Abstract

0.70Bi1−xLaxFeO3–0.30BaTiO3 + 1 mol% MnO2 multiferroic ceramics were prepared by using the solid state reaction and their phase structure, dielectric, ferroelectric and ferromagnetic properties were studied. All the ceramics possess perovskite structure and exhibit good insulation and densification. A morphotropic phase boundary of rhombohedral and tetragonal phases is formed at x = 0.02. As the concentration of La3+ is increased, the ferroelectric–paraelectric phase transition of the ceramics at Curie temperature becomes gradually more diffusive. A small amount of the substitution of La3+ for Bi3+ improves effectively the ferroelectricity of the ceramics and the optimum remanent polarization of 27.2 μm/cm2 reaches at x = 0.04. After the addition of La3+, the ferromagnetism of the ceramics is greatly enhanced and the remanent magnetization M r monotonously increases from 0.0321 to 0.147 emu/g with x increasing from 0 to 0.10. Our results show that the ceramics possess simultaneously improved ferroelectric and ferromagnetic properties and may a promising candidate for room-temperature multiferroic materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Perovskite Pb(Zr,Ti)O3 and Pb(Ti,Zr)O3-based multi-systems have been widely used in piezoelectric actuators, sensors and filters due to their excellent piezoelectricity. However, the use of these lead-based ceramics has caused serious environmental problem because of the strong toxicity of lead oxide. Therefore, lead-free piezoelectric and ferroelectric ceramics have attracted considerable attention in recent years.

As a room-temperature single-phase multiferroic material, perovskite BiFeO3 with rhombohedral structure has been extensively studied in recent years due to its coexistence of ferromagnetism and ferroelectricity and potential applications in various advanced devices [1–4]. Due to its high Curie temperature T C of 830 °C and Néel temperature T N of 370 °C [5], BiFeO3 material may be considered as an interesting candidate for room-temperature multiferroic and/or high temperature piezoelectric materials. However, pure BiFeO3 generally shows poor electric insulation due to the reduction of Fe ions from Fe3+ to Fe2+ during sintering at high temperature and the formation of oxygen vacancies for charge compensation, which leads to the difficulties in enduring high electric voltage for electric poling and measuring the ferroelectricity of the material [6, 7]. As a result, for BiFeO3 ceramic, saturated polarization hysteresis loop and strong piezoelectric response are rarely obtained. In order to enhance the electric insulation of the materials, many ABO3-type perovskites (e.g., SrTiO3 [8], CaTiO3 [9], NaNbO3 [10], BaTiO3 [11], etc.,) have been introduced into BiFeO3 to form solid solutions. Among these BiFeO3-based systems, BiFeO3–BaTiO3 is most frequently studied as a classic multiferroic solid solution. [11–13] These studies on BiFeO3–BaTiO3 reported mainly the dielectric and magnetic properties of the materials, which rarely exhibit strong ferroelectricity and piezoelectricity because of their poor insulation and high loss tangent [11–13]. Recently, Leontsev [14] and Zhou [15] et al. studied Mn-doped BiFeO3–BaTiO3 with good piezoelectricity. On the other hand, it is also noted that the doping of rare earth ions (e.g., La3+, Sm3+, Nd3+, etc.) can effectively enhance the ferroelectricity and ferromagnetism of the BiFeO3. [16–19] Therefore, it is expected that modification with rare earth ions may enhance the multiferroic properties of BiFeO3–BaTiO3. In the present work, La-modified BiFeO3–BaTiO3 multiferroic ceramics, 0.70Bi1−xLaxFeO3–0.30BaTiO3 + 1 mol% MnO2, were fabricated by using the solid state reaction method, in order to study the effects of La3+ on phase transition, dielectric and multiferroic properties. MnO2 was used to improve the insulation of the materials [15, 16]. Our results showed that the addition of La3+ effectively improves the ferroelectricity and ferromagnetism of the ceramics.

