Abstract

Lithium and nitrogen dual-doped ZnO films [ZnO: (Li, N)] with Li concentrations of 4 at.% were grown on glass substrates by ion beam enhanced deposition (IBED) and then annealing in Ar flow. The influence of post-annealing time on their structural, optical and electrical properties was studied. The co-doped ZnO: (Li, N) films have a ZnO wurtzite structure. Electrical property studies indicated that the ZnO: (Li, N) film annealed at 500 °C in Ar showed p-type conductivity with a lowest resistivity of 10.83 Ω cm. The transmittance of ZnO: (Li, N) film is above 80 % in visible range and the band gap of ZnO: (Li, N) film have a evident narrowing after p-type doping.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Zinc oxide is considered as a promising material for ultraviolet (UV) light-emitting diodes, laser diodes and photodetectors [1, 2]. It is necessary to obtain p-type and n-type ZnO films for the development of ZnO based devices. Now, high quality n-type ZnO films have been prepared easily by doping with Al, Ga, In [3]. However, p-type ZnO is difficult to achieve due to the rise of lattice Madelung energy [4], low solubility of acceptor doping and self-compensation [5]. Nitrogen has been regarded as the more soluble group-V impurity, having the shallowest acceptor level compared to P and As [6]. However, the low solubility of N acceptor doping is unfavorable for successful p-type doping. Li is also better acceptor with shallower acceptor levels, but there are two kinds of doping position in the ZnO lattice, substitutional Li occupying Zn sites (denoted as LiZn) and interstitial sites (denoted as Lii). Theoretical calculations predicted that Li prefers to occupy interstitial sites (Lii), acting as the donor, rather than the Zn sites (LiZn), acting as the acceptor [7], So Li doping easily form Lii atom and LiZn–Lii donor complex [8]. Yamamoto [9] has supposed Li–N dual-acceptor co-doping method may be the best way for producing high quality p-type ZnO based on their strain effects and energy levels of substitutional LiZn and NO acceptors. Up to now, several groups have fabricated Li–N dual-doped ZnO [denoted as ZnO: (Li, N)] by various techniques such as radio-frequency magnetron sputtering [10], pulsed laser deposition [11], sol–gel [12], molecular beam epitaxy [13]. Although p-type ZnO: (Li, N) films have been investigated widely, its stable properties still need enhancement, and the mechanism of the p-type conductivity is not clear yet. Ion beam enhanced sputtering can prepare high purity thin film under high vacuum. Deposition is carried out in the field-free region. The substrate is not a part of electric circuits and will not produce the substrate temperature caused by electron impact. It is known that ion beam sputtering can offer some technological parameters to control the growth of thin film. We used ion beam enhanced deposition (IBED) method to prepare ZnO: (Li, N) films and studied the influence of post-annealing time on properties of ZnO: (Li, N) thin film.

2 Experiment

ZnO (99.9 % in purity) powder mixed with 4 at.% Li2O (99.9 % in purity) powder was pressed as the sputtering target. Before the deposition, the glass substrates were cleaned thoroughly with acetone, isopropanol, deionized water and finally cleaned with the help of an ultrasonic bath for 30 min and dried. Subsequently, Li-doped ZnO ceramic target was sputtered by Ar+ ions with an energy of 2.5 keV. N+/Ar+(flow ratio 5/1) mixed ions beam extracted from the ion source with energy of 25 keV and a beam current of 2 mA was vertically implanted into the deposited ZnO films. The direction of sputtering beam was 45° with respect to the target. The substrates were placed on a round holder rotated with a speed of 24 rpm [14]. All the films were deposited for 3 h 45 min and the thickness of the films was about 190 nm measured by dektak 150 surface profiler. After deposition, the films were annealed under different atmosphere and temperature. The annealing treatment was performed in rapid thermal annealing (RTA) oven. All the samples were characterized by X-ray diffraction (XRD) with Cu kα radiation (λ = 0.1541 nm). XRD patterns were recorded from 15° to 70° (2θ) with a scanning step of 0.02°. A SDY-4 four-point probe system was used to determine the conductive type and sheet resistance. The electrical properties of the ZnO:(Li, N) films were measured by the Hall effect measurement system [MMR’s Variable Temperature Hall System (VTHS)] in the Van der Pauw configuration at room temperature. Electrodes were fabricated by depositing metal indium on the surface of films and sintering at a pressure of 10−3 Pa. Ohmic contact between the indium spots and film was confirmed prior to Hall measurement. The optical transition through the film was measured with a spectrophotometer (SHIMADZU UV3600). Room temperature photoluminescence (PL) spectra were recorded in the range of 300–700 nm by a spectrophotometer. The 325 nm laser line from helium-cadmium laser with a power of 50 mW was employed as excitation source for the PL measurement.

