Abstract

Cobalt-modified manganese–zinc (MnZn) power ferrites with good thermal stability were prepared by conventional ceramic technique. The influences of TiO2 and Nb2O5 additives on the properties of cobalt-modified MnZn power ferrite were investigated. It was shown that moderate amount of TiO2 and Nb2O5 additives could increase the permeability and reduce the power loss effectively while keeping the better thermal stability of cobalt-modified MnZn ferrite. The best magnetic properties were obtained at addition amount of 0.03 wt% TiO2 and 0.02 wt% Nb2O5 with an initial permeability (µ i ) of 3200 at room temperature and power loss keeping below 400 kW/m3 from 20 to 100 °C. The related mechanisms were briefly discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Owing to high permeability, high saturation magnetic flux density and low power loss, MnZn ferrite are widely used as core materials for transformers in switching mode power supplies and DC–DC converters [1]. However, the power loss of most MnZn ferrites usually exhibits a minimum under a specific temperature [2]. The power loss increases quickly once the temperature deviates from the specific value, which will greatly influence the stability of the devices. Therefore, development of power ferrite materials with thermal stability is especially important.

In the past several decades, a variety of techniques have been developed to improve the electronic and magnetic properties of MnZn ferrites. One of the most effective methods is doping small amount of additives [3–6]. Currently, the effects of single oxide (SiO2, Bi2O3, TiO2, Nb2O5, SnO2, Co2O3, et al.) on the magnetic properties of power MnZn ferrites have been systematically studied [7–13]. Among these oxides, Co2O3 is considered to be an effective additive in optimizing the temperature stability of MnZn ferrites [6]. However, it was found that the initial permeability reduced and power loss increased with the increase of Co2O3 concentrations in most studies [7, 8]. In order to acquire the MnZn ferrites with high initial permeability, low power loss and good thermal stability simultaneously, further works still need to be done.

On the other side, researchers have identified several oxides that could effectively improve initial permeability and reduce power loss. Yu and his co-workers have revealed that moderate Nb2O5 could improve initial permeability and reduce power loss [3]. Nie and his partners have obtained the MnZn ferrites with low power loss by doping moderate TiO2 [10]. Based on these results, it is reasonable to predict that low power loss, high permeability and good thermal stability could be simultaneously obtained in the MnZn ferrites by doping multiple oxides. In this paper, moderate amount of TiO2 and Nb2O5 additives were doped into the cobalt-modified MnZn power ferrite. The influences of Nb2O5 and TiO2 on the properties of cobalt-modified MnZn ferrite were studied.

2 Experimental

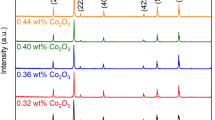

A series of MnZn power ferrite samples adopted with a basic composition (Mn0.673Zn0.246Fe2.073Co0.006O4) were prepared by traditional ceramics process. The raw materials were weighed according to the stoichiometric ratio, with Fe2O3 (99.36 %), Mn3O4 (98.86 %), ZnO (99.73 %), Co2O3 (99.9 %) as starting materials.

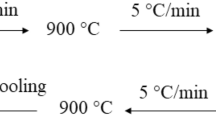

The raw materials were wet mixed in deionized water via ball milling for 2 h. Then, the mixtures were dried at 100 °C and calcined at 900 °C in air for 2 h. After that, small amount of TiO2 and Nb2O5 additives were doped into the mixtures (shown in Table 1) and then the mixed powders were ball milled for 4 h. After drying at 100 °C, the mixed powders were pressed (8 MPa) into the toroid specimens (22 mm outside diameter, 14 mm inner diameter, and 7 mm height) with 5–8 wt% of poly-vinyl alcohol (PVA). Finally, the specimens were sintered for 4 h at 1320 °C under controlled equilibrium oxygen partial pressure in bell-type furnace.

