Abstract

The Bi1−x Eu x FeO3 (B1−x E x FO, x = 0, 0.03, 0.05, 0.07) films were grown on quartz substrates by pulsed laser deposition. X-ray diffraction analysis indicates the B1−x E x FO films exhibit the distorted rhombohedral perovskite structure, and the substitution of Eu into the Bi site. Atomic force microscopy and scanning electron microscopy show that the B1−x E x FO films are smooth and uniform. With increasing Eu content, the fundamental absorption edges of B1−x E x FO films show red shift. At the wavelength of 720 nm, the refractive index increases and the extinction coefficient decreases with increasing the amount of Eu. The band gap of the B1−x E x FO films decreases from 2.694 ± 0.007 to 2.501 ± 0.005 eV with increasing Eu content from x = 0 to x = 0.07, which provides potential application for optoelectronic and photovoltaic devices due to the enhanced photovoltaic conversion ability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, BiFeO3 (BFO) is one of the most extensively investigated materials because of its potential applications [1–4]. And the properties of BFO material, including its remarkable magnetoelectric coupling effects [5, 6], optical properties [7–9] and ferroelectric properties [10–12] have been reported.

BFO is a room temperature, single phase, multiferroic material with a high ferroelectric Curie temperature (TC ~ 1,100 K) [13] and high antiferromagnetic Neel temperature (TN ~ 640 K) [14], thus it offers an exciting way for room temperature device integration. Recently, researchers have reported photovoltaic effect in BFO bulk [15] and film [16–18] structures, which promises potential applications in photovoltaic devices. Therefore it is necessary to study the optical properties of the BFO material.

The rare earth ions doping for bismuth in BiFeO3 help to control the volatilization of the Bi element [19], decrease the formation of oxygen vacancies [20], and eliminate the impurity and secondary phases [21]. Since Eu has a smaller ionic radius (0.95 Å) as compared to other rare-earth ions, thus Eu doping could introduce lager structural distortions. In this way the magnetoelectric response of the structural distortions will be highlighted.

In previous work, Eu doped BFO films were deposited on LaNiO3 coated Si (LNO/Si) substrates [22], and the Raman spectra and spectroscopic ellipsometry have been reported [23, 24]. Thus the results can be used directly on silicon integrated devices. In this paper, the B1−x E x FO (x = 0, 0.03, 0.05, 0.07) films were grown on quartz substrates by pulsed laser deposition (PLD), and the effects of Eu doping on the crystal structures, surface morphologies, and optical properties of BFO films were investigated. The main emphasis is the transmittance spectra and band gap of B1−x E x FO films. The quartz substrate is transparent. And the band gap of B1−x E x FO films on quartz substrate decreases from 2.694 ± 0.007 to 2.501 ± 0.005 eV, the decreased band gap corresponds to higher photon absorption efficiency, thus the photovoltaic conversion ability is enhanced. The results could be helpful in the applications of photovoltaic devices, and could improve applicability in optoelectronic devices.

2 Experimental

A series of B1−x E x FO films were grown on quartz substrates by PLD method. The ceramic targets used in the PLD were synthesized by the conventional solid state reaction, using high purity Bi2O3, Eu2O3 and Fe2O3 powders (99.9 %, Sinopharm Chemical Reagent Co. Ltd, China) as starting chemicals. These oxides were mixed and grinded together in absolute alcohol media for 8 h. Then the uniform-mixed powders were pressed into targets with diameter of 33 mm and thickness of 4 mm, and then sintered for 2 h at 810 °C in air. An excimer laser (COMPexPro, Coherent) with a wavelength of 248 nm (KrF), a repetition rate of 5 Hz, and a pulsed laser energy of 200 mJ was used to prepare the films. The B1−x E x FO films were deposited on quartz substrates at 700 °C with oxygen pressure of 10 Pa.

Crystalline structures analysis of B1−x E x FO films were performed by X-ray diffraction (XRD, D8 Advanced XRD, Bruker) with CuKα radiation (λ = 1.54 Å). The tube voltage and tube current is 40 kV and 40 mA, respectively. The surface morphologies of the films were characterized using the atomic force microscopy (AFM, Digital Instruments Dimension 3100, Veeco) and scanning electron microscope (SEM, S-4700, Hitachi), respectively. The optical properties were determined using transmittance spectra (UV/VIS Lambda 2S, PerkinElmer). The optical constants of the B1−x E x FO films were derived from the transmittance spectra using the envelope method. All these measurements were carried out at room temperature.