3 Results and discussion

ZnO:(Li, N) films were annealed at different temperature in Ar, N2, O2 atmosphere for various annealing time. We found that the p-type conductive properties of ZnO:(Li, N) films were better in Ar than in N2 and O2, and better at 500 °C than at other temperatures, so we mainly studied the properties of ZnO:(Li, N) films annealed under 500 °C in Ar.

3.1 X-ray diffraction

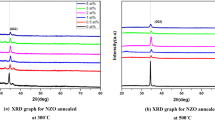

Figure 1 shows the XRD patterns of ZnO: (Li, N) films annealed in Ar at 500 °C for different time. There are five prominent peaks which correspond (100), (101), (110), (112) and (201) planes of ZnO crystal. The positions and relative intensities of the five dominant peaks match well with the standard XRD pattern of bulk zinc oxide (JCPDS PDF card No: 79-2205). There are no other peaks related to Li3N, Li2O, Zn3N2, or other mixed compounds. It can be seen from Fig. 1 that all ZnO: (Li, N) films exhibit the preferential orientation of (100) plane and possess ZnO hexagonal wurtzite structure. The (100) peak becomes stronger and sharper, and the diffraction angle shifts towards a higher angle but changes little with the increase of annealing time as shown in Fig. 1. The former implies improvement of crystal quality of the film, and the latter is due to relaxation of tensile stress in the film [15]. Table 1 shows 2θ value, FWHM of (100) peak and grain size of the ZnO: (Li, N) film. The FWHM values of (100) peak is related to the grain size of the films. A smaller FWHM means a larger grain size and better crystal quality of the whole film. It can be seen from Table 1 the position of (100) peak increased from 31.440° to 31.640° and the FWHM value gradually decreased from 0.678° to 0.602° with increase of annealing time. Meanwhile the grain size of ZnO: (Li, N) films increased from 13.59 to 15.33 nm. The increase of 2θ means the decrease of lattice constant of the ZnO: (Li, N) films with increase of annealing time. This reveals that substitution mechanism is executed [16, 17]. This can be attributed to the fact that the length of LiZn–O (0.197 nm) and Zn–NO (0.196 nm) bonds is slightly shorter than that of Zn–O (0.199 nm) bond [18, 19]. This could make the lattice constant decrease and produce some strain in the films, the strain changes among atomic spacing of semiconductors will affect the energy gap [20]. However, the a-axis lattice constant is calculated to be 0.3381 nm for the ZnO: (Li, N) film annealed 35 min, which is somewhat larger than the value of 0.3249 nm of bulk ZnO [21]. It is well known that Li doped in ZnO has two chemical states of Lii donor and LiZn acceptor and that Lii increases the lattice while LiZn reduces it. Therefore, the increment of the a-axis lattice constant implies the existence of many Lii in the ZnO:(Li, N) films.

