Abstract

Tb-doped BiFeO3 nanoparticles were prepared using sol–gel method. The effect of Tb substitution on crystal structure and magnetism of BiFeO3 nanoparticles were investigated. It is shown that the crystal structure and magnetism of BiFeO3 nanoparticles are regulated by rare-earth Tb substitution. Particularly, the sizes of the particles are reduced to smaller than 100 nm after doping with Tb. The magnetization of Tb-doped BiFeO3 nanoparticles has been enhanced in magnitude, which is mainly attributed to the suppression of spin cycloid structure belonging to R3c phase fraction in the process of rhombohedral-to-orthorhombic structural phase transformations. At the meantime, the magnetic hysteresis loops show exchange bias towards negative axis. The exchange bias behaviors originate from the coupling interaction between antiferromagnetic core and ferromagnetic surface. The present work provides a route regulating the magnetization of BiFeO3 particles as well as further promoting its applications in multiferroic materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Multiferroics are defined within this context for materials in which there is a coexistence and coupling of ferroelectric and magnetic ordering parameters [1]. Such magnetoelectrically coupled materials exhibit the ability to switch the magnetic state upon the application of an electric field or vice versa. Multiferroics could create new opportunities for nonvolatile memories with lower power consumption, fast switching speed, and more robust cycling characteristics, as well as other novel spintronic-based applications such as antennae, motors, or sensors [2]. As one of most outstanding multiferroic material, BiFeO3 has attracted enormous curiosities because of its high ferroelectric Curie temperature (TC ~ 1103 K) and G-type antiferromagnetic order below Néel temperature (TN ~ 643 K) [3, 4], which makes it favorable to exhibit magnetoelectric coupling at and above room temperature. Multiferroic BiFeO3 based heterostructures have captured immense interest due to their potential applications in nondestructive and high density integrated memory devices [5, 6]. However, the G-type antiferromagnetic order and this spin structure which modified by a spin cycloid with periodicity of 62 nm along axis cancel the net macroscopic magnetization and inhibit linear magnetoelectric effect [7].

Hence, suppressing the spiral spin structure becomes an important route to enhance the magnetic properties. At present, there are two ways to suppress the spiral spin structure. One is to result in lattice mismatch with larger or smaller cations substitution at A-site or B-site. The rare earth ion substitution at Bi-site has been already established to achieve magnetic enhancement in BiFeO3 via destroying its structure [8]. Another is to make the particle size smaller than 62 nm by increasing dopant concentration and other methods for preparing or applying external force [9–11]. Enhanced magnetism was detected in the BiFeO3 nanorods under room temperature owing to the small diameters [12]. Therefore, size dependent magnetic properties of multiferroic BiFeO3 nanoparticles has been investigated widely and to some degree improved the magnetism [13, 14]. Moreover, uncompensated spins at the surface have been confirmed in this size dependent system through following experiments: one indicated that Fourier Transform Infrared Spectroscopy (FTIR Spectroscopy) peaks of BiFeO3 nanoparticles shift to lower wave number with the decreasing particle size [15], another also shown a shift towards negative axis in the magnetic hysteresis (M–H) loop of BiFe0.95Sc0.05O3 [16]. Though, remarkable achievements have been obtained in both of two systems respectively. Up to now, there is little discussion combined the effect of the crystal structural distortion and the size of nanoparticles on the magnetic properties by regulating rare earth ions substitution. Though rare-earth Tb possesses large magnetic moment, it does not help modulate the magnetic structure of BiFeO3 with its magnetic moment because no long-range magnetic ordering forms in the crystal lattice [17]. And it owns a smaller ionic radius than Bi ion so that Tb ions could enter Bi sites easily. Therefore, it is properly that substituting Bi with Tb to study how the doped cations affect the structure and magnetization magnetism of BiFeO3 particles. Bi1−xTbxFeO3 (x = 0, 0.5, 0.1, 0.15 and 0.2) polycrystalline nanoparticles were prepared in this work. The samples have been characterized by several instruments. Following two distinct facts motivate the progress of present work: (a) both lattice constants and interplanar distance reduced with increasing Tb concentration, (b) the magnetic hysteresis (M–H) loops show the exchange bias towards negative axis. The origins of the effect of doping concentration on the structure and magnetism are discussed in detail.