2 Experimental

The conventional ceramic fabrication technique was used to prepare the 0.70Bi1−xLaxFeO3–0.30BaTiO3 + 1 mol% MnO2 (BFO-BTO-La-x) ceramics using Bi2O3 (99.9 %), La2O3 (99.9 %), Fe2O3 (99 %), BaCO3 (99 %), TiO2 (99.9 %) and MnO2 (99 %). All mixtures were mixed thoroughly using ZrO2 balls in ethanol for 12 h. The mixtures were dried and calcined at 800 °C for 4 h. After calcination, MnO2 powder was added and the resulting mixtures were ball-milled again for 12 h, mixed thoroughly with a poly (vinyl alcohol) binder solution and then pressed into disk samples. The binder in the samples was removed at 650–700 °C and then the samples were sintered at 1,000 °C for 2 h in air. For evaluating electrical properties, silver electrodes were fired on both surfaces of the sintered ceramics at 650 °C for 15 min. A dc field of 5 kV/mm was used to polarize the samples at 120 °C for 30 min.

X-ray diffraction (XRD) with CuK α radiation (SmartLab, Rigaku, Japan) was used to examine crystalline structure of the sintered samples. Lattice parameters of the ceramics were refined by the Rietveld refinement using a general diffraction/reflectivity analysis program MAUD [20]. Surface microstructures of the sintered samples were observed using scanning electron microscopy (SEM, FEI-Quanta 250, USA). Average grain size D A was obtained by multiplying the average D L (linear intercept length) of grains by 1.56. [21, 22] Bulk density ρ was measured by using the Archimedes’ method. A LCR meter (Agilent E4980A, Agilent Technologies Inc., USA) and temperature controlled probe stage (Linkam TS1500E, Linkam Scientific Instruments Ltd., UK) were used to measure temperature dependence of relative permittivity ε r of the sintered samples at 1 MHz. Polarization hysteresis (P–E) loops and resistivity R at room temperature were measured by using a precision materials measuring system (Premier II, Radiant Technologies Inc., Northford, USA). The planar electromechanical coupling factor k p was determined by the resonance method according to the IEEE Standards 176 using an impedance analyzer (Agilent 4294A, Agilent Technologies Inc., USA). A piezo-d 33 meter (ZJ-3A, Institute of Acoustics, China) was used to measure piezoelectric constant d 33. Magnetic hysteresis loops were measured by using a vibrating sample magnetometer (VSM, Lakeshore 7404, USA).

3 Results and discussion

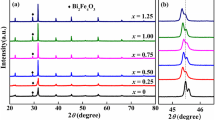

XRD patterns of the BFO-BTO-La-x ceramics are shown in Fig. 1. It has been frequently reported that some impurity phases (e.g., Bi2Fe4O9, Bi25FeO39, etc.) appear in BiFeO3 ceramics prepared by using the ordinary sintering processes [5–7]. However, from Fig. 1, all the BFO-BTO-La-x ceramics exhibit a single phase perovskite structure, suggesting that La3+ have diffused into the BiFeO3–BaTiO3 lattices to form homogenous solid solutions. Similar to BiFeO3, the BFO-BTO-La-0 ceramics (i.e., 0.70BiFeO3–0.30BaTiO3) exhibit rhombohedral symmetry. This is consistent with the previous results [14, 15]. As x is increased, a tetragonal phase appears. At x ≥ 0.04, the ceramics become a pure tetragonal phase. It can be concluded that a morphotropic phase boundary (MPB) of rhombohedral and tetragonal phases is formed at x = 0.02. The structure transformation of the ceramics can be attributed to the chemical pressure related response caused by the substitution of La ions for Bi ions because of the smaller ionic radius of La3+ than that of Bi3+. Similar effect has been observed in Nd-modified BiFeO3 ceramics [17].

Based on the rhombohedral and tetragonal phases, the lattice parameters (a, c and V) of the BFO-BTO-La-x ceramics were refined by using the Rietveld method according to all the diffraction peaks shown in Fig. 1 and the results are shown in Table 1. From Table 1, the small values of the reliability R wp (8.72–11.57 %) and the goodness-of-fit indicator S (1.21–1.53) are smaller than 15 % and 2, respectively. This indicates a good matching between the observed and calculated patterns. A coexistence can be identified in the ceramic with x = 0.02. Within the coexistence zone of two phases, the relative concentrations of rhombohedral and tetragonal phases are 4.71 % (R) and 95.29 % (T), respectively. The observed lattice parameters a, c and V are 5.6393, 13.8736 Å and 382.0940 Å3 for the BFO-BTO-La-0 ceramic with rhombohedral symmetry, while they decrease from 3.9911 Å/3.9953 Å/63.6407 Å3 to 3.9854 Å/3.9828 Å/63.2605 Å3 with x increasing from 0.04 to 0.10 for the ceramics with tetragonal symmetry.

