Abstract

Ceramics in the solid solution system, Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ (x = 0.000–0.030) were prepared by hydrothermal and were assisted by microwave sintering. Effects of Bi3+ content on the phase transition, microstructure, and electrical properties of ceramics were investigated. The single phase perovskite-type ceramics showed different polymorphs and the grain size was significantly influenced with the doping of Bi3+. Dielectric measurements indicated excellent dielectric relaxation behavior for x = 0.005 and x = 0.030. At x = 0.015 and x = 0.020, samples show giant dielectric constant (near 200,000) and lower dielectric loss (lower than 1.2), compared with other giant permittivity materials such as CCTO. The relationship between T C and 2E C was investigated and a novel conclusion of the 2E C was increased with increasing T C was reached. A maximum value of d 33 = 265 pC/N was observed at x = 0.025 for the emergence of T O–T . That is because piezoelectrics always possessed high d 33 near morphotropic phase boundary.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to their attractive physical properties, such as high dielectric permittivity, diffuse phase transition and strong electrostriction, relaxor ferroelectric materials have attracted special attention during the last few decades. Most of these materials belong to complex lead-based perovskite compounds, such as PMN-PT and PMN-PZT, whose superior dielectric properties and relaxor behaviour have had considerable contributions in the development of relaxor ferroelectric materials [1–4]. For a half century, Pb-based piezoelectric ceramics, such as lead zirconium titanate [PbTiO3–PbZrO3 (PZT)], have dominated the field of piezoelectric ceramics worldwide. Because of its high d 33 and k p , PZT have been successfully applied in a wide range of systems and technologies, including sensors, actuators, transducers, and memory elements. These materials have, however, often been reported to pose a number of environmental and health concerns due to the volatility and toxicity of lead [5–7].

These disadvantages have motivated the search for new, efficient, and eco-friendly lead-free relaxor ferroelectric materials and piezoelectric materials. Several lead-free materials with perovskite structure, such as Ba1−x Sr x TiO3–Bi have been investigated, and in 2009, BCTZ ferroelectric system with a super high d 33 was designed, and since then, BCTZ system materials have attracted considerable attention and been considered as one of the promising candidates for lead-free piezoelectric ceramics. However, relaxor ferroelectric materials always show poor piezoelectric properties and there is little work to combine these two properties in one single materials [7–13].

In present work, the Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics were prepared by hydrothermal method and were assisted by fast microwave sintering method. Compared with the conventional method, the hydrothermal method has advantages of high purity and homogeneous grain size in synthesizing powders. Microwave sintering (MS) is a unique technique alternative to the conventional sintering, by which the heat is generated internally within the material through microwave–material interaction instead of originating from external sources [14, 15]. It is particularly a suitable sintering method for the ceramics with ultrafine powders prepared by hydrothermal method. The Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics in this study show excellent relaxor behavior as well as high d 33 with x = 0.005 and x = 0.030.

2 Experimental

Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics were prepared by hydrothermal method and the BaCl2·2H2O (SCRC), CaCl2, TiCl4, ZrOCl2·8H2O and Bi(NO3)3 were used as raw materials. BaCl2·2H2O, CaCl2 ZrOCl2·8H2O and Bi(NO3)3 were first dissolved in distilled water respectively and then were mixed. The TiCl4 was added into the mixtures dropwise to obtain Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ precursors. Finally the NaOH was added to regulated the pH > 14. The three precursors were put into the heating-autoclave, followed by distilled water until the total volume reached to ~80 % of the autoclave. The hydrothermal reactions were carried out at 180 °C for 10 h and finally the three powders were mixed before dried. After that, the powders were pressed into pellets of 12 mm diameter and the pellets were sintered at 1280 °C for 10 min under microwaves.

