Abstract

Magnetic full Heusler alloys are extremely important for spintronics because of their half-metallicity. Since they can be synthesized without any rare-earth elements, they are interesting for applications based on their magnetic behavior also. Hence solid solutions of the two Heusler alloys Fe2MnSi and Co2MnSi, Fe2−xCoxMnSi with 0 ≤ x ≤ 0.4 have been synthesized so that their magnetic moment as well as Curie temperature can be tuned. The structural characterization using a combination of X-ray diffraction and Rietveld refinement of the structure shows that all the alloys are single phase with a cubic Fm\(\overline {3}\)m structure. The lattice parameter does not change with Co-substitution in all the alloys. The magnetization studies as a function of temperature clearly shows a paramagnetic to ferromagnetic transition in all the alloys with the Curie temperature increasing from 220 K for x = 0 to ̴ 580 K for x = 0.4. It is found that the re-entrant antiferromagnetic transition observed in x = 0 alloy at 62 K can be suppressed either with a substitution of Co for Fe or by increasing the external magnetic field. The isothermal magnetization shows an extremely soft behavior with low remanence in all the alloys. The saturation magnetic moment is found to increase from 2.5 μB for x = 0 to 3.6 μB for x = 0.4 at 100 K with a simultaneous increase in the magnetocrystalline anisotropy energy density constant from 1.3 × 105 to 3.3 × 105 Jm−3. These results clearly show the capability of magnetic properties tunability of Heusler alloys with substitution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

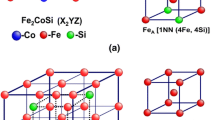

Magnetic materials both hard and soft are key to many applications ranging from household appliances to alternate energy technologies. This requirement has been driving the search for materials with higher specific energy delivery capability. Permanent magnets with rare-earth elements have successfully fulfilled this requirement till date. However, the scarcity of rare-earth elements necessitates development of non-rare-earth based magnets with comparable specific energy densities. In this context, ternary Heusler alloys and their variants have become extremely promising as they offer compositional tunability to design materials with specific magnetic behavior. The versatility offered by these alloys leads to exhibition of a wide variety of behaviors ranging from metallic magnetic to superconducting and topologically insulating [1,2,3,4,5,6]. The magnetic full Heusler alloys with the general formula X2YZ where X is the most electropositive element belonging to groups 3–12 and Z is the most electronegative element belonging to groups 13–16, have a cubic L21 structure made of four interpenetrating sub-lattices. The magnetic moment of these alloys depends on the total valence electron count, VEC and is found to scale linearly exhibiting a Slater-Pauling like behavior. In particular, Co2MnSi based Heusler alloys have been found to exhibit a high magnetic moment with a high Curie temperature T C of ~ 985 K and most importantly a nearly complete polarized conduction electron [7,8,9,10,11]. An analogous alloy Fe2MnSi on the other hand exhibits a ferromagnetic behavior with a low T C of ~ 215 K [12]. A solid solution of these two alloys therefore should facilitate tuning of both the magnetic moment as well as T C . Such alloys can be of potential use in magnetoresistive devices with highly polarized conduction electrons [13,14,15,16].

In the present work, solid solution Heusler alloys Fe2−xCoxMnSi with 0 ≤ x ≤ 0.4 (≤ 20% Fe substitution) have been investigated in detail. The Co2MnSi alloy with a VEC of 29 should have a magnetic moment of 5 μB while the Fe2MnSi alloy with a VEC of 27 has a magnetic moment of 3 μB. As per the Slater-Pauling rule the Fe2−xCoxMnSi alloys should have magnetic moments between these two limiting values and should scale linearly at the rate of 1 μB per electron. Associated with this change in magnetic moment, T C should also scale between 215 and 985 K and thus facilitate controlling the magnetic properties. The magnetic properties of the synthesized solid solutions therefore have been studied both as a function of temperature T and external magnetic field H. The variation of alloy magnetic moment μalloy, T C and effective magnetic anisotropy constant K 1 with amount of Co-substitution have been determined.

