Abstract

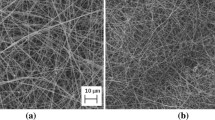

This study reports, for the first time, the use of lower-cost, more sustainable, electrospun carbon nanofiber from asphaltene-based precursors as interleaves in multifunctional composites with improved mechanical and electrical performance. First, asphaltene-based nanomats were electrospun with and without prior asphaltene feedstock purification, including multistage purification. The carbon nanofiber mats, extracted after purification, spinning, thermal stabilization, and carbonization, exhibited improved quality and morphology with reduced beading after purification. Hybrid composites were fabricated using vacuum-assisted resin infusion, incorporating commercially available plain weave carbon fabric layers and the developed nanofiber mats as interleaves in an epoxy matrix. The nanofiber mat reinforcement increased the interlaminar shear strength of the composites by 18% without compromising flexural properties. In general, it was found that purification of asphaltene did not affect the interleave effects, whereas all nanomats resulted in similar enhancement of interlaminar strength and modulus at the interlaminar region. However, using purified nanofiber mats significantly improved the electrical conductivity of the hybrid composites, which can be attributed to an increase in their specific surface area after purification. Hybrid composites produced using purified nanofiber mats showed the highest electrical conductivity, improving both in-plane and out-of-plane conductivities by 173% and 198%, respectively, compared to control carbon fiber—epoxy composites.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

The data supporting the findings of this study are available upon request from the authors.

Abbreviations

- CFRP:

-

Carbon fiber-reinforced polymers

- CF:

-

Carbon fibers

- PAN:

-

Polyacrylonitrile

- ILSS:

-

Interlaminar shear strength

- GHG:

-

Greenhouse gases

- AOA:

-

Alberta oilsands asphaltene

- DMF:

-

Dimethylformamide

- THF:

-

Tetrahydrofuran

- Mw:

-

Molecular weight

- SEM:

-

Scanning electron microscope

- EDX:

-

Energy-dispersion X-ray

- XPS:

-

X-ray photoelectron microscopy

- TGA:

-

Thermogravimetric analysis

- ATR:

-

Attenuated total reflection

- FTIR:

-

Fourier-transform infrared

- BET:

-

Brunauer–Emmett–Teller

- BJH:

-

Barrett, Joyner, and Halenda

- AFM:

-

Atomic force microscopy

- HOPG:

-

Highly ordered pyrolytic graphite

- DMT:

-

Derjaguin–Muller–Toporov

- TPU:

-

Thermoplastic polyurethane

- SAN:

-

Styrene acrylonitrile

References

Xu H, Tong X, Zhang Y et al (2016) Mechanical and electrical properties of laminated composites containing continuous carbon nanotube film interleaves. Compos Sci Technol 127:113–118. https://doi.org/10.1016/j.compscitech.2016.02.032

Guo Y-E, Shang D-G, Zuo L-X et al (2022) Identification of fatigue damage modes for carbon fiber/epoxy composites using acoustic emission monitoring under fully reversed loading. Polym Compos 43:3371–3385. https://doi.org/10.1002/pc.26622

Ahmad F, Mehboob H, Abbassi F et al (2022) Numerical investigation to evaluate the energy effect on the impact resistance of an aircraft carbon fiber-reinforced polymer composite. Mech Adv Mater Struct 29:4457–4467. https://doi.org/10.1080/15376494.2021.1931731

Chung DDL (2001) Electromagnetic interference shielding effectiveness of carbon materials. Carbon 39:279–285. https://doi.org/10.1016/S0008-6223(00)00184-6

Todoroki A, YOSHIDA J, (2004) Electrical resistance change of unidirectional CFRP due to applied load. JSME Int J Ser Solid Mech Mater Eng 47:357–364. https://doi.org/10.1299/jsmea.47.357

Zhu J, Imam A, Crane R et al (2007) Processing a glass fiber reinforced vinyl ester composite with nanotube enhancement of interlaminar shear strength. Compos Sci Technol 67:1509–1517. https://doi.org/10.1016/j.compscitech.2006.07.018

