Abstract

Lead-free perovskite (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 (BCZT) ceramics are prepared using the traditional solid-state reaction technique. Dielectric, ferroelectric and piezoelectric properties of the specimens sintered at different temperatures have been investigated. X-ray diffraction was used to understand the phase transition of the BCZT specimens. The Curie–Weiss law and the modified Curie–Weiss law were used to analyze the dielectric properties of BCZT specimens. Diffuse phase transitions are observed in BCZT specimens and the Curie–Weiss exponents are all >1.5. The dielectric permittivity versus temperature characteristics and the γ in the modified Curie–Weiss law, as a function of the dc bias field was obtained for BCZT ceramics. Piezoelectric properties have been studied and the d 33 is as high as 291 pC/N.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Perovskite-type titanate oxide with formula ABO3 such as PbTi1−x Zr x O3(PZT) and Pb (Mg1/3Nb2/3)O3–PbTiO3 (PMN-PT) have attracted much attention in the past decades due to the excellent dielectric, ferroelectric and piezoelectric properties [1–3]. However, with the recent growing demand of global environmental protection, the application of the Pb-based materials were bably restricted by the obvious disadvantage of volatility and toxicity of lead. Therefore, many researchers have greatly focused on lead-free materials with appropriate chemical and physical properties in order to replace the Pb-based compounds for environmentally friendly application.

Barium titanate (BaTiO3, with formula ABO3) is one of the most extensively studied Pb-free materials. BaTiO3 (BT) undergoes a cubic paraelectric to tetragonal ferroelectric phase transition at 393 K. However, pure BT ceramics show a narrow dielectric constant-temperature (ε − T) curve near T c . Much effort has been expended to improve the electrical properties by different A-site and B-site dopants. These kinds of solid solution will be of interest for investigation for their interesting dielectric and ferroelectric behaviors and their potential applications. In particular, barium zirconate titanate Ba(ZryTi1−y)O3 (BZT) have been intently investigated because Zr4+ is chemically more stable than Ti4+ [4] and the Zr content can modify the microstructure and dielectric properties. Hennings et al. [5] Reported that the phase-transition temperatures approach to room temperature with the increasing of Zr content and only one phase transition exists at y ~ 0.20. Meanwhile, calcium is an important dopant of A-site. Wang et al. [6] reported that the high electro-strictive strain of the Ba(1−x)Ca x TiO3 ceramics. Liu and Ren [7] reported the surprisingly high piezoelectric coefficient of d33 = 620 pC/N of Ba(Ti0.8Zr0.2)O3–(Ba0.7Ca0.3)TiO3 ceramics, Zhang et al. [8] reported the piezoelectric coefficient d33 = 200 pC/N and higher dielectric constants of 1900 of the (Ba0.95Ca0.05)(Ti0.88Zr0.12)O3 ceramics sintered in N2. These results make the system a promising candidate for piezoelectric and dielectric materials to instead of Pb-based materials. The electrical properties of (Ba0.9Ca0.1)(Ti0.85Zr0.15)O3 ceramics can be improved by an increase in grain size [9]. In ferroelectric materials, the grain size is mainly and significantly affected by sintering temperature. The dielectric and piezoelectric properties of the (Ba x Ca1−x )(Ti y Zr1-y)O3 (BCZT) ceramics were intensively studied, there are few report on the sintering temperature effect on the properties of the BCZT ceramics.

Therefore, in the present work, the (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 (BCZT) ceramics were synthesized by solid state reaction method. The samples were sintered at different temperature. The influence of sintered temperature on microstructure and electrical properties of BCZT ceramics were studied and discussed in details.