2 Experiment details

The pure and Tb-doped BiFeO3 nanoparticles were prepared using sol–gel method. The precursor materials, including Bi(NO3)3·5H2O (3 % excess), Tb(NO3)3·6H2O and Fe(NO3)3·9H2O with the concentration of 0.025 mol/L in stoichiometric cation ratio were first mixed into dilute nitric acid (HNO3:H2O = 4:1). After stirred at 60 °C for 1 h, C4H6O6 with the concentration of 0.025 mol/L was also dissolved in above solutions. Then, the solutions were stirred at 60 °C for 3 h unceasingly and dried in hot air oven at 150 °C for about 5 h. Finally, the samples were sintered at 550 °C for 3 h and grinded. X-ray diffraction (XRD, Panalytical Empyrean) measurements were performed with Cu-Kα radiation source to analyze the crystal structure of Bi1−xTbxFeO3 particles. The crystal structural phase transformation was analyzed using Rietveld crystal structure refinement software, General Structure Analysis System (GSAS). Further evidence for the quality and composition of the particles was obtained from X-ray photoelectron spectra (XPS) studies. Transmission electron microscopy (TEM) images of the samples were taken through a FEI F20 electron microscope with an accelerating voltage of 200 kV. Physical Property Measurement System (PPMS) was used to measure M–H loops.

3 Results and discussion

Figure 1a shows the XRD patterns of the pure and Tb-doped BiFeO3 particles. The pure BiFeO3 agrees well with the R3c space group of rhombohedral structure as the (104) and (110) diffraction peaks are almost completely separated. With the increasing of Tb-doped concentration x from 0 to 0.20, the positions of all the peaks shift towards higher 2θ values, which originates from a structural distortion of BiFeO3 lattice due to the smaller radius of Tb3+ (~0.923 Å) than that of Bi3+(~1.03 Å). Notably, some peaks merge in 10 % Tb-doped BiFeO3 such as: (104) and (110), (006) and (202) etc. And some new diffraction peaks belonging to Pbnm space group appear in Bi1−xTbxFeO3 (x = 0.15, 0.2) nanoparticles, for instance: (111), (020), (021) etc. All the phenomena above indicating a new structure like Pbnm has joined in this crystal, which result in lattice distortions. These lattice distortions show a possible influence on the lattice parameter of Tb-substituted BiFeO3 nanoparticles.

Figure 1b further gives an expanded view on the location of diffraction peaks in the range of 20°–35° (2θ). It shows that the peak positions of diffraction peaks shift toward higher diffraction angle 2θ value with the increase of Tb doped concentration, which means that the lattice parameter of BiFeO3 particles is shortened after doping Tb. The corresponding degree of distortion induced by the dopants in perovskite structure was calculated using Goldschmidt tolerance factor [18]:

where rA is the ionic radius of the A-site cations, rB is that of B-site cations, and rO is O anions, respectively. In an ideal cubic perovskite without the tilt of oxygen octahedral, the corresponding value of tolerance factor τ exactly equals 1 [19], while the tolerance factor value of Bi1−xTbxFeO3 was calculated to be 0.8404, 0.8385, 0.8367, 0.8348 and 0.8330 for x = 0, 0.05, 0.1, 0.15 and 0.2 respectively, which indicates that the distortion increases with the increase of dopants. This kind of distortion arises on account of Tb3+ owning smaller radius than that of Bi3+, which leads to the smaller average A-site ionic radius of Tb-doped BiFeO3. This size mismatch between the two A-site cations (Tb3+ and Bi3+) gives rise to the chemical stress effect and makes the original R3c structure unstable [20]. Meanwhile, Fe–O and Bi–O bonds are under compression and tension, respectively [21]. In order to relieve chemical stress and gain the stabled structural, the lattice parameters (a, c) and unit cell volume (V) belonging to R3c phase decreased. For the sake of confirm this distortion and phase transformation, the XRD patterns were analyzed using the Rietveld refinement method with the GSAS software to calculate the lattice parameters and phase fraction.

