Abstract

Nitrogen doping is applied to improve the thermal stability and power consumption of Sb70Se30 phase change thin film. Comparing to un-doped Sb70Se30 thin film, N-doped Sb70Se30 thin film has a higher crystallization temperature and better data retention. The measurement of atomic force microscopy indicated that the crystallization is inhibited and the surface of thin films becomes smoother after N doping. The analysis of X-ray diffraction proved that nitrogen doping can suppress the grain growth of the films and limit the grain size. The phase transition speed between the amorphous and crystalline state was investigated by the picosecond laser pulses. Phase change memory devices based on N-doped thin films were fabricated to test and evaluate the electrical properties. The results indicate that nitrogen-doped Sb70Se30 films have the potential in phase change memory application.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In the past decades, with the rapid development of information technology, phase change memory (PCM) is one of the most promising candidates for next generation non-volatile memory. Many advantages of PCM have been reported, such as high stability, fast speed, lower power consumption and compatibility with complementary metal-oxide semiconductor (CMOS) technology [1, 2]. In PCM devices, the phase change material is used to store data, which is realized by electrical pulses inducing reversible structure change between high resistivity amorphous phase (RESET state, “1”) and low resistivity crystalline phase (SET state, “0”), respectively [3, 4]. Therefore, the performance of PCM device is determined by the properties of phase change material [5].

Phase change materials have been extensively studied for application in nonvolatile memories due to their excellent optical and electrical characteristics. Among the many phase change materials, Ge2Sb2Te5 (GST) is most studied and used because of its overall qualified performance [6–8]. However, the crystallization temperature and 10-year retention temperature of GST is about 165 and 85 °C, respectively [2]. The crystallization temperature was associated with thermal stability. A higher crystallization temperature means better thermal stability. The 10-year retention temperature is required at higher than 125 °C in the consumer appliances and automotive systems [2]. The shortcomings of the low crystallization temperature and the short retention time of GST, which makes it difficult for its application in high thermal stable PCM. In order to improve the characteristics of phase change material, doping such as nitrogen and oxygen is a common way to improve data retention by hindering crystallization [9, 10]. According to recent research, Sb-rich phase change materials such as Al19Sb54Se27 [4], Al1.3Sb3Te [11], Zn15Sb85 [3], Sn12Sb88 [12] have high stability and high phase change speed due to their special crystallization mechanism.

In this work, nitrogen-doped Sb70Se30 phase-change thin films were prepared to by RF sputtering method and their potential for PCM application was evaluated. The influence of nitrogen doping on the thermal stability, optical and electric characterizations were investigated in details.

2 Experiments

Nitrogen-doped and un-doped Sb70Se30 thin films were deposited on Si/SiO2 substrate at room temperature via magnetron sputtering. The purity of Sb70Se30 target was 99.999 % and thin film thickness was set to 40 nm through controlling the deposition time. The sputtering power of Sb70Se30 target was set at 30 W. The pressures of the background and sputtering were 2.5 × 10−4 Pa and 3 × 10−1 Pa, respectively. Nitrogen-doped thin film was obtained by mixture of Ar and N2 sputtering gas. The doping content of nitrogen was controlled by adjusting the flow ratio of N2/Ar while the total gas flow was fixed. The chemical composition of the thin films were determined using energy dispersion X-ray spectrometry (EDS). The different N concentration and corresponding symbols of five samples were listed in Table 1.

The crystallization process of N-doped and un-doped Sb70Se30 of thin films was analyzed in situ film resistance measurements under an Ar atmosphere. The data retention time was estimated using Arrhenius equation. The surface morphology of the films was observed by AFM. The crystallization structure was investigated by XRD. The diffraction patterns were taken in the 2θ range from 20° to 60° using Cu Kα radiation with a scanning step of 0.01°/min. Laser irradiation (pumping) was performed to measure the reflectivity change in real time during the phase-transition process using a picosecond frequency-doubled model-locked neodymium yttrium aluminum garnet laser operating at 532 nm wavelength with a pulse duration of 30 ps. The PCMs based on SbSeN3 and GST thin films were fabricated and the resistance–voltage property was measured by a Tektronix AWG5012B arbitrary waveform generator and a Keithley 2602A parameter analyzer.

