Abstract

Polycrystalline CuO thin film was deposited by reactive RF magnetron sputtering technique. The samples obtained from CuO film were annealed in air for different times. The structural, compositional and optical properties of unannealed and annealed samples were characterized. The SEM studies showed that the samples have a homogeneous surface morphology. All of the samples exhibited strong \((\bar{1}11)\) diffraction peak and optical transmittance above 70%. As the annealing time was increased, the grain size increased and the optical band gap decreased.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Copper oxides have considerable importance in improving the electrical performance of p-type thin-film transistors (TFTs) [1–3]. Until recently, the copper oxides have attracted great interest because of their applications in the fields of energy collection and storage such as solar cells, lithium-ion batteries and photoelectrochemical cells (PECs) [4, 5]. Among the copper oxides, CuO (tenorite, cupric oxide) is one of the most widely used absorber layers in solar cells due to its narrow optical band gap [6–8]. Most of the modern applications require CuO thin films. In order to improve the performance of devices, many researchers have studied the effect of annealing temperature on the physical and chemical properties of CuO thin films. In our previous work [9], we have also reported the changes in the structural and optical properties of CuO thin film annealed at temperatures up to 600 °C. However, a limited number of studies have investigated the influence of annealing time. Therefore, in this study, CuO thin film samples were annealed at 400 °C for different times. The samples were analyzed for morphological, optical properties, elemental composition and phase.

2 Experimental

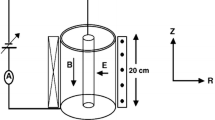

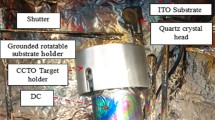

CuO thin film was deposited using a magnetron sputtering system (NANOVAK). The microscope glass slide was used as substrate. The substrate (20 mm × 20 mm) was washed ultrasonically in acetone and methanol for 10 min and then dried in air. The cleaned substrate was placed on a rotating and temperature-controlled substrate holder in the deposition chamber. The copper target with a purity of 99.999% was presputtered for 10 min before film deposition. Then, CuO thin film was grown under the sputtering conditions given in Table 1. The deposited thin film was cut into pieces of equal size. The prepared samples were annealed at 400 °C in air for 2, 4 and 6 h. The samples were coated with gold for morphological analysis. The surface morphology, chemical composition, crystal phase and optical properties of the thin film samples were characterized by SEM (JEOL JSM-7001F), EDX detector (OXFORD INCA), X-ray diffractometer (RIGAKU SmartLab) and UV–Vis Spectrometer (Perkin Elmer Precisely Lambda 45), respectively. CuKα1 radiation was used for XRD analyses (\(\uplambda_{{{\text{CuK}}\upalpha_{1} }} = 1.544\) Å).

3 Results and discussion

Figure 1 presents the SEM images of the thin film samples. The surface morphologies of the samples consist of the grains separated by voids. The grains have a random and uniformly distribution. The arrayed small grains in the unannealed sample are remarkable. After the annealing at 400 °C, these grains disappeared and the new grains appeared. Actually, the large grains produced by recrystallization replaced the small grains. The large grains in the coalescence stage can be seen from the SEM images. The individual grains approached a uniform size and tended toward a spherical shape at the annealing times of 4 and 6 h (Fig. 1c, d). The longer annealing time produced the coarser grains. The unannealed sample has a small grain size in the range of 7–60 nm. The grain size of the samples annealed for 2, 4 and 6 h lies in the range ~15–88, 10–72 and 13–99 nm, respectively. No surface cracks were observed in the SEM images. The EDX spectra in Fig. 2 were obtained from the whole region with X50000 magnification for each film sample. The EDX results given in Table 2 disclose that the samples have CuO composition. Furthermore, a silicon (Si) peak was not observed in the EDX spectra. Therefore, there is no contribution of substrate elements to the EDX results.

Figure 3 illustrates the XRD patterns of the samples. The XRD peaks were indexed by JCPDS card no. 01-080-0076 (a = 4.6797 Å, b = 3.4314 Å, c = 5.1362 Å, β = 99.262°). It has been identified that the thin film samples are polycrystalline and have a monoclinic crystal structure. The annealing process in air did not change the phase of CuO thin film. Because, the oxygen in the air penetrated into the film structure during annealing. The XRD finding supports the accuracy of EDX results. However, the samples showed a strong \((\bar{1}11)\) diffraction peak. The main peaks were located at high diffraction angles as a result of prolonged annealing. This peak shift toward high angles indicates that the residual stresses in the samples can be reduced by annealing [10]. The high-intensity and sharp XRD peaks reveal the well-crystallization [11–13].