Figure 2 exhibits the results of Rietveld refinements. And the optimal goodness of fit [χ2 (less than 1)] and R-factors [Rp (less than 0.06), Rwp (less than 0.09)] as numerical criteria of the fitting quality were obtained. All of the unit cell parameters and reliability factors obtained from the Rietveld refinement analysis are summarized in Table 1. It is shown that pure BiFeO3 are indexed by a rhombohedral structure (R3c), while other samples are indexed by multi-phase states mixed by rhombohedral and orthorhombic (Pbnm) structure. The normalized unit cell parameters including a, c and c/a with the reference of R3c phase show as a function of Tb-doped concentration. From x = 0 to 0.2, the fraction of R3c phase gradually reduces from 1 (x = 0) to 0.7849 (x = 0.05), 0.6695 (x = 0.10), 0.4590 (x = 0.15) to 0.0296 (x = 0.2), respectively. At the same time, the lattice parameters (a, c, V) belonging to R3c phase in the coexistent structural state clearly present a gradual reduction. These changes of unit cell parameters belonging to R3c phase put down to the lattice distortion occurring in the structural transformation from R3c to Pbnm space group due to the smaller ionic radius of Tb3+ than that of Bi3+. When Tb doping concentration reaches to 20 %, the crystal structure almost completely belongs to Pbnm space group especially.

X-ray photoelectron spectroscopy (XPS) is an excellent technique to investigate the chemical composition and the charge state of the elements presented in the compound [22]. The survey spectrum in Fig. 3a confirms the presence of Bi, Fe, and O in the prepared BiFeO3 sample. The oxidation states of Fe in BiFeO3 nanoparticles were also investigated. The representative scans of the Fe2p lines of the pure and Tb-doped BiFeO3 nanoparticles are shown in Fig. 3b. It is shown that all the positions of Fe 2p3/2 lines are at around 710 eV, which means the coexistence of Fe3+ and Fe2+ states [17]. Thus, a detailed examination of the oxidation states of Fe ion is carried out through the peak fitting analysis. The positions of Fe 2p are expected to be at 711 eV for Fe3+ and 709.5 eV for Fe2+ [23]. The fitting analysis results of Fe 2p3/2 peaks of Bi1−xTbxFeO3 (x = 0, 0.05, 0.1, 0.15 and 0.2) are shown in Table 2. It is worth noting that the fraction of Fe3+ increases with the doping concentration of Tb concentration, implying a higher content of Fe3+ and lower content of Fe2+ after doping with Tb. Thus Tb substitution could depress oxygen vacancies. Apart from this, both the Fe3+ and Fe2+ peaks fitting lines shift to higher bonding energy, which agrees well with the results obtained from Goldschmidt tolerance factor theory that Fe–O bonds are under compression.

To investigate the effect of Tb substitution on the size of particles, TEM images are shown in Fig. 4. It is shown that the average size of particles calculated from the images in Fig. 4 is 147.05 nm (x = 0), 55.71 nm (x = 0.05), 49.88 nm (x = 0.1), 27.45 nm (x = 0.15), 28.48 nm (x = 0.15), 70.32 nm (x = 0.2), respectively. Noticed that the pure BiFeO3 particles are bigger, which are bigger than 100 nm. While the average size of Tb-doped BiFeO3 particles is smaller than 100 nm, and the particle size decreases with the Tb doping concentration increasing from 0.05 to 0.15. The reduction in particle size is attributed to the addition of Tb3+ ions in BiFeO3 lattice, which depresses the grain growth. Furthermore, it is clearly observed that the average sizes of particles become more and more smaller with the increasing of Pbnm fraction, when the two phases mentioned above coexist. However, as Tb-doped concentration reaches 0.2, the particle grows large conversely because the crystal structure almost transfers to Pbnm space group. Overall, when only R3c or Pbnm structure exits, particles can grow lager easily.

Figure 5 shows the high resolution TEM images where pronounces lattice fringes, which indicates very good level of crystallinity. Through TEM data analysis software Gatan Digitalmicrograph, the distance between two crystal planes of Bi1−xTbxFeO3 is found to be 0.282 nm [(104) in R3c], 0.281 nm [(104) in R3c], 0.278 nm [(112) in Pbnm], 0.280 nm [(020) in Pbnm], 0.277 nm [(112) in Pbnm], 0.271 nm [(200) in Pbnm] for x = 0, 0.05, 0.1, 0.15, 0.15 and 0.2, respectively. Although the interplanar distance above is not from the same crystal planes, the result is in great agreement with interplanar distance calculated from X-ray diffraction showing in Fig. 2. Thus, it is easy to draw a conclusion that the interplanar distance decreases with the increasing of Tb doping concentration compared with the same crystal plane. This result agrees well with the conclusion drawn from XRD Rietveld refinements that unit cell volume (V) decreases with the increasing of Tb doping concentration.

