Abstract

The impact of Cu doping on the martensitic transformation and shape memory properties of a high-temperature shape memory alloy system, Ti31.5Hf15Zr5Ni48.5−xCux (x = 0, 5, 10, 15, 20), was investigated. Both the martensitic transformation temperature (Ms) and the transformation enthalpy decrease monotonically with increasing Cu content x, while the recoverable strain exhibits a saddle curve with a minimum value at x = 10. These Cu content-dependent behaviors were attributed to the constraint effect caused by the different size distribution of Ti2Ni-like second phases. Additionally, a scaled linear relationship between Ms and several elemental features, including the modified valence electron concentration, electronegativity, and atomic volume, was established to describe the Cu content dependence of Ms across various Cu-containing TiNi-based systems. The experimental results presented herein, along with the proposed functional form, offer insights for the design of Cu-containing shape memory alloys.

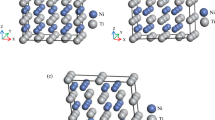

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

The data that support the findings of this study is available from the corresponding authors upon reasonable request.

References

Jani JM, Leary M, Subic A, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des 56:1078–1113

Humbeeck JV (1999) Non-medical applications of shape memory alloys. Mater Sci Eng A 273:134–148

Nnamchi P, Younes A, González S (2019) A review on shape memory metallic alloys and their critical stress for twinning. Intermetallics 105:61–78

Ma J, Karaman I, Noebe RD (2013) High temperature shape memory alloys. Int Mater Rev 55(5):257–315

Zeng Z, Oliveira JP, Yang M, Song D, Peng B (2017) Functional fatigue behavior of NiTi-Cu dissimilar laser welds. Mater Des 114:282–287

Karakoc O, Hayrettin C, Bass M, Wang SJ, Canadinc D, Mabe JH, Lagoudas DC, Karaman I (2017) Effects of upper cycle temperature on the actuation fatigue response of NiTiHf high temperature shape memory alloys. Acta Mater 138:185–197

Humbeeck JV (2001) Shape memory alloys: a material and a technology. Adv Eng Mater 3(11):837–850

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge

Bozzolo G, Mosca HO, del Grosso MF (2008) Energy of formation, lattice parameter and bulk modulus of (Ni, X)Ti alloys with X = Fe, Pd, Pt, Au, Al, Cu, Zr, Hf. Intermetallics 16(5):668–675

Shi H, Delville R, Srivastava V, James RD, Schryvers D (2014) Microstructural dependence on middle eigenvalue in Ti–Ni–Au. J Alloys Compd 582:703–707

Panduranga MK, Shin DD, Carman GP (2006) Shape memory behavior of high temperature Ti–Ni–Pt thin films. Thin Solid Films 515(4):1938–1941

Sawaguchi T, Sato M, Ishida A (2002) Microstructure and shape memory behavior of Ti51.2(Pd27.0Ni21.8) and Ti49.5(Pd28.5Ni22.0) thin films. Mater Sci Eng A 332(1–2):47–55

Meng XL, Cai W, Zheng YF, Zhao LC (2006) Phase transformation and precipitation in aged Ti–Ni–Hf high-temperature shape memory alloys. Mater Sci Eng A 438–440:666–670

Sakurai J, Hata S (2012) Search for Ti–Ni–Zr thin film metallic glasses exhibiting a shape memory effect after crystallization. Mater Sci Eng A 541:8–13

Evirgen A, Pons J, Karaman I, Santamarta R, Noebe RD (2018) H-phase precipitation and martensitic transformation in Ni-rich Ni–Ti–Hf and Ni–Ti-Zr high-temperature shape memory alloys. Shape Memory Superelast 4(1):85–92

Yang F, Coughlin DR, Phillips PJ, Yang L, Devaraj A, Kovarik L, Noebe RD, Mills MJ (2013) Structure analysis of a precipitate phase in an Ni-rich high-temperature NiTiHf shape memory alloy. Acta Mater 61(16):6191–6206

Hong SH, Kim JT, Park HJ, Kim YS, Suh JY, Na YS, Lim KR, Shim CH, Park JM, Kim KB (2017) Influence of Zr content on phase formation, transition and mechanical behavior of Ni-Ti–Hf–Zr high temperature shape memory alloys. J Alloys Compd 692:77–85

Karakoc O, Atli KC, Evirgen A, Pons J, Santamarta R, Benafan O, Noebe RD, Karaman I (2020) Effects of training on the thermomechanical behavior of NiTiHf and NiTiZr high temperature shape memory alloys. Mater Sci Eng A 794:139857

Oliveira JP, Schell N, Zhou N, Wood L, Benafan O (2019) Laser welding of precipitation strengthened Ni-rich NiTiHf high temperature shape memory alloys: microstructure and mechanical properties. Mater Des 162:229–234

Meng XL, Zheng YF, Wang Z, Zhao LC (2000) Effect of aging on the phase transformation and mechanical behavior of Ti36Ni49Hf15 high temperature shape memory alloy. Scr Mater 42(4):341–348