2 Experimental methods

The full Heusler alloys Fe2−xCoxMnSi were prepared by arc using melting high purity elements, Fe (99.98%), Co (99.5%), Mn (99.98%) and Si (99.95%), in an inert Ar gas environment. In order to obtain a homogeneous single phase Heusler alloy the ingots were melted several times by flipping before cooling to room temperature. The ingots were then ground to powder for structural characterization and magnetic properties study. The phase identification and crystallographic structure determination were performed by X-ray diffraction using Cu-Kα radiation and FULLPROF structural refinement program respectively. The variation of magnetization M with temperature T and external magnetic field H in the range 2–400 K and ± 20 kOe was studied using a Superconducting Quantum Interference Device (SQUID) detector magnetometer. The variation of M with T has been studied both under field cooled (FC) and zero field cooled (ZFC) conditions in the presence of an external magnetic field. The sample was cooled to 2 K in the absence of external magnetic field and then M was measured as a function of increasing T in the presence of external H—zero field cooled magnetization. Subsequently the sample was cooled to 2 K in the presence of H and then M was measured as a function of increasing T—field cooled magnetization.

3 Results and discussion

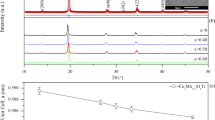

The X-ray diffraction patterns obtained from Fe2−xCoxMnSi alloys are shown in Fig. 1a. The diffraction patterns show peaks corresponding to a cubic single-phase structure in all the alloys. In order to determine the structural space group and position of different atomic species Fe/Co, Mn and Si in the crystallographic structure, Rietveld refinement of the diffraction patterns was performed and the results are shown together with the experimental data in Fig. 1a. The fitting parameters are given in Table 1. It is found that all the alloys are perfectly single phase with a cubic L21 structure corresponding to the space group Fm\(\overline {3}\)m. The clear presence of (111) and (200) superlattice reflections in all the alloys indicates presence of a high degree of chemical order conforming to the L21 structure. The cubic lattice parameter does not change and is found to be nearly constant due to increasing substitution of Co for Fe as seen in Fig. 1b, in contradiction to earlier report of lattice contraction with increasing Co-substitution as per Vagard’s law [17, 18]. This is because of the small difference in atomic radii of Fe, Mn and Co, < 4 pm and complete solubility of the two Heusler alloys, Fe2MnSi and Co2MnSi in each other. The Fm\(\overline {3}\)m structure has three unique atomic positions: 4a (0,0,0), 4b (1/2,1/2,1/2) and 8c (1/4,1/4,1/4) (3/4,3/4,3/4) which can be occupied by Mn, Si and Fe/Co atoms. In the chemically ordered L21 structure Mn-atoms should occupy the 4a sites while the Fe/Co atoms should occupy the 8c sites. However due to their similar atomic radii and electro positivity Fe/Co and Mn can have partial occupancy of 8c and 4a sites leading to chemically disordered DO3 structure [12]. Hence in order to determine the partial occupancy if any of these atoms which can lead to the formation of anti-site defects, Rietveld refinement of the structure was performed with different fractions of these atoms at these sites. It was observed that the goodness of fit of refined structure diffraction data was relatively insensitive to exchange of Mn positions with Si positions while it varied significantly when Mn atoms position was exchanged with that of Fe/Co. The goodness of fit was found to be lowest for occupancies given in Table 1. Therefore, the structural refinement has been performed considering the Fe/Co atoms to be occupying the 8c sites while the Mn atoms are in predominantly 4a sites as given in Table 1. These results clearly show that all the alloys have a high degree of chemical order corresponding to the L21 structure. It should be noted here that exact occupancy of the atoms however can have an effect on the electronic structure and hence the effective magnetic moment. Determination of the detailed band structure with varying occupancy of different species however is beyond the scope of present work and hence the magnetic behaviour is discussed qualitatively.

