Abstract

Ti4O7 submicron rods were successfully fabricated by heat-treating H2Ti3O7 nanowires doped with nano-sized carbon black. This novel method combines the technical superiority of hydrothermal method and carbothermal reduction. In order to investigate reaction process and the influence of the addition of carbon black and reaction temperature on the reduction process, we synthesized substoichiometric titanium oxides in different conditions. The results showed that Ti4O7 submicron rods could be prepared with carbon black content of 3.7 % wt% by heating at 1075 °C for 3 h. The Ti4O7 samples with higher specific surface area showed outstanding conductivity and optical properties. The UV–Vis spectra of Ti4O7 submicron rods showed that the absorption band covered the visible region and part of the near-infrared region. The light absorption property of Ti4O7 submicron rods is quite different with that of TiO2.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Substoichiometric titanium oxides [1, 2], commercially known as Magneli phase, have the generic formula TinO2n−1 (3 < n < 10) [3, 4]. The crystalline structure of Magneli phase can be described as rutile-tupe slabs of infinite extension with different thickness [5]. As the typical member of Magneli phase, Ti4O7 interested people because of outstanding electronic properties, which due to Ti3+ and Ti4+ [6]. The crystalline structures and electronic properties of Ti4O7 have been extensively studied experimentally and theoretically since 1956 [7]. However, researchers have focused more on the preparation and application of this kind of material in recent years. On the one hand, numerous methods have been developed for producing Ti4O7, including reducing TiO2 by carbon or PVA [8], H2 [9, 10], Ti [11], NH3 [12] and C [13]. Using different reductant, TiO2 can be reduced to Ti4O7 under different conditions, including reduction temperature and time. On the other hand, Ti4O7 exhibits high conductivity, high resistance to chemical corrosion, and high over potential of hydrogen. In addition, it is electrochemically stable and competes well with carbon-based materials [14]. Therefore, Ti4O7 is a good candidate as electrode conductive material applied in some batteries beneficially. It has been reported that Ti4O7 could be used as catalyst support for a PEMFC cathode, and the high-potential holding test revealed that Pt/Ti4O7 showed significantly greater stability than a conventional Pt/C catalyst [15]. Ti4O7 particles can be added to Zn electrodes for use in Ni/Zn batteries. Compared with the Zn electrode with acetylene black, the Zn electrode with conductive ceramic shows superior cycle stability, lower charge voltage, higher discharge capacity and discharge voltage [16]. Beyond that, Ti4O7 have been employed to prepare substrate plates in acid batteries, which indicated that the bipolar batteries are about 40 % on the basis of keeping capacity unchanged, compared with the monopolar acid batteries [17].

One-dimensional (1D) submicron oxides have attracted great attention due to their novel properties, such as optical property and gas sensitivity, which lead to new technological applications [18–20]. According to the reports, Ti4O7 submicron rods can be produced by reduced H2Ti3O7 under hydrogen atmosphere [21]. However, hydrogen reduction is complicate and dangerous, furthermore, requires large amount of energy and time. In the present work, we described a simple and low-cost route to prepare Ti4O7 submicron rods by heat-treating H2Ti3O7 nanowires doped with nano-sized carbon black. This novel method for producing 1D Ti4O7 materials combined the technical superiority of hydrothermal method and carbothermal reduction.

2 Experimental details

The method for preparing Ti4O7 submicron rods was basically similar to that in the previous reports for nanotubes and nanowires preparation [22, 23] except for the starting materials and the following carbothermal reduction.

TiO2 (TiO2 ≥ 99.0 %, mass fraction, average particle size <100 nm, Pangzhihua Tianlun Chemical Co. Ltd, China) and carbon black (C ≥ 99.5 %, mass fraction, average particle size <100 nm, Zigong carbon Factory, China) were used as starting materials. 1 g of TiO2 and a certain amount of carbon black were mixed and dispersed in the prepared NaOH (AR, Chengdu Kelong Chemical Co. Ltd, China) solution (10 M). On the basis of the theoretical calculation of chemical equation, the carbon black content of mixture researched in this work was 3.5–3.9 wt%. We choose a clean kettle (50 ml) as a reaction tank for hydrothermal synthesis. The kettle was sealed at ordinary temperature and pressure, and then heated at 170 °C for 48 h in Muffle furnace. The obtained products were washed by means of supersonic dispersion and suction filtration with 0.1 M HCl (36 wt%, AR, Chengdu Kelong Chemical Co. Ltd, China) and deionized water in sequence. In order to analysis the reduction process from H2Ti3O7 nanowires to Ti4O7 submicron rods, the as-prepared H2Ti3O7 nanowires mixed with nano-sized carbon black were moved into crucibles and put into vacuum carbon tube furnace, and then the prepared samples were heated up to different reaction temperatures (950–1075 °C) at a heating rate of 10 °C/min and held for 3 h when the system pressure was 50 Pa. The main reaction process can be expressed as follows:

The microstructure was studied using scanning electron microscopy (SEM). Phase identification was performed by an X-ray diffraction (XRD) instrument using Cu Kα radiation. The free carbon content was detected by infrared carbon and sulfur analyzer. The conductivity was tested by Four Point Probes testing system. The ultra-violet spectrophotometer was collected on ultraviolet spectrophotometer.