The transmittance spectrums of the unannealed and annealed samples are shown in Fig. 4. The transparency was affected by the variation in grain size. Beyond 4 h’ annealing time, the light transmission of the film did not change markedly. All the samples exhibited the optical behaviour of an opaque material below a certain wavelength. The variation of peak position in Fig. 4 revealed that the absorption edge at about 540 nm was shifted to approximately 575 nm.

The allowed direct optical band gap (E g) for all the film samples was estimated from the following equation:

where A is a constant, h is Planck’s constant, α is absorption coefficient and ν is frequency [14–16]. The optical band gap values were determined from the graph of (αhν)2 versus hν (Fig. 5). The band gap of the unannealed sample was found to be 2.299 eV. After annealing for 2, 4 and 6 h, the band gap value dropped off to 2.207, 2.199 and 2.159 eV, respectively. Figure 6 shows the reduction in the band gap value as a function of annealing time. This result is due to the absorption edge shifting toward longer wavelengths in visible range [17, 18]. However, the annealing atmosphere is one of the main factors affecting the optical band gap [19].

4 Conclusion

The nanostructured CuO film was prepared by reactive RF magnetron sputtering. The time-dependent annealing caused significant changes in the morphological and optical properties of film. The XRD results showed that the annealed samples have a single CuO monoclinic phase. The EDX studies confirmed these results. The unannealed and annealed samples are highly transparent. The long annealing time led to an increase in the grain size and a decrease in the optical band gap. As compared with previous studies, these findings have demonstrated that the annealing temperature is a much more dominant factor than annealing time.

References

J. Sohn, S.-H. Song, D.-W. Nam, I.-T. Cho, E.-S. Cho, J.-H. Lee, H.-I. Kwon, Semicond. Sci. Technol. 28, 1 (2013)

E. Fortunato, P. Barquinha, R. Martins, Adv. Mater. 24, 2945 (2012)

K.C. Sanal, L.S. Vikas, M.K. Jayaraj, Appl. Surf. Sci. 297, 153 (2014)

M.F. Al-Kuhaili, Vacuum 82, 623 (2008)

A.H. Jayatissa, K. Guo, A.C. Jayasuriya, Appl. Surf. Sci. 255, 9474 (2009)

S. Visalakshi, R. Kannan, S. Valanarasu, H.-S. Kim, A. Kathalingam, R. Chandramohan, Appl. Phys. A 120, 1105 (2015)

C.R. Gobbiner, A.V.M. Ali, D. Kekuda, J. Mater. Sci. Mater. Electron. 26, 9801 (2015)

R. Shabu, A.M.E. Raj, C. Sanjeeviraja, C. Ravidhas, Mater. Res. Bull. 68, 1 (2015)

U. Akgul, K. Yildiz, Y. Atici, Eur. Phys. J. Plus 131(89), 1 (2016)

J.F. Chang, W.C. Lin, M.H. Hon, Appl. Surf. Sci. 183, 18 (2001)

F.A. Harraz, A.A. Ismail, S.A. Al-Sayari, A. Al-Hajry, J. Photochem. Photobiol. A 299, 18 (2015)

K. Huang, Q.N. Ling, C.H. Huang, K. Bi, W.J. Wang, T.Z. Yang, Y.K. Lu, J. Liu, R. Zhang, D.Y. Fan, Y.G. Wang, M. Lei, J. Alloys Compd. 646, 837 (2015)

Y. Zhang, J. Gu, M. Murugananthan, Y. Zhang, J. Alloys Compd. 630, 110 (2015)

J. Zhao, R. Liu, Z. Hua, Superlattice Microstruct. 81, 243 (2015)

L. Chabane, N. Zebbar, M.L. Zeggar, M.S. Aida, M. Kechouane, M. Trari, Mat. Sci. Semicond. Proc. 40, 840 (2015)

U.C. Bind, R.K. Dutta, G.K. Sekhon, K.L. Yadav, J.B.M. Krishna, R. Menon, P.Y. Nabhiraj, Superlattice Microstruct. 84, 24 (2015)

M. Thambidurai, N. Muthukumarasamy, A. Ranjitha, D. Velauthapillai, Superlattice Microstruct. 86, 559 (2015)

P.B. Nair, V.B. Justinvictor, G.P. Daniel, K. Joy, V. Ramakrishnan, D.D. Kumar, P.V. Thomas, Thin Solid Films 550, 121 (2014)

U. Akgul, Ph.D. Thesis, Firat University, Turkey (2015)

Acknowledgements

This study was supported by Scientific Research Projects Coordination Unit of Firat University (Project No. 1386).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akgul, U., Yildiz, K. & Atici, Y. Influence of annealing time on the physical properties of reactively sputtered CuO thin film. J Mater Sci: Mater Electron 28, 4758–4762 (2017). https://doi.org/10.1007/s10854-016-6120-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-6120-y