Abstract

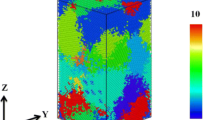

The demolding process of electroforming technology in fabricating microstructured optical-functional thin films produces the problem of excessive bonding between the metal substrate and the metal replica, which triggers the deformation of the microstructure and the reduction of precision, and the deposition of Cr–O–C discrete nuclei at the interface can play a good role in assisting the demolding effect. In this paper, the tensile deformation of polycrystalline Cu/Ni and Cu/Cr–O–C/Ni composites is investigated using molecular dynamics methods. The results show that the Cu/Ni model produces a large number of HCP structures during stretching, with holes at the interface and a large number of Cu atoms transferring to the Ni layer. The addition of the Cr–O–C layer reduces the yield strength of the Cu/Cr–O–C/Ni model by 26.41%, and at the same time, the dislocation proliferation at the interface is reduced, and the fracture is at the centralized interface, and the fracture time is reduced by 90.8%. The higher number of Cr–O–C atoms at the interface decreases the transfer of Cu atoms to the Ni layer. The results provide a possible explanation for the Cr–O–C layer-assisted precision electrodeposition debonding.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data and code availability

The molecular dynamics codes that were used in this work are available upon request to the corresponding author, Dr. Guang Yang.

References

Roeder M, Guenther T, Zimmermann A (2019) A review on fabrication technologies for optical mold inserts. Micromachines 10(4):233. https://doi.org/10.3390/mi10040233

Zhang S, Zhou Y, Zhang H et al (2019) Advances in ultra-precision machining of micro-structured functionasurfaces and their typical applications. Int J Mach Tools Manuf 142:16–41. https://doi.org/10.1016/j.ijmachtools.2019.04.009

Lotnyk A, Behrens M, Rauschenbach B (2019) Phase change thin films for non-volatile memory applications. Nanoscale Adv 1(10):3836–3857. https://doi.org/10.1039/C9NA00366E

Gota Y, Mimura H (2020) Effect of electrodeposition conditions on surface roughness of copper electroformed replicas. Int J Electr Mach 25:33. https://doi.org/10.2526/ijem.25.33

Yang G, Li Y, Pi J et al (2019) Control of the adhesion strength between nickel replica and copper mold by electrochemical nucleation of lead. J Appl Electrochem 49:1003–1011. https://doi.org/10.1007/s10800-019-01342-X

Tabandeh-khorshid M, Kumar A, Omrani E et al (2019) Synthesis, characterization, and properties of graphene reinforced metal-matrix nanocomposites. Compos Part B: Eng 183:107664. https://doi.org/10.1016/j.compositesb.2019.107664

Li Y, Yang G, Wu Q et al (2019) A Cr anti-sticking layer for improving mold release quality in electrochemical replication of PVC optical molds. Micromachines 10(10):702. https://doi.org/10.3390/mi10100702

Lee BK, Cha KJ, Kwon TH (2009) Fabrication of polymer micro/nano-hybrid lens array by microstructured anodic aluminum oxide (AAO) mold. Microelectron Eng 86:857–860. https://doi.org/10.1016/j.mee.2008.11.066

Mimura H, Ishikura H, Matsuyama S et al (2011) Electroforming for replicating nanometer-level smooth surface. J Nanosci Nanotechnol 11:2886–2889. https://doi.org/10.1166/jnn.2011.3889

Qi Y, Zhao M, Feng M (2021) Molecular simulation of microstructure evolution and plastic deformation of nanocrystalline CoCrFeMnNi high-entropy alloy under tension and compression. J Alloy Compd 851:156923. https://doi.org/10.1016/j.jallcom.2020.156923

Joshi SK, Pandey K, Singh S et al (2019) Molecular dynamics simulations of deformation behaviour of gold nanowires. J Nanotechnol 2019:5710749. https://doi.org/10.1155/2019/5710749

Zhou K, Liu B, Shao S et al (2017) Molecular dynamics simulations of tension-compression asymmetry in nanocrystalline copper. Phys Lett A 381(13):1163–1168. https://doi.org/10.1016/j.physleta.2017.01.027

Cao A, Wei Y (2007) Atomistic simulations of crack nucleation and intergranular fracture in bulk nanocrystalline nickel. Phys Rev B 76(2):024113. https://doi.org/10.1103/PhysRevB.76.024113