3 Results and discussions

3.1 Effects of the addition of carbon black

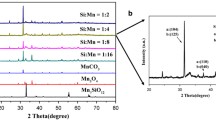

In this work, on the basis of theoretical calculation according to the chemical equation, we prepared products reduced by different black carbon content (3.6, 3.7, 3.9 wt%) at 1075 °C for 3 h, and the composition and crystal structure of the products were characterized by XRD. There is no diffraction peak of carbon as shown in Fig. 1. The mother phase of Ti4O7 is formed, but several peaks correspond to Ti9O17, Ti6O11, Ti5O9 can be detected in Fig. 1a, which means that the carbon content 3.6 wt% is too low to obtain Ti4O7 phase. Figure 1b shows that the most desired phase Ti4O7, almost without any other impure diffraction peaks, can be obtained when the carbon content reaches up 3.7 wt%. The main diffraction peaks of Ti4O7 and miscellaneous peaks of Ti3O5 can be detected in Fig. 1c, which indicates that the higher content of carbon black (3.9 wt%) lead to the over reduction. Above all, the proper addition of carbon black in raw material is 3.7 wt%.

3.2 Effects of reaction temperature

The as-prepared H2Ti3O7 nanowires with carbon content 3.7 wt% were reduced at different temperatures ranging from 975 to 1075 °C for 3 h, as shown in Fig. 2. The phases of the sample reduced at 975 °C contain Ti7O19 and Ti8O15. During the reduction processes, monoclinic H2Ti3O7 decomposed into tetragonal TiO2 and H2O, and TiO2 could be reduced initially to Ti7O19 and Ti8O15 by carbon black. At a higher temperature (1000 °C), the mother phase transformed to Ti8O15 along with the reduction. The samples reduced at 1025 °C mainly contain Ti6O11 and little Ti5O9, and the diffraction peaks of Ti8O15 disappeared. In the further process, the primary phase of the sample turned to be Ti4O7 with the reduction at 1050 °C, but little diffraction peaks of Ti5O9 can be identified. Only Ti4O7 phase was formed when the products reduced at 1075 °C. The free carbon content of the product is 0.06 %, which can indicate that the synthesized catalyst is almost the isolation of the Ti4O7 phase and the reduction temperature is suitable to synthesize Ti4O7 submicron rods.

In order to study the conductivity of the Ti4O7 submicron rods, the samples were compacted in a uniaxial press under 20 kgf cm−2 pressure into round pellets to measure its resistivity, as shown in Table 1. The sample reduced at 1075 °C showed the highest conductivity, which is higher than the Ti4O7 powders fabricated by us before [13]. The result affected by phase composition was consistent with the conductivity of titanium oxides depending on their oxygen content [5]. Because of the outstanding conductivity, the Ti4O7 submicron rods can be potentially used as electrode material or conductive additive in lead-acid batteries [24], fuel cells [25] to improve the battery performance.

3.3 Structural characteristic of the Ti4O7 submicron rods

As shown in Fig. 3a, the H2Ti3O7 nanowires with the length 1–4 μm were unordered and dispersive. The nano-sized carbon black powders dispersed on the surface or interspersed among the H2Ti3O7 nanowires, which contributed to the harmonious reduction. The Ti4O7 submicron rods with the length of 0.5–2 μm could be formation, as shown in Fig. 3b. During the reduction process, the closely packed nanowires could stick together and then the thick rods came into being. The nanowires got shorter during the reduction progress, which was attributed to the defects in the H2Ti3O7 intermediate nanowires formed as a result of the wetchemistry production mode at low temperature. The nanowires with more defects are easy to be broke into parts at high temperature.

As mentioned before, the Ti4O7 submicron rods have outstanding conductivity. The conductive additive used in batteries should have high surface area and good dispersion, which make the conductive additive and active material contact fully, and the performance of batteries could be further improved. Compared with previous research results [13, 21], Ti4O7 submicron rods have higher BET surface area (8.107 m2 g−1), which has been improved obviously. They can be potentially applied to lithium ion batteries [26] and Ni/Zn batteries [16], which can possibly help to develop energy storage batteries to meet the demand of green energy sources environmental protection.

3.4 Optical property of the Ti4O7 submicron rods

Compared with TiO2 [27], the light absorption of the Ti4O7 submicron rods were much higher. As shown in Fig. 4, the absorption spectrum of the Ti4O7 submicron rods exhibited two absorbing bands from 200 to 1100 nm. The weak absorbing band of Ti4O7 appeared in the UV region. A strong absorbing band from 305 nm to 1100 nm showed outstanding light absorption properties in the visible light and near-infrared region. Compared with TiO2, Ti4O7 have special ionization states of oxygen vacancies, which lead to different light absorption properties. The Ti4O7 submicron rods with larger surface area and good optical absorption are expected to improve the utilization of the photoelectrodes [28–30].