2 Experiment

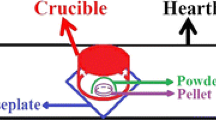

The (Ba0.7Ca0.3)(Zr0.2Ti0.8)O3(BCZT) ceramics were prepared by conventional solid state reaction technique. High-purity starting materials of barium carbonate (BaCO3), calcium carbonate (CaCO3), titanium dioxide (TiO2) and zirconium dioxide (ZrO2) were weighed in stoichiometric proportion, all powders were mixed and ball milled for 24 h in ethanol using zirconia balls as the grinding media, then dried and calcined at 1100 °C for 6 h in a high-purity alumina crucible. The resulting powders were mixed thoroughly with the PVA binder solution and then pressed into disk pellets under 20 MPa pressure. PVA is burned out in the electric furnace at 650 °C. The disk samples were separately sintered at 1200, 1230, 1250, 1270 and 1300 °C for 24 h with a heating rate of 5 °C/min in air. For the measurement of electrical properties, both sides of the samples were polished and silver pasted, then calcined at 650 °C for 60 min to form the electrodes. The crystal structures of ceramic samples sintered at different temperatures were characterized by High Resolution X-ray Diffraction (XRD; Panalytical, X′ Pert PRO CuKα λ = 1.5404 Å). The temperature dependence of permittivity and loss tangent of the samples were measured using a programmable furnace with impedance analyzer (Precision LCR Meter Agilent E4980) at different frequencies from 500 to 100 kHz in a temperature range of 25–250 °C. Ferroelectric hysteresis loops were measured at room temperature using the Precision Premier II (RADIANT Italy). The piezoelectric constants d33 were measured using ZJ-6A series quasi-static d 33 measurement instrument.

3 Results and discussion

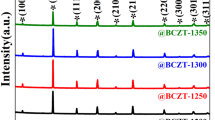

The structures of (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 ceramics are determined by X-ray diffraction technique. The XRD patterns of BCZT ceramics sintered at 1200, 1230, 1250, 1270 and 1300 °C, respectively, are shown in Fig. 1. It can be seen that the diffraction peaks of the samples sintered in the range of 1200–1300 °C were indexed belonging to the perovskite-type tetragonal structure with space group P4 mm in agreement with the reported [10], suggesting that Ca and Zr diffuse into the BaTiO3 lattice to form a solid solution [11]. All the samples and stable crystallizes into the desired perovskite structure at room temperature as shown in the figure, only traces of BaCaTiO4 could be detected as a secondary phase for the ceramics sintered at 1300 °C. It is also found that the strength of the main diffraction peak of the BCZT ceramics become higher and the subtle shift of diffraction peaks to lower angles as the sintering temperature increases, which indicates the expansion of the cell volume. This also indicates a more effective substitution of Ti4+ with ionic radius of 0.605 Å by Zr4+ with ionic radius of 0.72 Å in octa-hedral coordination for the higher sintering temperature, which will give place to a cell volume increase [12]. The traces of BaCaTiO4 may be also related with the radio of the Zr and Ti ions. Mishra et al. reported that with the increase in sintering temperature the competition between Ti and Zr ions increase to occupy the same crystallographic site B, which lead to increase in composition fluctuation [13]. It can be concluded that the Ti ions is competitive to Zr ions in the system.

The temperature dependence of dielectric constant ε and dissipation factor tanδ for the BCZT samples sintered at different sintering temperatures are shown in Fig. 2a and b, respectively. Figure 2a shows the dielectric constant ε versus temperature curves of the BCZT samples which sintered at 1200, 1230, 1250, 1270 and 1300 °C at 1 kHz in the range of 298–523 K. It is found that two peaks at 320–355 K (50–80 °C) are observed on the dielectric constant versus temperature curves in the measured temperature range between 298 and 523 K, which is correspond to the polymorphic phase transitions from orthorhombic phase to tetragonal phase (T 0 − T) and tetragonal phase to cubic phase (T C ), respectively [14, 15]. The maximal dielectric constant (ε) of the BCZT ceramics increases rapidly with the increase of sintering temperature and reaches the maximum value of 9530 of the sample sintered at 1300 °C. The phase-transition region is diffused with the full width at half maximum (FWHW) extending to between 52 and 85 K for BCZT ceramics. The temperature dependence of the dielectric loss are shown in Fig. 2b. The dielectric loss peaks are located at 314 K which correspond to the phase temperatures of T 0 − T. The dielectric loss is larger at a higher measurement frequency and <0.15 for all the samples. In the following section, for the convenience of discussion and analysis, all the results are obtained at the measurement frequency of 1 kHz. The properties of a typical ferroelectric material meet the Curie–Weiss law,

