Abstract

SnSb4S7 thin films were deposited on glass substrate by vacuum thermal evaporation method. The effect of annealing on the structural and electrical properties of the SnSb4S7 thin films was investigated. The X-ray diffraction analysis revealed that the powder crystallized in monoclinic structure with a preferred orientation along (\(\bar{2}1\bar{3}\)) plane. SnSb4S7 thin films are polycrystalline in nature and the average grain size increases by increasing annealing temperature. Atomic force microscopy and scanning electron microscopy were used to characterize the surface morphology of the layers. Electrical properties have been investigated by ac impedance spectroscopy over a wide range of temperature up to 673 K starting from room temperature in the frequency range 5 Hz–13 MHz. The complex impedance plots display one semicircle with equivalent circuit functions as typical parallel RC. By increasing the temperature, the Impedance spectroscopy analysis shows that the resistance decreases from 107 Ω to 104 Ω. In addition, the analysis of conductivity indicates that both AC and DC conductivities of materials increase with increasing temperature The activation energy values calculated from DC conductivity and angular frequency relaxation are almost identical, indicating that the conduction mechanism was thermally activated and was assured by hopping between localized states.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, researchers paid particular attention to the sulfosalt semiconductors which had many applications field. Because of their excellent optical properties, sulfosalt materials are very attractive for a wide variety of technological applications such as thin film photovoltaic applications [1], phase change memory devices [2], thermoelectric energy conversion applications [3] and also it is promising to use sulfosalt in the sensor technologies field. SnSb4S7 is one member of the sulfosalt family SnxSbySz and is a very promising semiconductor that possesses important and advantageous properties for optoelectronic and solar cells applications [4–6].

Impedance spectroscopy (IS) is a valuable means for inquiring and has been extensively applied to study the frequency-dependent electrical properties of materials. The resistance and capacitance of crystallites and grain boundaries, which is frequency and temperature dependent, can be evaluated from IS spectra. This technique permits us to separate the real and imaginary part of the complex impedance and related parameters, and therefore provides information of the structure-properties correlation in the studied samples. We report in this work and for the first time at our knowledge a study of the electrical properties of the material SnSb4S7 by impedance spectroscopy. The objective is the understanding of electrical conduction mechanisms in this new semiconductor material. So, in the present work, SnSb4S7 thin films were deposited by vacuum thermal evaporation on no heated glass substrates after what they were annealed under nitrogen atmosphere at 423, 523 and 625 K during 1 h. Therefore, the annealed SnSb4S7 thin films were examined by the well-known impedance spectroscopy method to investigate the electrical properties and the conduction processes. The results of the electrical properties were correlated with those of structural and morphological properties.

2 Experimental detail

The compound SnSb4S7 was synthesized by direct fusion of the component elements weighted in the stoichiometric proportions 1: 4: 7. The mixture was sealed in vacuum in a quartz tube. In order to avoid explosions due to sulfur vapor presses, the quartz tube was heated slowly (10 °C/h). A complete homogenization could be obtained by keeping the melt at 600 °C for 51 h.

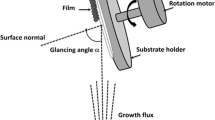

The tube was then cooled at the rate 10 °C/h. Therefore cracking, due to thermal expansion of the melt on solidification, was avoided. The compound obtained is gray color [6]. X-ray diffraction of SnSb4S7 powder analysis showed that only the SnSb4S7 phase was present in the ingot. Crushed powder of this ingot was used as raw material for thin films deposition (see Fig. 1).

SnSb4S7 thin films were deposited by single source thermal evaporation from a Molybdenum boat onto no heated glass substrates under vacuum of 10−5 Torr. After what the as deposited thin films were annealed under nitrogen atmosphere at 423, 523 and 625 K during 1 h.

The structural properties of the evaporated thin films were determined by X-ray diffraction (XRD) using CuKα radiation (λ = 0.154056 nm). Impedance measurement is made by the method of impedance spectroscopy with the HP4192A impedance analyzer over a wide range of temperature up to 673 K starting from room temperature in the frequency range 5 Hz–13 MHz. The measurements were performed using two-electrodes, which were painted on the two extremities of the sample using silver paste.