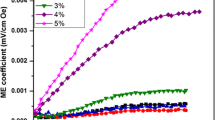

Figure 6 shows magnetic hysteresis loops of the pure and Tb-doped BiFeO3 nanoparticles at room temperature. The pure BiFeO3 demonstrates linear M–H loop with a shift towards negative axis, and its exchange bias field (H eb) equals 100 Oe, as shown in Fig. 6b which indicates that the system exists exchange coupling effect. Bulk BiFeO3 exhibits G-type antiferromagnetic order below Néel temperature [24], so it acts as an antiferromagnetic core. According to the model proposed by Néel for antiferromagnetic nanoparticles based on the presence of two sublattices: one with spins up and another with spins down at the surface. Any imbalance in the number of spins at the surface is the origin of a net magnetic moment in “antiferromagnetic” nanoparticles below the ordering temperature of spins [25]. Because the size of grain is smaller than that of bulk BiFeO3, long-range antiferromagnetic order frequently interrupted by grain surface, so uncompensated spins formed at the surface. Compared with bulk BiFeO3, the decrease of grain size in this work makes the surface-to-volume ratio increase, therefore, the role of the surface in the magnetism behaves more important. Indicating that the system exists exchange coupling effect between antiferromagnetic core and ferromagnetic surface. As 5 % Tb was doped, remanent magnetization (M r), spontaneous magnetization (M s) and coercivity (H c) are increased to 0.0469 emu/g, 0.0236 emu/g and 2208.5Oe, respectively, however, H eb decreases to 39.5 Oe, as shown in Fig. 6c. The average size of particles is reduced to 55.71 nm leading to uncompensated spins increased at the surface and strengthened the magnetism in this system. At the same time, Tb3+ substituting for Bi3+ gives rise to uncompensated spins around Tb3+ in antiferromagnetic core which can also strengthen the magnetism [26]. Therefore, the destruction of the long-range antiferromagnetic orders would result in the thinner antiferromagnetic layer, which abates the antiferromagnetic pinning effect. So M r and H c increase and H eb decreases. When Tb doping concentration reaches 10 %, M r, M s, H c and H eb are increased to 0.0817, 0.0314 emu/g, 2555.5 and 50.5 Oe, separately, as shown in Fig. 6d. Both the reduction of the average particle size (49.88 nm) and increase of Tb3+ substitution result in the improvement of magnetism. So exchange bias field increased either. When Tb-doped concentration x reaches to 0.15, M r and M s decrease, while H c increased slightly. With the average particle size reducing to 27.45 nm, uncompensated spins increase at the surface, which causes the enhanced magnetism. But it is invalid to create additional uncompensated spins by increasing the doping concentration further. Because ions with uncompensated spins in antiferromagnetic layer will be replaced conversely [26], which decreased the magnetism causing magnetic layer became thinning and exchange bias field increased to 129 Oe accompanied with coercive field increased slightly. With Tb-doping concentration increasing to 20 %, M r and H c decreases, and almost no spontaneous magnetization phenomenon existed, as shown in Fig. 6f. In addition, uncompensated spins decreased on account of the increase of average particle size and too much dopant. Overall, ferromagnetism and antiferromagnetism became weaken, and the samples presented paramagnetic [27].

Anyway, it is legitimate to infer that the change of magnetism for Bi1−xTbxFeO3 (x = 0.05, 0.1, 0.15, 0.2) nanoparticles is attributed to following factors. First of all, a small amount of doping ions make uncompensated spins generate around it and distort its cyclical spin spiral structure belongs to R3c space group. Therefore, the net magnetic moments locked within spiral spin structure are released so that the values of the M r, M r and Hc increase gradually with the increase of the Tb-doped concentration x from 0.05 to 0.1. While doping ions increase from 15 % to 20 %, the uncompensated spins in antiferromagnetic layer are replaced by excess doped ions and results in the weaken magnetism, meanwhile, Pbnm phase becomes dominated which is certified by Rietveld refinements. Secondly, the reduction of particles size causes uncompensated spins augmenting at the surface and to some extent enhancing the magnetism of the samples. Besides, the reduction of Fe2+ with the doping concentration increasing leads to the decreasing of magnetism to some degree.

