Abstract

Y3−yAl5−xGaxO12:Ce3+y phosphors were prepared by high temperature solid state reaction method. The crystal structures, the influence of Ga3+ concentration on the photoluminescence (PL), cathodoluminescence, thermal stability and morphology of the phosphors were studied in detail. The results indicated that diffraction angle of the samples decreased gradually with the increase of Ga3+ ions content in XRD pattern. The emission peak of the spectra show a progressive blue-shift, the intensity increased first and then decreased and the optimal Ga3+ concentration in Y2.94Al5−xGaxO12:Ce3+0.06 phosphors is x = 0.75. The critical concentration of Ce3+ in YAGG:Ce3+ phosphors is affected with the ratio of Ga3+ to Al3+ and the Y2.9Al4.25Ga0.75O12:Ce3+0.1 phosphor showed the best performance on PL. However, the optimum concentration of Y3−yAl5−xGaxO12:Ce3+y phosphors is x = 1.5 and y = 0.04 when they were excited by cathode ray.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Yttrium aluminum garnet (YAG) phosphors are an important class of materials for luminescence [1,2,3]. YAG crystal belongs to cubic crystal system with Ia3d (230) space group, the lattice parameters are a = b = c = 12.008 Å, α = β = γ = 90°, Z = 8. It possesses excellent chemical, physical and thermal stability, and is an excellent matrix for inorganic phosphor materials for lighting [4,5,6]. Rare-earth-doped phosphors have been used widely in field emission displays and white light-emitting diodes because of advantages such as excellent luminescent characteristics, good stability and high luminescence efficiency [7, 8].

In recent years, Ga3+-substituted YAG:Ce3+ phosphors have attracted much attention due to their high light yield compared with YAG:Ce3+ phosphors [9]. However, there is rare research on the occupancy sites of Ga3+ and Al3+ in garnet structure and their effects on optical properties in large Ga3+ concentration range. The main reason is that it is difficulty for Ga3+ to occupy tetrahedral site when three or more Al3+ were displaced, which leads to the appearance of impurities [10]. Meanwhile, as we know, there is no research on the comparison between cathodoluminescence and photoluminescence (PL) on YAGG:Ce3+ phosphors.

In this paper, a series of Y3−yAl5−xGaxO12:Ce3+y phosphors were successfully synthesized by high temperature solid state reaction method. We solve the problem that the YAGG garnet phase is difficult to form when the amount of Ga3+ content is large and the optimal concentration of Ga3+ and Ce3+ in PL and cathodoluminescence was discussed in detail. What’s more, the effects of Ga3+ concentration on the thermal quenching, fluorescence lifetime and morphology properties were discussed.

2 Experimental

Y2O3 (99.99%), CeO2 (99.99%), Al2O3 (99.99%), Ga2O3 (99.99%) were used as starting materials, which were precisely weighed according to the formula Y3−yAl5−xGaxO12:Ce3+y with stoichiometric ratio. The appropriate amount of AlF3 was additionally added as a fluxing agent. The raw powders were mixed, grained thoroughly and then sintered at 1500 °C for 4 h in reduction atmosphere.

Phases identification was performed by X-ray powder diffraction on a Rigaku D/max-II B diffractometer, operating at 40 kV and 20 mA, using Cu Kα radiation, (λ = 1.54056 Å). PL spectra were measured on a Hitachi F-7000 luminescence spectrophotometer equipped with a 150 W xenon lamp as the excitation. The temperature-dependence PL spectra were collected on a QE Pro high performance spectrometer equipped with a heating stage (THMS600, Linkam Scientific Instruments Ltd, UK), with a xenon lamp as the excitation source. The morphology was observed by scanning electron microscopy (SEM, JSM-6701F, JEOL, Japan). Cathodoluminescence (PL) spectra were measured on a OpticZenith Elec-ray system, operating at 6 kV. The luminescence decay curves were measured using a Lecroy Wave Runner 6100 digital oscilloscope (1 GHz) with a tunable laser (pulse width = 4 ns; gate = 50 ns) as the excitation (Continuum Sunlite OPO).