The mass densities of the specimens were measured by the Archimedes method and the fracture surface microstructures of the specimens were examined by scanning electron microscopy (SEM, JSM-6460). The initial permeability (f = 1 kHz, B < 0.25 mT) of samples was measured at room temperature on a HP2874 LCR meter, and the power loss(100 kHz, 200 mT) of the samples was measured by Clarke-Hess 2335 power analysis at different temperature.

3 Results and discussion

Table 2 shows the initial permeability of cobalt-modified MnZn ferrites with different amount of TiO2 and Nb2O5 additives. As can be seen, all the samples with additives exhibit higher initial permeability than the one without additives. For the MnZn ferrite without any additives, the initial permeability is only about 2817(Sample T1). The initial permeability increases to 2900 once the concentrations of TiO2 and Nb2O5 additives are increased to 0.02 wt% respectively. The highest value of initial permeability (3200) is obtained at the additive amounts of 0.03 wt% TiO2 and 0.02 wt% Nb2O5. However, further increasing the concentrations of additives leads to the decrease of the initial permeability.

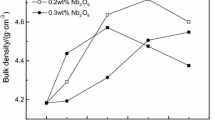

The variation of the initial permeability is considered to be strongly related to the microstructures. Figure 1 shows the SEM micrographs of MnZn ferrites with different concentration of TiO2 and Nb2O5. As can be observed, the non-uniform grains with a lot of pores appeared in the sample without TiO2 and Nb2O5 additives (Fig. 1a). Comparing with the samples without additives, the grains become more homogeneous and the porosity reduces in the sample with the concentrations of TiO2 and Nb2O5 of 0.02 and 0.02 wt% respectively (Fig. 1b). When the concentrations of the TiO2 and Nb2O5 are increased to 0.03 and 0.02 wt% respectively, the sample shows the lowest porosity and exhibits the most uniform microstructures (Fig. 1c). As known, the permeability is a superposition of magnetic domain twirl and domain wall displacement [7]. It has been reported that both the non-uniform grain size distribution and pores in the grain will greatly influence the twirl of magnetic domain and the displacement of domain walls, which will lead to the decrease of the initial permeability [1, 7]. Therefore, it is reasonable that moderate amount of TiO2 and Nb2O5 can effectively raise the initial permeability by inducing more uniform microstructures and decreasing the porosity. Correspondingly, the decrease of the initial permeability in the sample with further increased concentrations of TiO2 and Nb2O5 is acceptable as many abnormal grains with some pores appeared (Fig. 1d), which will restrict the magnetic domain twirl and domain wall displacement.

Moreover, the initial permeability (µ i ) is also closely related to the magnetic anisotropy constant K 1 [14]. The lower the |K 1| is, the higher the initial permeability is. As the K 1 of MnZn ferrites is negative, moderate amount of additives with positive magnetic anisotropy constant are needed. However, the magnetic anisotropy constant K 1 of Ti4+ and Nb5+ ions equal 0, as both of them are non-magnetic ions. Therefore, the variation of the initial permeability can not be directly described to the additives of TiO2 and Nb2O5. Nevertheless, it has been confirmed in the previous studies that although most of the Ti4+ and Nb5+ ions exist on grain boundaries, small amount of Ti4+ and Nb5+ ions can also dissolve into the spinel lattice and replace the Fe3+, inducing an amount of Fe2+ for keeping neutral (Fe3+ + e → Fe2+) whose magnetic anisotropy constant K 1 is positive [11, 13]. Furthermore, according to the charge neutrality, Fe2+ ions must be increasing with the increase of Ti4+ and Nb5+ concentrations. Therefore, TiO2 and Nb2O5 additives could indirectly increase the initial permeability by inducing moderate amount of Fe2+ ions to compensate the negative magnetic anisotropy constant of the MnZn ferrites. Correspondingly, further increasing of the TiO2 and Nb2O5 will generate excess amount of Fe2+ ions, leading to the increase of |K 1| of the MnZn ferrites and reducing the initial permeability.

