Abstract

In this work, a new modified carbon paste electrode (CPE) was constructed for potentiometric determination of naproxen (NAP) based on its imprinted polymer as a chemical modifier. An efficient precipitation polymerization method was applied for the synthesis of nano-sized NAP molecular imprinted polymer (MIP). In the preparation of MIP, methacrylic acid and ethylene glycol dimethacrylate were used as the functional monomer and cross-linking agent, respectively. The nano-sized NAP-MIP was characterized by Fourier transform infrared spectroscopy and scanning electron microscopy (SEM). SEM images confirmed the nanostructure morphology of the prepared MIP, with a particle size range of 50–80 nm. The MIP based sensor with the optimum composition exhibits a good linear response with a slope of −59.5 ± 1.5 mV per decade over the concentration range of 1.0 × 10−9.5–1.0 × 10−1 mol L−1. It has a very low limit of detection, 3.0 × 10−10 mol L−1, with a response time of 3 s. The potentiometric response of the sensor was independent of the pH of test solution in a wide range of 5.0–11.0. The proposed electrode shows a very good selectivity for NAP over other drugs. The chemically modified CPE indicated an excellent applicability for the determination of NAP in NAP capsules.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Naproxen (NAP) [(S)-6-methoxy-α-methyl-2-naproxenphthalene acetic acid] is a non-steroidal anti-inflammatory drug for mild to moderate pain relief [1]. It works by reducing hormones that cause inflammation and pain in the body. Moreover, NAP is extensively used in the treatment of many diseases like rheumatoid arthritis, degenerative joint disease, ankylosing spondylitis, acute gout and primary dismenorrea [2]. Many efforts have been focused on the development of new technologies for determining NAP, such as UV–vis absorption spectrophotometry [3], spectrofluorimetry [4, 5], ion selective electrode [6], liquid chromatography [7], chemiluminescence [8], voltammetry [9], high-performance liquid chromatography [10], capillary electrophoresis [11], coulometry [12], and oscillometric titration [13]. However, some of these methods are expensive for most analytical laboratories, time-consuming, involving the use of organic solvents [14]. Also, these methods are characterized by a long and complicated preparation of sample for analysis as well as expensive instrumental apparatus [6]. An alternative method for measurement of this drug is modified carbon paste electrodes (CPEs) assisted by potentiometric methods and incorporation of a selective recognize element as modifier in the paste composition. The application of chemically modified CPEs in analytical chemistry has attracted considerable attention due to their advantages over membrane electrodes such as stable response, low ohmic resistance, no need for internal solution [15]. Also, the important factors that promote the use of CPE are simplicity of preparation, the versatility of chemical modification, and rapid renewal of the electrode surface [16, 17].

On the other hand, in the recent decades, molecularly imprinted polymers (MIPs), which are cross-linked macromolecules bearing “tailor-made” binding sites for target molecules, have received great attention as efficient modifiers in modified electrodes [18]. MIP-based electrochemical sensors were first reported in the early 1990s by Mosbach’s group [19], and to date, remarkable progress in MIP-based electrochemical sensors have been achieved in the use and the performance of electrochemical MIP nanomaterials [20–24]. Due to high selectivity, chemical stability, and easy preparation characteristics, MIPs are proper material for selective recognitions [25, 26]. Meanwhile, CPEs modified with nano-sized MIPs due to enhancement in the number of surface reactive sites, surface area, and a three-dimensional structure lead to improvement in electrochemical response [27]. The formation of nano-sized IIP particles through the used polymerization method can increase surface area and the porosity of the polymeric network [28]. Therefore the synthesis of nano-sized MIP’s particles is desirable to improve the sensitivity of the sensor. The proposed sensor that was constructed from nano-sized MIP’s particles improves the sensitivity of the electrode for low level monitoring of the NAP drug. This would impart high diffusion rates of selected target analytes to a large number of accessible binding sites, which constitutes definite key factor in designing sensor devices with high sensitivity [29].