3 Results and discussion

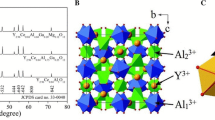

Figure 1 shows XRD patterns of the Y2.94Al5−xGaxO12:Ce3+0.06 (x = 0, 0.25, 0.5, 0.75, 1, 1.5, 2, 3, 3.5, 4, 4.5, 5) phosphors, the PDF#33-0040 corresponding to the standard card of YAG (Y3Al5O12) and the PDF#43-0512 is the standard card of YGG (Y3Ga5O12). The results indicate that the yttrium aluminium garnet phases were successfully obtained under the conditions of different Ga3+ doping concentration. From the figure, we can find that the diffraction angle decreased gradually with the increase of Ga3+ ions content. Which can be explained by the Bragg equation 2dsinθ = λ, the interplanar spacing d value becomes larger with the lattice expansion when Al3+ ions were replaced by Ga3+ ions (the lattice parameters of YAG are a = b = c = 12.008 Å, α = β = γ = 90°, Z = 8, and the lattice parameters of YGG are a = b = c = 12.27 Å, α = β = γ = 90°, Z = 8), the diffraction angle will decrease because of the ionic radius of Ga3+ is more than that of Al3+, exhibits a slight shift toward to lower 2θ angles. When Al3+ ions were completely replaced by Ga3+ ions, the sample becomes YGG. Besides, the diffraction intensity of (211), (321), (521), (532) crystal plane decreased gradually and the diffraction intensity of (400), (422), (642) increased simultaneously.

Figure 2 displays the SEM images of the Y2.94Al5−xGaxO12:Ce3+0.06 (x = x = 0, 0.75, 2, 3, 4, 5) phosphors. From the images, we can find that the particles of the sample replaced with a small number of the Ga3+ ions performs irregular shape, which consist of several small particles as shown in Fig. 2a–c. With the improvement of Ga3+ content, the size of individual particles increased gradually and the dispersion of the particles is getting better as shown in Fig. 2d–f. The doping of Ga3+ ions can help reduce the sintering temperature of YAG. Thus, the samples which content more Ga3+ ions are beneficial to the development of lattice.

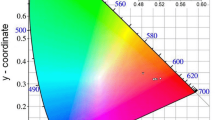

Figure 3 shows emission spectra and excitation spectra of the Y2.94Al5−xGaxO12:Ce3+0.06 (x = 0, 0.25, 0.5, 0.75, 1, 1.5, 2, 3, 3.5, 4, 4.5, 5) phosphors. The emission spectra exhibit an emission band ranging from 480 to 650 nm under the 460 nm excitation, which corresponds to the 5d → 4f transition of the Ce3+ ions. The results indicate that with the increasing of Ga3+ ions concentration, the positions of the emission peak of Ce3+ ions show a greatly blue-shift. Meanwhile, the luminous intensity increased gradually first and then decreased and the luminous intensity becomes the strongest when x = 0.75. When Al3+ ions were completely replaced by Ga3+ ions, the sample shows no luminescence.

To explain the phenomenon, we draw the configuration coordinate diagram of YAG:Ce3+, YAGG:Ce3+, and YGG:Ce3+, which is showed in Fig. 4. From Fig. 4, we can find that the 5d energy level curve of Ce3+ will shift to the right with the increasing of Ga3+ ions concentration. Thus, the energy level difference between 5d and 4f in the garnet structure is YGG > YAGG > YAG. Then the luminous intensity of the samples increased with the increase of Ga3+ ions concentration. According to the equation of ΔE = h/λ (where h is Planck constant and λ is the wavelength), the λ will decrease when ΔE increased [11, 12]. But when the dopant volume of Ga3+ is too large, the 5D levels of Ce3+ are buried inside the conductance band that results in absence of Ce3+ luminescence in Y3Ga5O12:Ce3+ at room temperature [13].

As we all know, the optimal concentration of Ce3+ in YAGG:Ce3+ phosphors is affected with the ratio of Ga3+ to Al3+ [10, 12]. Figure 5 shows the emission spectra (a) and excitation spectra (b) of the Y3−yAl4.25Ga0.75O12:Ce3+y (y = 0.02, 0.04, 0.06, 0.08, 0.10, 0.12, 0.14, 0.16) phosphors. The inset shows the trend of wavelength and luminous intensity with Ce3+ concentration. The inset indicates that with the increasing of Ce3+ ions concentration, the positions of the emission peak of Ce3+ ions show a red-shift, while the intensity increased first and then decreased, and the optimal concentration of Ce3+ in Y3−yAl4.25Ga0.75O12:Ce3+y phosphors is y = 0.1.