Chen Q, Zhao Y, Zhou Z et al (2013) Fabrication and mechanical properties of hybrid multi-scale epoxy composites reinforced with conventional carbon fiber fabrics surface-attached with electrospun carbon nanofiber mats. Compos Part B Eng 44:1–7. https://doi.org/10.1016/j.compositesb.2012.09.005

Vallack N, Sampson WW (2022) Materials systems for interleave toughening in polymer composites. J Mater Sci 57:6129–6156. https://doi.org/10.1007/s10853-022-06988-1

Kanari K, Wisnom MR, Harniman R, Eichhorn SJ (2022) Interlaminar fracture toughness of carbon fibre composites with electrospun nanofibrous interleaves of polystyrene and cellulose nanocrystals. J Mater Sci 57:21080–21103. https://doi.org/10.1007/s10853-022-07953-8

Kumar A, Sharma K, Dixit AR (2020) Carbon nanotube- and graphene-reinforced multiphase polymeric composites: review on their properties and applications. J Mater Sci 55:2682–2724. https://doi.org/10.1007/s10853-019-04196-y

Chen C, Li Y, Yu T (2014) Interlaminar toughening in flax fiber-reinforced composites interleaved with carbon nanotube buckypaper. J Reinf Plast Compos 33:1859–1868. https://doi.org/10.1177/0731684414548084

Hiremath N, Young S, Ghossein H et al (2020) Low cost textile-grade carbon-fiber epoxy composites for automotive and wind energy applications. Compos Part B Eng 198:108156. https://doi.org/10.1016/j.compositesb.2020.108156

Fang W, Yang X, Li Q et al (2020) Improved mode l interlaminar fracture toughness of random polypropylene composite laminate via multiscale reinforcing formed by introducing functional nanofibrillated cellulose. Compos Part B Eng 203:108481. https://doi.org/10.1016/j.compositesb.2020.108481

Nasirmanesh A, Singh AK, Villaflor D, Blandford B (2022) Effects of midplane carbon nanotube sheet interleave on the strength and impact damage resistance of carbon fiber reinforced polymer composites. Polym Compos 43:3085–3095. https://doi.org/10.1002/pc.26601

Bilisik K, Syduzzaman Md (2021) Carbon nanotubes in carbon/epoxy multiscale textile preform composites: a review. Polym Compos 42:1670–1697. https://doi.org/10.1002/pc.25955

Mulqueen DW, Sattar S, Kravchenko OG (2023) Mechanical and thermal properties of carbon fiber epoxy composite with interlaminar graphene at elevated temperature. Compos Part B Eng 255:110609. https://doi.org/10.1016/j.compositesb.2023.110609

Qian X, Kravchenko OG, Pedrazzoli D, Manas-Zloczower I (2018) Effect of polycarbonate film surface morphology and oxygen plasma treatment on mode I and II fracture toughness of interleaved composite laminates. Compos Part Appl Sci Manuf 105:138–149. https://doi.org/10.1016/j.compositesa.2017.11.016

Cheng C, Chen Z, Huang Z et al (2020) Simultaneously improving mode I and mode II fracture toughness of the carbon fiber/epoxy composite laminates via interleaved with uniformly aligned PES fiber webs. Compos Part Appl Sci Manuf 129:105696. https://doi.org/10.1016/j.compositesa.2019.105696

Ning N, Wang M, Zhou G et al (2022) Effect of polymer nanoparticle morphology on fracture toughness enhancement of carbon fiber reinforced epoxy composites. Compos Part B Eng 234:109749. https://doi.org/10.1016/j.compositesb.2022.109749

Abbasi S, Ladani RB, Wang CH, Mouritz AP (2020) Improving the delamination resistance of fibre reinforced polymer composites using 3D woven metal Z-Filaments. Compos Sci Technol 198:108301. https://doi.org/10.1016/j.compscitech.2020.108301