3 Results and discussion

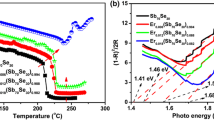

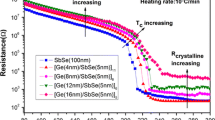

Figure 1 showed the resistance of N-doped and un-doped Sb70Se30 alloys as a function of temperature at a heating rate of 10 °C/min from room temperature to 350 °C. The temperature at which the resistance begins to reduce rapidly is defined as the crystallization temperature T c. With the increase of doped nitrogen, the crystallization temperature T c increases from about 200 °C of SbSeN0 thin film to about 230 °C of SbSeN4 thin film. Nitrogen doped inhibits the crystallization and increases the crystallization temperature. In general, we can roughly consider that high T c means better thermal stability. Good thermal stability of the phase change materials will benefit the data retention and enhance the reliability of the PCM devices, which is very significant in practical application. In addition, the resistances of N-doped Sb70Se30 thin film are higher than un-doped Sb70Se30 thin film both in amorphous and crystalline states. The resistance contrasts between the amorphous and crystalline states for SbSeN1, SbSeN2, SbSeN3 and SbSeN4 films are more than two orders of magnitude, which is enough for practical application. Moreover, the resistances of both amorphous and crystalline states for N-doped Sb70Se30 thin film increase with the increasing N concentration. Higher resistance can facilitate heating and contribute to reducing the read-write current of PCM devices, especially in reset operation. In this respect, PCM devices based on N-doped Sb70Se30 thin film will have lower power consumption.

Data retention capability, determined by thermal stability of amorphous state of the thin film, is a very important property of PCM devices. The plot of logarithm failure time versus \(1/(k_{b} T)\), which fits a linear Arrhenius relationship due to its thermal activation nature, can be described as [13–15]

where t, τ 0 , k b and T are failure time, the pre-exponential factor depending on material’s properties, Boltzmann constant, and absolute temperature of concern, respectively. Figure 2 shows that the PCM cells based on SbSeN1, SbSeN2, SbSeN3 and SbSeN4 thin films can keep data for 10 years at 134, 138, 146 and 156 °C, respectively. The un-doped Sb70Se30 thin films can keep a stable amorphous state for 10 years only when the environment temperature is 131 °C. In comparison with un-doped Sb70Se30 thin films, N-doped Sb70Se30 thin films possess better reliability of resistance state at higher temperature, which can meet the demands of data-storage applications at higher temperature. In addition, crystallization activation energies for SbSeN0, SbSeN1, SbSeN2, SbSeN3 and SbSeN4 thin films, obtained from the slope of the Failure-time and \(1/(k_{b} T)\) curves, are 4.01, 3.88, 3.97, 4.15 and 4.72 eV, respectively. From the Failure-time and \(1/(k_{b} T)\) curves, we can conclude that the PCM cells based on the N-doped Sb70Se30 thin films have a better reliability.

Film surface roughness has a great impact on device performance, because the induced stress can affect the quality of the electrode-film interface during the phase change process [3, 16–18]. Figure 3 shows the AFM images of SbSeN0, SbSeN1, SbSeN2 and SbSeN3 thin films after annealing at 300 °C for 5 min. The root-mean-square surface roughness of SbSeN0, SbSeN1, SbSeN2 and SbSeN3 thin films are 3.521, 3.032, 2.563, and 1.785 nm, respectively. The results show that nitrogen doping further decreases the surface roughness of the thin films, which is beneficial to improve production yield of PCM devices. Moreover, the result indicates that N doping inhibits the crystallization of the Sb70Se30 thin films and reduces the grain growth rate. Comparing to un-doped Sb70Se30 thin films, nitrogen doping results in smaller grain size and better thermal stability.

In order to verify the crystalline structure of N-doped and un-doped Sb70Se30 thin films, XRD was employed. Figure 4 shows the XRD patterns of the N-doped and un-doped Sb70Se30 thin films annealed at 300 °C for 5 min in Ar gas. The Si diffraction peak in the curve is caused by the Si/SiO2 substrate. The diffraction peaks (230) and (211) belonging to Sb2Se3 appeared in SbSeN0, SbSeN1, SbSeN2, SbSeN3 and SbSeN4 thin films. After N-doped, the diffraction peak (211) was suppressed and broadened, which demonstrated that N-doped suppresses the grain growth and limits the grain size. The small grain size may induce more grain boundaries and more carriers scattering, which may leads to the increased resistance of N-doped Sb70Se30 films [19, 20]. Besides, the Sb diffraction peak emerged with increasing nitrogen concentration, which indicated Sb is excessive [4, 11]. On the whole, the thermal stability of the N-doped Sb70Se30 thin films is improved and the resistances of the crystalline films increase, which can lower the power consumption and improve the reliability of the PCM.

