Abstract

The addition of rare earth Pr into Sn3.8Ag0.7Cu solder results in the formation of PrSn3 phase, which can induce the whiskers growth. After several hours’ exposure at room temperature in air, different morphologies of whiskers appear in the regions of PrSn3 intermetallic compounds. The Pr content and storage time are the main parameters for affecting the whiskers growth at ambient temperature. The oxidation mechanism of PrSn3 phase was used to explain the whiskers growth, the compressive stress is proposed as the driving force for whisker growth.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Owing to the increasing environmental and human health concerns of the toxicity of lead, international legislation (EU RoHS) has prohibited the use of Pb in manufacturing consumer electronic products in 2006, so it is imperative to research lead-free solders [1, 2]. In the past few years, the SnAgCu family of solders has obtained a wide acceptance as replacement for traditional SnPb eutectic solder in electronic applications [3]. In order to improve the properties of SnAgCu solders, rare earth alloying was selected as an effective way to modify the microstructure of alloys due to the vitamin effect of rare earth elements [4]. For example, with the addition of 0.03 % Ce into Sn3.8Ag0.7Cu solder, the fatigue life can be enhanced significantly, is 30.2 % higher than that of SnAgCu [5]. Adding appropriate amount of rare earth Pr in Sn3.8Ag0.7Cu alloys can evidently improve the wettability, mechanical properties, refine matrix microstructure and reduce the intermetallic compounds growth [6].

But with the addition of rare earth elements, the whiskers can grow from lead-free solders. In Sn9Zn0.5Ga0.08Nd solder, no whisker can be observed, for 0.1 % Nd addition, long whiskers can be found [7]. Sn3.8Ag0.7Cu solders bearing 1 % Er or 1 % Ce, will be oxidized and rapid tin whisker growth will simultaneously appear on the surface of the oxidized RE–Sn phase [8]. Liu [9] reported after exposure to ambient conditions, the Sn–0.7Cu–(0.1 ~ 5)Nd solders have a strong tendency toward whisker growth, with a short incubation time for whisker nucleation (only several hours). Zhang [10] reported the relationship between Ce content/CeSn3 sizes and the whiskers growth, the potential to promote whisker growth indicate that only dilute concentration of Ce can be tolerated in Sn3.8Ag0.7Cu alloys without whiskering effect. Dudek [11] analyzed the mechanisms for Sn whisker growth in Sn3.9Ag0.7Cu containing 2 % Ce, La or Y, the oxidation of RESn3 phase will induce Sn whisker growth. Li [12] used RESn3 alloy to investigate the whisker growth behavior, and a grow model was proposed to discuss the characteristics and growth mechanism of Sn whiskers.

In this paper, the effect of rare earth Pr on the whiskers growth of Sn3.8Ag0.7Cu solders was investigated. The relationship between Pr content/aging times on the whiskers sizes was studied, the results can provide an effective reference for the research of lead-free solders.

2 Experimental

Sn3.8Ag0.7Cu alloys bearing different Pr contents were prepared from the pure Sn, Sn–Cu alloy, Sn–Ag alloy, and Sn–Pr alloys. Series of investigated alloys are listed in Table 1. All the raw materials for SnAgCu–xPr solders were melted in a ceramic crucible, and melted at 550 ± 1 °C for 40 min. And the mechanical stirring was needed to homogenize the solder alloy. In order to protect the solder for oxidation during the melting, KCl + LiCl (1.3:1) were used over the surface of liquid solder. Then the molten alloys were chilled and cast ingots in a mold and solidified by nominally air-cooling. At last for stabilizing the microstructure of the solder alloys, all solder specimens were heated and treated at 125 °C for an hour. SnAgCu and SnAgCuPr samples were mechanical polished with 1 μm diamond paste for microstructural observation. The etching solution contained 93 % methanol, 5 % nitric acid, and 2 % hydrochloric acid. The microstructures of these solders were examined by scanning electron microscopy (SEM) with a voltage of 20 keV.

3 Results and discussion

The microstructure of SnAgCu solder consists of β-Sn and eutectic structures including binary eutectic structures (Ag3Sn + β-Sn and Cu6Sn5 + β-Sn) and ternary eutectic structure (Ag3Sn + Cu6Sn5 + β-Sn). With the addition of rare earth Pr, Pr has a higher affinity to Sn in the quaternary system to form PrSn3 intermetallic compounds. PrSn3 phases can be observed in Fig. 1, homogeneously distributed large-sized PrSn3 intermetallic phases form in the cross-section of Sn3.8Ag0.7Cu2.0Pr solder. The figure reveals that after storage with several hours at room temperature in air, different morphologies of whiskers appear in the regions of PrSn3 intermetallic compounds. The 0.4 ~ 1.5 μm diameter and the ~30 μm long whisker was grown after exposure in ambient temperature, which could result in the short circuits failure between the solder joints of the whole structure, especially for the microbump with a diameter of 20–10 μm and a thickness of 10–5 μm in 3D IC [13]. In service, the whiskers can grow so fast, when the whiskers are long enough, two neighboring legs of the lead frame will short in electronic devices.