Figure 2 shows surface SEM graphs of the BFO-BTO-La-x ceramics with x = 0.02, 0.06 and 0.10, while compositional dependence of relative density ρ r of the BFO-BTO-La-x ceramics is shown in Fig. 3. From Fig. 2, all the ceramics are dense and no pores can be observed. La doping has a slight influence on the grain size of the materials. The average grain sizes of the ceramics with x = 0.02, 0.06 and 0.10 are 2.67, 2.69 and 2.92 μm, respectively. From Fig. 3, the observed ρ r of the ceramics with x = 0 is 94.4 %. The partial substitution of La3+ for Bi3+ improved the densification of the materials and the observed ρ r increases significantly to 98.1 % as x is increased to 0.10.

Figure 4a, b show the dependences of current density J and resistivity R of the BFO-BTO-La-x ceramics with x = 0.02, 0.04 and 0.06 on electric field E, respectively. It has been frequently reported that pure BiFeO3 generally exhibits large leakage due to the reduction of Fe ions from Fe3+ to Fe2+ [7, 8, 23]. For comparison, a pure BiFeO3 ceramic was prepared at 775 °C for 2 h. Its dependences of J and R on electric field E are also shown in Fig. 4a, b, respectively. Consistent with previous reports [7, 8], the pure BiFeO3 ceramic exhibits very poor electric insulation, giving a very high J of 1.14 × 10−3 A/cm2 and low R of 2.27 × 107 Ω cm at 3.0 kV/mm. However, as shown in Fig. 4, after the addition of La3+, BaTiO3 and MnO2, the electric insulation of the BFO-BTO-La-x ceramics is greatly improved and a very low J of 5.58 × 10−5–1.25 × 10−5 A/cm2 and high R of 4.03 × 108–1.85 × 109 Ω cm at 3 kV/mm are obtained. This indicates that the introduction of La3+, BaTiO3 and MnO2 into BiFeO3 greatly suppresses the formation of Fe2+′ and \(V_{O}^{ \bullet \bullet }\) and thus improves the electric insulation of the ceramics due to the partial substitutions of Mn4+ and Ti4+ for Fe3+ in the ceramics [23]. This enhancement effect in electric insulation has been observed in Ti- or/and Mn-doped BiFeO3-based materials [9, 23]. It is also noted that as x is increased from 0.02 to 0.10, the observed J decreases from 5.58 × 10−5 to 1.25 × 10−5 A/cm2, while the observed R increases from 4.03 × 108 to 1.85 × 109 Ω cm, suggesting that partial substitution of La3+ for Bi3+ slightly improves the electric insulation of the ceramics. As known, Bi element is volatile at high temperatures. Partial substitution of La3+ for Bi3+ may suppress the possible volatility of Bi3+ and thus better electric insulation is obtained in La-modified BiFeO3–BaTiO3 ceramics.