3 Results and discussion

3.1 Structural analysis

3.1.1 X-ray diffraction of SnSb4S7 powder

Figure 2 shows the X-ray diffraction patterns of our synthesized SnSb4S7 powder and the one taken from the reference (ICSD-169941) [7]. The concordance between both patterns confirms that only the phase SnSb4S7 exists with a privileged orientation along the (\(\bar{2}1\bar{3}\)) plane located at 2θ = 31.5°. We note that SnSb4S7 material crystallizes in the monoclinic structure [6].

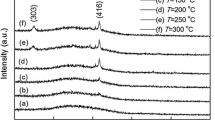

3.1.2 X-ray diffraction of SnSb4S7 thin film: effect of annealing temperature under nitrogen atmosphere

Figure 3 shows XRD patterns of as-prepared and annealed SnSb4S7 thin films. All the diffraction peaks could be attributed to the monoclinic structure of SnSb4S7 (ICSD-169941). All the films show preferred orientation along the (\(\bar{2}1\bar{3}\)) plane. By increasing annealing temperature it is clear that more peaks appear which assigned to the SnSb4S7 phase.

So, the appearance of these peaks confirms the enhancement of the crystallinity of the annealed films. Indeed, to confirm this, the crystallite size was calculated using the XRD patterns (see Table 1).

The crystallite size can be simply determined using the Debye–Scherrer formula [8] (Eq. 1):

where D is average crystallite dimension, λ is the wavelength of CuKα radiation, β size is the integral breadth of a Bragg peak located at 2θ corrected for the broadening caused by the instrumental setup of the diffraction experiment and θ is the diffraction angle of the peak. Peak broadening in X-ray or neutron powder diffraction can be attributed to one or more of the following sources: instrumental broadening, finite crystallite size, the presence of micro-strain and/or extended defects (stacking faults, micro-twinning, dislocations, etc.) [9, 10].

The total broadening β t is given by the Eq. (2)

where ε is the strain and β 0 the instrumental broadening (β 0 = 0.02°). When we plot \((\beta_{t}^{2} - \beta_{0}^{2} )\cos^{2} \theta\) versus \(\sin^{2} \theta\) we get a straight line with slope \((4\varepsilon )^{2}\) and intercept \(\left( {\frac{0.9\lambda }{D}} \right)^{2}\) (Eq. 3).

The average grain sizes of the layers were calculated using the principal diffraction. Table 1 summarizes all these values. We can note that the crystallite sizes were affected by annealing. So, we conclude that the crystallinity of the films was enhanced by increasing the annealing temperature.

3.2 Morphological properties

The morphology of SnSb4S7 thin films was investigated by atomic force microscopy (AFM, Taping mode) and scanning electron microscopy (SEM).

The surface morphology of SnSb4S7 thin films with and without annealing was analysed by atomic force microscope (AFM). Figure 4 shows the 3D AFM images taken in 0.1 µm × 0.1 µm area of the surface topography for the evaporated SnSb4S7 thin films. These images reveal that the surface morphology of the films changes by increasing the annealing temperature. It’s clear that the as-deposited film is formed by very small crystallites and the annealed films show that the small crystallites have coalesced because of the annealing temperature, resulting in rougher surfaces with some additional big grains. The root mean square roughness (RMS) values of the films are given in Table 1

AFM analysis on the films annealed at different temperatures reveal that the surface roughness increases with the increase of the annealing temperature, suggesting an increase in crystallite size with temperature.

As expected, the surface morphology of the films changes when the annealing temperature increases, this is in a good agreement with the XRD results and confirms that the increase in annealing temperature changes the thin film structure.

SEM images have been obtained for samples at different annealing temperatures in order to study their effects on the film surfaces. Figure 5 shows the micrographs of SnSb4S7 thin films. It is clear from the micrographs that all films surfaces are smooth and no isolated particles are observed. We noticed, for 623 K, a mixture of grains with different sizes and this morphology can explain the high values obtained for roughness. The surface is much more homogeneous than as-deposited thin film. For this case, the particles were distributed homogeneously on the surfaces and a difference in number and size with increasing annealing temperatures is observed. Once again, these results confirm those obtained by X-ray diffraction and by AFM.