According to the crystal field theory, the red-shift of the emission spectra of Ce3+ mainly depends on the splitting of the 5d levels. The crystal field splitting (Dq) can be expressed as below:

where Dq represents the extent of energy level separation, Z is the charge of anion, e is the electron charge, r is the radius of the d wavefunction, and R is the bond distance between the Ce3+ and O2−. Ga3+ ions with the bigger ion radius and stronger electronegativity comparing with Al3+ have shorter bond and the stronger interactions with the coordinate O2−, which will induce the ligands of Al3+ sites shrinking [14,15,16]. So, the Dq decreases, and the emission spectra shift to longer wavelength (red-shift).

YAGG:Ce3+ phosphors are not only can be excited by blue light but also can be excited by cathode ray. Figure 6 shows the emission spectra of the Y2.94Al5−xGaxO12:Ce3+0.06 (x = 0, 0.5, 0.75, 1, 1.5, 2, 3, 4, 5) and Y3−yAl3.5Ga1.5O12:Ce3+y (y = 0.004, 0.006, 0.008, 0.01, 0.02, 0.04, 0.06, 0.08, 0.10, 0.12, 0.14) phosphors excited by cathode ray (6 kV). The results shows that the location of the emission peak is similar to the PL spectra, but the optimum concentration of the samples is x = 1.5 and y = 0.04 when they were excited by cathode ray. What’s more, the cathodoluminescence intensity is much higher than that of the PL. It might be because of the energy of cathode ray is higher than blue light. All these results indicate that the YAGG:Ce3+ phosphors are excellent in cathodoluminescence.

Furthermore, we measured fluorescence lifetimes of Ce3+ in Y2.94Al5−xGaxO12:Ce3+0.06 (x = 0, 0.75, 2, 3, 4, 5) phosphors (with emission at 535 nm upon excitation at 330 nm). As displayed in Fig. 7, it is observed that all the decay curves can be well fitted with a single-exponential equation. The lifetime increased first and then decreased with the increasing of the incorporation content of Ga3+ ion, which is accord with the trend of the emission intensity discussed above.

As is known, the thermal quenching is one of the important parameters for phosphors. Figure 8 displays the temperature-dependent luminescence intensity of Y2.94Al5−xGaO12:Ce3+0.06 (x = 0, 0.75, 2, 3, 5) excited by 460 nm, Fig. 8f shows the trend of the normalized emission intensity. The results indicate that all intensities drop gradually with temperature increase and the decline is getting worse with the increase of the concentration of Ga3+. The thermal quenching may be resulted from the two main reasons: (1) The garnet structure of Y2.94Al5−xGaO12:Ce3+0.06 phosphors become more and more relaxed and rigidity gradually decreases with Ga3+ increasing; (2) The thermal ionization is more likely to arise as the Ga3+ concentration increases [17,18,19].

4 Conclusions

A series of Y3−yAl5−xGaxO12:Ce3+y phosphors were successfully synthesized by high temperature solid state reaction method. The diffraction angle decreased gradually with the increase of Ga3+ ions content because of the he lattice expansion. In PL, the critical concentration of Ga3+ ions in Y2.94Al5−xGaxO12:Ce3+0.06 is x = 0.75 and the optimal concentration of Ce3+ in Y3−yAl4.25Ga0.75O12:Ce3+y is y = 0.1. The fluorescence lifetimes of the Y2.94Al5−xGaxO12:Ce3+0.06 phosphors showed a similar trend to the emission intensity. The temperature-dependent luminescence intensity drop gradually with temperature increase and the decline is getting worse with the increase of the concentration of Ga3+. In cathodoluminescence, the optimum concentration of the samples is x = 1.5 and y = 0.04. With the improvement of Ga3+ content, the particle size increased gradually and the dispersion of the particles is getting better.