P–E loops of the BFO-BTO-La-x ceramics are shown in Fig. 5a, while Fig. 5b shows the variations of remanent polarization P r and coercive filed E c of the BFO-BTO-La-x ceramics with x. As shown in Fig. 4, the present ceramics possess much higher resistivity than pure BiFeO3 ceramic. Therefore, typical and very saturated P–E loops are observed in the BFO-BTO-La-x ceramics (Fig. 5a). From Fig. 5, the partial substitution of a small amount of La3+ (x ≤ 0.04) for Bi3+ in the A-site lattices of the BFO-BTO-La-x ceramics increases effectively the ferroelectricity of the ceramics. However, excess La3+ (x > 0.04) degrades significantly the ferroelectricity of the ceramics. It can be seen that the observed P r increases greatly from 18.5 to 27.2 μC/cm2 when x is increased from 0 to 0.04 and then decreases to 14.1 μC/cm2 with x further increasing to 0.10. The observed E c decreases from 3.75 to 2.84 kV/mm with x increasing from 0 to 0.10. Although La3+ (x ≤ 0.04) partially substitutes for Bi3+ in the ceramics with x = 0–0.04, the lone s 2 of electrons of Bi3+ still can hybridize with an empty p orbital of Bi3+ or O2− to form a localized lobe. This results in the noncentrosymmetric distortion [19]. As a result, ferroelectricity of the materials is improved [19]. However, excess La3+ (x > 0.04) can weaken the stereochemical activity of the Bi lone electron pair [19], which leads to the degradation in ferroelectricity.

Figure 6a–f show temperature dependences of relative permittivity ε r and loss tangent tanδ at 1 MHz for the BFO-BTO-La-x ceramics, while the variation of Curie temperature T C of the BFO-BTO-La-x ceramics with x is shown in Fig. 6g. It can be seen that all the BFO-BTO-La-x ceramics only exhibit one dielectric peak, which is associated with the paraelectric–ferroelectric phase transition at T C (Fig. 6a–f). As shown in Fig. 6g, as x is increased from 0 to 0.10, the observed T C decreases linearly from 613 to 400 °C. From Fig. 6a, the BFO-BTO-La-x ceramic with x = 0 shows a relatively sharp phase transition peak at T C. However, as x is increased, the phase transition peak at T C becomes gradually broader, which suggests that partial substitution of La3+ for Bi3+ causes a diffuse phase transition. In general, for normal ferroelectric–paraelectric transition, the temperature corresponding to the maximum value of relative permittivity is denoted as Curie temperature (T C), while for diffusive ferroelectric–paraelectric transition, T m is the temperature at which the relative permittivity ε r reaches maximum. The diffuseness of the phase transition can be obtained from the modified Curie–Weiss law 1/ε r − 1/ε m = C−1(T − T m)γ [24, 25], where ε r is relative permittivity at temperature T, ε m is the maximum value of relative permittivity at the phase transition temperature T C (T m), γ is the degree of diffuseness and C is the Curie–Weiss constant. For a normal ferroelectric, γ is 1, while for an ideal relaxor ferroelectric, γ is 2. Based on the temperature dependences of ε r shown in Fig. 6a, d, f, the graphs of ln(1/ε r − 1/ε m) versus ln(T − T m) for the BFO-BTO-La-x ceramics with x = 0, 0.06 and 0.10 are shown in Fig. 6h. For all the ceramics, a linear relationship is observed. γ is determined by least-squared fitting the experimental data to the modified Curie–Weiss law. It can be seen that the ceramic with x = 0 has a γ value of 1.69. As x is increased to 0.10, the observed γ increases to 2.08. These results indicate that partial substitution of La3+ for Bi3+ leads to more diffusive phase transition. Due to the small difference in the ionic radii between La3+ and Bi3+, partial substitution of La3+ for Bi3+ increases the A-site disordering degree and the local compositional fluctuation. Consequently, the phase transition becomes more diffusive and thus broadened phase transition peaks are observed.

a–f Temperature dependences of relative permittivity ε r and loss tangent tanδ at 1 MHz for the BFO-BTO-La-x ceramics; g compositional dependence of T C of the BFO-BTO-La-x ceramics; and h plots of ln(1/ε r − 1/ε m) versus ln(1/T − 1/Tm) for the BFO-BTO-La-x with x = 0, 0.06 and 0.10. The symbols denote the experimental data while the solid lines denote the least-squared fitting line to the modified Curie–Weiss law

Variations of d 33, k p, ε r and tanδ of the BFO-BTO-La-x ceramics with x are shown in Fig. 7. The observed d 33 of the BFO-BTO-La-x ceramics increases slightly from 118 to 121 pC/N with x increasing from 0 to 0.02 and then decreases greatly to 13 pC/N with x further increasing to 0.10. Similar to d 33, the observed k p increases from 28.6 to 28.8 % with x increasing from 0 to 0.02 and then decreases greatly to 9.4 % with x further increasing to 0.10. The observed ε r decreases from 620 to 525 with x increasing from 0 to 0.10, while the observed tanδ exhibits weak compositional dependence, with relatively small values of 4.12–4.58 %.