3.2 Electrical properties

Table 2 shows the electrical parameters of the ZnO: (Li, N) films annealed in Ar at 500 °C. The measurement results show that the ZnO: (Li, N) film had no conductive type before annealing, indicating that Li and N had not been incorporated into the lattice. When annealed for 5 min, the n-type conduction appeared and sheet resistance was 3 M Ω/□. When annealed for 10–30 min, the p-type conduction appeared and sheet resistance decreased from 1.80 to 0.57 M Ω/□ with the increase of annealing time. This indicated that the LiZn and NO atoms in ZnO:(Li, N) films increased with the increase of annealing time. After annealed for 35 min, the conduction type of ZnO: (Li, N) film was strong p-type but the sheet resistance began to increase (0.82 M Ω/□). And the conduction type of ZnO: (Li, N) film changed to n-type when annealed over 35 min. The transition of the electrical properties induced by annealing may be attributed to the activation of the p-type doped elements (LiZn, NO). However, the lowest sheet resistance of p-type ZnO: (Li, N) films was 0.57 M Ω/□ which behaved high resistance conductivity. This may be ascribed to the following reasons: (1) The formation enthalpy of −348.28 kJ mol−1 for ZnO is much smaller than −20 kJ mol−1 for Zn3N2, there would be a low tendency for Zn3N2 to form, resulting in the low solubility of N acceptor doping [5].This is in agreement with XRD analyze. There are no peaks related to Zn3N2 in our XRD patterns. (2) Existence of some main intrinsic donor defects such as interstitial Zn and O vacancy which balanced out the act of acceptors. (3) Total energy calculations show that the formation energy of the LiZn–O bond is higher, some Li atom prefers to occupy the interstitial sites (Lii), acting as the donor [7]. When annealed above 40 min, the p-type conduction disappeared. This indicated that overlong annealing time made nitrogen escape from the thin film [14], especially escaped from the substitutional sites and led to more oxygen vacancies, and made Li atoms separate out from the lattice of ZnO, which decreased the hole concentration of film and resulted in the p-type conduction disappearing. Table 3 is the results of the Hall-effect measurements carried out at room temperature. ZnO: (Li, N) film annealed for 30 min shows a hole concentration of 3.72 × 1017 cm−3, hole mobility of 1.82 cm2/V s, and resistivity of 10.83 Ω cm. Compared to other preparation methods, the electrical properties of ZnO: (Li, N) film prepared by IBED are superior to that by RF-magnetron sputtering method [22, 23] and plasma-assisted molecular beam epitaxy [24], but inferior to that by pulsed laser deposition method [11, 25]. We may draw the conclusion from what has been discussed above: appropriate annealing can eliminate the sputtering damage and improve the crystal quality, and help lithium to incorporate in ZnO lattice and realize the substitutional action. But overlong annealing time made nitrogen escape from the thin film, especially escaped from the substitutional sites and led to more oxygen vacancies, and made Li atoms separate out from the lattice of ZnO.

3.3 Optical transmittance and reflectance spectra

Figure 2 shows the optical transmittance and reflectance spectra of p-type ZnO: (Li, N) films annealed in Ar at 500 °C for 0–35 min. It can be seen that the As-deposited film has a relatively lower transparency, but still exhibits a visible light transmittance above 70 %. The optical transmittance of annealed ZnO:(Li, N) films increases as the annealing time goes up. The average transmittance in the visible region is above 80 % for all annealed films. Meanwhile, the absorption edge of ZnO:(Li, N) films has a red shift with increase of annealing time. This result indicates that annealing makes the crystal grain size enlarge, which reduces deformation and damage induced by ion implantation, and is in agreement with XRD analyze. The band gaps of the ZnO:(Li, N) films are estimated by optical absorption spectra. The absorption coefficient α of the ZnO:(Li, N) films is calculated according to Eq. (1) from the transmittance and reflectance spectra in Fig. 2.

