Abstract

In this paper, we report the synthesis results of Ga2O3 semiconductor nanowires (NWs) on GaAs (100) semi-insulator substrate by vapor liquid solid (VLS) method. Our study based on Ag nanoparticle (AgNP) catalyst, in which prepared by conventional sol–gel method. As the GaAs wafer, after being deposited an AgNP layer in HF/AgNO3 aqueous solution, which dried and loaded to vacuum-chamber. GaAs slices heated in vacuum-furnace by VLS method with two temperature modes. The results showed that the Ga2O3 NW morphologies and properties depend strongly on technological conditions, such as AgNP catalyst concentration, growth temperature, and vapor pressure. It is also indicated that the NW random grown over large area with the diameter in the region conform from 18 to 30 nm scale and lengths ranging from several tens of nm to a few hundred micrometers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

During past decades, the semiconductor nanowire (NWs) has been interest due to their potential in low dimension such as nano science, nano material and nanotechnology [1–4]. Due to their low dimension properties, that they are controllable, tunable conductivity, variable and diameter dependent band gap, flexible surface chemistry, large surface e area, enhanced exciton binding energy, and increased surface scattering for electrons and phonons, etc. [1]. Especially, the Ga2O3/GaAs NW growth have attracted substantial attention for various applications on nanoelectronics, optoelectronics, and nanosensors, etc. [2–5], as well as the Ga2O3/GaAs NWs growth will expect many exciting opportunities on nanoscale science and technology [6–9].

Up to now, we have had many number of methods for purpose of synthesis the semiconductor Ga2O3 NWs such as vapor liquid solid—VLS, chemical vapor deposition—CVD, laser ablation catalytic growth—LCG, pulsed laser deposition—PLD, solution liquid solid—SLS, oxide assisted growth—OAG, and molecular beam epitaxy—MBE [1, 6–8, 10], and among them, the VLS method has been a closely and usefully method. Because research the VLS method began as early as in 1964 by Wagner et al. [10] for silicon whisker growth, and then this method has being applied for NWs growth on GaAs substrate. In this case, the VLS method strongly depends on many technological factors: the growing temperature, catalyst metal, vapor pressure and gas volume, the bulk and surface diffusion of the catalyst metal [7, 9, 11]. Secondly, the sizes of catalyst metal particles also strongly effect the seed nuclear formation on the solid surface, the features of the phase diagram of the catalyst metal–material system to NWs growth process [1, 7, 9, 12].

Although, there have had studies on the successful synthesis of Ga2O3/GaAs NW by using different catalyst metals and structures as: nano thin-films, and nanoparticle of Au, Ag, Pt, Fe, Cr, Ni materials. But most of them have deposited on the surface of wafer by physical deposition methods, for example thermal evaporation, direct current—DC/or radio frequency—RF sputtering, thermal effusion, etc. [9]. On the other hand, several kinds of deposition methods have existed high cost and difficultly controlled. In order to solve these drawbacks, another choice of the deposition catalyst metal is of importance to deposit materials on the GaAs surface [1, 9].

The sol–gel method has widely used to synthesize nanoscale materials, which can produce solid nanoparticle materials from small molecules (precursors). This mechanism uses either a chemical solution (sol short for solution) or colloidal particles (sol for nano particle) to form an integrated network in a continuous liquid (gel) [13]. In this case, the monomers (precursors) for synthesizing the Ag colloid consisted AgNO3 salt and HF acid solvent. And then, these nanoparticles were dispersed in a solid and deposited on the substrate by spaying, dipping or doctor blade method.

According to our knowledge on both experimental and theory model, there has not been a combination between sol–gel and VLS method to grow Ga2O3/GaAs NW, yet. Therefore, in this paper, continuing several our before works [6, 7, 11], we report the producing Ag nanoparticle (AgNP) on GaAs wafer by using sol–gel method, which has investigated to effects of the AgNP concentration, growth temperature on formation Ga2O3/GaAs NW by VLS method. The morphology results and structural property of Ga2O3 NW are also discussed.