Figure 8 shows M–H hysteresis loops of the BFO-BTO-La-x ceramics with x = 0, 0.06 and 0.10. All the ceramics exhibit typical magnetization hysteresis loops. From Figs. 5 and 8, it can be concluded that the present ceramics exhibit simultaneously ferromagnetism and ferroelectricity. The ceramic with x = 0 exhibits weak ferromagnetism with saturation magnetization M s of 0.0673 emu/g, remanent magnetization M r of 0.0321 emu/g and coercive field H c of 1.08 kOe. The addition of La3+ to the 0.70BiFeO3–0.30BaTiO3 + 1 mol% MnO2 enhances greatly the ferromagnetism of the ceramics. From Fig. 8, after the introduction of 10 mol% La3+, the remnant magnetization of the ceramics is increased by ~360 % (from M r ~ 0.0321 emu/g for the ceramic with x = 0 to M r ~ 0.147 emu/g for the ceramic with x = 0.10). It is well known that BFO is antiferromagnetic with a G-type structure and the Fe3+ magnetic moments ordering forms a long-rang cycloid and thus leads to zero net magnetization [6, 7, 26]. However, the addition of rare earth ions and ABO3-type perovskites into BiFeO3 generally leads to weak ferromagnetism and/or enhances the ferromagnetic properties of the materials [8–11, 16–19]. For the ceramic with x = 0, the addition of 30 mol% BaTiO3 and 1 mol% MnO2 to BiFeO3 suppresses the spatially modulated spin order in the ceramics and thus releases the locked magnetization, which results in nonlinear M–H hysteresis loops with very weak ferromagnetism and small M r of ~0.0321 emu/g. Also, as shown in Fig. 8, the substitution of La3+ for Bi3+ greatly increases the ferromagnetism of the ceramics. A small amount of La3+ (x < 0.02) suppresses the space-modulated spin structure of the BiFeO3, while high La3+ levels (x ≥ 0.02) causes a structural phase transformation from rhombohedral to tetragonal phases, which further destructs the space-modulated spin structure of the materials. As a result, the latent magnetization locked within the cycloid is released and thus a great increase in M r is observed in the ceramics with high La3+ levels. Similar effect on ferromagnetism induced by rare earth ions or structural transformation has been observed in Nd- and Sm-doped BiFeO3 [16–19, 27].

4 Conclusions

La doping showed effects on phase structure, dielectric, ferroelectric and ferromagnetic properties of the 0.70Bi1−xLaxFeO3–0.30BaTiO3 + 1 mol% MnO2 ceramics. A MPB of rhombohedral and tetragonal phases was formed at x = 0.02. The addition of a small amount of La3+ (x ≤ 0.04) effectively enhanced ferroelectricity of the ceramics, but excess La3+ (x > 0.04) degraded ferroelectricity of the ceramics. The ceramics with x = 0–0.04 possessed strong piezoelectric response and high Curie temperatures, giving the d 33 of 90–121 pC/N, k p of 19.7–28.8 % and T C of 526–613 °C. A diffusive ferroelectric–paraelectric phase transition was observed after the addition of La3+. Ferromagnetism of the ceramics was enhanced greatly by the substitution of La3+ for Bi3+ and the remanent magnetization M r was increased greatly by ~360 % as x was increased from 0 to 0.10.