where α is absorption coefficient, d is the thickness of the ZnO:(Li, N) film, R and T, the transmissivity and reflectivity of the ZnO:(Li, N) film. For direct band gap semiconductor, the relationship between α and energy gap Eg can be written as Eq. (2) [20]

where the coefficient A is a parameter related to the band tail states, Eg is energy gap and hν is the photon energy. The band gap of the ZnO:(Li, N) films can be evaluated in the standard manner from a plot of (αhν)2 as a function of the energy of the incident radiation and extrapolating the linear part of the curve to intercept the energy axis. Figure 3 shows the curve of (αhν)2 versus hν. The band gaps of ZnO:(Li, N) with different annealing time are evaluated to be 3.34 eV (as-deposited film), 3.31 eV (annealed 15 min), and 3.30 eV (annealed 35 min), respectively, all are smaller than that(3.37 eV) of intrinsic ZnO. This result reveals that there are more and more Li atoms incorporated into ZnO matrix with the increase of annealing time from 10 to 35 min. A widening of the band-gap is usually observed for n-type ZnO doped with donors; while p-type ZnO has shown band-gap reduction if doped with acceptors. According to previous discussion the band gap narrowing of p-type ZnO:(Li, N) may be ascribed to the following effects: (1) The formation of the Lii–No complex generates an additional fully occupied impurity band above the valance band maximum (VBM), resulting in an upward shift of the VBM and a decrease in the band gap [8, 10]. (2) The lattice constant of ZnO:(Li, N) films decreases and some compressive strain in the films produces as Li and N atoms are incorporated into the ZnO matrix because the radius of Li+ ions (0.076 nm) is little larger than that of Zn2+ ions (0.074 nm) and the radius of N− ions (0.013 nm) is smaller than O2− ions (0.014 nm), which leads to the relaxation of the compressive biaxial strain after annealing [26, 27].

4 Conclusion

ZnO:(Li, N) films were prepared on glass substrates by IBED method. The influence of post-annealing time on the structural, electrical and optical properties of p-type ZnO:(Li, N) films were investigated. It is found that the ZnO:(Li, N) films exhibit the ZnO wurtzite structure. The ZnO:(Li, N) films show p-type conduction when annealed in Ar at 500 °C for 10–35 min. The lowest resistivity of p-type ZnO:(Li, N) films is 10.83 Ω cm when annealed for 30 min. The transmittance of ZnO:(Li, N) thin films on the glass substrate are above 80 % in the visible range. The band gap energy of ZnO:(Li, N) films decreases with the increase of annealing time and is smaller than that of intrinsic ZnO (3.37 eV).

References

Ozgur U, Member IEEE, Hofstetter D et al. (2010) ZnO devices and applications: a review of current status and future prospects[J],Proceedings of the IEEE 98, 7:1255–1268

T.-H. Moon, M.-C. Jeong, W. Lee et al., The fabrication and characterization of ZnO UV detector[J]. Appl. Surf. Sci. 240, 280–285 (2005)

F. Paraguay D, M. Miki-Yoshida, J. Morales et al., Influence of Al, In, Cu, Fe and Sn dopants on the response of thin film ZnO gas sensor to ethanol vapour[J]. Thin Solid Films 373, 137–140 (2000)

H. von Wenckstern, H. Schmidt, M. Brandt et al., Anionic and cationic substitution in ZnO[J]. Prog. Solid State Chem. 37, 153–172 (2009)

T. Yamamoto, Codoping for the fabrication of p-type ZnO [J]. Thin Solid Films 420(421), 100–106 (2002)

T. Yamamoto, H. Katayama-Yoshida, Physics and control of valence states in ZnO by codoping method[J]. Phys. B 302–303, 155–162 (2001)

Q.Y. Hou, J.J. Li, C.W. Zhao, C. Ying, Y. Zhang, Phys. B 406, 1956 (2011)

Xin Tang, Xiangfeng Cheng, Dustin Wagner et al., The origin of p-type conduction in Li–N codoped ZnO: an ab initio calculation study[J]. J. Appl. Phys. 110, 1–4 (2011)

T. Yamamoto, H. Katayama-Yoshida, Unipolarity of ZnO with a wide-band gap and its solution using codoping method[J]. J. Cryst. Growth 214(215), 552–555 (2002)