Li J, Zhao Q, Xia R et al (2022) Molecular dynamics simulations on the mechanical properties of gyroidal bicontinuous Cu/Ni nanocomposites. J Market Res 18:4738–4747. https://doi.org/10.1016/j.jmrt.2022.04.142

Hirel P (2015) Atomsk: a tool for manipulating and converting atomic data files. Comput Phys Commun 197:212–219

Wang PC, Yu JG, Zhang QX (2020) Nano-cutting mechanical properties and microstructure evolution mechanism of amorphous/single crystal alloy interface. Comput Mater Sci 184:109915. https://doi.org/10.1016/j.commatsci.2020.109915

Wadley HNG, Zhou X, Johnson RA et al (2001) Mechanisms models and methods of vapor deposition. Prog Mater Sci 46(3–4):329–377. https://doi.org/10.1016/S0079-6425(00)00009-8

Zhou XW, Wadley HNG, Johnson RA et al (2001) Atomic scale structure of sputtered metal multilayers. Acta Mater 49(19):4005–4015. https://doi.org/10.1016/S1359-6454(01)00287-7

Mendelev MI, Kramer MJ, Becker CA et al (2008) Analysis of semi-empirical interatomic potentials appropriate for simulation of crystalline and liquid Al and Cu. Phil Mag 88(12):1723–1750. https://doi.org/10.1080/14786430802206482

Mendelev MI, Kramer MJ, Hao SG et al (2012) Development of interatomic potentials appropriate for simulation of liquid and glass properties of NiZr2 alloy. Phil Mag 92(35):4454–4469. https://doi.org/10.1080/14786435.2012.712220

Choi WM, Kim Y, Seol D et al (2017) Modified embedded-atom method interatomic potentials for the co-cr, co-fe, co-mn, cr-mn and mn-ni binary systems. Comput Mater Sci 130:121–129. https://doi.org/10.1016/j.commatsci.2017.01.002

Thompson AP, Aktulga HM, Berger R et al (2022) LAMMPS-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput Phys Commun 271:108171

Stukowski A (2009) Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model Simul Mater Sci Eng 18(1):015012. https://doi.org/10.1088/0965-0393/18/1/015012

Liu W, Han T, Wang L (2022) Molecular dynamics simulation study on the effect of Mn on the tensile behavior of a ferrite/austenite iron bicrystal. J Mater Eng Perform 32(15):6810–6820. https://doi.org/10.1007/s11665-022-07582-x

Zhang L, Shibuta Y, Huang X et al (2019) Grain boundary induced deformation mechanisms in nanocrystalline Al by molecular dynamics simulation: from interatomic potential perspective. Comput Mater Sci 156:421–433. https://doi.org/10.1016/j.commatsci.2018.10.021

Pan Z, Fu Y, Wei Y et al (2022) Deformation mechanisms of TRIP-TWIP medium-entropy alloys via molecular dynamics simulations. Int J Mech Sci 219:107098. https://doi.org/10.1016/j.ijmecsci.2022.107098

Li X, Wei Y, Lu L et al (2010) Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 464(7290):877–880. https://doi.org/10.1038/nature08929

Frederiksen SL, Jacobsen KW, Schiøtz J (2004) Simulations of intergranular fracture in nanocrystalline molybdenum. Acta Mater 52(17):5019–5029. https://doi.org/10.1016/j.actamat.2004.07.025

Pei L, Lu C, Tang Q et al (2019) Effect of temperature on deformation and fracture behaviour of nanostructured polycrystalline Ni under tensile hydrostatic stress by molecular dynamics simulation. J Nanosci Nanotechnol 19(5):2723–2731. https://doi.org/10.1166/jnn.2019.15890

Moradi M, Farrahi GH, Chamani M (2019) Effect of microstructure on crack behavior in nanocrystalline nickel using molecular dynamics simulation. Theoret Appl Fract Mech 104:102390. https://doi.org/10.1016/j.tafmec.2019.102390

Shi J, Hu C, Shen J et al (2020) Mechanical properties of bonded few-layered graphene via uniaxial test: a molecular dynamics simulation study. Comput Mater Sci 172:109295. https://doi.org/10.1016/j.commatsci.2019.109295

Liu J, Wang Q, Qi Y (2019) Atomistic simulation of the formation and fracture of oxide bifilms in cast aluminum. Acta Mater 164:673–682. https://doi.org/10.1016/j.actamat.2018.11.008