3.3 Electrical properties

3.3.1 Impedance spectroscopy

Impedance spectroscopy technique consists in the application of sinusoidal voltage \(v\left( t \right) = V_{0} exp\left( {j\omega t} \right)\) to the sample and extract the value of current \(i\left( t \right) = I_{0} exp(j\omega t - \varphi )\). The complex impedance is defined as \(Z = Z_{0} ej\varphi\); Z 0 and φ allows defining imaginary and real part:

In general, in the case of non-isotropic material, the response of excitation process is shown as a pure resistance and a pure capacity in the case of an insulator. So, the response of the sample can be modeled as a parallel RC circuit (Debye model).

The spectra will present one or many semicircular arc that we can retrieve all characteristics as relaxation time, resistance and capacity. We should indicate that each semi-circle was an equivalent circuit treated as a combination of resistance and capacitance usually placed in parallel. The complex impedance of each arc is given by [11]

We remind that Impedance measurements were performed with the HP4192A impedance analyzer in the measurable impedance range from 5 Hz to 13 MHz with data taken at 20 points per decade. Real and imaginary parts were measured and displayed in the complex plane.

Figure 6 Shows the Nyquist diagrams de of annealed SnSb4S7 thin films. These spectra were obtained by plotting Z” as function of Z’ in the temperature range for 593–673 K.

The obtained arcs present the response to excitatory electric fields applied to the sample and corresponds to intergranular polarization phenomenon intervening at higher frequencies. This combination is characterized by a time constant or characteristic relaxation time τ = RC = 1/ω m where ωm is the maximum angular pulsation. The top of arc was characterized by a maximum of angular frequency. We note that the maximum in Z” peak shifts to higher frequency with the temperature [12].

All spectra show a single semicircle slightly depressed indicating the single relaxation process. We note that their maximum shift to the higher frequencies as the temperature increases. Also, the diameter and the maximum of this semicircles decrease as the increasing of annealing temperature. These observations lead to the conclusion that the electrical conductivity is thermally activated well as the relaxation times distribution [13, 14]. As well, semi circles can indicate the homogeneity of evaporated SnSb4S7 thin films that is in good agreement with the morphological and structural results.

Tables 2, 3, 4, 5 shows the resistance values (Rp) of all samples. It is clear that the resistance decreases by increasing annealing temperature.

Figure 7 shows the dependence of imaginary part as angular frequency at various temperatures.

Therefore, the presence of peak frequencies shows an Arrhenius behavior which allows us to deduce the activation energy. Indeed, the relaxation time τ of these samples obeys to the well-known Arrhenius law [15]:

where ω m is a constant. k B is the Boltzmann constant and E a is the activation energy. As shown in Fig. 5. the expression of \(Ln(\omega_{m} ) \, = \, f\left( {1000/T} \right)\) leads to a linear function, in good agreement with expression Eq. (7). Ea values were given in Table 6.

3.3.2 DC conductivity and temperature dependence

To identify the conduction process in the annealed in SnSb4S7 thin films, we can study the variation of DC conductivity versus temperature. The experimental data of the DC conductivity was analyzed using the following equations [13]:

where B is a constant independent of temperature T, k B the Boltzmann constant and E a is the activation energy.

The values of specific DC conductivity have been calculated (see Table 2) from the admittance data using relation

where R p is the intersection of the arc with real axis, l presents sample thickness and S the sample area under investigation [16].

Figure 8 shows the temperature dependence of DC conductivity. It’s clear that DC conductivity is thermally activated and the values of the activation energy (E a ) have been estimated from the plots. As seen, the activation energy calculated from Eq. (8) is identical to the activation energy obtained from the angular relaxation frequency and E a values decrease by increasing annealing temperature (see Table 6). In this case, the dominant transport mechanism insure by hopping conduction. Indeed, the localized charge carriers can jump from one site to other by thermal excitation where τ present the time of hopping [12–14].