Figure 2 shows the effect of TiO2 and Nb2O5 additives on the power loss of MnZn ferrites. As shown, the power loss of all samples reduces firstly and then increases with increasing temperature, exhibiting typical power loss property of MnZn ferrite. The lowest loss point locates at the temperature between 60 and 100 °C. However, comparing with the MnZn ferrite without cobalt dopant, the power loss values of sample T1 change more slightly in the measured temperature range [4, 17]. It suggests that the cobalt doped in the MnZn ferrites could effectively improve the thermal stability, which agrees well with previous studies [7]. The values of power loss reduce obviously with the increase of the TiO2 and Nb2O5 additives. But the thermal stability does not change evidently with the increase of TiO2 and Nb2O5 concentrations. The power loss of sample T4 with 0.02 wt% Nb2O5 and 0.03 wt% TiO2 reaches a minimum, which is less than the value of Ref. [11]. Further increasing the concentrations of Nb2O5 and TiO2 leads to an increase of the power loss.

As known, the total power loss (P cv ) of MnZn ferrites consists of three parts: magnetic hysteresis loss (P h ), eddy current loss (P e ) and residual loss (P r ). The residual loss (P r ) usually could be ignored under low frequency (f < 500 kHz), so the total power losses (P cv ) can be expressed as P cv ≈ P h + P e [15, 16]. The temperature dependence of magnetic hysteresis loss (P h ) and eddy current loss (P e ) with different concentrations of TiO2 and Nb2O5 are presented in Figs. 3 and 4, respectively. It is clear that both the hysteresis loss and eddy current loss decrease with the increase of the concentrations of TiO2 and Nb2O5, and reach minima when the concentrations of TiO2 and Nb2O5 are 0.03 and 0.02 wt%, then increase for higher TiO2 and Nb2O5 concentrations.

The hysteresis loss (P h ) is inversely proportional to the cubic of initial permeability(P h ∝ 1/µ 3 i ). Similar to the initial permeability, it is considered to be closely related to the microstructure and magnetic anisotropy constant K 1 [17]. As shown in Fig. 1, the grains become more homogeneous and the porosity reduces in the sample with 0.03 wt% TiO2 and 0.02 wt% Nb2O5, which will lead to the magnetic domain twirl and domain wall displacement happen at lower magnetic field. The hysteresis loss will decrease as the reduction of the area of hysteresis loop. While for the sample with higher TiO2 and Nb2O5 concentrations, the abnormal grains with pores will restrict the magnetic domain twirl and domain wall displacement and lead to the increase of the hysteresis loss [18]. On the other side, small amount of Ti4+ and Nb5+ entered the grains will lead to the increase of Fe2+ ions, which make positive compensation to the magnetic anisotropy constant K 1. It also will lead to the decrease of the hysteresis loss [11, 13, 15, 16]. Similarly, the excessive TiO2 and Nb2O5 will cause a higher concentration of Fe2+ ions, which leads to a positive K 1 value and increase the hysteresis loss. This may be the other reason for the variation of hysteresis loss.

The P e is reported inversely proportional to the electrical resistivity and proportional to square of the average grain size (P e ∝ D 2 /ρ) [16, 19]. As the grain size slightly increases with the increase of the TiO2 and Nb2O5 concentration (shown in Fig. 1), it is speculated that the eddy current loss is mainly dominated by the electrical resistivity. The mechanism of electrical conductivity in MnZn ferrites is mainly caused by the electron hopping between the Fe3+ and Fe2+ ions [18]. Though the Fe2+ ions will increase with the increase of Ti4+ additives according to the charge neutrality, Ti4+ ions have the property of localizing Fe2+ ions and forming stable Ti4+ ~ Fe2+ pairs, which will restrict the electronic exchange between Fe2+ and Fe3+ [11]. Therefore, the grain resistivity will be improved with the increase of Ti4+ concentration. Meanwhile, the TiO2 and Nb2O5 existed in the grain boundary will form a high resistance layer, leading to the increase of the grain boundary resistivity [4, 13, 16]. The increase of both grain and grain boundary resistivity may be responsible for the decrease of P e when the concentration of TiO2 and Nb2O5 is less than 0.03 and 0.02 wt%. However, further increasing the concentrations of TiO2 and Nb2O5 might lead to the decrease of grain boundary resistivity, which may be due to the exaggerated grain growth and the decrease of the grain boundary thickness [15, 16]. Moreover, the excessive Nb5+ ions make the concentration of Fe2+ ions increase, which will improve the electronic exchange between Fe2+ and Fe3+ and result in the decrease of the grain resistivity. This may be the other reason for the increase of eddy current loss in the sample with higher TiO2 and Nb2O5 concentrations.