Hsieh SF, Wu SK (1998) A study on lattice parameters of martensite in Ti50.5−xNi49.5Zrx shape memory alloys. J Alloys Compd 270(1–2):237–241

Hsieh SF, Wu SK (2000) Martensitic transformation of quaternary Ti50.5−xNi495Zrx/2Hfx/2 (x = 0–20 at.%) shape memory alloys. Mater Charact 45(2):143–152

Hsieh SF, Chang WK (2002) Martensitic transformation of an aged/thermal-cycled Ti30.5Ni49.5Zr10Hf10 shape memory alloy. J Mater Sci 37(14):2851–2856

Pang JB, Xu YY, Tian J, Zhou YM, Xue DZ, Ding XD, Sun J (2021) Effects of Ti/Ni and Hf/Zr ratio on the martensitic transformation behavior and shape memory effect of TiNiHfZr alloys. Mater Sci Eng A 807:140850

Dang PF, Ye F, Zhou YM, Ding L, Pang JB, Zhang L, Ding XD, Sun J, Dai S, Lookman T, Xue DZ (2022) Low-fatigue and large room-temperature elastocaloric effect in a bulk Ti49.2Ni40.8Cu10 alloy. Acta Mater 229:117802

Nam TH, Saburi T, Shimizu K (1990) Cu-content dependence of shape memory characteristics in Ti–Ni–Cu alloys. Mater Trans JIM 31(11):959–967

Meng XM, Cai W, Lau KT, Zhao LC, Zhou LM (2005) Phase transformation and microstructure of quaternary TiNiHfCu high temperature shape memory alloys. Intermetallics 13:197–201

Hamilton RF, Sehitoglu H, Chumlyakov Y, Maier HJ (2004) Stress dependence of the hysteresis in single crystal NiTi alloys. Acta Mater 52:3383–3402

Ortin J, Delaey L (2002) Hysteresis in shape-memory alloys. Int J Non-Linear Mech 37:1275–1281

Kim WC, Kim YJ, Kim JS, Kim YS, Na MY, Kim WT, Kim DH (2019) Correlation between the thermal and superelastic behavior of Ni50−xTi35Zr15Cux shape memory alloys. Intermetallics 107:24–33

Li SH, Cong DY, Sun XM, Zhang Y, Chen Z, Nie ZH, Li RG, Li FQ, Ren Y, Wang YD (2019) Wide-temperature-range perfect superelasticity and giant elastocaloric effect in a high entropy alloy. Mater Res Lett 7(12):482–489

Shahmir H, Nill-Ahmadabadi M, Mohammadi M, Huang Y, Andrzejczuk M, Lewandowska M, Langdon TG (2020) Effect of Cu on amorphization of a TiNi alloy during HPT and shape memory effect after post-deformation annealing. Adv Eng Mater 22(1):1900387

Chang YT, Lee MH, Chu MW, Chen CH (2022) Phase formations and microstructures of Ti20Zr15Hf15Ni35Cu15 high-entropy shape memory alloy under different aging conditions. Mater Today Adv 14:100223

Li SH, Cong DY, Chen Z, Li SW, Song C, Cao YX, Nie ZH, Wang YD (2021) A high-entropy high-temperature shape memory alloy with large and complete superelastic recovery. Mater Res Lett 9(6):263–269

Firstova GS, Kosorukova TA, Koval YN, Verhovlyuk PA (2015) Electronic and crystal structure of the high entropy TiZrHfCoNiCu intermetallics undergoing martensitic transformation. Shap. Mwm. Superelasticity 1:400

Liang XL, Chen Y, Shen HM, Zhang ZF, Li W, Wang YN (2001) Thermal cycling stability and two-way shape memory effect of Ni–Cu–Ti–Hf alloys. Solid State Commun 119(6):381–385

Dang PF, Zhou YM, Pang JB, Ding XD, Sun J, Lookman T, Xue DZ (2023) Achieving stable actuation response and elastocaloric effect in a nanocrystalline Ti50Ni40Cu10 alloy. Scr Mater 226:115263

Acar E, Karaca HE, Basaran B, Yang F, Mill MJ, Noebe RD, Chumlyakov YI (2013) Role of aging time on the microstructure and shape memory properties of NiTiHfPd single crystals. Mater Sci Eng A 573:161–165

Saghaian SM, Karaca HE, Tobe H, Turabi AS, Saedi S, Saghaian SE, Chumlyakov YI, Noebe RD (2017) High strength NiTiHf shape memory alloys with tailorable properties. Acta Mater 134:211–220

Pfeuffer L, Lemke J, Shayanfar N, Riegg S, Koch D, Taubel A, Scheibel F, Kani NA, Adabifiroozjaei E, Luna LM, Skokov KP, Gutfleisch O (2021) Microstructure engineering of metamagnetic Ni–Mn-based Heusler compounds by Fe-doping: a roadmap towards excellent cyclic stability combined with large elastocaloric and magnetocaloric effects. Acta Mater 221:117390