Phase change speed is a very important index which affects the data switching rate for a PCM device [4]. During the process of phase change, the optical reflectivity changes as well as the resistivity. The energy of the pump laser is used to excite the phase change. The picosecond laser pump-probe system is applied to measure the phase change time, which indicates the phase change speed [21]. Figure 5 shows the normalized reflectivity evolution of SbSeN3 thin films in both crystallization and amorphization processes. For comparison, the reflectivity measurement of GST thin film was also presented. The abrupt increase in reflectivity, shown in Fig. 5a, is ascribed to the amorphous-to-crystal phase transition with a fluence of 6.542 mJ/cm2. Then the amorphizaiton can be achieved by a higher laser fluence of 15.138 mJ/cm2 with an obvious decrease of optical reflectivity (in Fig. 5b). Thus a reversible phase transition can be realized in SbSeN3 thin film with different laser pulse intensities. In the resistance switching of PCM devices, the reset operation needs more power and shorter time than the set operation. Accordingly, more attention is paid to the reset power and set speed [16, 22]. That is to say, the power consumption and operation speed of PCM are mainly limited by the reset and set processes, respectively. As is shown in Fig. 5a, the crystallization time of SbSeN3 thin film is about 11.5 ns, which is much shorter than that of GST (23.1 ns). Meanwhile, the amorphization time of SbSeN3 thin film is about 2.9 ns, which is also shorter than that of GST (6.7 ns). On the whole, the SbSeN3 thin film has an excellent phased-change speed than GST. It has been reported that the Sb-rich phase change materials have a growth-dominated crystallization behavior rather than nucleation-dominated one [4, 11]. The excessive Sb atom would form weak Sb–Sb bonds. In the process of crystallization, the dispersed Sb–Sb bonds are easily broken and can act as heterogeneous nucleating centers, which accelerates the crystallization of the phase change materials.

In order to test and verify the electrical properties of N-doped Sb70Se30 thin films, the PCM cells based on SbSeN3 thin films were fabricated by 0.18-μm complementary metal-oxide semiconductor (CMOS) technology. The inset in Fig. 6 shows the schematic diagram of the PCM cell structure [3, 4, 11]. Tungsten was used as a heating electrode 260 nm in diameter. Figure 6 shows the resistance–voltage (R–V) curves of PCM cell based on SbSeN3 thin film. The phase transition between the amorphous and crystalline states is achieved reversibly when the voltage pulse of 200 ns width is applied. The reset voltage (V reset ) for SbSeN3 is 2.43 V, which is lower than that of GST (3.63 V). According to the Joule heating equation \(Q = V^{2} t/R\), we can confirm the fact that the PCM cells based on SbSeN3 thin film will have a lower power consumption than GST.

4 Conclusions

N-doped and un-doped Sb70Se30 thin film were prepared and investigated. The resistances of both the amorphous and crystalline state for N-doped Sb70Se30 thin films monotonously increased with the increasing N concentration, which contributes to reduce the power consumption. Meanwhile, the crystallization temperature increased from about 200 °C of un-doped Sb70Se30 film to about 230 °C of SbSeN4 film. The crystallization was inhibited and the data retention was improved with the increasing of N doping content. The SbSeN4 film had the higher crystallization activation energy 4.72 eV than other N-doped Sb70Se30 films. XRD showed that N doping suppressed the grain growth and limited the grain size, which lead to the increase of the resistance for the N-doped Sb70Se30 thin films. The surface roughness, evaluated with AFM, became smaller after N doping. A reversible phase transition of SbSeN3 thin film was achieved by picosecond laser pulses. The crystallization and amorphization time of SbSeN3 thin film is about 11.5 and 2.9 ns, which proved SbSeN3 thin film had faster phase change speed than GST. The resistance–voltage measurements of PCM cells based on SbSeN3 thin film demonstrated that the threshold voltage for the RESET operation is 2.43 V, which indicated the lower power consumption than GST.