4 Conclusions

The pure and Tb-doped BiFeO3 nanoparticles were prepared using sol–gel method. Tb substitution can reduce the oxygen vacancy and enhance the magnetism. The enhancement of magnetism is attributed to the distortion of the crystal structure and reduction of particle size. Tb substitution suppresses the spiral spin structure and releases the net magnetic moment. At the same time, the reduction of the particle size makes the uncompensated spins at the surface play more important role. The influence of ferromagnetism at the surface becomes more remarkable and the samples demonstrate weak coupling behavior. The present work provides a route to regulate the magnetism of BiFeO3 materials.

References

F.Z. Huang, Z.J. Wang, X.M. Lu, J.T. Zhang, K.L. Min, W.W. Lin, R.X. Ti, T.T. Xu, J. He, C. Yue, J.S. Zhu, Peculiar magnetism of BiFeO3 nanoparticles with size approaching the period of the spiral spin structure. Sci. Rep. 3, 2907 (2013)

C.D. Pham, J. Chang, M.A. Zurbuchen, J.P. Chang, Synthesis and characterization of BiFeO3 thin films for multiferroic applications by radical enhanced atomic layer deposition. Chem. Mater. 27, 7282 (2015)

M. Arora, P.C. Sati, S. Chauhan, H. Singh, K.L. Yadav, S. Chhoker, M. Kumar, Structural, magnetic and optical properties of Bi−xDyxFeO3 nanoparticles synthesized by sol–gel method. Mater. Lett. 96, 71 (2013)

B. Hu, J.F. Wang, J. Zhang, Z.B. Gu, S.T. Zhang, Synthesis, structures and properties of single phase BiFeO3 and Bi2Fe4O9 powders by hydrothermal method. J. Mater. Sci. Mater. Electron. 26, 6887–6891 (2015)

L. Feng, S.W. Yang, Y. Lin, D.L. Zhang, W.C. Huang, W.B. Zhao, Y.W. Yin, S.N. Dong, X.G. Li, Effects of Interface layers and domain walls on the ferroelectric-resistive switching behavior of Au/BiFeO3/La0.6Sr0.4MnO3 heterostructures. ACS Appl. Mater. Interfaces 7, 26036 (2015)

G. Tian, F.Y. Zhang, J.X. Yao, H. Fan, P.L. Li, Z.W. Li, X. Song, X.Y. Zhang, M.H. Qin, M. Zeng, Z. Zhang, J.J. Yao, X.S. Gao, J.M. Liu, Magnetoelectric coupling in well-ordered epitaxial BiFeO3/CoFe2O4/SrRuO3 heterostructured nanodot array. ACS Nano 2016, 10 (1025)

M. Arora, S. Chauhan, P.C. Sati, M. Kumar, S. Chhoker, Evidence of spin-two phonon coupling and improved multiferroic behavior of Bi1−xDyxFeO3 nanoparticles. Ceram. Int. 40, 13347 (2014)

Y.J. Wu, J.G. Wan, C.F. Huang, Y.Y. Weng, S.F. Zhao, J.M. Liu, G.H. Wang, Strong magnetoelectric coupling in multiferroic BiFeO3–Pb(Zr0.52Ti0.48)O3 composite films derived from electrophoretic deposition. J Appl. Phys. Lett. 93, 192915 (2008)

J.L. Mi, T.N. Jensen, M. Christensen, C. Tyrsted, J.E. Jørgensen, B.B. Iversen, High-temperature and high-pressure aqueous solution formation, growth, crystal structure, and magnetic properties of BiFeO3 nanocrystals. Chem. Mater. 23, 1158 (2011)

X.G. Huang, J. Zhang, W.F. Rao, T.Y. Sang, B. Song, C.P. Wong, Tunable electromagnetic properties and enhanced microwave absorption ability of flaky graphite/cobalt zinc ferrite composites. J. Alloys Compd. 662, 409 (2016)

X.G. Huang, J. Zhang, Z.H. Liu, T.Y. Sang, B. Song, H.L. Zhu, C.P. Wong, Facile preparation and microwave absorption properties of porous hollow BaFe12O19/CoFe2O4 composite microrods. J. Alloys Compd. 2015, 648 (1072)

Y. Deng, D. Wu, Q. Chen, Y.W. Du, Synthesis, microstructure, magnetic properties and Raman scattering of single-crystalline BiFeO3 nanorods prepared by hydrothermal technique. Optoelectron. Adv. Mater. 6, 370 (2012)

