Abstract

Polyvinyl alcohol (PVA) complexed with different weight percent ratios of Nickel Bromide (NiBr2) salt were prepared by using solution cast technique. X-ray diffraction analysis confirmed the complexation of the salt with the polymer. Differential scanning calorimetry was used to determine the glass transition and melting temperatures of pure PVA and PVA:NiBr2 complexed films. Electrical conductivity was measured using ac impedance analyzer in the frequency and temperature range 1 Hz–1 MHz and 303–373 K respectively. It was observed that the magnitude of electrical conductivity increases with NiBr2 salt concentration as well as temperature. Frequency dependence electrical conductivity of the complexed polymer electrolyte films follows the Jonscher’s equation. The dielectric behavior was analyzed using dielectric permittivity\(\left( {{\varepsilon ^\prime}} \right)\) and loss tangent \(\left( {\tan \delta } \right)\) of the samples. Relaxation time was determined from the variation of loss tangent with frequency at different temperatures. The modulus spectra indicated the non-Debye nature of the material.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

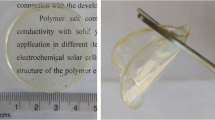

Solid polymer electrolytes (SPEs) are extensively studied in the last two decades because of their numerous technological advantageous such as special mechanical properties, ease of fabrication in thin films of desirable sizes and suitability for electrode–electrolyte contacts in different electrochemical devices such as high-performance solid-state batteries, smart windows, chemical sensors, microelectronic and electrochromic devices [1, 2]. Among different SPEs, PEO is one of the best polymer electrolytes, but it has poor ionic conductivity and mechanical strength at ambient temperature [3]. The development of polymer electrolyte system with high electrical conductivity at ambient temperatures is one of the main objectives in recent polymer research. The conduction in polymer electrolyte takes place in two different ways: one is the charge migration of ions between the coordinate sites of the host polymer and the second is associated with the polymeric chain segmental motion [4].

Efforts have been made to improve the performance of existing polymer electrolytes and find new polymer electrolytes with better electrical and dielectric properties. Vargas and coworkers [5] investigated polyvinyl alcohol (PVA)-based polymer electrolyte for the Vogel–Tamman–Fulcher (VTF) behavior. PVA is a polar polymer having good charge storage capacity, high dielectric strength and it has dopant-dependent electrical properties. PVA has carbon chain backbone with hydroxyl groups attached to methane carbons, these O–H groups can be a source of hydrogen bonding and therefore, assist the formation of polymer complexes [6, 7]. The higher film forming ability, inexpensive and good electronic properties of PVA has some technological advantages in electrochromic devices and fuel cells because of its superior mechanical properties and better ionic conduction. Hence, in the present study PVA has been chosen as host polymer material for preparation of complexed polymer electrolytes.

Polymeric materials forms complexes in combination with suitable metal salts are useful for the development of advanced high-energy electrochemical devices, display devices, and photoelectrochemical cells. Divalent systems are now receiving attention [8, 9] because their charge distribution may produce electrolyte structure different from monovalent systems. Therefore, the NiBr2 salt is chosen as a dopant material to enhance electrical conductivity properties of host PVA matrix. In the present study, we focused our attention on investigating the effect NiBr2 addition on the structural, electrical and dielectric properties of host PVA matrix. In this work, the effect of nickel bromide addition on PVA properties is reported.

2 Experimental

Films (thickness 150 μm) of pure PVA and various compositions of complexed films of PVA with NiBr2 salt were prepared by solution casting technique using double distilled water as a solvent. The solution was vigorously stirred for 10–12 h to get a homogeneous mixture and was cast onto polypropylene dishes and allowed to evaporate at room temperature to remove all traces of solvent. The dried polymer electrolyte films were carefully removed from the polypropylene dishes and stored inside a dry vacuum box. In the present study, X-ray diffraction spectra were recorded at room temperature in the Bragg angle 2θ range from 10° to 70° by a SEIFERT X-ray diffractrometer. CuKα radiation was used along with Zr filter for monochromatic radiation. Differential scanning calorimetry (DSC) measurements were carried out to determine the glass transition and melting temperatures of pure and PVA:NiBr2 complexed polymer electrolyte films. The impedance measurements were carriedout by a computer controlled phase sensitive multimeter (PSM 1700) in the frequency range 1 Hz–1 MHz and temperature range 303–373 K. For electrical measurement the complexed polymer electrolyte films were cut into circular pieces and sandwiched between a pair of stainless steel foils with the configuration SS/polymer electrolyte/SS. The total setup was kept inside a furnace and recorded the electrical measurements with rising temperature upto 373 K, and the temperature was measured by copper–constantan thermocouple.