3.3.3 Dependence of AC conductivity on frequency and temperature

AC conductivity measurements have been widely used to investigate the nature of defect centers in disordered systems since it is assumed that they are responsible for this conduction type [14, 17]. Generally, σ AC in most of the cases has been observed to follow a universal power law [18] and dependence of AC conductivity on frequency is as given below

where A is the temperature dependant constant and s (in general: \(0 < s < 1\)) is the frequency exponent.

The electrical conductivity σ(ω) of SnSb4S7 thin film at a particular temperature over a frequency range can be written in the combination of DC and AC part [19]:

Figure 9 shows the dependence of conductivity as the function of angular frequency at different temperatures. It is clear that all plots present the same behavior. For all plots the conductivity increases with increasing of frequency showing a distinct change in slope from the critical maximum angular pulsation ω m . Indeed, it is obvious that from Fig. 7 that for each plot, the linear region occurs from the maximum angular pulsation ω m , which can be a sign of release of trapped charges in the disorder system. Whereas for the pulsations lower than ω m the conductivity remains stable which may be due of free charge formation in the films [19]. On the other hand the slopes of the curves ln(σAC) versus ln(ω) were calculated at different temperatures and the slope has been designated as “s” [19, 20]. The interaction between all the charge species participating in the polarization process is characterized by the parameter “s” [19, 20]. The parameter s is used to describe the AC component contributing to the dispersive region [19, 20] (see Fig. 9; Tables 2, 3, 4, 5).

The values of “s” found in this work are less the unity and correlated to the charge carriers or extrinsic dipoles arising from the presence of defects and impurities in the film [21, 22]. Therefore, The AC conductivity shifts to higher frequency with the temperature which agrees with the observed shift of the relaxation frequency. It has been shown [23, 24] that the observed shift is originated from a thermally activated process. Then the conductivity dependence on frequency is an indication of hopping conduction at higher frequency between localized states [14, 17]. The temperature behavior of s could determine the conduction mechanism. In the CBH model that describes charge carrier hops between sites over the potential barrier separating them s decreases with the increment in temperature [25–28]. It is worth mentioning that the calculated values of s decrease with increasing rising temperature which is in good agreement with CBH model proposed by Elliot et al. [28, 29].

The results of the morphological properties indicate that as-deposited thin film was composed by very small crystallites containing grain boundaries. The free electrons passing through these grain boundaries at risk to make recombination [30]. With annealing treatment under nitrogen, crystallite size increases by increasing annealing temperature and the grain boundaries effect decrease. Indeed, the possibility of recombination decreases also and the number of charge carriers increases which promotes the conduction [31].

4 Conclusion

In conclusion, we have studied the effect of annealing under nitrogen atmosphere at 423, 523 and 625 K on structure and electrical behavior of SnSb4S7 thin films deposited on glass substrates by single source vacuum thermal evaporation method. All samples have a typical monoclinic structure and grown in a preferred orientation along the (\(\bar{2}1\bar{3}\)) plane located at 2θ = 31.5°. The crystallinity of the films was enhanced and the grain sizes were increased from 25 nm to 44 nm by increasing the annealing temperature. The morphological properties have been enhanced by annealing under nitrogen. Impedance spectroscopy analysis of SnSb4S7 thin film annealed under nitrogen atmosphere was performed in this work. The DC conductivity shows an increasing tendency with the increase of the annealing temperature. The results of this investigation reveal that the dielectric behaviour strongly depends on the annealing temperature. The activation energy obtained from both angular relaxation pulsation and DC conductivity suggest that the carrier transport mechanism is a hopping mechanism thermally activated in the band gap. Additional, the temperature dependent AC conductivity and the values of frequency exponent “s” suggest that correlated barrier hopping model (CBH) is the most suitable model to characterize the electrical conduction mechanism of the obtained SnSb4S7 thin films. So, all these electrical properties in addition of the optical ones of SnSb4S7 material show the interest of this material in optoelectronic applications [6].