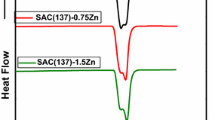

From the SEM microstructure, it is found that the whiskers sprout from the PrSn3 phase, no whisker can be observed in the β-Sn matrix. In order to assess the growth behavior of whiskers, the average length of 20 longest whiskers was selected to calculate the growth rate. With the increase of storage time, the length of whisker can grow rapidly. At initial stage, the whisker growth rate was extremely rapid, then the grow rate of whisker gradually decreased, which indicates that at initial stage, the PrSn3 phase can provide enough force to drive the growth of whisker, after a period, the force will decrease, so the growth rate will be reduced obviously. In addition, it is found that with the increase of Pr content and storage time (Fig. 2), the average length of whiskers can be enhanced obviously, which represents that the Pr content and storage time are the main parameters for affecting the whiskers growth at ambient temperature. On NdSn3 powder, tin whiskers grew rapidly and spontaneously, and the length of whisker and elapsed time was found [14]. Among the four SnAgCu solder bearing rare earth Pr, the growth behavior (growth rate and length) of whisker in SnAgCu–2.0Pr solder is the most sever. On the contrary, by decreasing the Pr content in SnAgCu solder, the growth of whisker may be inhibited, to some degree. In SnAgCu–xCe solder [10], when the Ce content is 0.03 %, no whisker can be observed in the matrix microstructure. Moreover, Zhang [15] demonstrated that only excessive rare earth Eu can induce the growth of whiskers.

Because rare earth elements are notable for their high chemical activity, they can much more easily react with the oxygen in the air and accelerate tin whisker growth in a rare earth element-containing solder [16]. In SnAgCu–xPr solder, the PrSn3 phases are unstable at storage and can react with oxygen or H2O in air (4 Pr Sn3 + 3O2 → 2 Pr2 O3 12 Sn and 2 Pr Sn3 + 6H2O → 2 Pr (OH)3 + 3H2 + 6 Sn), based on the reactions, the Sn can be squeezed out as the whiskers. With the oxidation reaction on the surfaces of Pr Sn3 intermetallics, whiskers can sprout on the oxide region. The whisker growth would experience two thermodynamic activation processes [17], the selective oxidation of PrSn3 compound and the fast diffusion of released tin to the whisker root. Chen [18] found the stress resulted in the Sn whisker growth was tensile residual stress not compressive stress in Sn–Mn alloy electrodeposits, the volume shrinkage by reactive interdiffusion can result in the tensile stress, while the compressive stress is caused by the volume expansion from the dominant diffusion [19]. In this paper, due to oxidation of PrSn3 phase, the compressive stress can form in the structure, which is the driving force for whisker growth. Moreover, due to the volume expansion induced by oxidation of PrSn3 phases, the neighboring Sn matrix and PrSn3 phase will deform simultaneously, so the cracks can be observed around or in PrSn3 phase, as shown in Fig. 3. These cracks can play as paths for the diffusion of oxygen and vapor, only when PrSn3 phase completely reacts with oxygen and vapor to form Pr2O3 and Pr(OH)3, all Sn in the PrSn3 phase will be squeezed into whiskers, the oxidation procedure and whiskers growth will be ceased. So the compressive stress induced by oxidation will decreased, and the growth rate of whisker will decrease.

4 Conclusions

The addition of rare earth Pr into Sn3.8Ag0.7Cu solder have been reported to be a beneficial effect on wettability, mechanical, however, which can induce the whiskers growth. With several hours’ storage at ambient temperature, different morphologies of whiskers can be observed in the regions of PrSn3 intermetallic compounds. The Pr content and storage time are the main parameters for affecting the whiskers growth. The oxidation of PrSn3 phase will happen during storage, the compressive stress can form in the structure, which is the driving force for whisker growth. The results can provide a reference for the research of lead-free solders.

