Abstract

CdSe nanoparticles were prepared through a cetyltrimethyl ammonium bromide (CTAB) assisted hydrothermal method. In this route, cadmium salt and SeCl4 as precursors and hydrazine hydrate (N2H4·H2O) as reductant were used. By varying the cadmium salt, reaction time, temperature, surfactant and molar ratio of Cd:Se:CTAB, the method permits us to synthesize nanoparticles with diameters less than 20 nm. SEM and TEM images show the morphology and particle size of the as-synthesized CdSe. XRD patterns show a pure hexagonal phase of CdSe. Chemical composition of nanoparticles is characterized by EDS. It is found that uniform CdSe nanoparticles are successfully produced from sulfate salt using 2 ml of hydrazine at 180 °C for 12 h.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The semiconductor compounds have attracted much attention because of their optoelectronic properties and applications. The CdSe as an II–VI group semiconductor has a direct band gap of 1.74 eV at room temperature. It is attracting growing interest because of its applications in light emitting diodes [1], solar cells [2], biological fluorescent labels [3], photovoltaic device, electroluminescence, catalyst [4], and also due to its optoelectronic properties [5]. The CdSe often possesses n-type conductivity in bulk as well as in thin film form. Many methods are developed to prepare the CdSe nanostructures with various morphologies [6–8].

Among the numerous methods developed for the synthesis of CdSe nanostructures, hydrothermal reaction has been proven to be a convenient way, especially to control the morphology and phase structure of the resulting products [9–11]. Herein, we report a hydrothermal method to synthesize CdSe nanostructures from the reaction of cadmium salt with SeCl4. This is first report on the hydrothermal synthesis of CdSe nanosturctures using SeCl4 as Se source. Using of the novel compounds can be useful and open a new way for preparing and controlling shape and size distribution of nanocrystals. This method is simple and cost effective; and provides a convenient way to the synthesis of other metal selenides [12–19]. We have studied the influences of cadmium salt, surfactant, reaction time, temperature and molar ratio of Cd:Se:CTAB on the morphology, phase and particle size of the nanocrystals. The semiconductor nanocrystal systems, especially CdSe nanocrystals, are more or less the best studied colloidal nanocrystal systems in terms of size and shape control [8].

2 Experimental

All the chemicals used in our experiments were of analytical grade, were purchased from Merck and used as received without further purification. The XRD patterns were collected from a diffractometer of Philips company with X’PertPro monochromatized Cu Kα radiation (λ = 1.54 Å). Microscopic morphology of products was visualized by a LEO 1455VP scanning electron microscope (SEM). TEM images were obtained on a Philips EM208S transmission electron microscope with an accelerating voltage of 100 kV. EDS analysis with 20 kV accelerated voltage was done. Room temperature PL was studied on a Perkin Elmer (LS 55) fluorescence spectrophotometer. The electronic spectrum of the samples was taken on a UV–Vis V-670 spectrophotometer (Jasco, Japan).

In a typical preparation, 3CdSO4·8H2O (0.186 g) and SeCl4 (0.16 g), with molar ratio 1:1, were dissolved in water to form a clear solution. In the next step, a certain amount of CTAB (0.3 g) was added into the above solution under stirring. Then, 2 ml of hydrazine was added drop-wise to the solution and the final solution transferred into a stainless steel Teflon-lined autoclave. The autoclave was sealed and maintained at 180 °C for 12 h. When the reaction was completed, the final product was filtered and washed with ethanol and water several times, then dried in vacuum at 60 °C for 4 h. Some control experiments, in which 3CdSO4·8H2O, temperature 180 °C and time 12 h were replaced by other salts, temperatures and times, and other operational processes were unchanged, were performed. The results have been listed in Table 1.

3 Results and discussion

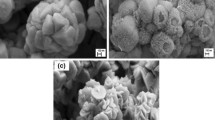

Figure 1a–d illustrates SEM images of as-synthesized samples from different cadmium salts. According to this figure, CdSe nanoparticles obtain from SeCl4 and different Cd salts in the presence of CTAB and hydrazine, at 180 °C for 12 h. With change at the metal salt from sulfate (Fig. 1d) to nitrate (Fig. 1b), acetate (Fig. 1a) and then chloride salt (Fig. 1c), the size and agglomeration of the nanoparticles are increased, respectively. The morphology, particle size and crystal phase of the CdSe nanostructures are sensitive to the added cadmium sources. We consider that the above phenomena result from the different interactions between anions and Cd2+ cations. During the growth of CdSe crystals, SO4 2−, NO3 −, CH3COO− and Cl− anions have different coordination with Cd2+ cations and might influence the adsorption and desorption rates at the CdSe nuclei, which might favor the preferential crystal growth [20].