where T 0 denotes the Curie–Weiss temperature and C corresponds to the Curie–Weiss constant. As a pure crystal, the values of T 0 and C are 383 and 1.56 × 105 K, respectively [16]. By satisfying the real part of the dielectric permittivity ε of the BCZT sample to the Curie–Weiss law of (1), we get the Fig. 3a which shows the plot of the reciprocal of the dielectric permittivity versus temperature for the BCZT sample sintered at 1270 °C, T 0 and C for all the samples are listed in the Table 1. Obviously all the Curie–Weiss constant C of the BCZT are lower than those of the pure BaTiO3 crystal, and the Curie–Weiss temperature T 0 are compatible that of pure BaTiO3 crystal. It is seen that the dielectric constant of all the BCZT samples follows the Curie–Weiss law at temperature much higher than the T m . An empirical parameter ΔT cwm , defined as ΔT m = T cw − T m , is often used as a measure of the degree of deviation from the Curie–Weiss law. Where T cw denotes the temperature from which the dielectric permittivity starts to deviate from the Curie–Weiss law and T m represents the temperature of dielectric peak. The values of the BCZT samples are also given in the Table 1.

a The inverse dielectric permittivity (ε r ) as a function of temperature at 1 kHz. (Symbols, experimental data; solid line, fitting to the Curie–Weiss law); b Plot of ln(1/ε r − 1/ε m ) as a function of ln(T − T m ) for BCZT ceramics measured at 1 kHz. The solid line is the fit using Eq. (2)

Uchino and Nomura [17] modified the Curie–Weiss law for the diffuseness of the phase transition:

where γ and C1 are assumed to be constant, with 1 ≤ γ ≤ 2. The value of the parameter γ gives information about the character of the phase transition. Its limiting values are γ = 1 for abnormal ferroelectric materials and γ = 2 for perfect relaxor ferroelectric materials [18–20]. In general, the value of γ can characterize the relaxor behaviour [21]. Figure 3b shows a ln(1/ε r − 1/ε m ) versus ln(T − T m ) plot for the experimental and theoretical curves of the BCZT ceramics sintered at 1270 °C measured at 1 kHz. The γ value of all the BCZT samples sintered at different temperature plotted in Fig. 4. A linear relationship exists for all the samples and the γ is determined by least-squared fitting the experimental data to the modified Curie–Weiss law. It can be seen that the γ value decrease to 1.4 with the sintering temperature to 1270 °C, but the γ value increase to 1.5 when the sintering temperature is 1300 °C. The BCZT ceramic sintered at 1270 °C for 24 h is a normal ferroelectric while the samples sintered at the other temperature gradually be the ferroelectric relaxor. The diffuse phase transition and deviation from Curie–Weiss law may be assumed to be due to disordering. The diffusiveness occurs mainly because of the compositional fluctuation and structural disordering in the arrangement of cation in one or more crystallite graphic sites of the structure [22].

The hysteresis loops of polarization versus electric field of the BCZT ceramics sintered at 1200, 1230, 1250, 1270, and 1300 °C measured at room temperature are shown in Fig. 5. It can be seen that the remnant polarization P r is as low as 6.1 μC/cm2 and coercive fields E c is as high as 9.9 kV/cm of BCZT ceramics sintered at 1200 °C, respectively. With the increase of sintering temperature to 1230, 1250, 1270 and 1300 °C, the values of P r are 7.41, 11.6, 17.4 and 14.8 μC/cm2, respectively. The parameters of Ps, Pr, Ec are plotted in Fig. 6. It can be seen that the values of P r and P s of the sample sintered at 1270 °C is higher than that of the other samples and the value of Es is smaller than that of the other samples. It is indicated that the BCZT ceramics is an easy polarization mechanism of the materials. The piezoelectric constant d 33 increase with increase of the sintering temperature, from the value of 81.1 at 1200 °C to a maximum value of 291 pC/N at 1270 °C. The d33 results are listed in Table 1. It is believed that the observed high piezoelectric properties of the BCZT ceramics should be attributed to the transition from orthorhombic phase to tetragonal phase occurring near room temperature [23]. Compared with the results in Figs. 5 and 6, it can be seen that the sample sintered at 1270 °C have superior ferroelectric and piezoelectric properties, which is maybe related to the diffuse degree of the phase transition.