Bhagyaraj J, Ramaiah KV, Saikrishna CN, Bhaumik SK (2013) Behavior and effect of Ti2Ni phase during processing of NiTi shape memory alloy wire from cast ingot. J Alloys Compd 581:344–351

Karaca HE, Saghaian SM, Ded G, Tobe H, Basaran B, Maier HJ, Noebe RD, Chumlyakov YI (2013) Effects of nanoprecipitation on the shape memory and material properties of an Ni-rich NiTiHf high temperature shape memory alloy. Acta Mater 61(19):7422–7431

Meng XL, Tong YX, Lau KT, Cai W, Zhou LM, Zhao LC (2002) Effect of Cu addition on phase transformation of Ti–Ni–Hf high-temperature shape memory alloys. Mater Lett JIM 57(2):452–456

Ur Rehman S, Khan M, Khan AN, Ali L, Jaffery SIH, Khurram M (2019) Quaternary alloying of copper with Ti50Ni50Pd25 high temperature shape memory alloys. Mater Sci Eng A 763:138–148

Frenzel J, Wieczorek A, Opahle I, Maaß B, Drautz R, Eggeler G (2015) On the effect of alloy composition on martensite start temperatures and latent heats in Ni–Ti-based shape memory alloys. Acta Mater 90:213–231

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50(5):511–678

Zarinejad M, Liu Y, Tong Y (2009) Transformation temperature changes due to second phase precipitation in NiTi-based shape memory alloys. Intermetallics 17(11):914–919

Zarinejad M, Liu Y (2008) Dependence of transformation temperatures of NiTi-based shape-memory alloys on the number and concentration of valence electrons. Adv Funct Mater 18(18):2789–2794

Wang RL, Yan JB, Xiao HB, Xu LS, Marchenkov VV, Xu LF, Yang CP (2011) Effect of electron density on the martensitic transformation in Ni–Mn–Sn alloys. J Alloys Compd 509:6834–6837

Zarinejad M, Wada K, Pahlevani F, Katal R (2021) Valence electron ratio for design of shape memory alloys with desired phase transformation temperatures. Shape Memory Superelast 7(1):179–189

Tian Y, Yuan RH, Xue DZ, Zhou YM, Wang YF, Ding XD, Sun J, Lookman T (2021) Determining multi-component phase diagrams with desired characteristics using active learning. Adv Sci 8(1):2003165

Tian XH, Shi DD, Zhang K, Li HX, Zhou LW, Ma TY, Wang C, Wen QL, Tan CL (2022) Machine-learning model for prediction of martensitic transformation temperature in NiMnSn-based ferromagnetic shape memory alloys. Comput Mater Sci 215:111811

Xue DZ, Xue DQ, Yuan RH, Zhou YM, Balachandran PV, Ren XB, Ding XD, Sun J, Lookman T (2017) An informatics approach to transformation temperatures of NiTi-based shape memory alloys. Acta Mater 125:532–541

Liu HX, Yan HL, Zhao Y, Jia N, Tang S, Cong DY, Yang B, Li ZB, Zhang YD, Esling C, Zhao X, Zuo L (2024) Machine learning informed tetragonal ratio c/a of martensite. Comput Mater Sci 233:112735

Xue DZ, Balachandran PV, Hogden J, Theiler J, Xue DQ, Lookman T (2016) Accelerated search for materials with targeted properties by adaptive design. Nat Commun 7(1):1–9

Zadeh SH, Behbahanian A, Broucek J, Fan MZ, Vazquez G, Noroozi M, Trehern W, Qian XN, Karaman I, Arroyave R (2023) An interpretable boosting-based predictive model for transformation temperatures of shape memory alloys. Comp Mater Sci 226:112225

Minami D, Uesugi T, Takigawa Y, Higashi K (2019) Artificial neural network assisted by first-principles calculations for predicting transformation temperatures in shape memory alloys. Int J Mod Phy B 33:1950055

Zhang Y, Xu XJ (2020) Transformation temperature predictions through computational intelligence for NiTi-based shape memory alloys. Shape Memory Superelast 6(4):374–386

He SY, Wang YM, Zhang ZY, Xiao F, Zuo SG, Zhou Y, Cai XR, Jin XJ (2023) Interpretable machine learning workflow for evaluation of the transformation temperatures of TiZrHfNiCoCu high entropy shape memory alloys. Mater Des 225:111513

Acknowledgements

The authors gratefully acknowledge the support of the National Natural Science Foundation of China (Nos. 52173228, 52271190 and 51931004).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Nima Haghdadi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pang, J., Dang, P., Tian, J. et al. Effect of Cu content on martensitic transformation and shape memory behavior in Ti31.5Hf15Zr5Ni48.5−xCux alloys. J Mater Sci 59, 11096–11109 (2024). https://doi.org/10.1007/s10853-024-09820-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09820-0