In previous work, transmittance spectra have been used to calculate refractive index n and extinction coefficient κ using the envelope technique [23, 24]. The envelope technique is a method to determine the optical constants of the films. The refractive index n is given by [25, 26]

where \(N = \frac{{(1 + n_{s}^{2} )}}{2} \pm 2n_{s} \frac{{(T_{M} - T_{m} )}}{{T_{M} T_{m} }}\), + for n > n s , − for n < n s n s is the refractive index of substrate, T M and T m are respectively the maximum and minimum of film transmittance obtained from the envelopes of extrema of film transmittance spectrum at a particular wavelength λ.

The extinction coefficient κ of the film is given by \(x = \pm \frac{{(n + 1)(n + n_{s} )}}{{(n - 1)(n - n_{s} )}}\left[ {\frac{{\sqrt {T_{M} /T_{m} } - 1}}{{\sqrt {T_{M} /T_{m} } + 1}}} \right]\), + for n > n s , − for for n < n s where \(x = \exp {\kern 1pt} {\kern 1pt} ( - \alpha d);\) α is the absorption coefficient of film (equals 4πκ/λ).

3 Results and discussion

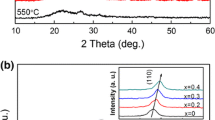

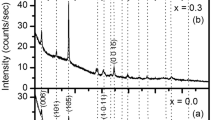

Figure 1 shows the XRD patterns of B1−x E x FO (x = 0, 0.03, 0.05, 0.07) films deposited on quartz substrates. In terms of the standard XRD patterns (PDF#14-0181), strong diffraction peaks (101), (021), (202) and (211) peaks are found in the B1−x E x FO films. While the B1−x E x FO films deposited on LNO/Si substrates are the dominant orientation of (100) [22]. The diffraction peaks in the patterns indicate that B1−x E x FO films characterize a polycrystalline perovskite structure with rhombohedral R3c symmetry, and no impurity phases and secondary phases are observed. Closer observation of peak (101) of B1−x E x FO films is shown in Fig. 1b, it can be seen that as Eu content increases, the peak position shifts toward higher 2θ value. This may be caused by the distortion of lattice due to Eu doping because the radius of Eu3+ is smaller than that of Bi3+, which is similar to that report in [13]. The peak intensity increases with the increasing Eu content, which indicates Eu doping could improve crystallization properties of the B1−x E x FO films.

Figure 2a–d shows the 2-dimensional (2D) AFM and cross-sectional SEM images of the B1−x E x FO (x = 0, 0.03, 0.05, 0.07) films deposited on the quartz substrates. The AFM images are over 2 × 2 μm2 area in tapping mode. It can be clearly seen that all the B1−x E x FO films are well crystallized since favorable grains can be identified clearly. The grain size of the B1−x E x FO (x = 0, 0.03, 0.05, 0.07) films is 50 ± 2, 80 ± 3, 100 ± 4 and 150 ± 3 nm, respectively. The results suggest that the grain size of B1−x E x FO films on quartz substrate is smaller than that of [22], which indicates the B1−x E x FO films on quartz substrate are smoother. It can been seen that the grain size increases with increasing Eu content, which indicates Eu doping could improve crystallization properties of BFO films. The root-mean-square (RMS) roughness of the B1−x E x FO (x = 0, 0.03, 0.05, 0.07) films is 8.9 ± 0.3, 7.7 ± 0.2, 6.7 ± 0.5 and 5.2 ± 0.4 nm, respectively. Thus the smooth and uniform B1−x E x FO films are obtained. The RMS roughness decreases with the increasing x, which results from the substitution of Eu because Eu doping could control the volatility of the Bi element and restrain the formation of voids [19–21]. As shown in the cross-sectional SEM images (inset of Fig. 2a–d), the interfaces between the B1−x E x FO films and quartz substrates are obvious, and the thickness of B1−x E x FO (x = 0, 0.03, 0.05, 0.07) films are about 300 ± 8, 250 ± 9, 270 ± 6 and 280 ± 7 nm, respectively.

Figure 3 shows the transmittance spectra of B1−x E x FO films in the wavelength range from 300 to 2,400 nm. As shown in Fig. 3, the transmittance for all the B1−x E x FO films decreases to zero at the wavelength of about 450 nm. Furthermore, the absorption edges of B1−x E x FO films show red shift with increasing Eu content. It is clearly seen that the B1−x E x FO films are highly absorbent in the blue and purple light area, which promises potential applications in optoelectronic and photovoltaic devices because of the higher photon absorption efficiency [27, 28]. Transmittance spectra have been used to calculate refractive index n and extinction coefficient κ using the envelope technique. The envelope of pure BFO film is shown in inset of Fig. 3.