2 Experimental procedures

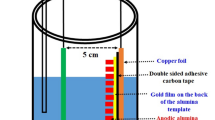

The (100) GaAs semiconductor undoped single crystalline wafer with resistivity of 1.3–2.7 × 108 Ωcm was used as the substrate, which provided from AXT, Inc. The chemical HF 40 % solution, and 2.5 % (w/v) AgNO3 powder reagents provided from Sigma Aldrich, Alfa Aesar, respectively. Before experiments, the GaAs wafers were cut of 0.5 × 0.5 cm2 pieces. The Ag deposition on the GaAs surface was done by immersing the wafers in the aqueous solution of 0.4 mM AgNO3 and 0.14 M HF at 25 °C for 5, 20, and 35 s, respectively. According to previously reported of authors [14–17], we decided to use above concentration reagents and deposition time for AgNP high uniformity. Neither too sparse nor too dense, this condition chose to obtain the AgNP size diameter of range from 50 to 70 nm and ~1 × 1010 cm−2 of particle density, respectively. After silver coated, the samples were rinsed with deionized water and dried at room temperature by pure nitrogen gas. For steps of the NW growth process, with which are experimentally carried out and repeated many times on the different investigation temperatures range from 650 to 830 °C at the low vapor-pressure inside of ~10−1 Torr (listed Table 1). The growth temperature profiles in the closed quartz tube were automatically measured and controlled by a Keithley 2000 multimeter (see Fig. 2b). And then, the morphology of NWs were investigated by field emission scanning electron microscope (FE-SEM) (Hitachi, Japan) equipment, energy-dispersive X-ray (EDX) techniques on JED-2300 AnalysStation equipment.

3 Experimental results and discussions

The Fig. 1a–c shown the AgNP densities and sizes on (100) surface GaAs substrate after AgNP deposited by the HF/AgNO3 solution. As same concentration of HF/AgNO3 solution and the different deposition times, we can see the density and size of AgNPs as a function of deposition time. The Fig. 1c shown the ~2 × 1010 of AgNP density, which is uniformly distributed in whole GaAs wafer surface. The diameter of the congregated particles are clearly observed ~70 nm of the short deposition time (Fig. 1a) and ~50 nm of long deposition time (Fig. 1c). Also, SEM cross-sectional image analysis of AG153 sample (Fig. 1d) shown that the average height and width of particles are ~70, ~50 nm in range, respectively. These results can use to estimate the diameters of Ga2O3 NWs, which will be grown by below VLS mechanism. From the SEM results of AgNPs-coated, we shall select AgNP concentration as in Fig. 1c to next experiments. According to technology conditions [6, 7, 11], especially growth temperature was exactly controlled by a Keithley 2000 multimeter with two-steps as Fig. 2b. For step one at 400 °C of T2 for 10 min, the AgNP will divide into smaller nanosize and adhere to the GaAs surface. These affected factors have still not understood yet to control in the first stage of VLS method, such as the contact angle, alloy temperature, and metal–crystalline. They can also use to determine the surface energy of a NW growth process [9, 18, 19].

For step two at (from 650 to 830 °C range) T3 of different growth temperatures of this process (Fig. 2b), the gallium and oxygen atoms partly will be entered into the AgNP by surface absorb mechanism. Therefore, the NWs are immediately grown. So far, we also regard to investigate our experimental series due to the effect of NW morphologies at growth (T3) temperature, and AgNP sizes. At the T3 temperature, the NWs are continuously synthesized, in which will survey most of growth conditions depend on NW morphologies. The Fig. 3 shows the NW morphologies as a function of AgNP density that the NW successfully grown at 830 °C of substrate temperature and ~10−1 Torr of vacuum–pressure inside quarts tube. In this case, we will investigate the effect of NW growth process depend on silver NPs density. At the high AgNP density (Fig. 3a, b), the NW has been random grown with very long of few hundred micrometers of length, and plentifully of area surface, as well as they also have smaller in diameter. In contrast, they have larger diameter and shorter length, in which we can see existent of Ag droplets on the top of the NW (Fig. 3c) that this phenomenon is in good agreement with the previously conventional explanation on VLS method [6, 7, 9, 10]. Also, they looked like tangly whisker structure and sidewall smooth shape. The different morphologies of NWs are often appeared during the NW growth that due to effects of monocentric and polycentric nucleation and its combination with periodic stable and unstable growth. As a NW begins to grow, its height increases by an amount and the radius of the contact area decreases by an amount, then the NW growth continues, also the base of the NWs increases from the zero value follow Young’s model. The detail explains of this mechanism could be found elsewhere [1, 2, 7, 9–11]. As far, these NW morphologies (Fig. 3a, b) will better candidate to nano electric circuit, nanosensor, and applications in the future.