3 Results and discussion

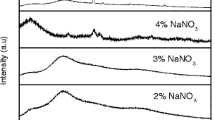

3.1 XRD analysis

The XRD profiles of pure and doped PVA with different weight percentages of NiBr2 complexed polymer electrolyte films are shown in Fig. 1. As can been seen from the figure, the NiBr2 salt XRD pattern exhibits well defined peaks, which indicate its crystalline nature. Pure PVA shows a well defined broad peak centread at 20° and less intensive peak at 23.7°, which attributed to the crystalline phase in the PVA and associated crystalline planes are (101) and (200), respectively [10, 11]. With the addition of salt, the intensity of this peak decreases suggesting a decrease in the degree of crystallinity of the host polymer matrix [12]. This could be due to the disruption of the PVA polycrystalline structure by NiBr2 salt as suggested by Hodge et al. [13]. Hodge et al. reported that the intensity of XRD pattern decreases as the amorphous nature increases with the addition of dopant. This amorphous nature results in greater ionic diffusivity and high ionic conductivity, which can be observed in amorphous polymers having flexible back-bone [14]. In addition to this, the peak at 20° is slightly shifted and the peak at 23.7° is almost disappeared in the NiBr2 doped polymer films, which indication the complex formation. No peaks corresponding to NiBr2 salt were observed in complexed polymer films, indicating the complete dissolution of the salt in the polymer matrix.

3.2 DSC analysis

Differential Scanning Calorimetry (DSC) is a best technique to study the thermal transitions of a polymer matrix. Using this technique the glass transition temperature (\({T_g}\)), melting temperature (T m) and the degree of crystallinity (χc) of the material can be identified. Figure 2 shows the DSC curves of pure PVA and PVA: NiBr2 complexed polymer electrolyte films in the temperature range 300–550 K. From DSC thermo grams it is clear that an endothermic peak was observed around 315–355 K, associated to the glass transition temperature (\({T_g}\)) of the polymer electrolytes. With the addition of NiBr2 salt the \({T_g}\) decreases, this may be due to structural disruption of the host polymer i.e., when the NiBr2 is incorporated into the PVA matrix it will interact with the host polymer and reduces the intermolecular interaction between the polymer chains. The 70PVA:30NiBr2 complexed polymer electrolyte exhibits the low glass transition temperature, which causes the higher segmental motion of the complex polymer electrolyte system. In this system the ions can easily move throughout the polymer matrix i.e., ionic mobility is high. This can help to enhance the ion transportation and 70PVA:30NiBr2 complex system exhibits high electrical conductivity. Further, the observed shift in \({T_g}\) values of the polymer electrolytes in DSC thermograms indicates that the interaction between the polymer and the salt i.e., confirms the complexation [15]. Another endothermic peak was observed around 498–520 K corresponding to the melting point of PVA based polymer electrolytes. Melting temperatures and enthalpies were determined at the endothermic peak and from peak areas respectively. The relative percentage of crystallinity (%χc) was estimated using the equation [16].

where \(\Delta H_{m}^{0}\) is the melting enthalpy of pure PVA and \(\Delta {H_m}\) is melting enthalpy of related NiBr2 complexed PVA. The measured values of glass transition temperature (\({T_g}\)), melting temperature (\({T_m}\)) and relative percentage of crystallinity (% χc) values are listed in Table 1.