Phase structure of Ba0.9Ca0.1Ti0.9Zr0.1O3–xLa ceramics was examined using an X-ray diffraction (D/max 2200 pc, Rigaku, Tokyo, Japan) with CuKα radiation. The microstructure morphologies were obtained by scanning electron microscopy (JEOL JSM-6390A JEOL Ltd. Tokyo), and the densities were measured according to Archimedes principle. Dielectric and ferroelectric measurements were carried by Agilent 4980A impedance analyzer and a ferroelectric analyzer (Premier II, Radiant, USA). The ceramics were poled under a DC field of 4 kV/mm in silicon oil bath for 10 min at different temperatures and the d 33 of the poled ceramics was measured using a quasi-static meter d33 meter (ZJ-4AN, China).

3 Results and discussion

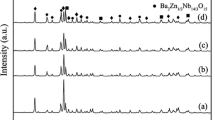

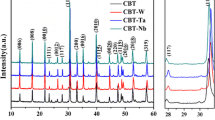

The XRD patterns of the Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics are shown in Fig. 1. All the ceramics have pure perovskite structure and no second phases were detected, suggesting that Bi3+ was incorporated into the BCTZ lattices to form a solid solution. The Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics exhibit different polymorphs with different x: Samples with x = 0.000 and x = 0.020 show single orthorhombic (O) phase for the narrow and single (002)/(200) peak. The broadening peak with (002)–(200) less than 1 indicates the coexistence of tetragonal (T) and cubic (C) phase for x = 0.005, x = 0.010 and x = 0.030. Samples with x = 0.015 and x = 0.025 possess single tetragonal phase and the coexistence of orthorhombic and tetragonal phase respectively, which is characterized by the (002)–(200) is greater than 1 and is approximate to 1 [2–4]. And these will be studied detailedly in temperature dependence of dielectric constant in the following discussion. The radius of Bi3+ (0.117 nm) is very close to those of Ba2+ (0.161 nm) and Ca2+ (0.134 nm) in A site of the BCTZ ceramics and therefore Bi3+ most likely occupy the A sites firstly with smaller amount of addition according to the principles of crystal chemistry [4–9]. With further addition of Bi3+, it maybe probably enter the oxygen octahedron for substituting Ti4+ and Zr4+ for the saturated solid solubility in A site. It is also noticed that the (200)/(002) peak shifts towards higher degree of 2θ with increasing Bi3+ content for the decreasing lattice parameter d.

Figure 2 shows SEM micrographs (a–g) of thermally etched surface for Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics (0.000 ≤ x ≤ 0.030) and the corresponding average grain size (h), and the grain size was measured using the Mean Lineal Intercept Method (ASTM Standard E112-88). It can be observed that the grain size is influenced significantly with the introduction of Bi3+. The sample with x = 0.005 possesses smaller and more homogeneous grain size compared with Bi3+ free sample and the grain size is increased sharply to ~7.8 μm when x = 0.010. With further doping, the grain size decreases gradually again. These phenomenons can be understood as follows: The grain size of Ba0.9Ca0.1Ti0.9Zr0.1O3 ceramics firstly decreased for the refining mechanism of micro-doping of Bi3+, and then increased significantly at x = 0.010 because of the reduction of interfacial free energy [2, 4]. With further increasing x, more Bi3+ dissolved in Ba0.9Ca0.1Ti0.9Zr0.1O3 lattice at high temperature during sintering process, while in the cooling step, extra Bi3+ separated out and aggregated in grain boundaries, the migration of grain boundaries was inhibited and thus the grain growth was decreased.

Figure 3 shows the dielectric constant of Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics as a function of temperature measured at frequencies 1, 10, 100 and 1,000 kHz respectively (a–g), and T C and resistivity as a function of x (h). Some novel phenomenons can be observed: Plots of Fig. 3a, e indicate Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramic with x = 0.000 x = 0.025 of single transition peak with wide T C range, which is agreed with former literatures [3–9]. While sample of x = 0.025 exhibits two phase peaks of T C and T O–T (orthorhombic to tetragonal), suggesting the coexistence of orthorhombic and tetragonal phase at room temperature, which is agreed with the conclusions of XRD. Samples of x = 0.010 and x = 0.015 can be used as giant permittivity materials, and judging from the significant disparity of permittivities between different frequencies, it can be assumed that the giant dielectric behavior results from some relaxation polarizations with the addition of Bi3+. As our earlier research [10, 11], the defect chemical reactions of Bi3+ (donor doping) for A-site ions at higher x are represented as:

Relaxation polarizations such as dipole polarization and space charge polarization caused by the emergence of e′ and \(V_{Ti}^{{{\prime \prime \prime \prime }}}\) cannot keep pace up with the electrical field with higher frequency, only making contribution in increasing the permittivity significantly of samples at f = 1 kHz and f = 10 kHz. Figure 3h indicates that the resistivity of Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics decreases firstly and then increases with increasing Bi3+ content, exhibiting the minimum value at x = 0.010 of 2.7 × 102 Ω cm. The sharp decreasing of resistivity is due to the e′ and \(V_{Zr}^{{{\prime \prime \prime \prime }}}\) serving as carriers in ceramics, and the sample with the lowest resistivity always exhibits the largest grain size in BCTZ ceramics with donor doping. With the further doping of Bi3+ in the A site of BCTZ ceramics, the carriers disappeared and the so did the PTC behavior. The samples became to dielectrics again. Both the permittivities and the Tc decreased and the P–E loops can also be detected. This variation is in accordance with the former literature [12, 13]. Plots of Fig. 3b, g indicate that Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ solid solutions with x = 0.005 and x = 0.030 are relaxor ferroelectrics with excellent frequency dispersion and diffused phase transition.

The relaxation behaviors at 10 kHz of Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics with x = 0.005 and x = 0.030 are shown in Fig. 4. Plots of inverse dielectric permittivity versus temperature are shown in (a) and (b). The deviation from the Curie–Weiss law for relaxor ferroelectrics can be defined by ΔT m as follows:

where T cm refers to the temperature from which dielectric permittivity starts to deviate from the Curie–Weiss law and T m to the temperature at which dielectric permittivity reaches the maximum [4]. The ΔT m value calculated at 10 kHz was 37 and 30 °C for x = 0.005 and x = 0.030 respectively, and was noted to be almost invariable with the increase in frequency. The dielectric characteristics of relaxor ferroelectrics are known to deviate from the typical Curie–Weiss behavior and can be well described by the Uchino and Nomura function, a modified Curie–Weiss relationship:

where ε m refers to the maximum value of dielectric permittivity, ε to the dielectric permittivity at temperature T, T m to the temperature at the peak of the dielectric permittivity, C to the Curie constant, and γ to the diffuseness degree indicator, taking the value between 1 (for a normal ferroelectric) and 2 (for a complete diffuse phase transition). The value of γ can, therefore, be used to characterize the relaxor behavior [2, 5]. The plot of ln (1/ε − 1/ε m ) as a function of ln (T − T m ) is shown in (c) and (d). By fitting the Uchino equation, the exponent γ which determines the diffuseness degree of the phase transition, was obtained from the slope of log ln(1/ε − 1/ε m )-vs-ln(T − T m ) plots. The value obtained for the parameter was 1.65 and 1.74, suggesting that samples with x = 0.005 and x = 0.030 are relaxor ferroelectric with strong diffuse phase transition. The ΔT relax was also introduced to investigate the relaxor feature of the two samples, and The degrees of relaxation behaviour and diffuseness were defined as:

a, b The plot of the inverse dielectric constant versus temperature at 10 kHz: (a) x = 0.005; (b) x = 0.030. c, d ln(1/ε − 1/ε m ) as a function of ln (T − T m ) at 10 kHz: (c) x = 0.005; (d) x = 0.030. e Temperature of maximum permittivity, versus lnf for x = 0.005 and x = 0.030. f, g Arrhenius plot of the dielectric relaxation peak from the frequency spectra: (f) x = 0.005; (g) x = 0.030

Based on the experimental data, the values calculated for ΔT relax are 13 °C and 15 °C for x = 0.005 and x = 0.030 respectively. The temperature of maximum permittivity versus lnf for x = 0.005 and x = 0.030 are shown in Fig. 4e. These excellent dielectric relaxor behaviors are attributed to the structural fluctuation caused by more homogeneous grain size, which is shown in Fig. 2b, g.