Kara Y, Molnár K (2022) Development of single-polypropylene composites interleaved with MWCNT-doped melt-blown fine fiber mats. Polym Compos 43:5208–5221. https://doi.org/10.1002/pc.26812

Daelemans L, van der Heijden S, De Baere I et al (2015) Nanofibre bridging as a toughening mechanism in carbon/epoxy composite laminates interleaved with electrospun polyamide nanofibrous veils. Compos Sci Technol 117:244–256. https://doi.org/10.1016/j.compscitech.2015.06.021

Shakil UA, Hassan SBA, Yahya MY, Nauman S (2020) Mechanical properties of electrospun nanofiber reinforced/interleaved epoxy matrix composites—a review. Polym Compos 41:2288–2315. https://doi.org/10.1002/pc.25539

Sasidharan S, Anand A (2022) Interleaving in composites for high-performance structural applications. Ind Eng Chem Res 62:16–39

Dzenis Y, Reneker D (2001) Delamination Resistant Composites Prepared by Small Diameter Fiber Reinforcement at Ply Interfaces

Dzenis Y (2008) Structural nanocomposites. Science 319:419–420

Liu L, Huang Z-M, He CL, Han XJ (2006) Mechanical performance of laminated composites incorporated with nanofibrous membranes. Mater Sci Eng A 435–436:309–317. https://doi.org/10.1016/j.msea.2006.07.064

Chen B, Cai H, Mao C et al (2022) Toughening and rapid self-healing for carbon fiber/epoxy composites based on electrospinning thermoplastic polyamide nanofiber. Polym Compos 43:3124–3135. https://doi.org/10.1002/pc.26605

Neisiany RE, Khorasani SN, Lee JKY et al (2018) Interfacial toughening of carbon/epoxy composite by incorporating styrene acrylonitrile nanofibers. Theor Appl Fract Mech 95:242–247. https://doi.org/10.1016/j.tafmec.2018.03.006

Neisiany RE, Khorasani SN, Naeimirad M, et al (2017) Improving Mechanical Properties of Carbon/Epoxy Composite by Incorporating Functionalized Electrospun Polyacrylonitrile Nanofibers. Macromol Mater Eng. 302:. https://doi.org/10.1002/mame.201600551

Chen Q, Zhang L, Rahman A et al (2011) Hybrid multi-scale epoxy composite made of conventional carbon fiber fabrics with interlaminar regions containing electrospun carbon nanofiber mats. Compos Part Appl Sci Manuf 42:2036–2042. https://doi.org/10.1016/j.compositesa.2011.09.010

Khan SU, Kim J-K (2012) Improved interlaminar shear properties of multiscale carbon fiber composites with bucky paper interleaves made from carbon nanofibers. Carbon 50:5265–5277. https://doi.org/10.1016/j.carbon.2012.07.011

Yang X, Chen Y, Zhang C et al (2023) Electrospun carbon nanofibers and their reinforced composites: preparation, modification, applications, and perspectives. Compos Part B Eng 249:110386. https://doi.org/10.1016/j.compositesb.2022.110386

Khayyam H, Jazar RN, Nunna S et al (2020) PAN precursor fabrication, applications and thermal stabilization process in carbon fiber production: experimental and mathematical modelling. Prog Mater Sci 107:100575. https://doi.org/10.1016/j.pmatsci.2019.100575

Arshad SN, Naraghi M, Chasiotis I (2011) Strong carbon nanofibers from electrospun polyacrylonitrile. Carbon 49:1710–1719. https://doi.org/10.1016/j.carbon.2010.12.056

Qin F, Jiang W, Ni G et al (2019) From coal-heavy oil co-refining residue to asphaltene-based functional carbon materials. ACS Sustain Chem Eng 7:4523–4531. https://doi.org/10.1021/acssuschemeng.9b00003

Zuo P, Leistenschneider D, Kim Y et al (2021) The effect of thermal pretreatment temperature on the diameters and mechanical properties of asphaltene-derived carbon fibers. J Mater Sci 56:14964–14977. https://doi.org/10.1007/s10853-021-06249-7