From the Table 1 it is clear that \({T_m}\) values and relative crystallinity (χc) decrease with the increase of salt concentration. In addition, the melting endotherm is found to broaden with increase of salt concentration .The decrease in melting temperature and the broadening of the melting endotherm are clear indications of decrease in the degree of crystallinity and dominant presence of amorphous phase. The glass transition temperature (Tg) and χc have been found to be low for 30 wt% NiBr2 doped polymer electrolyte system. The lower values of Tg and χc represents the high amorphous nature of the above mentioned polymer, which is good consistent with the XRD results.

3.3 Total conductivity analysis

The logarithmic plots of the electrical conductivity as a function of angular frequency at different temperatures for PVA: NiBr2 (70:30) is shown in Fig. 3. The rise in conductivity on increasing frequency and temperature is common for disordered semiconductor and polymeric materials [17]. From the figure it is clear that, the plot follows two trends. The first one is frequency independent conductivity i.e., low frequency plateau region. Another one is frequency dependent i.e., high frequency dispersive region which is attributed to the space charge polarization at the blocking electrodes. Low frequency region is associated with the dc conductivity (σ dc) of the complexed polymer electrolyte. In the high frequency dispersion, the ionic conductivity increases with increasing frequency which is associated with the ac conductivity (σ ac) of the polymer electrolyte. DC conductivity values were obtained by taking the intercept of log at zero frequency. Activation energy values (E a) are evaluated from log σ versus 1000/T graphs. These graphs follow the Arrhenius relation. Activation energy values (E a) decreases with increase in salt concentration and the values are given in Table 1.

The total conductivity of polymer electrolytes may be expressed using Jonscher’s universal power law equation [18].

where \(\alpha\) is the temperature dependent frequency exponent, A, is a temperature dependent parameter, \({\sigma _{dc}}\), the dc conductivity and ω = 2πf is the angular frequency. According to the jump relaxation model reported by Funke [19] the power law exponent relates the backhop rate to the site relaxation time as

The high frequency region of ac conductivity data was fit to least square linear lines. The slopes of the least square fit lines gave directly the frequency exponent \(\alpha\) values. The \(\alpha\) values are almost less than unity and decrease with temperature. This range of values suggests that the charge carrier transport is predominantly due to ion hopping. The evaluated \(\alpha\) parameters are shown in Table 1. The low values of \(\alpha \left( {\alpha <1} \right)\) suggests the formation of free sites for Ni2+ ion transport [20].

3.4 Frequency dependant loss tangent analysis

Figure 4 shows the variation of loss tangent with frequency at different temperatures for PVA:NiBr2 (70:30) complexed polymer electrolyte film. Dielectric loss is the electrical energy lost as heat in the polarisation process in the presence of an applied ac field. The dielectric loss is a function of frequency and temperature and is related to relaxation polarization, in which a dipole cannot follow the field variation without a measurable value because of the retarding or frictional forces of the rotating dipoles. The dielectric loss tangent \(\left( {\tan \delta } \right)\) can be defined as tan δ = ε″/ε′. The tan δ increases with frequency, reaches a maximum and thereafter decreases with further increase in frequency. The loss peaks and their shifts with temperature suggest a dielectric relaxation process [21]. Relaxation times of the complex polymer electrolyte films are obtained from the relation \(\omega \tau \approx 1\), where τ is the relaxation time and ω is the angular frequency of the applied signal [22]. The relaxation parameters are calculated and are tabulated in Table 1. As the temperature increases, the charge carriers have been thermally activated and the loss tangent peak shifts towards higher frequency. This indicates that the relaxation time decreases with increase of temperature, which results in increase in the ionic conductivity.

The log (f max) versus 1000/T plot is shown inside the Fig. 4, which follows the Arrhenius behaviour represented by the equation

where \({f_{\max }}\)is the frequency at the relaxation peak, \({f_o}\) is a constant, k is the Boltzmann constant, T is the absolute temperature and \({E_m}\) is the ion migration energy. From the slopes, activation energy \(\left( {{E_m}} \right)\) values were calculated and presented in Table 1. Form the table it is observed that E m values are comparable with the E a values, suggesting that the charge carriers responsible for both relaxation and conductivity are the same.