References

J.Y. Choe, D. Ravichandran, S.M. Blomquist et al., Cathodoluminescence study of novel sol–gel derived Y3-xAl5O12:Tbx phosphors. J. Lumin. 93, 119–128 (2001)

V. Tucureanu, A. Matei, A.M. Avram, Synthesis and characterization of YAG:Ce phosphors for white LEDs. Opto-Electron. Rev. 23, 239–251 (2015)

N. Wei, T.C. Lu, F. Li et al., Transparent Ce:YAG ceramic phosphors for white light-emitting diodes. Appl. Phys. Lett. 101, 216–225 (2014)

H.L. Shi, C. Zhu, J.Q. Huang et al., Luminescence properties of YAG:Ce, Gd phosphors synthesized under vacuum condition and their white LED performances. Opt. Mater. Express 4, 649–655 (2014)

M. Rejman, V. Babin, R. Kucerková et al., Temperature dependence of CIE-x,y color coordinates in YAG:Ce single crystal phosphor. J. Lumin. 187, 20–25 (2017)

G. Feng, W.H. Jiang, Y.B. Chen et al., A novel red phosphor NaLa4(SiO4)3F:Eu3+. Mater. Lett. 65, 110–112 (2011)

W.J. Ding, J. Wang, M. Zhang et al., A novel orange phosphor of Eu2+-activated calcium chlorosilicate for white light-emitting diodes. J. Solid State Chem. 179, 3582–3585 (2006)

K. Ohno, T. Abe, Effect of BaF2 on the synthesis of the single-phase cubic Y3Al5O12:Tb. J. Electrochem. Soc. 133, 638–643 (1986)

M. Mori, J. Xu, G. Okada et al., Scintillation and optical properties of Ce-doped YAGG transparent ceramics. J. Rare Earth 34, 763–768 (2016)

S. Fu, J. Tan, X. Bai et al., Effect of Al/Ga substitution on the structural and luminescence properties of Y3(Al1-xGax)5O12:Ce3+ phosphors. Opt. Mater. 75, 619–625 (2018)

C.C. Chiang, M.S. Tsai, M.H. Hon, Luminescent properties of cerium-activated garnet series phosphor: structure and temperature effects. J. Electrochem. Soc. 155, 2074–2078 (2008)

J. Ueda, S. Tanabe, T. Nakanishi, Analysis of Ce3+ luminescence quenching in solid solutions between Y3Al5O12 and Y3Ga5O12 by temperature dependence of photoconductivity measurement. J. Appl. Phys. 110, 2–6 (2011)

O. Sidletskiy, V. Kononets, K. Lebbou et al., Structure and scintillation yield of Ce-doped Al-Ga substituted yttrium garnet. Mater. Res. Bull. 47, 3249–3252 (2012)

M.M. Shang, J. Fan, H.Z. Lian et al., A double substitution of Mg2+-Si4+/Ge4+ for Al(1) 3+-Al(2) 3+ in Ce3+-doped garnet phosphor for white LEDs. Inorg. Chem. 53, 7748–7755 (2014)

P. Dorenbos, Crystal field splitting of lanthanide 4f 5d-levels in inorganic compounds. J. Lumin. 99, 283 (2002)

J.M. Ogicglo, A. Katelnikovas, A. Zych et al., Luminescence and luminescence quenching in Gd3(Ga,Al)5O12 scintillators doped Ce3+. J. Phys. Chem. A 117, 2479–2484 (2013)

Y.C. Qiang, Y.X. Yu, G.L. Chen et al., Synthesis and luminescence properties of Y2.94Al5-mGamO12:0.06Ce3+ green phosphors for white LEDs. Ceram. Int. 42, 767–773 (2016)

W.M. Yen, M. Raukas, S.A. Basun et al., Optical and photoconductive properties of cerium-doped crystalline solids. J. Lumin. 69, 287–294 (1996)

B.B. Yang, J. Zou, F.C. Wang et al., Optical and reliability properties studies of green YAG phosphors by Ga substitution. J. Mater. Sci.: Mater. Electron. 27, 3376–3383 (2016)

Acknowledgements

This project is financially supported by the National Natural Science Foundation of China (Grant Nos. 51602027, 61307118, and 21501167), the education project of Jilin Provincial Department, China (JJKH20170607KJ). This work was supported by the “111” project of China (D17017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, L., Zhang, X., Zhu, S. et al. Preparation and luminescence properties of Y3−yAl5−xGaxO12:Ce3+y phosphors. J Mater Sci: Mater Electron 29, 9045–9051 (2018). https://doi.org/10.1007/s10854-018-8930-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-8930-6