On the basis of the relationship between lnf and T C , we can calculate the relaxor activated parameters of the T C peak. For a relaxation process, the relaxation time generally follows the Arrhenius law:

where τ 0 is the pre-exponential factor (or the relaxation time at infinite temperature), E denotes the activation energy of the relaxation process, T is the absolute temperature, and K B is the Boltzmann constant. The condition ω p τ p = 1 is fulfilled at the peak position, where ω = 2πf is the angular frequency of measurement and the subscript p denotes values at peak position. If we plot the ln(ω p ) as a function of the reciprocal of peak temperature (Arrhenius plots), a linear relation would be obtained. The relaxation parameters E and τ 0 can thus be deduced from the slope and intercept of this line, respectively [4, 5, 15, 17, 19]. Figure 4f, g shows the Arrhenius plots for the dielectric constant peak, where the solid line is the result of a linear least-square fitting. The relaxation parameters E = 4.24 eV; τ 0 = 3.32 × 10−14 s for x = 0.005 and E = 3.68 eV; τ 0 = 3.34 × 10−14 s for x = 0.030 are obtained from the fitting line.

Figure 5 shows the dielectric loss of Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics as a function of temperature measured at frequencies 1, 10, 100 and 1,000 kHz respectively. Figure 5a, e shows single peak (T C ) while (f) shows two peaks (T C and T O–T ), which is agreed with Fig. 3. Contrary to the others, the dielectric loss increases with increasing frequency in (b) and (g), which is a character of relaxor ferroelectrics. Figure 5c indicates the highest dielectric loss of x = 0.015, which caused by the relaxation polarizations as discussed above. Ba0.9Ca0.1Ti0.9Zr0.1O3–0.015Bi3+ ceramic shows giant dielectric behavior especially in low frequencies and dielectric loss lower than 0.6. Compared with other giant dielectric constant materials such as CaCu3Ti4O12 (CCTO), which shows dielectric loss over 10, this materials has advantages in much higher dielectric constant and lower dielectric loss.

Figure 6 shows the ferroelectric hysteresis loops measured at room temperature of the Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics with x = 0.000, 0.005, 0.020, 0.025 and 0.030, and all these samples possess a typical ferroelectric polarization hysteresis loop. Ferroelectric properties can not be detected in samples with x = 0.010 and x = 0.015 for the lower resistivity as shown in Fig. 3h. In this case, the ceramics are easily to be broken down under a high voltage, which is agreed with the conclusion of our early studies [10, 11]. Sample with x = 0.020 shows a maximum value of P r = 10.10 μC/cm2 and the minimum value of P r = 1.52 μC/cm2 exists in sample with x = 0.005, and the relationship between x and Pr is shown in (f). To characterize the breadth of P–E loops, the relationship between T C and 2E C is illustrated in (g): A novel conclusion can be obtained that the 2E C increases with increasing T C . It is known to all that in normal ferroelectrics, the ferroelectric properties such as P–E loops can only be detected under T C (ferroelectric phase) while in relaxor ferroelectrics it can be observed in all the T C range, even at temperature over TC, for the existence of ferroelectric domains in all the T C range. In T C peak, the amounts of ferroelectric domains decreases and the ferroelectric properties weakens with increasing temperature, and it can be deduced that the P–E loops will be narrower and finally be a single line with the T C moving to lower temperature [10–15].