3.5 Temperature dependent loss tangent analysis

Figure 5 shows the variation of loss tangent (tan δ) with temperature at different frequencies for PVA: NiBr2 (70:30) polymer electrolyte. From the plots, it is clear that a loss peak was observed at 334 K. In general polymers possess three dielectric relaxations, \(\alpha\), β and γ in decreasing order of temperature. For amorphous polymers \(\alpha\)- peak is absent and β and γ peaks occur at temperatures less than the glass transition temperature [23]. The relaxation peak observed at 334 K in the present investigations may be attributed to β relaxation because as it is below the glass transition temperature (the glass transition temperature is about 354.2 K). This relaxation peak may be due to the orientation of the polar groups present in the side group of the polymer. This type of relaxation is called a dipolar group relaxation [24]. In the amorphous phase, dipolar molecules are able to orient from one equilibrium position to another and contribute to absorption over a wide frequency and temperature range [25].

3.6 Modulus analysis

The dielectric modulus spectroscopy provides wider insight on charge transport processes such as relaxation mechanism and ion dynamics as a function of frequency and temperature. It suppresses the effects of electrode polarization to give a clear picture of electrical property inherited in the polymer electrolyte. Figure 6 shows the variation of the normalized imaginary part of the electric modulus as a function of frequency over a range of temperature for PVA:NiBr2 (70:30) polymer electrolyte films. The frequency region below peak maximum determines the range in which charge carriers are mobile on long-range distances and above the peak maximum, the carriers are confined to potential wells being mobile on short distances. The mobility of charge carriers increases with increase in temperature leading to decreased relaxation time with a consequent shift of the peak value in \(M^ {\prime\prime}\) toward higher frequencies. This behaviour suggests that the relaxation is thermally activated, and charge carrier hopping is taking place [26].

The frequency dependence of modulus exhibits non-Debye behaviour defined by the stretched Kohlrausch–Williams–Watts (KWW) function Ø (t). This function represents the distribution of relaxation times in ion-conducting materials [27].

The dielectric modulus can be represented as:

where \({t_\infty }\) the conductivity relaxation time and is the Kohlrausch exponent respectively. Smaller the value of \(\beta\), larger the deviation of relaxation with respect to Debye type relaxation \((\beta =1)\). The parameter \(\beta\) corresponding to all compositions was calculated using the formula \(\beta\) = 1.14/FWHM, and is listed in Table 1. The \(\beta\) values indicate the non-Debye nature of the material which corresponds to long-time slow polarization and relaxation of hopping charges. The increase in the value of \(\beta\) for increasing NiBr2 concentrations is due to an increase in charge–carrier concentration [28].

4 Conclusions

PVA doped with NiBr2 complexed polymer electrolyte films were prepared and their structural, thermal, electrical and dielectric properties were studied by using different experimental techniques. XRD analysis confirmed the complexation of salt with polymer. Thermal analysis indicates that the glass transition temperature and crystallinity are low for PVA:NiBr2 (70:30) polymer electrolyte. Electrical conductivity values increases with increasing salt concentration as well as temperature. The 70PVA:30NiBr2 complexed polymer electrolyte exhibits a low activation energy and high electrical conductivity compared to the other complexed systems. From conduction spectra, values are calculated. The values decrease with increase in salt concentration. From E a and E m values, it may be concluded that the charge carriers responsible for both conductivity and relaxation are same. Modulus analysis shows the non-Debye nature of the polymer electrolyte films. From the observed results, we conclude that the NiBr2 addition will changes the host PVA properties significantly, are useful for electronic devices applications.