In the present research, combining the advantages of high selectivity of the MIP technique and high sensitivity of CPE detection, a new chemically modified CPE based on MIP nanoparticles has been developed for the determination of NAP. The aim of this work was to develop a new chemically modified CPE based on MIP nanobeads for selective and sensitive potentiometric determination of NAP in pharmaceutical products. The prepared MIP was characterized by some techniques such as scanning electron microscopy and Fourier transform infrared (FT-IR) spectroscopy, then, it was used as a selective modifier in the paste composition. Some advantages of this work are simplicity, rapidity, high selectivity, being operative and cheap, easy to usage and sensitive determination of low levels of NAP in aqueous solution.

2 Experimental

2.1 Reagents and materials

All chemicals were of analytical reagent grade. Paraffin oil and graphite powder were obtained from Merck. In the synthesis of NAP-MIP nanoparticles; methacrylic acid (MAA), ethyleneglycoldimethacrylate (EGDMA), and 2,2′-azobisisobutyronitrile (AIBN) was supplied by DaeJung chemical & metal Co., Ltd (Shiheung, Korea). NAP and other drugs were obtained from Tehran Darou Pharmaceutical Company (Tehran, Iran). All solutions were prepared in double-distilled water.

2.2 Apparatus

All the potential and pH measurements were carried out with a pH/ion meters model PTR-79 (ZAGCHIMI, Iran). The surface morphology of the polymeric nanobeads was recorded on a Philips XL30 series instrument using a gold film for loading the dried particles on the instrument. The FT-IR spectra (4000–500 cm−1) were recorded on a Shimadzu FT-IR 8300 spectrophotometer.

2.3 Preparation of NAP-MIP nanobeads

NAP-MIP particles were synthesized using MAA as the functional monomer, EGDMA as the cross-linker, and acetonitrile/ethanol mixture as porogen solvent by a polymerization method reported previously [30, 31] (Scheme 1). Briefly, NAP (0.1 mmol), MAA (0.4 mmol), EGDMA (2.0 mmol) and AIBN (50 mg) were dissolved in 23 mL of acetonitrile/ethanol mixture (15:8; v/v) in conical flask. After degassing and nitrogen purging for 5 min, the flask was sealed and allowed to polymerize at 80 °C for 24 h, with stirring. After polymerization, the polymerized particles were crushed and then washed using a mixture of methanol-acetic acid (9:1; v/v) to remove the template molecule [32], and then the residual acetic acid was removed by washing with methanol [33]. In the same way, the non-ion imprinted polymer (NIP) was also prepared with the similar approach; but without the addition of template molecule.

2.4 Electrode preparation and potential measurements

The carbon pastes were prepared by hand-mixing 58 mg graphite powder, 8 mg NAP-MIP/NIP, and 34 mg paraffin oil adequately in agate mortar. A portion of the resulting paste was then packed into a syringe tube with a radius of 2.0 mm and compresses it tightly. Fix a copper wire into the electrode. The wire, make electrically connection between the paste and the potentiometer instrument. Then, the electrode surface carefully smoothed on a weighing paper and rinsed with twice distilled water prior to each measurement. The unmodified CPE was prepared in a similar way using 72 mg graphite powder and 26 mg paraffin oil.

All electromotive forces (emf) measurements were carried out with the following cell assembly:

All measurements were done versus Ag, AgCl(s) reference electrode. The calibration graph was drawn by plotting the potential, E, versus the logarithm of the various NAP concentration. The performance of the electrodes was investigated by measuring the emfs of NAP solution which was prepared with a concentration rang of 1.0 × 10−11–5.0 × 10−1 mol L−1 by serial dilution. The ionic strength of all solutions was adjusted at 0.5 by sodium chloride as electrolyte. The obtained graphs then employed for the characterization of the slope and linear range of the CPE and also subsequent determination of unknown concentration of NAP. All measurements were carried out at ~25 °C.

2.5 Determination of NAP content in capsule samples

The constructed modified CPE applied for the determination of NAP concentration in capsule samples. For this purpose, three capsule of naproxen were accurately weighed and ground to a fine powder. A naproxen stock (0.1 mM) solution was prepared by dissolving of grounded naproxen capsule in buffer solution in a 25 mL volumetric flask and dilutes it to the mark. Different of capsules sample were prepared by serial dilution technique and analyzed by modified CPE, using standard addition method [34].

