Abstract

Molybdenum disulfide thin films have been deposited from an aqueous acidic bath using sodium thiosulphate as sulphide ion source. The various preparative parameters are optimized and growth mechanism is discussed. X-ray diffraction analysis reveals that the films are polycrystalline in nature with hexagonal structure. A microstructural study has been carried out by field emission scanning electron microscopy. EDAX analysis shows that the films are nearly stoichiometries of the Mo:S i.e. 1:2. Electrical conductivity was found to be in the order of 10−5–10−3 (Ω cm)−1. From optical absorption studies the energy band gap of MoS2 is estimated to be 1.7 eV.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The inventions of novel materials lead progress of science and technology. These materials have assorted characteristics and applications. A lot of recent interest is in the preparation of polycrystalline thin films of semiconducting transition metal dichalcogenides e.g. WS2, WSe2, MoS2, MoSe2 and its ternary mixed compounds. The molybdenum disulphides belong to the VI group with a layered structure. MoS2 is built up of van der Waals bonded S–Mo–S units [1–3]. MoS2 has remarkable importance because of its distinctive electronic, optical, and catalytic properties, as well as its applications include intercalation compounds, PEC solar cells, catalysis, solid lubricants, rechargeable batteries, sensors, transistors and integrated circuits [4–13].

There are several methods reported for the preparation of molybdenum disulfide thin film like chemical methods [14, 15], electrodeposition [16–18], SILAR [19] vapor deposition, [20–22] etc. Some researchers have synthesis MoS2 in the form nanoplates, nanoribbons, inorganic nanotubes, and fullerene-like nanoparticles [23–27].

In this paper, we report that a synthesize of the nanocrystalline molybdenum disulfide thin film by a chemical route in acidic solution using ammonium molybdate and sodium thiosulphate were used as precursors and citric acid as a complexing agent. The film was studied for structural, compositional and opto-electrical measurement.

2 Experimental

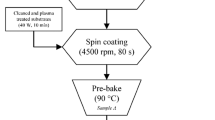

The deposition of nanocrystalline MoS2 films is based on slow release of Mo4+ and S2− ions in the solution which condense onto the substrate. The substrates used for depositing the films were non-conducting commercial glass slides of the size 75 × 25 × 2 mm. The glass slides were cleaned with detergent, ethanol and kept immersed in distilled water prior to deposition..

For deposition of molybdenum disulfide thin films, 15 mL (0.25 M) ammonium molybdate solution was taken in a beaker. 10 mL (1 M) citric acid, 12 mL (15 %) hydrazine hydrate, 30 mL (0.25 N) sodium thiosulphate was added to it. The total volume of the reaction mixture was made to 100 mL by adding double distilled water. The solution was stirred vigorously before dipping glass substrates, which were kept vertically slightly tilted in the reactive bath. The temperature of the reactive bath was maintained at 298 K, speed of rotation of substrates adjusted between 65 and 70 rpm, timing for deposition 4 h and string speed of precursor is 30 rpm set on the automatic chemical bath unit (A-CBD unit). After completion commanded experimental time the automatic-chemical bath unit stops. Then the slides were removed and washed several times with double-distilled water. The deposited substrate was dried naturally, preserved in dark desiccators over anhydrous CaCl2 and subjected to various characterizations. Automatic chemical bath unit (A-CBD unit) and deposited materials in the form of thin film are shown Fig. 1a, b.

3 Results and discussion

3.1 Growth mechanism

MoS2 thin films were deposited from am aqueous acidic medium containing Mo-citrate complex and S2− ion. In the beginning, hydrazine hydrate reduces Mo6+ to Mo4+. The dissociation of Mo–citric acid complex at higher temperature liberates bear Mo4+ ions.

Similarly, the sodium thiosulphate forms S2− ions. It is followed by the formation of MoS2, it occurs by condensation on ion by ion basis on glass substrate. The formation of MoS2 is possible when the ionic product of Mo4+ and S2− ions exceeds the solubility product of MoS2.

In the growth process, no film formation occurs within first 50 min. This is the induction period required to from nucleation centers on the substrates. Speed of rotation 65–70 rpm was optimized to deposit molybdenum disulphide thin films. The films obtained are uniform, well adherent to substrate and yellow in color. The thickness of molybdenum disulfide thin film was calculated by the gravimetric method and found to be 0.52 μm.

3.2 Crystallographic studies

The crystal properties and phase purity of the samples were characterized by X-ray diffraction. The XRD pattern of molybdenum disulfide thin film is shown in Fig. 2.