4 Conclusions

Cobalt-modified MnZn ferrites doped with different concentrations of TiO2 and Nb2O5 were prepared by conventional ceramic technique. The influence of Nb2O5 and TiO2 additives on the initial permeability, microstructure, and power loss were discussed. Moderate concentrations of TiO2 and Nb2O5 additives can enhance the initial permeability of ferrites and reduce the power loss. When the concentrations of TiO2 and Nb2O5 is 0.03 and 0.02 wt%, the initial permeability reaches maximum and the power loss reaches minimum. Excess Nb2O5 and TiO2 will increase the power loss and reduce the initial permeability.

References

X. Li, J.X. Zhang, G.P. Liu, L.C. Yan, Mater. Rev. 22(8), 9 (2008)

L.Z. Li, Z.W. Lan, J. Alloys Compd. 476, 755 (2009)

S.L. Zhang, Y.G. Wang, Magn. Mater. Devices 40, 7–8 (2009)

Y.D. Zhang, W.Z. Lan, Z. Yu, J. Magn. Mater. Devices 34(5), 8–10 (2003)

Z. Yu, Z.W. Lan, J.M. Wang, Y.D. Zhang, H.C. Wang, Mater. Rev. 17(12), 80–82 (2003)

K. Janghorban, H. Shokrollahi, J. Magn. Mater. 308, 238 (2007)

T.J. Liang, H.H. Nien, J.F. Chen, IEEE Trans. Magn. 43(10), 3816–3820 (2007)

H.H. Nien, T.J. Liang, J.F. Chen, in IEEE Conference, vol. 332 (Kumamoto, Japan, 2007)

J.H. Nie, H.H. Li, Z.K. Feng, J. Magn. Magn. Mater. 265, 172–175 (2003)

J. Zhu, K.J. Tseng, IEEE Trans. Magn. 40(5), 3339–3345 (2004)

H.N. Ji, Z.W. Lan, Z. Yu, L.Z. Li, Mater. Rev. 22(2), 101 (2008)

H.N. Ji, Z.W. Lan, Z. Yu, L.Z. Li, Mater. Rev. 22(8), 5–8 (2008)

Y.C. Li, S.Y. Dong, L.J. Shen, J. Magn. Mater. 39(5), 53 (2008)

Q.Y. Zhang, P. Zheng, L. Zheng, J.J. Zhou, H.B. Qin, J. Electroceram. 32(2–3), 230–233 (2013)

W. Wang, J.H. Wang, J. Alloys Compd. 463, 115–118 (2008)

H. Shokrollani, K. Janghorban, Mater. Sci. Eng B 141, 91–107 (2007)

M. Guyot, A. Globus, J. Appl. Phys. 38(4), 157–168 (1977)

L. Li, Z.W. Lan, Z. Yu et al., J. IEEE Trans. Magn. 44(9), 2107–2112 (2008)

H.N. Ji, Z.W. Lan, Z. Yu, Z.Y. Xu, IEEE Trans. Magn. 46(4), 974–978 (2010)

Acknowledgments

This work was supported by the nonprofit technology Research program of Zhejiang Province (No. 2013C31064), Natural Science Foundation of China (No. 51302056).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, Z., Zheng, P., Zheng, L. et al. Effect of TiO2 and Nb2O5 additives on the magnetic properties of cobalt-modified MnZn ferrites. J Mater Sci: Mater Electron 27, 6048–6052 (2016). https://doi.org/10.1007/s10854-016-4529-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4529-y