3 Results and discussion

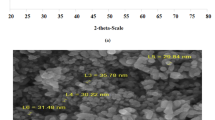

3.1 Characterization of the prepared NAP-MIP

Scanning electron microscopy (SEM) was employed to capture the detailed morphology of the NAP-MIP particles prepared by precipitation polymerization method. As shown in Fig. 1, the NAP-MIP particles were in a regular shape, with homogeneous distributions. The diameters of the NAP-MIP particles were about 50–80 nm.

The IR spectra of NAP, unleached and leached MIPs are presented in Fig. 2. As seen, IR spectra of unleached and leached MIP samples show similar pattern; which it is concluded that both samples have similar polymeric backbones, it suggested that the polymeric network does not affect by leaching process [35]. The FT-IR spectra shows broad absorption band at ~3451 and 3461 cm−1 in the unleached and leached MIP, respectively, which is related to the –OH groups and the hydrogen binding with the –COOH group of the methacrylic acid functional monomer. Furthermore, presence of an absorption band in the IR spectra of the unleached and leached NAP-MIP, at 1729 cm−1 is related to carboxyl groups (ν c=o). Moreover, vibrations at 1170 and ~1465 cm−1 in the unleached MIP materials were shifted to ~1166 and 1456 cm−1 in the corresponding leached MIP sample. As it can be seen, a distinct peak around 2300–2400 cm−1, presence in the IR spectra of NAP and unleached NAP-MIP, has been removed in the IR spectrum of leached NAP-MIP sample. It can be concluded that NAP imprinted molecules has been successfully removed by leaching process.

3.2 Optimization of the CPE composition

The imprinted polymer use in the drug determination has been the subject of extensive research recently. This work, to the best of our knowledge, is the first attempt to apply the MIP-based CPE for the selective determination of NAP by potentiometric method. In the first period of research on the electrodes, investigations were mainly performed on the optimization of the CPE composition, due to the critical role of the quantitative composition of the paste on the response characteristics of the sensor. Some analytical parameters such as the amount of modifier, graphite, paraffin oil, and solvent mediator have considerably effect on the electrode behavior. Among the parameters, the carrier or modifier is the most important sensing component in a selective electrode; because the modifier largely determines sensitivity and selectivity of the electrode toward target analyte [36]. Thus, the effect of the paste composition on the potentiometric response of the electrodes was investigated by varying the proportions of the MIP and the graphite powder and the results were summarized in Table 1.

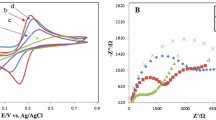

As seen from Table 1, the key ingredient in the response characteristics of the sensor toward NAP is the MIP modifier. The amount of MIP nanoparticles was found to play a key role in the sensor performance since the weight of MIP particles determines the number of binding sites available for selective rebinding of NAP. In fact, in the absence of MIP, the resulting electrode (No. 1) revealed a very limited slope (−28.3 mV per decade) and linear range (1 × 10−4–1 × 10−1 mol L−1). However, in the presence of the NAP-MIP nanoparticles, the electrode showed a remarkable sensitivity and dynamic linear range for NAP drug (sensor No. 2). As seen, the MIP-CPE potentiometric response is improved with an increasing amount of MIP in the paste up to 8 % (sensors No. 5). However, further increase of NAP-MIP in the paste (sensors No. 6), resulted in some considerable change in the slopes and sensitivity. It most probably can be due to some inhomogeneities and possible saturation of the paste, as well as the diminished conductivity of the electrode in the presence of higher amount of MIP [37–39]. The results thus obtained indicate that the best sensitivity, detection limit, and linear ranges are obtained for sensor No. 5 with the weight ratio of MIP/graphite powder/paraffin oil paste composition of 8/34/58. Thus, the No. 5 electrode with a slope of −59.60 mV per decade and a wide linear range of 1.0 × 10−9.5–1.0 × 10−1 mol L−1 was selected as the optimal electrode composition for further experiments (Fig. 3).

The detection limit of the developed sensor was determined according to IUPAC recommendations from the intersection of two extrapolated linear portions of the curve [40] and was found to be 3.0 × 10−10 mol L−1. It is worth to note that the according to the previous results, the observed slope of the Ep versus pH indicates that the electrode process is equal proton–electron [34]. Thus, the obtained slope of the NAP selective electrode in the optimized conditions is in very good agreement with the obtained data by different electrochemical techniques such as cyclic voltammetry [9, 34] and ion selective electrodes [6, 14, 41, 42].

