 344 keV) has a more influence on shielding properties. The number of passing gamma rays through the composites strongly decreases with the sharp slope. These results indicate that the prepared composites based on silicone rubber with W and Bi2O3 fillers have excellent γ-ray shielding properties under the irradiation of 152Eu point source with energy levels of 122 and 344 keV.

Transmittance percent (y/yo × 100) versus thickness in different energy levels are plotted in Fig. 10 for all of the composites. These graphs also confirmed again high performance of prepared composites for shielding of gamma-ray in 122 and 344 keV energy levels. The gamma- ray transmittance at the energy levels of 122 and 344 keV were around 2 and 10% respectively. This shielding property can be observed almost for all of the prepared composites. It is noticeable that the required thickness for 2% (122 keV) and 10% (344 keV) transmittance are 1.5 and 6 mm respectively. However, the transmittance increased as the irradiation energy increased (779 and 964 keV) and the gamma ray shielding properties became poor because the penetrating power of gamma-ray increased as the energy of the point source increased. It can be concluded that the prepared composites with lower filler content (37.5%) showed better performance in shielding of gamma-ray in comparison with the commercial sample with high filler content (76% Pb).

Other important factors determining the effectiveness of the shielding material is using the concepts of HVL and TVL. HVL, which means as the thickness of the material at which the intensity of radiation entering it is reduced by one-half given by Eq. (2).

One TVL is defined as the thickness of the material at which the intensity of radiation entering it is reduced by one-tenth given by Eq. (3).

The linear attenuation coefficient, HVL and TVL values of the composites for different gamma- ray energies are listed in Table 2. According to this table, the linear attenuation coefficients depend on the gamma-ray energy which has larger value at lower energies and decreases rapidly toward higher energies while the HVL and TVL values increase with increasing of energy level (Eqs. (2) and (3)). As the energy of the photons increase, they are able to penetrate the attenuator materials more deeply, resulting in a higher HVL and TVL. The lower value of HVL and TVL the better radiation material in terms of thickness requirements. From this table, we noticed that the HVL and TVL values for silicone rubber composites (lead-free composites) are less than commercial lead composite for same energy level. Particularly, silicone rubber composites show better values and shielding property in high levels energy (779 and 964 keV) when compared with commercial lead composite. For example, at 964 keV, HVL and TVL values for silicone rubber composite (37.5 wt% W) are 2.66 and 8.86 mm respectively while HVL and TVL values for commercial lead composite (Pb 76 wt%) at the same energy level are 13.86 and 46.05 mm respectively. Among the silicone rubber composites, the sample containing 18.75 wt% W + 18.75 wt% Bi2O3 has the lowest values of HVL and TVL in high energy levels consequently shows better performance in shielding of gamma-ray. The data presented in Table 2 confirms the high capability of prepared composites in shielding of gamma-ray.

3.2 Morphology investigations

Figures 11, 12, 13, 14 and 15 show the SEM images of the prepared silicone rubber lead-free composites and commercial lead composite. These images show a spherical structure of particles in all of the composites. Also the SEM images of silicone rubber composite show the efficiency of the mixing method and a good distribution of particles in the silicone rubber matrix in comparison with commercial lead composite. Some of the large particles are observed in magnified images due to the particle agglomerations. This phenomenon causes that the surfaces of silicone rubber composites become rough (Figs. 11, 12, 13) while Fig. 14 which related to the sample containing 18.75 wt% W + 18.75 wt% Bi2O3 shows smooth surface in comparison with other composites. It seems that the simultaneous presence of Bi2O3 and W in an equal amount in composite prevents the aggregation of fillers. Different size particles of Bi2O3 and W may be due to the uniform distribution of particles in silicone rubber matrix. Therefore, this composite (18.75 wt% W + 18.75 wt% Bi2O3/silicone rubber) shows high capability for gamma ray shielding, particularly in high energy levels (Table 2).

3.3 Mechanical properties

The mechanical properties of silicone rubber composite are relatively poor without reinforcing fillers. Figure 16 shows the stress–elongation curves of silicone rubber composites and the physic-mechanical properties (density, peak stress, peak strain and peak energy) are summarized in Table 3. The obtained results show that the tensile strength and elongation at break improved with increasing of Bi2O3 in composites. The presence of Bi2O3 probably reduces the aggregation of the fillers and consequently the structural defects are decreased in matrix. These results have good agreement with morphology observations.

4 Conclusion

The efficient light, flexible and lead-free gamma-ray shielding composites have been successfully prepared by using the RTV silicone rubber matrix with W and Bi2O3 as filler materials through the simple open mould cast method. The γ-ray-shielding properties, mechanical properties and morphology of the W/Bi2O3/silicone rubber (37.5 wt %) and commercial (76 wt% Pb) composites were compared. The W/Bi2O3/silicone rubber composites exhibited better γ-ray-shielding properties than commercial composite, especially at high energy levels (low HVL and TVL values). The sample that was treated with 18.75 wt% W + 18.75 wt% Bi2O3 shows the lowest values of HVL and TVL in high energy levels and this sample also exhibited better mechanical properties than the other silicone-based composites. In other words, increasing of Bi2O3 in matrix causes good and uniform distribution of fillers in matrix and consequently modified the gamma-ray shielding and mechanical properties.