The Fig. 4 shows the investigation results of NW which depend on different substrate temperatures at the similar AgNP density. As you see the Fig. 4a–c, the NWs have successfully synthesized as a function of substrate temperature, that mean the NWs can easily grow at the higher substrate temperature (~Te), as well as longer in length. This believed due to low impurity incorporation at high growth temperature [9]. To more detailed explain, we need to understand eutectic point (Te) of Ag–GaAs alloy [20] and the important role of AgNP catalytic during growth process. At the nearly Te (Fig. 4d), and phase edge region of catalytic liquid alloy, in which can rapidly absorb a vapor to become stability levels of thermodynamic equilibrium state, and then a new crystal growth can subsequently appear as nucleated seed at the liquid–solid interface. However, if growth temperature is too high (above Te) causing a significant amount of gallium and oxygen desorption then reduce the NW quality. On the other hand, the high substrate will reduce impurity of alloy and just only alloy phase desired to form NW nuclear seeds [9], as well as the high growth temperature (>850 °C) is unacceptable for the real usage. But the advantages of high growth temperature is offset (~Te) by the degrading effect of vacancies from contamination.

The Fig. 5 shows EDX measurement result of Ga2O3 NW on AG159 sample which grown at 830 °C of substrate temperature for 30 min. Among NW length, the structure composition of NW has similar chemical element. From the EDX results, the wt% composition magnitudes of NW configuration are Oxygen of 47.99 wt%, Gallium of 37.60 wt% and small Carbon amount impurity of 7.10 wt%. Also, we obtained the Arsenic of 7.31 wt%. Evidence of the residual As molecular small amount was absorbed on the NW surface by physical absorption during cooling down process of the substrate. Nevertheless, this As amount will not effect on NW structure and they also will disappear at As vapor temperature/or high temperature. To deeply understand these mechanisms, we can consider the surface physical absorption/or desorption mechanism.

4 Conclusions

In summary, we have successfully synthesized Ga2O3/GaAs NWs using VLS method based on Ag catalytic metal NPs deposited on the GaAs substrate by chemical deposition of HF/AgNO3 solution and investigated the effects of Ag catalyst as well as the NW growth properties. During investigation process, we finally found that: (a) the NW can random grow at anywhere of GaAs wafer surface area and the NW morphology strongly depend on the AgNP density, (b) the NW growth temperature is found around the Te: 700–830 °C, (c) the two-step temperature modes for dividing Ag catalyst metal particles into smaller size and grow NW at low vacuum–pressure (~10−1 Torr), at which can synthesis longer of length and control diameter of NWs depend of AgNP size. These results indicated also that the VLS mechanism is still dominated with Ag droplet on the top of NW. Therefore, in future, these Ga2O3 NWs are good candidate for the micro/or nano device applications.