The variations of the d 33 with different x except for 0.010 and 0.015 for the Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics are shown in Fig. 7. Piezoelectric properties can not be detected as well in samples with x = 0.010 and x = 0.015 for the same reason in Fig. 6. Sample for x = 0.025 exhibits the maximum value of d 33 for the coexistence of orthorhombic and tetragonal phase while the d 33 in x = 0.000 and x = 0.020 samples is much lower, and the samples for x = 0.005 and x = 0.030 show the medium value of d 33. That is because the piezoelectrics exhibit optimistic piezoelectric properties near the morphotropic phase boundary (MPB) [3, 13–19]. Ba0.9Ca0.1Ti0.9Zr0.1O3–0.025Bi3+ possesses the coexistence of orthorhombic and tetragonal phase thus show higher d 33, and the inferior piezoelectric properties of sample for x = 0.000 and x = 0.020 results from the single orthorhombic phase at room temperature. The x = 0.005 and x = 0.030 samples also possess higher d 33 for the coexistence tetragonal and cubic phase. As discussed above, these two samples are also excellent relaxor ferroelectrics and in this case, piezoelectric materials with dielectric relaxor behavior were obtained.

4 Conclusions

Lead-free Ba0.9Ca0.1Ti0.9Zr0.1O3–xBi3+ ceramics have been prepared by hydrothermal method and the effects of Bi3+ on the phase transition, microstructure, dielectric relaxation behavior, ferroelectric and piezoelectric properties of these ceramics were studied. Samples with x = 0.000 and x = 0.020 possess orthorhombic phase and show poor piezoelectric properties at room temperature. The Ba0.9Ca0.1Ti0.9Zr0.1O3–0.010Bi3+ and Ba0.9Ca0.1Ti0.9Zr0.1O3–0.015Bi3+ ceramics exhibit giant dielectric behavior and have advantages in lower dielectric loss over CCTO, but are not ferroelectrics nor piezoelectrics. Sample for x = 0.025 show coexistence of orthorhombic and tetragonal phase and exhibits the maximum value of d 33. Samples with x = 0.005 and 0.030 exhibit excellent dielectric relaxation behavior and the relaxation parameters were obtained. These two samples also shows better d 33 and in this case, the piezoelectric materials with dielectric relaxation behavior were obtained.

References

J. Lee, S. Lee, V.A. Hackley, U. Paik, Influence of [Ba+Ca]/[Ti+Zr] ratio on the interfacial property of (Ba,Ca)(Ti,Zr)O3 (BCTZ) powders in an aqueous medium. J. Am. Ceram. Soc. 86(6), 1034–1036 (2003)

L.F. Zhu, B.P. Zhang, X.K. Zhao, L. Zhao, P.F. Zhou, J.F. Li, Enhanced piezoelectric properties of (Ba1−x Ca x )(Ti0.92Sn0.08)O3 lead-free ceramics. J. Am. Ceram. Soc. 96(1), 241–245 (2013)

J.G. Wu, D.Q. Xiao, W.J. Wu, J.G. Zhu, J. Wang, Effect of dwell time during sintering on piezoelectric properties of (Ba0.85Ca0.15)(Ti0.90Zr0.10)O3 lead-free ceramics. J. Alloys. Compd. 509, 359–361 (2011)

J.G. Wu, D.Q. Xiao, W.J. Wu, Q. Chen, J.G. Zhu, Z.C. Yang, J. Wang, Composition and poling condition-induced electrical behavior of (Ba0.85Ca0.15)(Ti1−x Zr x )O3 lead-free piezoelectric ceramics. J. Eur. Ceram. Soc. 32, 891–898 (2012)

S.O. Leontsev, R.E. Eitel, Progress in engineering high strain lead free piezoelectric ceramics. Sci. Technol. Adv. Mater. 11, 044302 (2010)

Z. Aurang, J.M. Steven, Stability of high-temperature dielectric properties for (1−x)Ba0.8Ca0.2TiO3–xBi(Mg0.5Ti0.5)O3 ceramics. J. Am. Ceram. Soc. 96(9), 2887–2892 (2013)

J.G. Wu, W.J. Wu, D.Q. Xiao, J. Wang, Z.C. Yang, Z.H. Peng, Q. Chen, J.G. Zhu, (Ba, Ca)(Ti, Zr)O3–BiFeO3 lead-free piezoelectric ceramics. Curr. Appl. Phys. 12, 534–538 (2012)