The variation of magnetization M with T in H of 1 kOe and 10 kOe is shown in Fig. 2a and b respectively for all the alloys, Fe2−xCoxMnSi. All the alloys exhibit a clear paramagnetic to ferromagnetic transition and the Curie temperature T C is found to increase with increasing Co substitution from ~ 220 K for Fe2MnSi to ̴ 580 K for Fe1.6Co0.4MnSi. The low field M exhibits clear thermomagnetic irreversibility in all the alloys which is completely suppressed at high fields of 10 kOe, Fig. 2b. This irreversibility is mainly due to anisotropy and some short-range chemical disorder that exists in the alloys. The presence of magnetic short range disordered entities can also be clearly noticed in the low temperature M variation with Co-substitution which shows non-monotonic changes in a field of 1 kOe, a field lower than the saturation field limit. The base alloy Fe2MnSi exhibits ferromagnetic behaviour in the range 62–220 K. For T < 62 K it undergoes an antiferromagnetic transition due to spin ordering of Mn moments into a canted state. The ground state for this alloy has been found to have canted antiferromagnetic Mn spins at an angle of 60° to the [111] direction [19]. Hence this low temperature transition is referred to as re-entrant temperature T R and is known to be dependent on the chemical composition of the alloy and the magnitude of H. The re-entrant temperature T R in the present work is found to shift to lower temperatures as Co-substitution increases. A substitution of just 5% i.e. Fe1.9Co0.1MnSi lowers T R from 62 to 8 K and for x > 0.1 this transition is completely suppressed. Increasing H on the other hand from 1 to 10 kOe lowers T R from 62 to 55 K in Fe2MnSi showing that the compositional dependence of T R is strong compared to H dependence. Additionally, it is seen that even the thermal history of magnetization affects the transition temperature T R . Field cooling the Fe2MnSi alloy in 1 kOe field shifts T R from 62 to 55 K, clearly showing the irreversible nature of this transition. The magnetic field H which facilitates ferromagnetic alignment of the atomic spins suppresses canting and antiferromagnetic alignment of Mn-spins. These results clearly show that the spin canting phenomenon is a dynamic process whose kinetics depends on thermal history apart from chemical composition and the magnitude of external field H. The variation of M with H in the range ± 20 kOe at 100 K, a temperature at which all the Fe2−xCoxMnSi alloys are in ferromagnetic state is shown in Fig. 3. All the alloys exhibit an extremely soft nature with coercivity ~ 30 Oe and saturation for fields H > ± 2 kOe. The isothermal variation of M with H of Fe2MnSi at different temperatures shown in the inset of Fig. 3 clearly shows paramagnetic behaviour at 400 K and a ferromagnetic behaviour at 100 and 2 K. The saturation magnetic moment μsat at 2 and 100 K is nearly identical, 2.5 μB and 2.7 μB respectively, a feature typical to Mn-based Heusler alloys due to their re-entrant ferromagnetic to antiferromagnetic transition at ~ 62 K. The peak in magnetization at this transition temperature leads to nearly identical moments below and above T R as seen in Fig. 2b. The variation of saturation magnetic moment μsat at 100 K with amount of Co-substitution is shown in Fig. 4a and is found to increase from 2.5 μB for x = 0 to 3.6 μB for x = 0.4. The Curie temperature has been determined from the derivative of magnetization obtained in an external field of 1 kOe, Fig. 2a and is shown in Fig. 4a. The Curie temperature T C is a measure of the strength of ferromagnetic exchange interactions and an increase in T C with increasing Co-substitution indicates strong ferromagnetic interactions in substituted alloys. The variation of TC with amount of Co-substitution shown in Fig. 4a has a near linear variation which facilitates easy tuning for required applications. For the x = 0.2 and 0.4 alloys T C has been obtained by extrapolating the magnetization measured in the temperature range 250–400 K to high temperatures. The alloy with x = 0.1, i.e. Fe1.9Co0.1MnSi exhibits a clear paramagnetic transition above room temperature, 343 K, in disagreement with earlier studies [18] wherein a paramagnetic phase was observed in this alloy at room temperature. This is probably due to high degree of order in the structure and absence of antiferromagnetic clusters. The spin only magnetic moment of Heusler alloys has been predicted to depend on VEC and is given by the relation;

a The variation of saturation magnetic moment µsat at 100 K and Curie temperature T C of the different Fe2−xCoxMnSi alloys increases nearly linearly with amount of Co-substitution. The predicted magnetic moment variation as per Slater-Pauling rule is also shown for comparison. b The magnetocrystalline anisotropy energy constant K1 also shows a steady increase with Co-substitution in the alloys