Abedi Z, Leistenschneider D, Chen W, Ivey DG (2020) Superior performance of electrochemical double layer supercapacitor made with asphaltene derived activated carbon fibers. Energy Technol 8:2000588. https://doi.org/10.1002/ente.202000588

Saad S, Zeraati AS, Roy S et al (2022) Transformation of petroleum asphaltenes to carbon fibers. Carbon 190:92–103. https://doi.org/10.1016/j.carbon.2022.01.011

Bisheh H, Abdin Y (2023) Carbon fibers: from PAN to asphaltene Precursors. A State-of-Art Review C 9:19

Baritto M, Oni A, Kumar A (2023) The development of a techno-economic model for the assessment of asphaltene-based carbon fiber production. J Clean Prod 428:139489

Baritto M, Oni A, Kumar A (2023) Estimation of life cycle greenhouse gas emissions of asphaltene-based carbon fibers derived from oil sands bitumen. Sustain Mater Technol 36:e00627

Al Bari MA, Nabil SK, Saad S et al (2023) Economic and environmental assessment of asphaltene-derived carbon fiber production. Green Chem 25:6446–6458

Hussain A, Bahi A, Ko F, Abdin Y (2023) Development of low-cost electrospun carbon nanofibers using asphaltene precursor. Adv Nat Sci Nanosci Nanotechnol 14:025012. https://doi.org/10.1088/2043-6262/acd6e7

De Crisci AG, Gieleciak R, Mobarok MH et al (2023) Producing asphaltene fibres from bitumen-derived asphaltenes for carbon fibre development: Part one–Electrospinning. Can J Chem Eng 101:2633–2645. https://doi.org/10.1002/cjce.24683

Alberta Innovates Carbon Fiber Grand Challenge Asphaltene Sample Bank Sample S2 Analytical Properties, Innotech Alberta

Daelemans L, Van Paepegem W, De Clerck K (2020) Chapter 11 - Effect of interleaved polymer nanofibers on the properties of glass and carbon fiber composites. In: Han B, Sharma S, Nguyen TA et al (eds) Fiber-Reinforced Nanocomposites: fundamentals and Applications. Elsevier, Amsterdam, pp 235–260

Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates

Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

Qi Y, Jiang D, Ju S et al (2019) Determining the interphase thickness and properties in carbon fiber reinforced fast and conventional curing epoxy matrix composites using peak force atomic force microscopy. Compos Sci Technol 184:107877. https://doi.org/10.1016/j.compscitech.2019.107877

Naji A, Krause B, Pötschke P, Ameli A (2019) Hybrid conductive filler/polycarbonate composites with enhanced electrical and thermal conductivities for bipolar plate applications. Polym Compos 40:3189–3198. https://doi.org/10.1002/pc.25169

Guadagno L, Raimondo M, Vietri U et al (2015) Effective formulation and processing of nanofilled carbon fiber reinforced composites. RSC Adv 5:6033–6042. https://doi.org/10.1039/C4RA12156B

Maccaferri E, Mazzocchetti L, Benelli T et al (2022) Self-assembled NBR/Nomex nanofibers as lightweight rubbery nonwovens for hindering delamination in epoxy CFRPs. ACS Appl Mater Interfaces 14:1885–1899. https://doi.org/10.1021/acsami.1c17643

Chacón-Patiño ML, Neumann A, Rüger CP et al (2023) Chemistry and properties of carbon fiber feedstocks from bitumen asphaltenes. Energy Fuels 37:5341–5360. https://doi.org/10.1021/acs.energyfuels.2c04274

Wu M, Wang Q, Li K et al (2012) Optimization of stabilization conditions for electrospun polyacrylonitrile nanofibers. Polym Degrad Stab 97:1511–1519. https://doi.org/10.1016/j.polymdegradstab.2012.05.001

Rahaman MSA, Ismail AF, Mustafa A (2007) A review of heat treatment on polyacrylonitrile fiber. Polym Degrad Stab 92:1421–1432. https://doi.org/10.1016/j.polymdegradstab.2007.03.023