Z. Aurang, J.M. Steven, Dielectric and piezoelectric properties of (1−x)K0.5Bi0.5TiO3–xBa(Ti0.8Zr0.2)O3 ceramics. J. Am. Ceram. Soc. 96(10), 3089–3093 (2013)

T. Takenaka, H. Nagata, Current status and prospects of lead-free piezoelectric ceramics. J. Eur. Ceram. Soc. 25, 2693–2700 (2005)

Z.X. Sun, Y.P. Pu, Z.J. Dong, Y. Hu, X.Y. Liu, P.K. Wang, M. Ge, Dielectric and piezoelectric properties and PTC behavior of Ba0.9Ca0.1Ti0.9Zr0.1O3–xLa ceramics prepared by hydrothermal method. Mater. Lett. 118, 1–4 (2014)

S. Su, R.Z. Zuo, S.B. Lu, Z.K. Xu, X.H. Wang, L.T. Li, Poling dependence and stability of piezoelectric properties of Ba(Zr0.2Ti0.8)O3–(Ba0.7Ca0.3)TiO3 ceramics with huge piezoelectric coefficients. Curr. Appl. Phys. 11(3), S120–S123 (2011)

D.M. Finlay, C.S. Derek, R.W. Anthony, An alternative explanation for the origin of the resistivity anomaly in La-doped BaTiO3. J. Am. Ceram. Soc. 84(2), 474–476 (2001)

R.Z. Zuo, X.S. Fang, C. Ye, Phase structures and electrical properties of new lead free (Na0.5K0.5)NbO3–(Bi0.5Na0.5)TiO3 ceramics. Appl. Phys. Lett. 90, 092904 (2007)

J. Wu, D. Xiao, W. Wu, Q. Chen, J. Zhu, Z. Yang, J. Wang, Role of room-temperature phase transition in the electrical properties of (Ba, Ca)(Ti, Zr)O3 ceramics. Scr. Mater. 65, 771–774 (2011)

Y.C. Lee, Y.Y. Yeh, P.R. Tsai, Effect of microwave sintering on the microstructure and electric properties of (Zn, Mg)TiO3-based multilayer ceramic capacitors. J. Eur. Ceram. Soc. 32, 1725–1732 (2012)

C.Y. Tsay, K.S. Liu, I.N. Lin, Microwave sintering of (Bi0.75Ca1.2Y1.05)(V0.6Fe4.4)O12 microwave magnetic materials. J. Eur. Ceram. Soc. 24, 1057–1061 (2004)

T. Chen, T. Zhang, G. Wang, J. Zhou, J. Zhang, Y. Liu, Effect of CuO on the microstructure and electrical properties of Ba0.85Ca0.15Ti0.90Zr0.10O3 piezoceramics. J. Mater. Sci. 47, 4612–4619 (2008)

P. Wang, Y.X. Li, Y.Q. Lu, Enhanced piezoelectric properties of (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 lead-free ceramics by optimizing calcination and sintering temperature. J. Eur. Ceram. Soc. 31, 2005–2012 (2011)

J. Tao, Z.G. Yi, Y. Liu, M.X. Zhang, J.W. Zhai, Dielectric tunability, dielectric relaxation, and impedance spectroscopic studies on (Ba0.85Ca0.15)(Ti0.9Zr0.1)O3 lead-free ceramics. J. Am. Ceram. Soc. 96(6), 1847–1851 (2013)

Acknowledgments

This research was supported by the National Natural Science Foundation of China (51372144 and 51102159), the New Century Excellent Talents Program of Chinese Education Ministry (NCET-11-1042), the International Science and Technology Cooperation Project Funding of Shaanxi Province (2012KW-06), and Graduate Innovation Fund of Shaanxi University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Pu, Y., Sun, Z. et al. Effects of Bi3+ doping of the dielectric and piezoelectric properties of Ba0.9Ca0.1Ti0.9Zr0.1O3 ceramics prepared by hydrothermal method. J Mater Sci: Mater Electron 26, 3025–3034 (2015). https://doi.org/10.1007/s10854-015-2793-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2793-x