References

L. Zhang, K.N. Tu, Structure and properties of lead-free solders bearing micro and nano particles. Mater. Sci. Eng. R 82, 1–32 (2014)

Y.C. Huang, S.W. Chen, W. Gierlotka, C.H. Chang, J.C. Wu, Dissolution and interfacial reactions of Fe in molten Sn–Cu and SnPb solders. J. Mater. Res. 22(10), 2924–2929 (2007)

Y.W. Wang, Y.W. Lin, C.T. Tu, C.R. Kao, Effects of minor Fe Co, and Ni additions on the reaction between SnAgCu solder and Cu. J. Alloys Compd. 478(1–2), 121–127 (2009)

C.M.L. Wu, D.Q. Yu, C.M.T. Law, L. Wang, Properties of lead-free solder alloys with rare earth element additions. Mater. Sci. Eng. R 44(1), 1–44 (2004)

L. Zhang, J.G. Han, Y.H. Guo, C.W. He, Effect of rare earth Ce on the fatigue life of SnAgCu solder joints in WLCSP device using FEM and experiments. Mater. Sci. Eng. A 597, 219–224 (2014)

L.L. Gao, S.B. Xue, L. Zhang, Z.X. Xiao, W. Dai, F. Ji, H. Ye, G. Zeng, Effect of praseodymium on the microstructure and properties of Sn3.8Ag0.7Cu solder. J. Mater. Sci.: Mater. Electron. 21(9), 910–916 (2010)

P. Xue, S.B. Xue, Y.F. Shen, F. Long, H. Zhu, Wettability and interfacial whiskers of Sn–9Zn–0.5Ga–0.08Nd solder with Sn, SnBi and Au/Ni coatings. J. Mater. Sci.: Mater. Electron. 25(8), 3520–3525 (2014)

Hao H, He H W, Lu Y. Study of tin whisker growth accelerated by rare earth phase and the mechanism of tin whisker growth. in IEEE 15th International Conference on Electronic Packaging Technology (Chengdu, 2014), pp. 1120–1126

M. Liu, A.P. Xian, Tin whisker growth on the surface of Sn–0.7Cu lead-free solder with a rare earth (Nd) addition. J. Electron. Mater. 38(11), 2353–2361 (2009)

L. Zhang, L. Sun, J.G. Han, Y.H. Guo, Sizes effect of CeSn3 on the whiskers growth of SnAgCuCe solder joints in electronic packaging. J. Mater. Sci.: Mater. Electron. 26(8), 6194–6197 (2015)

M.A. Dudek, N. Chawla, Mechanisms for Sn whisker growth in rare earth-containing Pb-free solders. Acta Mater. 57(15), 4588–4599 (2009)

C.F. Li, Z.Q. Liu, Microstructure and growth mechanism of tin whiskers on RESn3 compounds. Acta Mater. 61(2), 589–601 (2013)

K.N. Tu, Reliability challenges in 3D IC packaging technology. Microelectron. Reliab. 51(3), 517–523 (2011)

H.C. Shi, A.P. Xian, Tin whisker growth on NdSn3 powder. J. Electron. Mater. 40(9), 1962–1966 (2011)

L. Zhang, L. Sun, Y.H. Guo, C.W. He, Wettability of SnAgCu–xEu solders and mechanical properties of solder joints. Chin. Rare Earths 36(4), 51–55 (2015)

T.H. Chuang, Rapid whisker growth on the surface of Sn–3Ag–0.5Cu–1.0Ce solder joints. Scr. Mater. 55(11), 983–986 (2006)

C.F. Li, Z.Q. Liu, J.K. Shang, The effects of temperature and humidity on the growth of tin whisker and hillock from Sn5Nd alloy. J. Alloys Compd. 550, 231–238 (2013)

K.M. Chen, G.D. Wilcox, Observations of the spontaneous growth of tin whiskers on tin–manganese alloy electrodeposits. Phys. Rev. Lett. 94(6), 066104 (2005)

K.S. Kim, J.H. Kim, S.W. Han, The effect of postbake treatment on whisker growth under high temperature and humidity conditions on tin-plated Cu substrates. Mater. Lett. 62, 1867–1870 (2008)

Acknowledgments

This study was funded by the Natural Science Foundation of China (51475220) and the State Foundation of Laboratory of Advanced Brazing Filler Metals and Technology (Zhengzhou Research Institute of Mechanical Engineering) (SKLABFMT-2015-03).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Yang, F. & Zhong, Sj. Whisker growth on SnAgCu–xPr solders in electronic packaging. J Mater Sci: Mater Electron 27, 5618–5621 (2016). https://doi.org/10.1007/s10854-016-4468-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4468-7