References

S. Bhandari, M. Deepa, A.K. Srivastava, S.T. Lakshmikumar, R. Kant, Solid State Ion. 41, 180 (2009)

K. Kiran Kumar, M. Ravi, Y. Pavani, S. Bhavani, A.K. Sharma, V.V.R. Narasimha Rao, J. Membrane. Sci. 454, 200 (2014)

C.V. Subba Reddy, Q.Y. Zhu, L.Q. Mai, W. Chen, J. Appl. Electrochem. 36, 1051 (2006)

D.K. Pradhan, R.N.P. Choudhary, B.K. Samantaray. Mater. Chem. Phys. 115, 557 (2009)

V.H. Zapata, W.A. Castro, R.A. Vargas, B.-E. Mellander, Electrochim. Acta 53, 1476 (2007)

S. Rajendran, M. Sivakumar, R. Subadevi, Solid State Ion. 167, 335 (2004)

C.-W. Liew, K.H. Arifin, J. Kawamura, Y. Iwai, S. Ramesh, A.K. Arof, J. Non-Crystalline Solids 425, 163 (2015)

K. Sownthari, S.A. Suthanthiraraj, Electrochim. Acta 174, 885 (2015)

M.A.G. Martins, C.A.C. Sequeira, J. Power Sources 32, 107 (1990)

S. Guzman-Puyol, L. Ceseracciu, J.A. Heredia-Guerrero, C.G. Anyfantis, R. Cingolani, A. Athanassiou, l.S. Bayer. Chem. Eng. J. 277, 242–251 (2015)

M. Kurumova, D. Lopez, R. Benavente, C. Mijangos, J.M. Perena, Polymer 41, 9265 (2000)

P. Balaji Bhargav, V. Madhu Mohan, A.K. Sharma, V.V.R. Narasimha Rao, Curr. Appl. Phys. 9, 165 (2009)

O.G. Abdullah, S.B. Aziz, D.R. Saber, R.M. Abdullah, R.R. Hanna, S.R. Saeed, J. Mater. Sci. doi:10.1007/s10854-017-6623-1

X. Tang, R. Muchakayala, S. Song, Z. Zhang, A.R. Polu, J. Ind. Eng. Chem. 37, 67 (2016)

R.I. Mohamed, J. Phys. Chem. Solids 61, 1357 (2000)

M. Ravi, S. Song, J. Wang, T. Wang, R. Nadimicherla, J. Mater. Sci. 27, 1370 (2016)

K. Funke, B. Roling, M. Langer, Solid State Ionics 105, 195 (1998)

G. Hirankumar, S. Selvasekarpandian, M.S. Bhuvaneswari, R. Baskaran, M. Vijayakumar, J. Solid State Electrochem. 10, 193 (2006)

N. Shukla, A.K. Thakur, A. Shukla, R. Chatterjee, J. Mater Sci. 25, 2759 (2014)

P. Pissis, G. Georgoussis, V.A. Bershtein, E. Neagu, A.M. Fainleib, J. Non-Cryst. Solids 305, 150 (2002)

B. Tareev, Physics of Dielectric Materials (MIR Publications, Moscow, 1979)

M. Marzantowicz, J.R. Dygas, F. Krok, Z. Florjanczyk, E. Zygadto-Monikowska, J. Non-Cryst. Solids 353, 4467 (2007)

L. Fan, Z. Dan, G. Wei, C.W. Nan, M. Li, Mater. Sci. Eng. B 99, 340 (2003)

S. Sen, P. Pramanik, R.N.P. Choudhary, Appl. Phys. A 82, 549 (2006)

M. Ravi, S. Bhavani, K. Kiran Kumar, V.V.R. Narasimha Rao, Solid State Sci. 19, 85 (2013)

A.K. Kulkarni, P. Lunkeneheimer, A. Loidl, Mater. Chem. Phys. 63, 93 (2000)

G. Williams, David C. Watts, Trans. Faraday Soc. 66:80 (1970)

K. Kiran Kumar, M. Ravi, Y. Pavani, S. Bhavani, A.K. Sharma, V.V.R Narasimha Rao, J. Non-Cryst. Solids 358:3205 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhavani, S., Ravi, M., Pavani, Y. et al. Studies on structural, electrical and dielectric properties of nickel ion conducting polyvinyl alcohol based polymer electrolyte films. J Mater Sci: Mater Electron 28, 13344–13349 (2017). https://doi.org/10.1007/s10854-017-7171-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7171-4