References

Q. He, C.H. Yeh, J.C. Yang, G. Singh-Bhalla, C.W. Liang, P.W. Chiu, G. Catalan, L.W. Martin, Y.H. Chu, J.F. Scott, R. Ramesh, Phys. Rev. Lett. 108, 067203 (2012)

J.H. Lee, M.-A. Oak, H.J. Choi, J.Y. Son, H.M. Jang, J. Mater. Chem. 22, 1667–1672 (2012)

T.R. Paudel, S.S. Jaswal, E.Y. Tsymbal, Phys. Rev. B 85, 104409 (2012)

S. Goswami, D. Bhattacharya, P. Choudhury, B. Ouladdiaf, T. Chatterji, Appl. Phys. Lett. 99, 073106 (2011)

M.M. Kumar, V.R. Palker, K. Srinvivas, S.V. Suryanarayana, Appl. Phys. Lett. 76, 2764 (2000)

A.K. Pradhan, K. Zhang, D. Hunter, J.B. Dadson, G.B. Loutts, Single Ph. J. Appl. Phys. 97, 093903 (2005)

S.K. Pradhan, B.K. Roul, Physica B 406, 3313–3317 (2011)

Z.Z. Ma, Z.M. Tian, J.Q. Li, C.H. Wang, S.X. Huo, H.N. Duan, S.L. Yuan, Solid Stat. Sci. 13, 2196–2200 (2011)

Q.Q. Wang, Z. Wang, X.Q. Liu, X.M. Chen, J. Am. Ceram. Soc. 95, 670–675 (2012)

Y. Ma, X.M. Chen, J. Appl. Phys. 105, 054107 (2009)

M.T. Buscaglia, L. Mitoseriu, V. Buscaglia, I. Pallecchi, M. Viciani, P. Nanni, A.S. Siri, J. Eur. Ceram. Soc. 26(14), 3027–3030 (2006)

A. Singh, V. Pandey, R.K. Kotnala, D. Pandey, Phys. Rev. Lett. 101, 247602 (2008)

T.H. Wang, Y. Ding, C.S. Tu, Y.D. Yao, K.T. Wu, T.C. Lin, H.H. Yu, H.Y. Lee, J. Appl. Phys. 109, 07D907 (2011)

S.O. Leontsev, R.E. Eitel, J. Am. Ceram. Soc. 92, 2957–2961 (2009)

H.B. Yang, C.R. Zhou, X.Y. Liu, Q. Zhou, G.H. Chen, W.Z. Li, H. Wang, J. Eur. Ceram. Soc. 33, 1177–1183 (2013)

S.T. Zhang, L.H. Pang, Y. Zhang, M.H. Liu, Y.F. Chen, J. Appl. Phys. 100, 114108 (2006)

Y.J. Wu, X.K. Chen, J. Zhang, X.J. Chen, J. Appl. Phys. 111, 053927 (2012)

K.S. Nalwa, A. Grag, J. Appl. Phys. 103, 044101 (2008)

G.L. Yuan, S.W. Or, J.M. Liu, Z.G. Liu, Appl. Phys. Lett. 89, 052905 (2006)

L. Lutterotti, MAUD, Material Analysis Using Diffraction (2011). http://www.ing.unitn.it/~maud/index.html

M.I. Mendelson, J. Am, Ceram. Soc. 52, 443–446 (1968)

X.H. Wang, P.L. Chen, I.W. Chen, J. Am. Ceram. Soc. 89, 431 (2006)

T. Kawae, Y. Terauchi, H. Tsuda, M. Kumeda, Appl. Phys. Lett. 94, 112904 (2009)

N. Setter, E. Cross, J. Mater. Sci. 15, 2478 (1980)

N. Setter, L.E. Cross, J. Appl. Phys. 51, 4356 (1980)

D. Lebeugle, D. Colson, A. Forget, M. Viret, A.M. Bataille, A. Gukasov, Phys. Rev. Lett. 100, 227602 (2008)

C. Lan, Y. Jiang, S. Yang, J. Mater. Sci. 46, 734–738 (2011)

Acknowledgments

This work was supported by the projects of Science and Technology Bureau of Sichuan Province (2010JQ0046), Sichuan Normal University and the Open Project of State Key Laboratory of Electronic Thin Films and Integrated Devices of University of Electronic Science and Technology of China (KFJJ201108).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, X., Tian, M., Guo, Y. et al. Phase transition, dielectric, ferroelectric and ferromagnetic properties of La-doped BiFeO3–BaTiO3 multiferroic ceramics. J Mater Sci: Mater Electron 26, 978–984 (2015). https://doi.org/10.1007/s10854-014-2492-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2492-z