3.3 Effect of pH of test solution

In order to study the pH-dependence of the modified electrode potential, graphs of E/mV versus pH were constructed at various NAP concentrations including 1.0 × 10−3, 1.0 × 10−4 and 1.0 × 10−5 mol L−1, over the pH range of 3–13. The potential measurement was read when it was steady, after addition of acid or base (nitric acid or sodium hydroxide), and pH measurement had been made. The obtained results are presented in Fig. 4. As it can be seen, the electrode potential was independent of pH in a wide range of 5.0–11.0, proving that the electrode can function effectively in this pH range. Therefore, this range can be taken as the working pH range of the electrode for NAP determination. However, as naproxen is a weak acid, with a pKa of 4.48 [43], the marked change in potential observed at below pH 5.0 can be due to the decrease in naproxen concentration. On the other hand, for pH > 11.0, the hydroxide ion interferes with the electrode’s response. Also, at high pH values the drug inclined to decompose, resulting in the decrease of the response [44].

3.4 Response time and life time of the MIP based CPEs

For analytical applications, the response time of a new fabricated sensor is of critical importance. The response time of the MIP modified CPE was measured in variation of concentration from 1.0 × 10−6 to 1.0 × 10−1 mol L−1 of NAP, by using IUPAC recommendation [44]. As obtained (Fig. 5), in whole the concentration range, the electrode reaches the equilibrium response in a reasonable time (approx. 3 s), which were shorter than the previously published NAP sensors reported by Lenik (15–20 s) [6], (11 s) [45], Norouzi (20 s) [46], and Pezza (10–35 s) [14]. It seems that in the CPE assisted by potentiometric determinations, the absence of the internal reference solution are generally considered to have a positive effect on the electrode response time. On the other hand, incorporation of nano-sized beads of MIP modifier affected the response time of the modified electrode. The fast response time in the modified sensor based on nano-sized materials can be explained by the fact that the presence of nano-sized beads of MIP can provide a large surface area and high tendency toward imprinted molecule (i.e. naproxen) [47].

The lifetime of a sensor is usually defined as the time interval between the first construction of the electrode and the moment when at least one of its response characteristics changes [45]. Day to day calibration was performed using the designed modified sensor to evaluate its useful lifetime. The electrode was kept in a buffer solution to avoid drying, cracking and poisoning when it was not in use. The modified CPE can be used for at least 90 day without any significant change in its response characteristics such as Nernstian slope, linear range, response time and detection limit (Table S1). It is worth to note that MIPs are stable polymers with molecular recognition abilities and resistant to a wide range of conditions (pH, organic solvents, temperature, pressure), and were used for several different applications [46].

In addition, some important characteristic of the proposed electrode was compared with the corresponding values previously reported for NAP electrodes based on different modifier [6, 14, 41, 42, 48, 49] (Table 2). It is noteworthy that in many cases, the linear range, slope and response time of the proposed electrode is considerably improved with respect to those of the previously reported NAP selective electrodes. As seen in Table 2, the proposed electrode shows superior behaviors to the electrodes prepared previously.

3.5 Electrode repeatability and its reproducibility

The electrode surface should be renewed when the NAP solution is changed from higher to lower concentration to remove residual NAP which still be adsorbed on the surface of modified CPE, this process will improve repeatability. For this goal, the slope, linear range, and standard deviations of five replicate measurements with one paste electrode were recorded. According to the obtained results, the modified electrode shows good repeatability with the slopes and correlation coefficients average of −59.52 mV and 0.996 at concentration range between 1.0 × 10−9.5 and 1.0 × 10−1 mol L−1 of NAP with a low RSD% 0.56 (Table S2).

In order to evaluate the reproducibility of the electrode, to test parallel results, five carbon paste electrodes with similar past composition were constructed and used at the same time to determine NAP solutions in the concentration range of 1.0 × 10−9.5 and 1.0 × 10−1 mol L−1. As results (−59.51, −59.35, −60.04, −59.13, −59.40 mV) illustrate all electrodes show similar potential response with a RSD% of 0.51 (Table S3).