T.T. Zhao, T. Yang, B. Yao et al., Growth ambient dependent electrical properties of lithium and nitrogen dual-doped ZnO films prepared by radio-frequency magnetron sputtering[J]. Thin Solid Films 518, 3289–3292 (2010)

Y.Z. Zhang, J.G. Lu, Z.Z. Ye et al., Effects of growth temperature on Li–N dual-doped p-type ZnO thin films prepared by pulsed laser deposition[J]. Appl. Surf. Sci. 254, 1993–1996 (2008)

C. Ravichandran, G. Srinivasan, C. Lennon et al., Investigations on the structural and optical properties of Li, N and (Li, N) co-doped ZnO thin films prepared by sol–gel technique[J]. Mater. Sci. Semicond. Process. 13, 46–50 (2010)

H.-J. Ko, Y. Chen, S.-K. Hong et al., Doping effects in ZnO layers using Li3 N as a doping source[J]. J. Cryst. Growth 251, 628–632 (2003)

N. Yuan, J. Li, L. Fan et al., Structure, electrical and optical properties of N-In codoped ZnO thin films prepared by ion-beam enhanced deposition method[J]. J. Crystal. Growth 290, 156–160 (2006)

T.M. Barnes, K. Olson, C.A. Wolden, Appl. Phys. Lett. 86, 112112 (2005)

S.-Y. Tsai, M.-H. Hon, Y.-M. Lu, Annealing effect on conductivity behavior of Li–doped ZnO thin film and its application as ZnO-based homojunction device[J]. J. Cryst. Growth 326, 85–89 (2011)

Y. Zhu, S. Lin, Y. Zhang et al., Temperature effect on the electrical, structural and optical properties of N-doped ZnO films by plasma-free metal organic chemical vapor deposition[J]. Appl. Surf. Sci. 225, 6201–6204 (2009)

J.B. Li, S.H. Wei, S.S. Li et al., Phys. Rev. B 74, 081201-1–081201-4 (2006)

Y. Hao, F. Guang-han, L.I. Jun, J. Mater. Sci. Eng. 27, 896–901 (2009)

D. Zhang, J. Zhang, Z. Guo et al., Optical and electrical properties of zinc oxide thin films with low resistivity via Li–N dual-acceptor doping. J. Alloy. Compd. 509, 5962–5968 (2011)

C. Suryanarayana, M.G. Norton, X-ray Diffraction: A Practical Approach (Plenum, New York, 1998), p. 263

X.H. Wang, B. Yao, Z.P. Wei et al., Acceptor formation mechanisms determination from electrical and optical properties of p-type ZnO doped with lithium and nitrogen. J. Phys. D Appl. Phys. 39, 4568–4571 (2006)

T.T. Zhao, T. Yang, B. Yao et al., Growth ambient dependent electrical properties of lithium and nitrogen dual-doped ZnO films prepared by radio-frequency magnetron sputtering [J]. Thin Solid Films 518, 3289–3292 (2010)

B.Y. Zhang, B. Yao, Y.F. Li et al., Investigation on the formation mechanism of p-type Li–N dual-doped ZnO. Appl. Phys. Lett. 97, 222101 (2010)

J.G. Lu, Y.Z. Zhang, Z.Z. Ye et al., Low-resistivity, stable -type ZnO thin films realized using a Li–N dual-acceptor doping method. Appl. Phys. Lett. 88, 222114 (2006)

T. Prasada Rao, M.C. Santhosh Kumar, Realization of stable p-type ZnO thin films using Li–N dual acceptors[J]. J. Alloy. Compd. 509, 8676–8682 (2011)

X.H. Wang, B. Yao, D.Z. Shen et al., Optical properties of p-type ZnO doped by lithium and nitrogen[J]. Solid State Commun. 141, 600–604 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, J., Lu, Qf. & Chen, Q. Influence of post-annealing time on properties of ZnO: (Li, N) thin films prepared by ion beam enhanced deposition method. J Mater Sci: Mater Electron 26, 2669–2673 (2015). https://doi.org/10.1007/s10854-014-2466-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2466-1