References

K. Ren, M.J. Xia, F. Rao, Z.T. Song, K.Y. Ding, X.L. Ji, L.C. Wu, B. Liu, S.L. Feng, Appl. Phys. Lett. 104, 173102 (2014)

Y.F. Hu, X.Y. Feng, S.M. Li, T.S. Lai, S.N. Song, Z.T. Song, J.W. Zhai, Appl. Phys. Lett. 103, 152107 (2013)

X.Q. Zhu, Y.F. Hu, J.Z. Xue, Y.X. Sui, W.H. Wu, L. Zheng, L. Yuan, S.N. Song, Z.T. Song, S.P. Sun, J. Mater. Sci. Mater. Electron. 25, 2943 (2014)

Y.F. Hu, S.M. Li, T.S. Lai, S.N. Song, Z.T. Song, J.W. Zhai, Scr. Mater. 69, 61–64 (2013)

Daniele. Ielmini, Andrea.L. Lacaita, Mater. Today 14, 600–607 (2011)

K.Y. Ding, K. Ren, F. Rao, Z.T. Song, L.C. Wu, B. Liu, S.L. Feng, Mater. Lett. 125, 143–146 (2014)

D. Loke, T.H. Lee, W.J. Wang, L.P. Shi, R. Zhao, Y.C. Yeo, T.C. Chong, S.R. Elliott, Science 336, 1566 (2012)

R.E. Simpson, M. Krbal, P. Fons, A.V. Kolobov, J. Tominaga, T. Uruga, H. Tanida, Nano Lett. 10, 414–419 (2010)

C. Peng, L.C. Wu, F. Rao, Z.T. Song, X.L. Zhou, M. Zhu, B. Liu, D.N. Yao, S.L. Feng, P.X. Yang, J.H. Chu, Scr. Mater. 65, 327–330 (2011)

Y. You, H. Sone, S. Hosaka, J. Appl. Phys. 102, 064503 (2007)

C. Peng, Z.T. Song, F. Rao, L.C. Wu, M. Zhu, H.J. Song, B. Liu, X.L. Zhou, D.N. Yao, P.X. Yang, J.H. Chu, Appl. Phys. Lett. 99, 043105 (2011)

F. Rao, Z.T. Song, K. Ren, X.L. Li, L.C. Wu, W. Xi, B. Liu, Appl. Phys. Lett. 95, 032105 (2009)

K.F. Kao, C.C. Chang, F.T. Chen, M.J. Tsai, T.S. Chin, Scr. Mater. 63, 8 (2010)

F. Rao, Z.T. Song, K. Ren, X.L. Zhou, Y. Cheng, L.C. Wu, B. Liu, Nanotechnology 22, 14 (2011)

Z.H. Zhang, S.N. Song, Z.T. Song, Y. Cheng, Y.F. Gu, B. Chen, Appl. Phys. Lett. 102, 252106 (2013)

Y.F. Hu, S.M. Li, T.S. Lai, S.N. Song, Z.T. Song, J.W. Zhai, J. Alloy. Compd. 581, 515–518 (2013)

S.N. Song, Z.T. Song, L.C. Wu, B. Liu, S.L. Feng, J. Appl. Phys. 109, 034503 (2011)

F.F. Wei, L. Wang, T. Kong, L. Shi, R. Huang, J. Zhang, G.S. Cheng, Appl. Phys. Lett. 103, 181908 (2013)

M. Zhu, L.C. Wu, F. Rao, Z.T. Song, X.L. Li, C. Peng, X.L. Zhou, K. Ren, D.N. Yao, S.L. Feng, J. Alloy. Compd. 509, 10105–10109 (2011)

X.L. Zhou, L.C. Wu, Z.T. Song, F. Rao, K. Ren, C. Peng, B. Liu, D.N. Yao, S.L. Feng, B. Chen, Thin Solid Films 520, 1155–1159 (2011)

Y.G. Lu, Z.H. Zhang, S.N. Song, X. Shen, G.X. Wang, L. Cheng, S.X. Dai, Z.T. Song, Appl. Phys. Lett. 102, 241907 (2013)

K. Ren, F. Rao, Z.T. Song, S.L. Lv, Y. Cheng, L.C. Wu, C. Peng, X.L. Zhou, M.J. Xia, B. Liu, S.L. Feng, Appl. Phys. Lett. 100, 052105 (2012)

Acknowledgments

The authors would like to acknowledge financial support of the Scientific Research Fund Project of Jiangsu University of Technology (KYY14011) and the Open Fund of State Key Laboratory of Functional Materials for Informatics (KYZ14031).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, W., Hu, Y., Zhu, X. et al. Improvement of the thermal stability and power consumption of Sb70Se30 through nitrogen doping. J Mater Sci: Mater Electron 26, 9700–9706 (2015). https://doi.org/10.1007/s10854-015-3637-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3637-4