According to this relation the magnetic moment of Fe2MnSi has to be 3 μB whereas the experimentally determined value is only 2.5 μB. The lower value of magnetic moment is probably because of the presence of antiferromagnetic clusters at 100 K and some DO3 chemical disorder present in the structure. With increasing Co-substitution for Fe the magnetic moment increases significantly due to suppression of formation of the antiferromagnetic clusters in the alloy as well as formation of an ordered structure. The variation of μalloy with Co-substitution has been predicted to follow the Slater-Pauling (SP) rule which states that μalloy should scale with VEC at the rate of 1 μB per electron addition to the alloy. According to this rule the magnetic moment of Fe1.6Co0.4MnSi should be 3.4 μB whereas the experimentally determined value is 3.6 μB corresponding to a rate of increase of ~ 2.6 μB per electron. These results clearly show that Slater-Pauling rule can at best give an estimate of the alloy magnetic moment while the actual magnetic moment of the alloy depends on the exact electronic band structure as well as the extent of chemical order. The discrepancy between the experimentally observed values of saturation magnetic moment and the moment predicted by the SP rule is possibly due to the fact that this rule is based entirely on just the total number of valence electrons and does not take into account factors such as the electronic band structure, long range chemical order and presence of antiferromagnetic clusters. Detailed magnetic moments determination using band structure as well as neutron diffraction indeed shows that they do not exactly follow the SP predictions [16, 20]. The magnetocrystalline anisotropy constant K 1 of the alloys can be determined from the isothermal magnetization variation with H using the law of approach to saturation by the equation [21]

where b is related to magnetocrystalline anisotropy as follows K 1 (=µ 0 M S [105b/8] 1/2 ) and aH signifies the forced magnetization constant. The anisotropy constant K 1 determined for the different Fe2−xCoxMnSi alloys is shown in Fig. 4b. It is seen that K 1 increases with increasing Co-substitution in accordance with magnetic moment and T C variations. The increasing Co-content in the alloys results in increasing spin–orbit coupling which increases the magnetocrystalline anisotropy constant in these alloys.

4 Conclusions

The Heusler alloys Co2MnSi and Fe2MnSi are known to be half-metallic ferromagnetic with possible application in spintronic devices. The magnetic moment of Fe2MnSi however is only 3.0 μB while that of Co2MnSi is 5.0 μB. Their Curie temperatures however vary drastically from ~ 220 to 985 K respectively for the two alloys. Hence in the present work solid solutions of these two Heusler alloys have been synthesized in single phase state and their magnetic properties investigated. The magnetic moment, Curie temperature as well as the magnetocrystalline anisotropy energy are found to increase with increasing Co-substitution for Fe. Qualitatively, this increase is in agreement with the increase in valence electrons count and the associated magnetic properties enhancement. The magnitude of increase however deviates from the simple Slater-Pauling prediction showing that the detailed electronic band structure of the alloys has a strong effect.

References

P.H. Dederichs, I. Galanakis, P. Mavropoulos, Half-metallic alloys: electronic structure, magnetism and spin polarization. J Electron. Microsc. 54, i53–i56 (2005)

C. Palmstrøm, Epitaxial Heusler alloys: new materials for semiconductor spintronics. MRS Bull. 28, 725–728 (2003)

K. Inomata, N. Ikeda, N. Tezuka, R. Goto, S. Sugimoto, M. Wojcik et al., Highly spin-polarized materials and devices for spintronics. Sci. Technol. Adv. Mater. 9, 014101 (2008)

O. Pavlosiuk, D. Kaczorowski, X. Fabreges, A. Gukasov, P. Wisniewski, Antiferromagnetism and superconductivity in the half-Heusler semimetal HoPdBi. Sci. Rep. 6, 18797 (2016)

A.M. Nikitin, Y. Pan, X. Mao, R. Jehee, G.K. Araizi, Y.K. Huang et al., Magnetic and superconducting phase diagram of the half-Heusler topological semimetal HoPdBi. J. Phys. Condens. Matter 27, 275701 (2015)

D. Xiao, Y. Yao, W. Feng, J. Wen, W. Zhu, X.Q. Chen et al., Half-Heusler compounds as a new class of three-dimensional topological insulators. Phys. Rev. Lett. 105, 096404 (2010)