Yang G, Chen J, Li B et al (2022) Impact of Cr nanocrystalline discrete crystal nuclei on demolding strength and surface roughness of precision electroforming Ni layer on Cu substrate. J Appl Electrochem 52:1091–1100. https://doi.org/10.1007/s10800-022-01697-8

Sun B, Ouyang W, Ren J et al (2019) FCC→ bcc→ HCP successive phase transformations in the strained ultrathin copper film: a molecular dynamic simulation study. Mater Chem Phys 223:171–182. https://doi.org/10.1016/j.matchemphys.2018.09.045

Qi Y, Zhao M, Feng M (2021) (2021) Molecular simulation of microstructure evolution and plastic deformation of nanocrystalline CoCrFeMnNi high-entropy alloy under tension and compression. J Alloy Compd 851:156923. https://doi.org/10.1016/j.jallcom.2020.156923

Qi Y, He T, Feng M (2022) Molecular dynamics-based tension simulation of plastic deformation of 2D nanotwinned copper under uniaxial stress conditions. Evolution of dislocations and secondary twinning. Met Mater Int 28:1611–1619. https://doi.org/10.1007/s12540-021-01041-3

Li JJ, Li J, Zhao Q et al (2022) Molecular dynamics simulations on the mechanical properties of gyroidal bicontinuous Cu/Ni nanocomposites. J Market Res 18:4738–4747. https://doi.org/10.1016/j.jmrt.2022.04.142

Chen X, Zhou H, Zhang T et al (2019) Mechanism of interaction between the Cu/Cr interface and its chemical mixing on tensile strength and electrical conductivity of a Cu-Cr-Zr alloy. Mater Des 180:107976. https://doi.org/10.1016/j.matdes.2019.107976

Hoagland RG, Mitchell TE, Hirth JP et al (2002) On the strengthening effects of interfaces in multilayer fee metallic composites. Philos Mag A 82(4):643–664. https://doi.org/10.1080/01418610208243194

Liu Y, Wang Q, Lu C et al (2022) Microscopic residual stress evolution at the SiC/Al interface during nanoindentation via molecular dynamics simulation. Surf Interfaces 33:102210. https://doi.org/10.1016/j.surfin.2022.102210

Yan Z, Lin Y (2019) Lomer-Cottrell locks with multiple stair-rod dislocations in a nanostructured Al alloy processed by severe plastic deformation. Mater Sci Eng, A 747:177–184. https://doi.org/10.1016/j.msea.2019.01.066

Zhang Y, Jiang S (2021) Molecular dynamics simulation on mechanisms of plastic anisotropy in nanotwinned polycrystalline copper with 111 texture during tensile deformation. Trans Nonferrous Met Soc China 31(5):1381–1396. https://doi.org/10.1016/S1003-6326(21)65584-X

Zhou J, Li Y, Lu C et al (2022) Molecular dynamics simulation of the tensile response and deformation mechanism of diamond/TiC combinations. Comput Mater Sci 215:111779. https://doi.org/10.1016/j.commatsci.2022.111779

Sun H, Yang L, Wu H et al (2023) Effects of element doping on the structure and properties of diamond-like carbon films: a review. Lubricants 11(4):186. https://doi.org/10.3390/lubricants11040186

Yin Q, Lian Y, Wen Z et al (2022) Atomic simulation of the effect of orientation on tensile/compressive properties in nickel-based single crystal superalloys. J Alloys Compd 893:162210. https://doi.org/10.1016/j.jallcom.2021.162210

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 52175407).

Author information

Authors and Affiliations

Contributions

Simulation, methodology, and writing-original draft were performed by Zhengchen Hu. Conceptualization, funding acquisition, supervision, project administration, writing review, and editing were performed by Guang Yang. Experimental design, carrying out measurements, and validation were performed by Ju Chen.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest exist for this work that could potentially influence or bias the submitted work.

Ethical approval

Not applicable.

Additional information

Handling Editor: Ghanshyam Pilania.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hu, Z., Yang, G. & Chen, J. Molecular dynamics simulation of Cr–O–C discrete nuclei to reduce the binding force of nanocrystalline Cu/Ni complexes. J Mater Sci 59, 3531–3543 (2024). https://doi.org/10.1007/s10853-024-09433-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09433-7