4 Conclusions

The Ti4O7 submicron rods were firstly fabricated by heat-treating H2Ti3O7 nanowires doped with nano-sized carbon black powders. The reaction progress and the influence of the addition of carbon black and heating temperature to synthesizing Ti4O7 submicron rods were discussed. The Ti4O7 submicron rods can be obtained by heating H2Ti3O7 nanowires with carbon content 3.7 wt% at 1075 °C for 3 h. The Ti4O7 submicron rods with larger surface area and outstanding conductivity can be a feasible candidate for batteries. In addition, Ti4O7 submicron rods have outstanding optical absorption. Therefore, it is believed that Ti4O7 submicron rods could have potential in photoelectrodes. In future, more efforts have to be done to deepen the research on application of Ti4O7 submicron rods.

References

S. Andersson, B. Collen, U. Kuylenstierna, A. Magneli, Acta Chem. Scand. 11, 1641 (1957)

S. Andersson, B. Collen, G. Kruuse, U. Kuylenstierna, A. Magneli, H. Pestmalis, S. Asbrink, Acta Chem. Scand. 11, 1653 (1957)

D.C. Lynch, D.E. Bullard, Metall. Mater. Trans. B 28, 447 (1997)

J.R. Smith, F.C. Walsh, R.L. Clarke, J. Appl. Electrochem. 28, 1021 (1998)

L.A. Bursill, B.G. Hyde, Prog. Solid State Chem. 7, 177 (1972)

L. Leandro, M. Giuseppe, Phys. Rev. B 79, 245133 (2009)

S. Andersson, A. Magneli, Naturwissenschaften 43, 495 (1956)

M. Toyoda, T. Yano, B. Tryba, S. Mozia, T. Tsumura, M. Inagaki, Appl. Catal. B Environ. 88, 160 (2009)

H. Harada, T. Ueda, Chem. Phys. Lett. 106, 229 (1984)

M.A.R. Dewan, G.Q. Zhang, O. Ostrovski, Metall. Mater. Trans. B 40, 62 (2009)

Y. Lu, Y. Matsuda, K. Sagara, L. Hao, T. Otomitsu, H. Yoshida, Adv. Mater. Res. 415–417, 1291 (2012)

C. Tang, D.B. Zhou, Q. Zhang, Mater. Lett. 79, 42 (2012)

R.J. Zhu, Y. Liu, J.W. Ye, X.Y. Zhang, J. Mater. Sci. Mater. Electron. 24, 4853 (2013)

F.C. Walsh, R.G.A. Wills, Electrochem. Acta 55, 6342 (2010)

T. Ioroi, H. Senoh, S. Yamazaki, Z. Siroma, N. Fujiwara, K. Yasuda, J. Electrochem. Soc. 155, B321 (2008)

Z.G. Luo, S.B. Sang, Q.M. Wu, S.Y. Liu, ECS Electrochem. Lett. 2, A21 (2013)

K. Ellis, A. Hill, J. Hill, A. Loyns, T. Partington, J. Power Sources 136, 366 (2004)

M. Dai, F. Xu, Y.N. Lu, Y.F. Liu, Y. Xie, Appl. Surf. Sci. 257, 3586 (2011)

B. Liu, L.H. Zhang, H. Zhao, Y. Chen, H.Q. Yang, Sens. Actuators B 173, 643 (2012)

M.R. Karim, J.H. Yeum, M.S. Lee, K.T. Lim, React. Funct. Polym. 68, 1371 (2008)

W.Q. Han, Y. Zhang, Appl. Phys. Lett. 92, 203117 (2008)

T. Kasuga, M. Hiramatsu, A. Hoson, T. Sekino, K. Niihara, Adv. Mater. 11, 1307 (1999)

Q. Chen, W. Zhou, G.H. Du, L.M. Peng, Adv. Mater. 14, 1208 (2002)

CSIRO Report DMR-098, Evaluation of the effect of Ebonex additive on lead-acid battery capacity at different discharge rates, Aug 1995

L.M. Vracar, N.V. Krstajic, V.R. Radmilovic, M.M. Jaksic, J. Electroana. Chem. 587, 99 (2006)

W.J. Macklin, R.J. Neat, Solid State Ionics 53–56, 694 (1992)

R. Kun, S. Tarjan, A. Oszko, T. Seemann, V. Zollmer, M. Bussed et al., J. Solid State Chem. 182, 3076 (2009)

S.N. Subbarao, Y.H. Yun, R. Kershaw, K. Dwinghta, A. Wold, Inorg. Chem. 18, 488 (1979)

M. Radecka, A. Trenczek-Zajac, K. Zakrzewska, M. Rekas, J. Power Sources 173, 816 (2007)

M. Watanabe, W. Ueno, T. Hayashi, J. Lumin. 122–123, 393 (2007)

Acknowledgments

This work was financially supported by The Open Fund Project from the Key Laboratory of Oil and Gas Material (X151515KCL12, 2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Lin, Y., Zhong, X. et al. Fabrication and characterization of Magneli phase Ti4O7 submicron rods. J Mater Sci: Mater Electron 27, 4861–4865 (2016). https://doi.org/10.1007/s10854-016-4368-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4368-x