References

Y.K. Kim, Y.I. Jang, J.M. Kim, J. Radiol. Sci. Technol. 26, 45 (2003)

S.C. Kim, K.R. Dong, W.K. Chung, J. Korean Phys. Soc. 60, 165 (2012)

T. Hayashi, K. Tobita, Y. Nakamori, S. Orimo, J. Nucl. Mater. 386, 119 (2009)

M.Y. Kim, J.W. Wilson, F.A. Cucinotta, Adv. Space Res. 37, 1741 (2006)

S. Nambiar, J.T.W. Yeow, ACS Appl. Mater. Interfaces 4, 5717 (2012)

N. V.Harish, H.G. Nagaiah, Harish kumar, Indian J. Pure Appl. Phys. 50, 847 (2012)

A. El-Sayed Abdo, M.A.M. Ali, M.R. Ismail, Radiat. Phys. Chem. 66, 185 (2003)

J.P. McCaffrey, H. Shen, B. Downton, E. Mainegra-Hing, Med. Phys. 34, 530 (2007)

R. Kunzel, E. Okuno, Appl. Radiat. Isot. 70, 781 (2012)

W.H. Zhong, G. Sui, S. Jana, J. Miller, Compos. Sci. Technol. 69, 2093 (2009)

M. Ni, X. Tang, H. Chai, Y. Zhang, T. Chen, D. Chen, Nucl. Eng. Technol. 48, 1396 (2016)

V. Harish, N. Nagaiah, T. Niranjana Prabhu, K.T. Varughese, J. Appl. Polym. Sci. 112, 1503 (2009)

N. Aral, F. Banu Nergis, C. Candan, J. Ind. Text. 86, 803 (2015)

J. Kim, D. Seo, B.C. Lee, Y.S. Seo, W.H. Miller, Adv. Eng. Mater. 16, 1083 (2014)

M.I. Sayyed, G. Lakshminarayana, M.G. Dong, M. Çelikbilek, A.E. Ersundu, I.V. Ersundu, Kityk, Radiat. Phys. Chem. 145, 26 (2018)

S. Pulford, M. Fergusson, J. Text. Inst. 107, 1610 (2016)

N. Aral, F.B. Nergis, C. Candan, Text. Res. J. 86, 803 (2016)

L.B.T. La, Y.K. Leongb, C. Leadtherdayc, P.I. Aub, K.J. Haywarda, L.C. Zhang, Colloids Surf. A 501, 75 (2016)

H. Wang, H. Zhang, Y. Su, T. Liu, H. Yu, Y. Yang, X. Li, B. Guo, Polym. Compos. 36, 651 (2014)

S.S. Obaid, D.K. Gaikwad, P.P. Pawar, Radiat. Phys. Chem. 144, 356 (2018)

G. Lakshminarayana, A. Kumar, M.G. Dong, M.I. Sayyed, N.V. Long, M.A. Mahdi, J. Non-Cryst. Solids 481, 65 (2018)

S.M. Badawy, A.A. Abd El-Latif, Polym. Compos. 38, 974 (2015)

M.R. Ambika, N. Nagaiah, V. Harish, N.K. Lokanath, M.A. Sridhar, N.M. Renukappa, S.K. Suman, Radiat. Phys. Chem. 130, 351 (2017)

M.I. Sayyed, H. Elhouichet, Radiat. Phys. Chem. 130, 335 (2017)

A.M. Zoulfakar, A.M. Abdel-Ghany, T.Z. Abou-Elnasr, A.G. Mostafa, S.M. Salem, H.H. El-Bahnaswy, Appl. Radiat. Isot. 127, 269 (2017)

H. Chai, X. Tang, M. Ni, F. Chen, Y. Zhang, D. Chen, Y. Qiu, J. Appl. Polym. Sci. 133, 43012 (2016)

K.A. Dubey, C.V. Chaudhari, S.K. Suman, N. Raje, R.K. Mondal, V. Grover, S. Murali, Y.K. Bhardwaj, L. Varshney, Polym. Compos. 37, 756 (2014)

S. Nambiar, E.K. Osei, J.T.W. Yeow, J. Appl. Polym. Sci. 127, 4939 (2012)

Acknowledgements

The authors wish to thank the University of Zanjan for their financial support for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Atashi, P., Rahmani, S., Ahadi, B. et al. Efficient, flexible and lead-free composite based on room temperature vulcanizing silicone rubber/W/Bi2O3 for gamma ray shielding application. J Mater Sci: Mater Electron 29, 12306–12322 (2018). https://doi.org/10.1007/s10854-018-9344-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9344-1