3.6 Response of the modified electrode in the presence of other drugs

The selectivity coefficients of the modified CPE were evaluated by two recommended methods including separate solution method (SSM) (using 0.01 M solutions of NAP and other drugs) and fixed interference method (FIM) (0.01 M interfering ions and varying concentrations of NAP). In this study, some of which are expected to interfere with NAP drug include ibuprofen, paracetamol, acyclovir, pyrazinamide, and dimenhydrinat have been chosen (Table 3). The calculated selectivity coefficients found by SSM and FIM are listed in Table 4. The resulting values show that the constructed sensor displays high selectivity for NAP over common drugs. The surprisingly high selectivity of the designed CPE modified with MIP for NAP over other drugs probably arises from the strong tendency of the carrier MIP for NAP target. However; at the same time, the response of the NIP–CPE toward NAP over other drugs is poor and doesn’t selective.

It is well known that molecular imprinting is one of the most efficient strategies that offer a synthetic route to artificial recognition systems by a template polymerization technique [50]. In MIP nanoparticles, so many active sites with high selectivity and surface area are present to recognize the imprinted target molecule. As a result, presence of the selective and active functional groups causes an increased interaction between the polymer sites and the target molecule [51]. This ability of the MIPs for the selective recognition of target strongly depends on the binding sites formed inside the polymer, which is determined by the components used in preparing the polymer matrix [52]. Since there were no imprinting effects on the NIP, it exhibited no selectivity. It can be concluded that the imprinting phenomenon is responsible for this observation [53].

3.7 Effect of temperature

To investigate the thermal stability of the electrode, calibration curves [Ecell vs. log (NAP)] were constructed at different temperatures covering the range 17–55 °C. The results are shown in Table S4. The results indicate that the slopes of the calibration graphs still in the Nernstian range in spite of the increase of the temperature of the test solutions up to 45 °C and the linear concentration ranges of the electrodes are almost unchanged with increasing the temperature of the test solution. The investigated electrodes were found to be usable up to 45 °C without noticeable deviation from the Nernstian behavior. However, at temperatures higher than 55 °C the slopes show a significant deviation from the theoretical values. This deviation may be related to destruction of the electrode surface at high temperatures. As the temperature increases, some leaching may be takes place in the paste matrix, thus a lower response is expected [54]. Moreover, in this context it is useful to consider the likely effects of increasing temperature on the components of the cell such as reference electrode [55]. Meanwhile, an increase in temperature causes an increase in the electrode potential due to increase in ionic mobility in the sample solution [56].

3.8 Application of the modified electrode for NAP analysis in capsule samples

In order to evaluate the applicability of the proposed MIP based CPE, the concentration of NAP in its pharmaceutical products was determined using this electrode. After preparation steps, the potential of the final NAP solutions are measured by the modified CPE, then standard additions are made and the potential changes are recorded. From these potential values the quantity of NAP is calculated. The results are illustrated in Table 5. As found, the results obtained for the determination of NAP in capsule sample show that concentration of the drug can be determined by the investigated sensors with high precision and accuracy. The RSD% values are between 0.8 and 2.4, and the recovery ranges are acceptable. Therefore, the proposed sensor was found to work well under laboratory conditions.

4 Conclusion

The carbon paste electrode modified with new synthetic MIP nanoparticles reveals an adequate response to NAP drug. The electrode presents wide linearity range, low detection and a suitable response time with a minor dependence on the pH. High selectivity of the constructed CPE related to the imprinted cavities of the imprinted polymer with high affinity of MIP toward NAP analyte. The proposed sensor was constructed from nano-sized MIP’s particles which improve the sensitivity of the electrode for monitoring the NAP. Furthermore, the presented method is simple, sensitive, selective and cost-effective. As found, the results indicated fairly high thermal stability of the carbon paste electrode modified with MIP nanoparticles. According to the results, the developed chemically CPE can be considered as a sensitive and selective potentiometric sensor for quick analyses of NAP in pharmaceutical products. In summary, it is noteworthy that the performances of the proposed electrode show superior behavior if compared with the best previously reported method for determination of naproxen in different real samples.