A. Jaiswal, R. Das, K. Vivekanand, P.M. Abraham, S. Adyanthaya, P. Poddar, Effect of reduced particle size on the magnetic properties of chemically synthesized BiFeO3 nanocrystals. J. Phys. Chem. C 114, 2108 (2010)

T.J. Park, G.C. Papaefthymiou, A.J. Viescas, A.R. Moodenbaugh, S.S. Wong, Size-dependent magnetic properties of single-crystalline multiferroic BiFeO3 nanoparticles. Nano Lett. 7, 766 (2007)

V.A. Reddy, N.P. Pathak, R. Nath, Particle size dependent magnetic properties and phase transitions in multiferroic BiFeO3 nano-particles. J. Alloys Compd. 543, 206 (2012)

D.P. Dutta, B.P. Mandal, R. Naik, G. Lawes, A.K. Tyagi, Magnetic, ferroelectric, and magnetocapacitive properties of sonochemically synthesized Sc-doped BiFeO3 nanoparticles. J. Phys. Chem. C 117, 2382 (2013)

Y. Wang, C.W. Nan, Effect of Tb doping on electric and magnetic behavior of BiFeO3 thin films. J. Appl. Phys. 103, 4103 (2008)

J. Liu, H.M. Deng, H.Y. Cao, X.Z. Zhai, J.H. Tao, L. Sun, P.X. Yang, J.H. Chu, Influence of rare-earth elements doping on structure and optical properties of BiFeO3 thin films fabricated by pulsed laser deposition. Appl. Surf. Sci. 307, 543 (2014)

W.Y. Xing, Y.N.N. Ma, Y.L. Bai, S.F. Zhao, Enhanced ferromagnetism of Er-doped BiFeO3 thin films derived from rhombohedral-to-orthorhombic phase transformations. Mater. Lett. 161, 216 (2015)

J. Zhang, Y.J. Wu, X.K. Chen, X.J. Chen, Structural evolution and magnetization enhancement of Bi1−xTbxFeO3. J. Phys. Chem. Solids 74, 849 (2013)

P. Ravindran, R. Vidya, A. Kjekshus, H. Fjellvåg, O. Eriksson, Theoretical investigation of magnetoelectric behavior in BiFeO3. Phys. Rev. B 74, 224412 (2006)

M. Gowrishankar, D.R. Babu, S. Madeswaran, Effect of Gd–Ti co-substitution on structural, magnetic and electrical properties of multiferroic BiFeO3. J. Magn. Magn. Mater. 3, 085 (2016)

A. Tamilselvan, S. Balakumar, M. Sakar, C. Nayek, P. Murugavel, K.S. Kumar, Role of oxygen vacancy and Fe–O–Fe bond angle in compositional, magnetic, and dielectric relaxation on Eu-substituted BiFeO3 nanoparticles. Dalton Trans. 43, 5731 (2014)

T.J. Park, G.C. Papaefthymiou, A.J. Viescas, Y. Lee, H.J. Zhou, S.S. Wong, Composition-dependent magnetic properties of BiFeO3–BaTiO3 solid solution nanostructures. Phys. Rev. B 82, 024431 (2010)

G. Dhir, P. Uniyal, N.K. Verma, Effect of particle size on magnetic and dielectric properties of nanoscale Dy-doped BiFeO3. J. Supercond. Nov. Magn. 27, 1569 (2014)

J.I. Hong, T. Leo, D.J. Smith, A.E. Berkowitz, Enhancing exchange bias with diluted antiferromagnets. Phys. Rev. Lett. 96, 117204 (2006)

J.S. Park, Y.J. Yoo, J.S. Hwang, J.H. Kang, B.W. Lee, Y.P. Lee, Enhanced ferromagnetic properties in Ho and Ni co-doped BiFeO3 ceramics. J. Appl. Phys. 115, 013904 (2014)

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 11264026, 11564028), and Inner Mongolia Science Foundation for Distinguished Young Scholars (Grant No. 2014JQ01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xing, Q., Han, Z. & Zhao, S. Crystal structure and magnetism of BiFeO3 nanoparticles regulated by rare-earth Tb substitution. J Mater Sci: Mater Electron 28, 295–303 (2017). https://doi.org/10.1007/s10854-016-5524-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5524-z