Sharp peaks indicate that the films exhibit polycrystalline nature. The observed d values are compared with JCPDS diffraction file No. 73-1508 to determine the crystal structure. The major detectable diffraction peaks can be readily indexed to the hexagonal phase of MoS2 [14]. No peaks corresponding to metallic Mo or S are found and hence it is concluded that the film deposited material is of single phase. The peaks are identified as (300), (320), (410), (600) (602) and (801). The intensity of peak (300) increases significantly faster than other peaks, indicating a relatively preferred structure orientation in the (300) plane. A method that evaluates the magnitude of the preferred orientation factor ‘f’ for a given plane (peak) relative to other planes (peaks) in material was employed. According to this method the preferred orientation factor ‘f’ (300) of the (300) plane for the MoS2 thin films has been calculated by evaluating the fraction of (300) plane intensity over the sum of intensities of all other peaks has been evaluated for the films. f(300) = 0.3170, f(320) = 0.1833, f(410) = 0.1494, f(600) = 0.1448, f(620) = 0.1175, f(801) = 0.0877.

The FWHM of most intense peak was used to calculate crystallite size (t) using Scherrer formula;

where t is the crystallite size (Å), λ is the X-ray wavelength (Å), β is the full width at half maximum (rad), θ is the Braggs diffraction angle and k is constant. The average crystallite size was calculated by resolving the highest intensity peak i.e. (300) planes.

The cell constants were computed for the peak observed in the XRD pattern of synthesized MoS2 thin film in order to check the presence of any micro strains using relation;

where h·k·l are Miller planes and d is inter planar distance. The cell constant is found to be a = 12.32 Å and c = 3.47 Å, respectively. These values are in good agreement with the earlier reported value [15].the unit cell volume can be calculated by using equation;

The obtained ‘d’ values are tabulated along with standard ‘d’ values, cell parameters, volume and the average crystallite size of the thin film in Table 1.

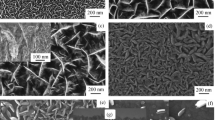

3.3 Surface morphology

A FESEM micrograph of as deposited molybdenum disulfide film is shown in Fig. 3. It is observed from field emission scanning electron microscopy (FESEM) that the substrates are well-covered with the deposited molybdenum disulfide layers without cracks and pinholes. The average grain size was calculated by using Contrell’s method. This method relates the number of intercepts of grain boundary per unit length ‘PL’ and is given by;

where n is the total number of intercepts, r is the radius of curvature, M is the magnification used. Using PL, the grain size ‘L’ was determined by using the following relation;

The mean grain size as calculated from FESEM was found to be in accord with those obtained from Scherer’s formula in XRD.

3.4 Compositional studies

EDAX patterns for the typical molybdenum disulfide thin film is shown Fig. 4. The stoichiometry of the grown crystals was analyzed by EDAX and it was found that the growth crystals possess nearly perfect stoichiometry with the chemical formula molybdenum disulfide (Mo: S.) i.e. 1:2.

3.5 Electrical properties

The electrical conductivity measurement was carried out in the temperature range 300-525 K. At room temperature, the specific conductance was found to be in the order of 10−5–10−3 (Ω cm)−1, which agrees well with the earlier reported value [15, 16, 19]. The low value of conductivity of the film may e due to high grain boundary density, discontinuities and small thickness of the film. It is observed that the conductivity of the film increases with increase in temperature. This indicates the semiconducting behavior of the thin film.

A plot of log (conductivity) versus inverse temperature (1000/T) is indicated in the Fig. 5. There are two distinct linear regions, suggesting the presence of two-conduction mechanism, the low-temperature intrinsic and high-temperature extrinsic. The high temperature region is due to grain boundary scattering limited conduction mechanism, while a low temperature region is due to variable range hopping conduction mechanism. The thermal activation energies were calculated using Arrhenius equation. Activation energies corresponding to the low and high temperature regions are 0.034 and 0.56 eV, respectively. Since; the temperature activation energy represents a mean value of the inter-crystalline barrier height combining the effects of both carrier concentration and mobility, it is expected that measured values will differ between workers using different preparation conditions. However, the general dependence of conductivity on temperature is clearly consistent, and indicates the existence of a well defined potential barrier between inter-crystalline grains; which may be overcome by thermal activation.

3.6 Optical properties

Figure 6 shows the variation of optical absorption with wavelength of MoS2 films at room temperature. From the absorption spectra, the optical absorptivity is determined using the relation;

where α = absorptivity (cm)−1, A = absorbance, t = thickness (µm). The optical studies show that the films are highly absorptive. The absorptivity was found 1.84 × 104 cm−1. Based on observed optical absorbance, (αhν)2 is plotted as a function of photon energy (hν) and shown in Fig. 7. The simplest form of the equation obeyed near and above the absorption edge is [28];

where α is the absorptivity (cm−1), hν the photon energy (eV). A and n are constants. A is complex parameter, which depends on temperature, photon phonon energies etc. The n values are 0.5, 1.5, 2 and 3 for allowed direct, forbidden direct, allowed indirect and forbidden indirect transition respectively. A plot of (αhν)2 versus hν should be a straight line whose intercept to the x-axis gives the optical band gap. The band gap value of the MoS2 was found to be 1.7 eV. The observed value is match with previously reported [15, 17, 19, 29]. The plot is linear in nature at absorption edge, confirming the material of the film has a direct band gap.