References

T. Haque, M.U. Talukder, S. Laila, K. Fatema, A.K.L. Kabir, J. Pharm. Sci. 1, 18–24 (2008)

P.A. Todd, S.P. Clissold, Drugs 40, 91–137 (1990)

M. Holzbecher, H.A. Ellenberger, J.M. Marsh, S. Boudreau, Clin. Biochem. 12, 66–67 (1979)

J.F. Fernández-Sánchez, A. Segura-Carretero, C. Cruces-Blanco, A. Fernández-Gutiérrez, Anal. Chim. Acta 462, 217–224 (2002)

P. Damiani, M. Bearzotti, M.A. Cabezón, J. Pharm. Biomed. Anal. 29, 229–238 (2002)

J. Lenik, Mater. Sci. Eng. C 33, 311–316 (2013)

E. María Costi, I. Goryacheva, M. Dolores Sicilia, S. Rubio, D. Pérez-Bendito, J. Chromatogr. A 1210, 1–7 (2008)

L.J. Wang, Y.H. Tang, Y.H. Liu, J. Pharm. Anal. 1, 51–56 (2011)

K. Sarhangzadeh, J. Iran Chem. Soc. 12(12), 2133–2140 (2015)

D.M. Chen, Q. Fu, N. Li, S.X. Zhang, Q.Q. Zhang, Chin. J. Anal. Chem. 35, 75–78 (2007)

M. Fillet, L. Fotsing, J. Bonnard, J. Crommen, J. Pharm. Biomed. Anal. 18, 799–805 (1998)

G. Kanoute, E. Nivaud, B. Paulet, P. Boucly, Talanta 31, 144–146 (1984)

T. Pomazanska-Kolodziejska, Acta Pol. Pharm. 40, 357–360 (1983)

A.O. Santini, J.E. de Oliveira, H.R. Pezza, L. Pezza, J. Braz. Chem. Soc. 17, 785–791 (2006)

R. Li, Y. Tai, J. Bai, H. Wang, J. Mater. Sci. Mater. Electron. 26, 2471–2479 (2015)

M. Shamsipur, M. Roushani, S.M. Pourmortazavi, N. Shahabadi, Cent. Eur. J. Chem. 12, 1091–1099 (2014)

M. Roushani, M. Shamsipur, S.M. Pourmortazavi, J. Appl. Electrochem. 42(12), 1005–1011 (2012)

Y. Lei, M. Klaus, J. Incl. Phenom. Macrocyclic. Chem. 41, 107–113 (2001)

L.I. Andersson, A. Miyabayashi, D.J. O’Shannessy, K. Mosbach, J. Chromatogr. 516, 323–331 (1990)

A. Nezhadali, Z. Rouki, M. Nezhadali, Talanta 144, 456–465 (2015)

K. Kor, K. Zarei, Talanta 146, 181–187 (2016)

T. Madrakian, E. Haghshenas, M. Ahmadi, A. Afkhami, Biosens. Bioelectron. 68, 712–718 (2015)

A. Shirzadmehr, A. Afkhami, T. Madrakian, J. Mol. Liq. 204, 227–235 (2015)

M.B. Gholivand, M. Torkashvand, Mater. Sci. Eng. C 59, 594–603 (2015)

H.R. Rajabi, M. Shamsipur, S.M. Pourmortazavi, Mater. Sci. Eng. C 33, 3374–3381 (2013)

M. Shamsipur, H.R. Rajabi, S.M. Pourmortazavi, M. Roushani, Spectrochim. Acta Part A 117, 24–33 (2014)

M. Goudarzi, M. Salavati-Niasari, M. Bazarganipour, M. Motaghedifard, J. Mater. Sci. Mater. Electron. 27, 3675–3682 (2016)

M.B. Gholivand, M. Shamsipur, S. Dehdashtian, H.R. Rajabi, Mater. Sci. Eng. C 36, 102–107 (2014)

A. Walcarius, Electroanalysis 13, 701–718 (2001)

H.R. Rajabi, M. Roushani, M. Shamsipur, J. Electroanal. Chem. 693, 16–22 (2013)