The refractive index n and extinction coefficient κ of the B1−x E x FO films are displayed in Fig. 4. Obviously, for each B1−x E x FO film, both the refractive index n and extinction coefficient κ decreases with the increasing wavelength. Furthermore, the refractive index n for Eu-doped BFO films is larger than that of the pure BFO film. The refractive index n as a function of the Eu content at wavelength of 720 nm is shown in the inset of Fig. 4a. The extinction coefficient is close to zero at the range of 800–2,400 nm. And it decreases sharply from 300 to 600 nm, which suggests strong photon absorption at the wavelength of 300 nm. The extinction coefficient κ as a function of the Eu content at wavelength of 720 nm is shown in the inset of Fig. 4b, which indicates that the extinction coefficient κ decreases with the increasing Eu content.

The refractive index n and extinction coefficient κ for the B1−x E x FO (x = 0, 0.03, 0.05, 0.07) films on quartz substrates. Offset of 0.2 for n and κ data one by one. The inset (a) and inset (b) show the refractive index n and extinction coefficient κ at wavelength of 720 nm versus Eu content, respectively

The (αE)2 versus E for B1−x E x FO films is plotted in Fig. 5. B1−x E x FO films belong to direct band gap material, so the band gaps can be calculated by the Tauc’s law [9]: αhv = A(hv − E g )1/2, where α is the absorption coefficient, h is Planck’s constant, v is the frequency of the incident photon, A is a constant, and E g is the optical band gap. The optical band gap (Eg) is determined by extrapolating straight line of (αE)2 verse photon energy curve to the intercept on horizontal photon energy axis [8], where α is the absorption coefficient (α = 4πκ/λ), and E is the photon energy. The optical band gap of BFO film is 2.694 ± 0.007 eV, which is in good agreement with that reported in [29]. And the band gap of other three B1−x E x FO (x = 0.03, 0.05, 0.07) films are 2.622 ± 0.004 eV, 2.58 ± 0.005 eV and 2.501 ± 0.005 eV, respectively. The band gap of B1−x E x FO films as a function of x is shown in inset of Fig. 5. It can be seen that the band gap decreases with the increasing x, and the functional relation can be expressed by (2.694−2.6x) eV. The decreased band gap corresponds to higher photon absorption efficiency. Thus the decreased band gap could improve applicability in optoelectronic devices due to the enhanced photovoltaic conversion ability.

In the fundamental absorption edges region, the absorption is due to the transition between the top of valence band and the bottom of conduction band [30]. Eu substitution in BFO film can increase density of states in the valence band and create localized states in the band gap, which results in a decrease in the optical band gap of the BFO films.

4 Conclusions

The B1−x E x FO (x = 0, 0.03, 0.05, 0.07) films were successfully fabricated on quartz substrates by PLD method. XRD patterns indicate that B1−x E x FO films characterize the distorted rhombohedral perovskite structure. AFM and SEM images show that the surfaces of the B1−x E x FO films are uniform and smooth. The absorption edges of B1−x E x FO films show red shift with increasing Eu content. The refractive index increases and the extinction coefficient decreases with increasing the amount of Eu. With increasing the x from x = 0 to x = 0.07, the optical band gap of B1−x E x FO films decreases from 2.694 ± 0.007 to 2.501 ± 0.005 eV.

References

M.K. Singh, S. Ryu, H.M. Jang, Phys. Rev. B 72, 132101 (2005)

N. Balke, S. Choudhury, S. Jesse, M. Huijben, Y.H. Chu, A.P. Baddor, L.Q. Chen, R. Ramesh, S.V. Kalinin, Nat. Nanotechnol. 4, 868–875 (2009)

D.J. Huang, H.M. Deng, P.X. Yang, J.H. Chu, Mater. Lett. 64, 2233–2235 (2010)

C.T. Nelson, P. Gao, J.R. Jokisaari, C. Heikes, C. Adamo, A. Melville, S.H. Baek, C.M. Folkman, B. Winchester, Y.J. Gu, Y.M. Liu, K. Zhang, E.G. Wang, J.Y. Li, L.Q. Chen, C.B. Eom, D.G. Schlom, X.Q. Pan, Science 334, 968–971 (2011)

N.A. Spaldin, M. Fiebig, Science 309, 391–392 (2005)