References

M.S. Dresselhaus et al., Nanowires, in Springer Handbook of Nanotechnology, ed. by B. Bhushan (Springer, Berlin, Heidelberg, 2004), pp. 99–146

T. Akiyama et al., Role of the Au/GaAs(111) interface on the wurtzite-structure formation during GaAs nanowire growth by a vapor–liquid–solid mechanism. Phys. Rev. B 79(15), 153406 (2009)

S.A. Dayeh et al., Structural and room-temperature transport properties of zinc blende and WURTZITE InAs nanowires. Adv. Funct. Mater. 19(13), 2102–2108 (2009)

C. Zhang et al., Site-controlled VLS growth of planar nanowires: yield and mechanism. Nano Lett. 14(12), 6836–6841 (2014)

K.P. Bassett, P.K. Mohseni, X. Li, Evolution of GaAs nanowire geometry in selective area epitaxy. Appl. Phys. Lett. 106(13), 133102 (2015)

K. Dao et al., On the formation of voids, etched holes, and GaO particles configuration during the nanowires growth by VLS method on GaAs substrate. J. Mater. Sci. Mater. Electron. 24(7), 2513–2520 (2013)

K. Dao et al., The effects of Au surface diffusion to formation of Au droplets/clusters and nanowire growth on GaAs substrate using VLS method. J. Mater. Sci. Mater. Electron. 23(11), 2065–2074 (2012)

N. Han et al., Low-temperature growth of highly crystalline β-Ga(2)O(3) nanowires by solid-source chemical vapor deposition. Nanoscale Res. Lett. 9(1), 347 (2014)

V. Schmidt et al., Silicon nanowires: a review on aspects of their growth and their electrical properties. Adv. Mater. 21(25–26), 2681–2702 (2009)

R.S. Wagner, W.C. Ellis, Vapor–liquid–solid mechanism of single crystal growth. Appl. Phys. Lett. 4(5), 89–90 (1964)

K. Dao et al., The influences of technological conditions and Au cluster islands on morphology of Ga2O3 nanowires grown by VLS method on GaAs substrate. J. Mater. Sci. Mater. Electron. 22(2), 204–216 (2011)

P. Krogstrup, Dynamical theory and experiments on GaAs nanowire growth for photovoltaic applications, Faculty of Science (University of Copenhagen, Denmark, 2012), p. 138

J. Zha, H. Roggendorf, Sol–gel Science, the Physics and Chemistry of Sol–gel Processing, edited by C. J. Brinker, G. W. Scherer (Academic Press, Boston, 1990), xiv, 908 pp. Adv. Mater. 3(10), 522 (1991)

M. Becker et al., Nanowires enabling signal-enhanced nanoscale Raman spectroscopy. Small 4(4), 398–404 (2008)

I. Yoon et al., Single nanowire on a film as an efficient SERS-active platform. J. Am. Chem. Soc. 131(2), 758–762 (2009)

M. Panagopoulou et al., Raman enhancement of rhodamine adsorbed on Ag nanoparticles self-assembled into nanowire-like arrays. Nanoscale Res. Lett. 6(1), 629 (2011)

Y. He et al., Silicon nanowires-based highly-efficient SERS-active platform for ultrasensitive DNA detection. Nano Today 6(2), 122–130 (2011)

Y.F. Zhang et al., Germanium nanowires sheathed with an oxide layer. Phys. Rev. B 61(7), 4518–4521 (2000)

S.A. Dayeh, E.T. Yu, D. Wang, Surface diffusion and substrate-nanowire adatom exchange in InAs nanowire growth. Nano Lett. 9(5), 1967–1972 (2009)

J.D. Scofield, J.E. Davison, S.R. Smith, Calculation of phase diagrams for metal-GaAs systems. DTIC Document (1991)

Acknowledgments

The authors wish to acknowledge the support of the National Foundation for Science and Technology Development (NAFOSTED) for funding the basic research Project 103.02-2013.14 in 2013–2015 period and the Agency for Defense Development (ADD) of Republic of Korea and was partially supported by Mid-career Researcher Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning (No. 2011-0029412).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nguyen, T., Kim, E. & Dao, K. Ag nanoparticle catalyst based on Ga2O3/GaAs semiconductor nanowire growth by VLS method. J Mater Sci: Mater Electron 26, 8747–8752 (2015). https://doi.org/10.1007/s10854-015-3552-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3552-8