The XRD pattern of sample prepared from sulfate salt (sample no. 4) is shown in Fig. 2a. All peaks in the pattern correspond to the reflections of hexagonal phase of CdSe with space group P63mc and JCPDS 77-2307. In order to further elucidate the size and the crystal structure of the nanoparticles prepared from sulfate salt, TEM images were taken. Figure 2b shows the TEM image of sample no. 4. Aggregated nanoparticles with semi-spherical shapes and diameters between 10 and 30 nm are obtained, when 3CdSO4·8H2O is used as cadmium precursor. The EDS pattern of CdSe (sample no. 4) in Fig. 2c, indicates that the elements in the product are Cd and Se only and a pure phase of CdSe obtains.

SEM and TEM images of the CdSe nanoparticles obtained at 180 °C for 6 h (sample no. 5) are shown in Fig. 3a–c. The diameters of nanoparticles are less than 20 nm. The SAED pattern of the sample no. 5 has been inserted in Fig. 3b, and approves high crystallinity of the product. The HRTEM image of a single CdSe nanoparticle in Fig. 3c shows that the nanoparticles are highly crystalline and distance between the two adjacent planes is measured to be 0.15 nm. This distance corresponds to (210) plane of XRD pattern. When the reaction time is increased of 6 h (Fig. 3a) to 12 h (Fig. 1d) and then 18 h (Fig. 3d), morphology and particle size of samples remain nearly constant and only agglomeration of nanoparticles increases a little. Figure 3e shows SEM image of sample prepared at 150 °C for 12 h. It can be observed that with decreasing temperature, the size and agglomeration of the nanoparticles increase. An increase of the reaction temperature always results in an increase of the rate of reaction; therefore at relatively high temperatures more CdSe nuclei will form before the growth process, which causes the formation of more particles with smaller diameters.

One of the impressive features of semiconductors is their ability to emit light. Upon excitation with wavelength shorter or equivalent to the absorption onset, an electron is promoted from the valance band to the conduction band and upon relaxation a phonon of light is emitted. The cadmium selenide is one of the groups II–VI semiconductors and has a direct bandgap. PL and UV–Vis spectra of sample no. 4 are showed in Fig. 4a, b respectively. The PL peak is narrow with an emission maximum at 430 nm. The estimated band gap of cadmium selenide using the PL spectrum is about 2.88 eV. The optical absorption edge 600 nm in Fig. 4b shows a blue shift in relation to bulk CdSe, 1.73 eV (716 nm) [21]. The first excitonic peak at 560 nm is due to the first electronic transition (1s–1s) occurring in the CdSe nanoparticles. The second at 460 nm can be assigned to the higher spin–orbit component of the 1s–1s transition [21].

XRD pattern of the sample prepared at 210 °C (sample no. 8) is presented in Fig. 5a. The diffraction peaks observed in this figure can be indexed to pure CdSe with hexagonal phase (JCPDS card no. 77-2307). XRD patterns in Figs. 2a and 5a verify that the crystal structure of CdSe nanoparticles is kept unchanged by increasing the temperature. In continues, the effect of molar ratio of Cd:Se:CTAB on the morphology of CdSe samples in the presence of hydrazine is investigated. The molar ratio is varied between 1:1:0.5 and 1:1:2. Figures 1d and 5b, c show the morphologies of the products obtained with different molar ratios of Cd:Se:CTAB. From the images, it can be seen that agglomerated nanoparticles are formed after the synthesis in all samples. When molar ratio of Cd:Se:CTAB is 1:1:2, due to large amount of surfactant, the surface of samples is covered by CTAB and the particles are buried in the large amount of surfactant, in conclusion the products separate well and have lower particle sizes. The size of the nanoparticles increases regularly with decreasing CTAB content.