References

H. Dittrich, A. Bieniok, U. Brendel, M. Grodzicki, D. Topa, Thin Solid Films 515, 5745–5750 (2007)

M.Y. Versavel, J.A. Haber, Thin Solid Films 515, 7171–7176 (2007)

A. Gassoumi, M. Kanzari, Physica E Low-Dimens. Syst. Nanostruct. 44(1), 71–74 (2011)

D. Abdelkader, M. BenRabeh, N. Khemiri, M. Kanzari, Mater. Sci. Semicond. Process. 21, 14–19 (2014)

N. Drissi, A. Gassoumi, H. Boughzala, J. Ouerfelli, M. Kanzari, J. Mol. Struct. 1047, 61–65 (2013)

A. Jebali, N. Khemiri, F. Aousgi, M. Ben, Rabeh, M. Kanzari. Mater. Sci. Semicond. Process. 27, 1057–1064 (2014)

ICSD-169941(Inorganic crystal structure database)

S.F. Bartram, Handbook of X-Rays, ed. by E.F. Kaelebe (McGraw-Hill, New York, 1967), Chap. 17

P. Karen, P.M. Woodward, J. Solid State Chem. 141, 78–88 (1998)

T. Theivasanthi, M. Alagar, Nano Biomed. Eng. 4(2), 58–65 (2012)

K. Prabakar, S.K. Narayandass, D. Mangalaraj, Mater. Chem. Phys. 78, 809–815 (2003)

N. Kılınç, S. Öztürk, L. Arda, A. Altındal, Z.Z. Öztürk, J. Alloys Compd. 536(25), 138–144 (2012)

B. Roy, S. Chakrabarty, M. Pal, A. Dutta, O. Mondal, Mater. Charact. 70, 1–7 (2012)

A. Mhamdi, B. Ouni, A. Amlouk, K. Boubaker, M. Amlouk, J. Alloys Compd. 582, 810–822 (2014)

T. Nagata, T. Shimura, A. Ashida, N. Fujimura, T. Ito. J. Cryst. Growth 237–239(Part 1), 533–537 (2002)

V. Tudić, Engineering 6, 449–461 (2014)

R. Ondo-Ndong, G. Ferblantier, F. Pascal-Delannoy, A. Boyer, A. Foucaran, Microelectron. J. 34, 1087–1092 (2003)

A.K. Jonscher, Dielectric Relaxation in Solids (Chelsea Dielectric, London, 1983)

N.D. Sankır, E. Aydın, M. Sankır, Int. J. Electrochem. Sci. 9, 3864–3875 (2014). www.electrochemsci.org

N.F. Mott, E.A. Davis, Electronic Processes in Non-Crystalline Materials (Clarendon Press, Oxford, 1979)

S.S.N. Bharadwaja, P. Victor, P. Venkateswarulu, S.B. Krupanidhi, Phys. Rev. B 65, 174106 (2002)

P. Venkateswarlu, A. Laha, S.B. Krupanidhi, Thin Solid Films 474, 1–9 (2005)

V. Biju, M.A. Khadar, J. Mater. Sci. 38, 4055 (2003)

S. Kurien, J. Mathew, S. Sebastian, S.N. Potty, K.C. George, Mater. Chem. Phys. 98, 470 (2006)

J.T. Gudmundsson, H.G. Svavarsson, S. Gudjonsson, H.P. Gislason, Phys. B 340, 324 (2003)

T. Winie, A.K. Arof, Ionics 10, 193 (2004)

M.A. Afifi, A.E. Bekheet, E.A. Elwahhab, H.E. Atyia, Vacuum 61, 9 (2001)

A.A. Ebnalwaled, Int. J. Basic Appl. Sci. IJBAS-IJENS 11(06), 194–207 (2011)

S.R. Elliott, Philos. Mag. 36, 1291 (1977)

C. Magne, Thesis “Optimisation de couches d’oxyde nano-structurees pour applications aux cellules solaires a colorant” Ecole doctorale de chimie physique et analytique de Paris centre (ED388) 90-94 (2012). https://tel.archives-ouvertes.fr/tel-00833234/document

I. Trabelsi, N. Ben Mehrez, M. Kanzari, J. Mater. Sci.: Mater. Electron. 26, 7763–7770 (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Trabelsi, I., Jebali, A. & Kanzari, M. Electrical characterization of SnSb4S7 thin films by impedance spectroscopy. J Mater Sci: Mater Electron 27, 4326–4335 (2016). https://doi.org/10.1007/s10854-016-4300-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4300-4