M. Shamsipur, H.R. Rajabi, M.H. Beyzavi, H. Sharghi, Microchim. Acta 180, 791–799 (2013)

X. Chen, Z. Zhang, X. Yang, J. Li, Y. Liu, H. Chen, W. Rao, S. Yao, Talanta 99, 959–965 (2012)

D. Miao Chent, Q. Ful, W. Ou’, S. Juan Sun’, P. Huang’, C. Chang, J. Poorm. Anal. 1, 26–31 (2011)

J. Tashkhourian, B. Hemmateenejad, H. Beigizadeh, M. Hosseini-Sarvari, Z. Razmi, J. Electroanal. Chem. 714–715, 103–108 (2014)

M. Javanbakht, S. Eynollahi Fard, A. Mohammadi, M. Abdouss, M.R. Ganjali, P. Norouzi, L. Safaralie, Anal. Chim. Acta 612, 65–74 (2008)

M.R. Huang, Y.B. Ding, X.G. Li, ACS Comb. Sci. 16, 128–138 (2014)

M. Shamsipur, M. Hosseini, K. Alizadeh, M.M. Eskandari, H. Sharghi, M.F. Mousavi, M.R. Ganjali, Anal. Chim. Acta 486, 93–99 (2003)

S.M. Saadeh, H.M. Abu-Shawish, A.M. Meqbela, G.I. Khraish, Int. J. Ind. Chem. 2, 253–260 (2011)

W. Zhihua, L. Xiaole, Y. Jianming, Q. Yaxin, L. Xiaoquan, Electrochim. Acta 58, 750–756 (2011)

E. Bakker, P. Buhlmann, E. Pretch, Chem. Rev. 97, 3083–3132 (1997)

J. Lenik, R. Dumkiewicz, C. Wardak, B. Marczewska, Acta Pol. Pharm. 59, 171–176 (2002)

G.N. Valsami, P.E. Macheras, M.A. Koupparis, Analyst 114, 387–391 (1989)

C. Ràfols, M. Rosés, E. Bosch, Anal. Chim. Acta 338, 127–134 (1997)

P.R. Buck, E. Lindner, Pure Appl. Chem. 66, 2527–2536 (1994)

A. Soleymanpour, M. Ghasemian, Measurement 59, 14–20 (2015)

T. Hishiya, H. Asanuma, M. Komiyama, Polym. J. 35, 440–445 (2003)

H.R. Rajabi, M. Shamsipur, M.M. Zahedi, M. Roushani, Chem. Eng. J. 259, 330–337 (2015)

J. Lenik, C. Wardak, B. Marczewska, Cent. Eur. J. Chem. 6, 513–519 (2008)

P. Norouzi, F. Dousty, M.R. Ganjali, P. Daneshgar, Int. J. Electrochem. Sci. 4, 1373–1386 (2009)

H.R. Rajabi, S. Razmpour, Spectrochim. Acta Part A 153, 45–52 (2016)

V. Vatanpour, S.S. Madaeni, S. Zinadini, H.R. Rajabi, J. Membr. Sci. 373, 36–42 (2011)

T.P. Rao, S. Daniel, J.M. Gladis, Trends. Anal. Chem. 23, 28–35 (2004)

M. Shamsipur, H.R. Rajabi, Microchim. Acta 180, 243–252 (2013)

A. Nezamzadeh Ejhieh, N. Masoudipour, Anal. Chim. Acta 658, 68–74 (2010)

H.M. Abu-Shawish, S.M. Saadeh, H.M. Dalloul, B. Najri, H.A. Athamn, Sens. Actuators B 182, 374–381 (2013)

S.M. Saadeh, H.M. Abu Shawish, H.M. Dalloul, N.M. EL-Halabi, B. KhDaher, Mater. Sci. Eng. C 32, 619–624 (2012)

Acknowledgments

We gratefully acknowledge the support of this work by Tehran Darou Pharmaceutical Company (Tehran, Iran).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rajabi, H.R., Zarezadeh, A. Development of a new chemically modified carbon paste electrode based on nano-sized molecular imprinted polymer for selective and sensitive determination of naproxen. J Mater Sci: Mater Electron 27, 10911–10920 (2016). https://doi.org/10.1007/s10854-016-5202-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5202-1