Y.H. Chu, L.W. Martin, M.B. Holcomb, R. Ramesh, Mater. Today 10, 16–23 (2007)

B. Kundys, M. Viret, D. Colson, D.O. Kundys, Nat. Mater. 9, 803–805 (2010)

N.F. Ding, H.M. Deng, P.X. Yang, J.H. Chu, Mater. Lett. 82, 71–73 (2012)

L. Peng, H.M. Deng, J.J. Tian, Q. Ren, C. Peng, Z.P. Huang, P.X. Yang, J.H. Chu, Appl. Surf. Sci. 268, 146–150 (2013)

T.L. Qu, Y.G. Zhao, D. Xie, J.P. Shi, Q.P. Chen, T.L. Ren, Appl. Phys. Lett. 98, 173507 (2011)

J.F. Scott, Nature 6, 256–257 (2007)

M. Bibes, A. Barthelemy, Nature 7, 425–426 (2008)

Z.Q. Hu, M.Y. Li, J. Liu, L. Pei, J. Wang, B.F. Yu, X.Z. Zhao, J. Am. Ceram. Soc. 93, 2743–2747 (2010)

H.R. Yan, H.M. Deng, N.F. Ding, J. He, L. Peng, P.X. Yang, J.H. Chu, Mater. Lett. 111, 123–125 (2013)

T. Choi, S. Lee, Y.J. Choi, V. Kiryukhin, S.W. Cheong, Science 324, 63–66 (2009)

S.Y. Yang, L.W. Martin, S.J. Byrnes, T.E. Conry, S.R. Basu, D. Paran, L. Reichertz, J. Ihlefeld, C. Adamo, A. Melville, Y.H. Chu, C.H. Yang, J.L. Musfeldt, D.G. Schlom, J.W. Ager III, R. Ramesh, Appl. Phys. Lett. 95, 062909 (2009)

S.Y. Yang, J. Seidel, S.J. Byrnes, P. Shafer, C.H. Yang, M.D. Rossell, P. Yu, Y.H. Chu, J.F. Scott, J.W. Ager III, L.W. Martin, R. Ramesh, Nanotechnology 5, 143–147 (2010)

J. Seidel, D. Fu, S.Y. Yang, E.A. Llado, J.Q. Wu, R. Ramesh, J.W. Ager, Phys. Rev. Lett. 107, 126805 (2011)

H. Uchida, R. Ueno, H. Funakubo, S. Koda, J. Appl. Phys. 100, 014106 (2006)

S.R. Das, P. Bhattacharya, R.N.P. Choudhary, R.S. Katiyar, J. Appl. Phys. 99, 066107 (2006)

S. Kazhugasalamoorthy, P. Jegatheesan, R. Mohandoss, B. Karthkeran, R.J. Joseyphus, S. Dhanuskodi, J. Alloys Compd. 493, 569–572 (2010)

Q. Sun, H.M. Deng, P.X. Yang, J.H. Chu, J. Infrared Millim. Waves 32, 128–131 (2013)

J. Liu, H.M. Deng, H.Y. Cao, X.Z. Zhai, J.H. Tao, L. Sun, P.X. Yang, J.H. Chu, Appl. Surf. Sci. 307, 543–547 (2014)

X.X. Li, H.M. Deng, J.Z. Zhang, P.X. Yang, J.H. Chu, J. Infrared Millim. Waves 33, 19–35 (2014)

J.J. Tian, H.M. Deng, L. Sun, H. Kong, P.X. Yang, J.H. Chu, Thin Solid Films 520, 5179–5183 (2012)

D. Poelman, P.F. Smet, J. Phys. D Appl. Phys. 36, 1850–1857 (2003)

R. Swanepoel, J. Phys. E: Sci. Instrum. 16, 1214–1222 (1983)

M. Kar, Surf. Interface Anal. 42, 145–150 (2010)

H.T. Huang, Nat. Photonics 4, 134–135 (2010)

L.P. Zhu, H.M. Deng, J. Liu, L. Sun, P.X. Yang, A.Q. Jiang, J.H. Chu, J. Cryst. Growth 387, 6–9 (2014)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (61474045), the State Key Basic Research Program of China (2013CB922300). The authors would like to thank the project from ECNU (Grant No. xrzz2014027).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Deng, H., Zhai, X. et al. Influence of Eu doping on structural and optical properties of BiFeO3 films deposited on quartz substrates by pulsed laser deposition method. J Mater Sci: Mater Electron 26, 2977–2981 (2015). https://doi.org/10.1007/s10854-015-2785-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2785-x