We used four different surfactants to investigate influence of the surfactant on the morphology of the products. The morphology of the products was characterized by SEM and shown in Fig. 6. From the Fig. 6a, we can see that sample prepared in the presence of PEG600 has a granular morphology and is close to the regular spheres with uniform distribution. When PEG is used, polymeric molecules are adsorbed preferentially on the nuclei surface to inhibit aggregation by steric hindrance mechanism. Changing the surfactant to PVA, small particles cluster together and form blocky structures (Fig. 6b). As can be seen in Fig. 6c, SDBS is not a good surfactant in the current experiment, because it is clear that the synthesized sample is in micro size and there are no particles. Figure 1d showed that aggregated nanoparticles are as-prepared product in the presence of CTAB.

4 Conclusions

In this paper, we synthesized CdSe nanoparticles by hydrothermal method using Cd salts and SeCl4 as raw materials in the presence of CTAB and hydrazine. The hexagonal CdSe nanoparticles with diameters 10–30 nm were obtained from sulfate salt at 180 °C for 12 h. Decreasing reaction time to 6 h, helped us to prepare nanoparticles with diameters less than 20 nm. In this work, we investigated effects of cadmium salt, surfactant, reaction time and temperature and also molar ratio of Cd:Se:CTAB.

References

V.I. Klimov, A.A. Mikhailovsky, S. Xu, A. Malko, J.A. Hollingsworth, C.A. Leatherdale, H.-J. Eisler, M.G. Bawendi, Science 290, 314 (2000)

M. Salavati-Niasari, M. Esmaeili-Zare, A. Sobhani, Micro Nano Lett. 7, 831 (2012)

A. Fu, W. Gu, B. Boussert, K. Koski, D. Gerion, L. Manna, M. Le Gros, C.A. Larabell, A.P. Alivisatos, Nano Lett. 7, 179 (2007)

H.N. Wang, Z.Y. Guo, F.L. Du, Mater. Chem. Phys. 98, 422 (2006)

C.B. Murray, D.J. Norris, M.G. Bawendi, J. Am. Chem. Soc. 115, 8706 (1993)

Q. Peng, Y.J. Dong, Z.X. Deng, Y.D. Li, Inorg. Chem. 41, 5249 (2002)

B. Pejova, A. Tanusevski, I. Grozdanov, J. Solid State Chem. 174, 276 (2003)

Z.A. Peng, X.G. Peng, J. Am. Chem. Soc. 123, 1389 (2001)

W.T. Yao, S.H. Yu, S.J. Liu, J.P. Chen, X.M. Liu, F.Q. Li, J. Phys. Chem. B 110, 11704 (2006)

H. Liu, Z. Zhigang, T. Xiaosheng, Opt. Mater. Express 4, 1762 (2014)

Z. Zang, X. Tang, J. Alloys Compd. 619, 98 (2015)

M. Salavati-Niasari, M. Esmaeili-Zare, A. Sobhani, Micro Nano Lett. 7, 1300 (2012)

A. Sobhani, M. Salavati-Niasari, F. Davar, Polyhedron 31, 210 (2012)

M. Salavati-Niasari, A. Sobhani, Opt. Mater. 35, 904 (2013)

A. Sobhani, M. Salavati-Niasari, Mater. Res. Bull. 47, 1905 (2012)

M. Esmaeili-Zare, M. Salavati-Niasari, A. Sobhani, Ultrason. Sonochem. 19, 1079 (2012)

A. Sobhani, M. Salavati-Niasari, Mater. Res. Bull. 48, 3204 (2013)

A. Sobhani, M. Salavati-Niasari, Mater. Res. Bull. 53, 7 (2014)

M. Esmaeili-Zare, M. Salavati-Niasari, A. Sobhani, J. Ind. Eng. Chem. 20, 3518 (2013)

J. Li, X. Tang, Z. Lu, Y. Qian, J. Alloys Compd. 497, 390 (2010)

M.A. Malik, N. Revaprasadu, P. O’Brien, Chem. Mater. 13, 913 (2001)

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sobhani, A., Salavati-Niasari, M. CdSe nanoparticles: facile hydrothermal synthesis, characterization and optical properties. J Mater Sci: Mater Electron 26, 6831–6836 (2015). https://doi.org/10.1007/s10854-015-3297-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3297-4