4 Conclusions

A molybdenum disulfide thin film on glass substrates in acidic precursor is possible to deposit at room temperature. The deposited molybdenum disulfide thin films are nearly stoichiometries, with crystalline nature, hexagonal structure. This type of morphology is typical of layered structure. MoS2 thin films shows hoping conduction behaviors. Optical study reveals that the films are highly absorptive which is mainly used in opto-electronic devices.

References

C. Ataca, H. Sahin, S. Ciraci, Phys. Chem. C 116, 8983 (2012)

J.A. Wilson, A.D. Yoffe, Adv. Phys. 1, 193 (1969)

R.M.A. Lieth, J.C.J.M. Terhell, in Preparation and Crystal Growth of Materials with Layered Structures, ed. by R.M.A. Lieth (D. Reidel Publ. Comp, Dordrecht, 1977), p. 141

H. Li, Z. Yin, Q. He, X. Huang, G. Lu, D.W.H. Fam, A.I.Y. Tok, Q. Zhang, H. Zhang, Small 8, 63 (2012)

F.K. Perkins, A.L. Friedman, E. Cobas, P.M. Campbell, G.G. Jernigan, B.T. Jonker, Nano Lett. 13, 668 (2013)

D.J. Late, Y.-K. Huang, B. Liu, J. Acharya, S.N. Shirodkar, J. Luo, A. Yan, D. Charles, U.V. Waghmare, V.P. Dravid, C.N.R. Rao, ACS Nano 7, 4879 (2013)

B. Radisavljevic, A. Radenovic, J. Brivio, V. Giacometti, A. Kis, Nat. Nanotechnol. 6, 147 (2011)

R. Samnakay, C. Jiang, S.L. Rumyantsev, M.S. Shur, A.A. Balandin, Appl. Phys. Lett. 106, 2311 (2015)

P.A. Lee, Physics and Chemistry of Materials with Layered Structures: Optical and Electrical Properties (Reidel, Dordrecht, 1976)

Q. Wang, K. Kalantar-Zadeh, A. Kis, J. Coleman, M. Strano, Nat. Nanotechnol. 7, 699 (2012)

K. Mak, C. Lee, J. Hone, J. Shan, T. Heinz, Phys. Rev. Lett. 105, 136805 (2010)

R.-S. Chen, C.-C. Tang, W.-C. Shen, Y.-S. Huang, R. Tenne, Nanotechnology 25, 415706 (2014)

M. Chhowalla, G. Amaratunga, J. Nat. 407, 164 (2000)

P. Pramanik, S. Bhattacharya, Mater. Res. Bull. 25, 15 (1990)

K.M. Garadkar, A.A. Patil, P.P. Hankare, P.A. Chate, D.J. Sathe, S.D. Delekar, J. Alloys Compd. 487, 786 (2009)

S.M. Delphine, M. Jayachandran, C. Sanjeeviraja, Mater. Res. Bull. 40, 135 (2005)

R.S. Patil, Thin Solid Film 340, 468 (1999)

T.J.S. Anand, S. Shariza, Electrochim. Acta 81, 64 (2012)

S.D. Sartale, C.D. Lokhande, Mater. Chem. Phys. 71, 94 (2001)

J. Ouerfelli, S.K. Srivastava, J.C. Bernede, S. Belgacema, Vacuum 83, 308 (2009)

C. Amory, J.C. Bernede, N. Hamdadou, Vacuum 72, 351 (2004)

J. Putz, M.A. Aegerter, Thin Solid Films 351, 119 (1999)

J. Hass, W. Heer, E.H. Conrad, J. Phys.: Condens. Matter 20(32), 323202 (2008)

R. Venkatasubramanian, E. Siivola, T. Colpitts, B. O’Quinn, Nature 413, 597 (2001)

Y. Zhan, Z. Liu, S. Najmaei, P.M. Ajayan, J. Lou, Small 8(7), 966 (2012)

D. Kong, W. Dang, J. Cha, J. Li, H. Meister, S. Peng, H. Liu, Y. Cui, Nano Lett. 10, 2245 (2010)

R. Tenne, Nat. Nanotechnol. 1, 103 (2006)

D.J. Sathe, P.A. Chate, P.P. Hankare, A.H. Manikshete, A.S. Aswar, Mater. Sci. Mater. Electron. 24, 438 (2013)

S. Shariza, T.J. Sahaya Anand, Chalcogenide Lett. 8, 529 (2011)

Acknowledgments

Authors are thankful to SERB-DST, New Delhi for the financial support under project NO.SB/FT/CS-018/2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sathe, D.J., Chate, P.A., Sargar, S.B. et al. Properties of chemically-deposited nanocrystalline MoS2 thin films. J Mater Sci: Mater Electron 27, 3834–3838 (2016). https://doi.org/10.1007/s10854-015-4230-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-4230-6