S. Picozzi, A. Continenza, A.J. Freeman, Role of structural defects on the half-metallic character of Co2MnGe and Co2MnSi Heusler alloys. Phys. Rev. B 69, 944231–944237 (2004)

M.P. Raphael, B. Ravel, Q. Huang, M.A. Willard, S.F. Cheng, B.N. Das et al., Presence of antisite disorder and its characterization in the predicted half-metal Co2MnSi. Phys. Rev. B 66, 1044291–1044296 (2002)

H.X. Liu, T. Kawami, K. Moges, T. Uemura, M. Yamamoto, F. Shi et al., Influence of film composition in quaternary Heusler alloy Co2(Mn,Fe)Si thin films on tunnelling magnetoresistance of Co2(Mn,Fe)Si/MgO-based magnetic tunnel junctions. J. Phys D 48, 164001 (2015)

N.V. Dai, M.S. Seo, T.W. Eom, Y.P. Lee, S.J. Lee, M. Jang, Magnetoresistive properties of Co2MnSi heusler alloy films. J. Korean Phys. Soc. 55, 1255–1258 (2009)

K. Moges, Y. Honda, H.X. Liu, T. Uemura, M. Yamamoto, Y. Miura et al., Enhanced half-metallicity of off-stoichiometric quaternary Heusler alloy Co2(Mn,Fe)Si investigated through saturation magnetization and tunneling magnetoresistance. Phys. Rev. B 93, 134403 (2016)

K.A.R. Ziebeck, P.J. Webster, The antiferromagnetic and ferromagnetic properties of Fe2MnSi. Philos. Mag. 34, 973–982 (1976)

Z. Nourbakhsh, The electronic and magnetic properties of half-metal type MnFexCo2–xSi (with x = 0, 0.25, 0.5, 0.75, 1, 1.25, 1.5, 1.75, and 2) alloys. J. Supercond. Nov. Magn. 24, 887–893 (2011)

M. Ležaić, P. Mavropoulos, S. Blügel, H. Ebert, Complex magnetic behavior and high spin polarization in Fe3–xMnxSi alloys. Phys. Rev. B 83, 094434 (2011)

M. Belkhouane, S. Amari, A. Yakoubi, A. Tadjer, S. Méçabih, G. Murtaza et al., First-principles study of the electronic and magnetic properties of Fe2MnAl, Fe2MnSi and Fe2MnSi0.5Al0.5. J. Magn. Magn. Mater. 377, 211–214 (2015)

B. Hamad, Q.-M. Hu, The effect of defects on the electronic and magnetic properties of Fe2MnSi Heusler alloy. Phys. Status Solidi (b), 248, 2893–2898 (2011)

Y. Kondo et al., Magnetic properties of the Heusler alloys Fe2−xCoxMnSi. J. Phys. 150, 042099 (2009)

L. Bainsla et al., Investigation of the quaternary Fe2 – x Cox MnSi (0 ≤ x ≤ 0.6) alloys by structural, magnetic, resistivity and spinpolarization measurements. J. Phys. D 48, 125002 (2015)

P. Mohn, E. Supanetz, Spin ordering in Fe3−x Mn x Si Heusler alloys. Philos. Mag. Part B 78, 629–636 (1998)

S. Ishida et al., Theoretical search of spintronic material in Fe2(Cr1−xMnx)Si and (Fe1−xCox)2MnSi. Mater. Trans. 49, 114–119 (2008)

Y. Melikhov, J. Snyder et. al., The effect of Cr-substitution on the magnetic anisotropy and its temperature dependence in Cr-substituted cobalt ferrite. IEEE Trans. Magn. 42, 2861–2863 (2006)

Acknowledgements

The authors wish to acknowledge the Nanomission, Department of Science and Technology, Govt. of India for financial support and IIT Bombay-Central facilities for magnetic characterization.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Mallick, M.M., Vitta, S. Enhanced magnetic moment and curie temperature due to co-substitution in Heusler alloys Fe2−xCoxMnSi. J Mater Sci: Mater Electron 29, 1420–1425 (2018). https://doi.org/10.1007/s10854-017-8049-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8049-1