Coleman MM, Petcavich RJ (1978) Fourier transform infrared studies on the thermal degradation of polyacrylonitrile. J Polym Sci Polym Phys Ed 16:821–832. https://doi.org/10.1002/pol.1978.180160507

Henrici-Olivé G, Olivé S (1983) The chemistry of carbon fiber formation from polyacrylonitrile. Industrial Developments. Springer, Berlin, Heidelberg, pp 1–60

Cipriani E, Zanetti M, Bracco P et al (2016) Crosslinking and carbonization processes in PAN films and nanofibers. Polym Degrad Stab 123:178–188. https://doi.org/10.1016/j.polymdegradstab.2015.11.008

Lin L-T (2017) Structure and properties of lignin-based composite carbon nanofibres. University of British Columbia

Ko FK, Wan Y (2014) Introduction to nanofiber materials. Cambridge University Press

Chang P, Mouritz AP, Cox BN (2007) Flexural properties of z-pinned laminates. Compos Part Appl Sci Manuf 38:244–251. https://doi.org/10.1016/j.compositesa.2006.05.004

Zhang J, Lin T, Wang X (2010) Electrospun nanofibre toughened carbon/epoxy composites: effects of polyetherketone cardo (PEK-C) nanofibre diameter and interlayer thickness. Compos Sci Technol 70:1660–1666. https://doi.org/10.1016/j.compscitech.2010.06.019

Niu Y-F, Yang Y, Gao S, Yao J-W (2016) Mechanical mapping of the interphase in carbon fiber reinforced poly (ether-ether-ketone) composites using peak force atomic force microscopy: interphase shrinkage under coupled ultraviolet and hydro-thermal exposure. Polym Test 55:257–260

Wang Y, Liu X, Chen L et al (2022) Simultaneously improve the mode II interlaminar fracture toughness, flexural properties, and impact strength of CFRP composites with short aramid fiber interlaminar toughening. Polym Compos 43:8437–8442. https://doi.org/10.1002/pc.27014

Mahato B, Lomov SV, Shiverskii A et al (2023) A Review of electrospun nanofiber interleaves for interlaminar toughening of composite laminates. Polymers. https://doi.org/10.3390/polym15061380

Zhao Q, Zhang K, Zhu S et al (2019) Review on the electrical resistance/conductivity of carbon fiber reinforced polymer. Appl Sci 9:2390

Acknowledgements

The authors would like to thank Alberta Innovates and the Clean Resource Innovation Network (CRIN) for co-funding this project. The funding of infrastructure and equipment provided by the Canada Foundation for Innovation (CFI) is greatly appreciated. The authors would like to thank the nanofab lab at the University of Alberta for the use of the XPS equipment.

Funding

Alberta Innovates,Clean Resource Innovation Network

Author information

Authors and Affiliations

Contributions

Atif Hussain and Parya Keyvani were involved in investigation, methodology, visualization, formal analysis, and writing—original draft. Rachel Cummings was performed investigation, methodology, and visualization. Muzaffer Karaaslan and Addie Bahi were done investigation, methodology, and formal analysis. Scott Renneckar and Frank Ko did resources, funding acquisition, and writing—review and editing. Yasmine Abdin was contributed conceptualization, formal analysis, supervision, project administration, resources, funding acquisition, and writing – review and editing.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not available

Supplementary information

Supplementary material includes elemental composition of the asphaltene sample used in the study, SEM images of the produced nanomats, differential scanning calorimetry (DSC) testing of the nanomats, additional images of the carbonized nanomats and composite samples, and thermogravimetric analysis (TGA) of the produced hybrid composites.

Additional information

Handling Editor: Annela M. Seddon.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hussain, A., Keyvani, P., Cummings, R. et al. Multifunctional hybrid composites from novel asphaltene-based carbon nanofiber mats and woven carbon fiber. J Mater Sci (2024). https://doi.org/10.1007/s10853-024-10217-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10853-024-10217-2