4 Conclusion

Dielectric and piezoelectric properties of (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 (BCZT) ceramics by solid state reaction method sintered at different temperature are obtained. The temperature dependence of the dielectric permittivity and losses of the samples are measured by the function of frequency and temperature. All the BCZT sintered at different temperatures have single phase with a perovskite structure. By using a modified Curie–Weiss law, the ceramics prepared show a typical diffuse phase transition characteristic under zero-field condition measured with 1 kHz in the cooling temperature ranged from 523 to 298 K. With Curie–Weiss exponent (CWE), the parameter γ of BCZT ceramics sintered in different temperatures are obtained. In conclusion, the sintering temperature was effective on promoting the dielectric and piezoelectric properties. The BCZT ceramics sintered at 1270 °C exhibit comprehensive and good properties: ε m = 7950, T c = 357 K, C = 1.16 × 105 K, d 33 = 291 pC/N. All the experimental results indicate that this system is a promising candidate for the lead-free piezoelectric applications.

References

G. Haertling, J. Am. Ceram. Soc. 82, 797 (1999)

S.W. Choi, T.R. Shruot, S.J. Jang, A.S. Bhalla, Mater. Lett. 8, 253 (1989)

K.V.S. Ramam, K.V.R. Murthy, K. Trinath, A. Bhanumathi, Bull. Mater. Sci. 18, 587 (1995)

X.G. Tang, Q.X. Liu, J. Wang, H.L.W. Chan, Appl. Phys. A 96, 945 (2009)

D. Hennings, A. Schnell, G. Simon, J. Am. Ceram. Soc. 65, 539 (1982)

X.S. Wang, H. Yamada, C.N. Xu, Appl. Phys. Lett. 86, 022905 (2005)

W.F. Liu, X.B. Ren, Phys. Rev. Lett. 103, 257602 (2009)

S.W. Zhang, H.L. Zhang, B.P. Zhang, G.L. Zhao, J. Eur. Ceram. Soc. 29, 3235 (2009)

J. Wu, D. Xiao, B. Wu, W. Wu, J. Zhu, Z. Yang, J. Wang, Mater. Res. Bull. 47, 1281 (2012)

W. Li, Z.J. Xu, R.Q. Chu, P. Fu, G.Z. Zang, Phys. B 405, 4513 (2010)

A.B. Haugen, K.J. Bowman, J.S. Forrester, D. Damjanovic, B. Li, J.L. Jones, J. Appl. Phys. 113, 014103 (2009)

A. Reyes-Montero, L. Pardo, P. LoPez-Juarez, A.M. Gonzalez, M.P. Cruz, M.E. Villafuerte-Castrejon, J. Alloys Compd. 584, 28 (2014)

J. Hao, W. Bai, W. Li, J. Zhai, J. Am. Ceram. Soc. 95, 1998 (2012)

Z. Yu, C. Ang, R.Y. Guo, A.S. Bhalla, J. Appl. Phys. 92, 2572 (2012)

L. Gao, J.W. Zhai, Y.W. Zhang, X. Yao, J. Appl. Phys. 107, 064105 (2010)

W.J. Merz, Phys. Rev. 91, 513 (1953)

K. Uchino, S. Nomura, Integr. Ferroelectr. 44, 55 (1982)

G.A. Smolenski, A.I. Agranovskaya, Sov. Phys. Tech. Phys. 3, 1380 (1958)

C. Ang, Z. Jing, Z. Yu, J. Phys.: Condens. Matter 14, 8901 (2012)

P. Victor, R. Ranjith, S.B. Krupanidhi, J. Appl. Phys. 94, 7702 (2003)

S. Mahajan, O.P. Thakur, D.K. Bhattacharya, K. Sreenivas, Mater. Chem. Phys. 112, 858–862 (2008)

N.R. Alluri, S.K.S. Parashar, K. Parashar, P.S. Mukherjee, B.S. Murty, Metal. Mater. Trans. A 44A, 5241 (2013)

W. Liu, X. Ren, Phys. Rev. Lett. 103, 257602 (2009)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11202054, 10774030 and 11032010), the Guangdong Provincial Natural Science Foundation of China (Grant Nos. 8151009001000003 and 10151009001000050), and the Guangdong Provincial Department of Education of China (Grant No. 2012KJCX0044).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Y.P., Tang, X.G., Ju, S.G. et al. Influence of sintering temperature on the ferroelectric and piezoelectric properties of (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 ceramics. J Mater Sci: Mater Electron 27, 3048–3052 (2016). https://doi.org/10.1007/s10854-015-4128-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-4128-3